Wiring in a wooden house: design rules + step-by-step installation

Wooden houses are chosen as housing for many reasons: one is contraindicated to live in concrete "boxes", while others like beautiful log houses. However, living in them is closely related to such a concept as security. That is why wiring in a wooden house is considered one of the key aspects.

We will talk about how to properly make the wiring of electricity in a wooden house. We will show you which schemes, consumables, and wiring products are used in laying lines along the walls of timber or logs. Based on our tips, you can make a secure and reliable network.

The content of the article:

Wooden house power supply project

Even if all logs, boards and boards are treated with flame retardants, they remain vulnerable to accidental fire. For this reason, the stages of the installation of the electrical system - from design to the installation of sockets and switches - must be known both by skilled "home-made" and owners who control the work of hired builders.

According to the legislation of the Russian Federation, for residential buildings with a power consumption of not more than 15 kW, the design of power grids is not required. But it is necessary to provide the scheme and data on the total power consumption to the company supplying electricity. This is necessary for calculating the allocated power on the line and installing the meter.

In the process of developing the project, you need to take into account all the nuances: the exact location of electrical installations, the choice of cable and wiring method, the need for grounding, etc.How is the preparation of the project and preparation for installation work, consider in more detail.

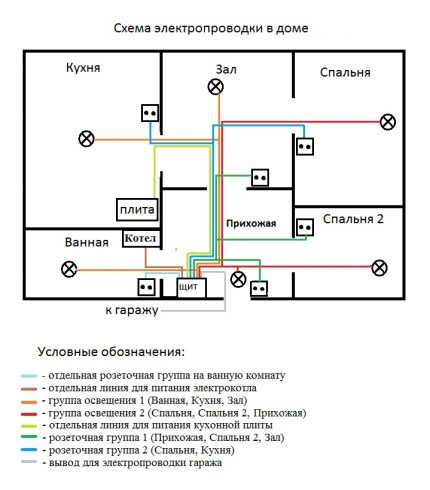

Step # 1 - drawing up the scheme and work plan

You can do the design yourself if you have experience with such work, or with the help of specialists, concluding an agreement with the design organization.

A professionally prepared document contains the following items:

- circuit board;

- electrical installation plan;

- calculations for installing the ground loop;

- conclusions outside the home, if any, autonomous sources of electricity;

- equipment installation plan with specifications;

- if agreement is ahead - a package of permits;

- explanatory note.

But first you should contact Energosbyt to obtain technical specifications - technical conditions that are signed in accordance with SNiP.

Least of all papers will have to be collected by owners who make out a connection with a capacity of less than 15 kW. They need to write a list of electrical appliances and calculate their total power. If the power consumption is more than 35 kW, a linear power supply circuit is needed. For 380 V networks, a three-line diagram is drawn up.

There are not enough 1-2 outlets in the kitchen, as in the bedrooms, you should definitely plan installation of outlet blocks. The location of the power points is not strictly regulated by either the PUE or the building codes. Socket mounting height justified only by ease of use.

In the corridors rational use breakers, in rooms - the usual 2-3-key. They are installed at a height of 90 to 160 cm.

The location of the electrical panel should be planned so that it has easy access, but only for adults - that is, it is better at a height of 150 cm.

All the rules regarding the project apply to any houses, not just wooden ones. But the risk of accidental fire with improper planning or installation of networks is higher precisely in buildings made of wood.

Step # 2 - study the rules and requirements for wiring

If events are held independently and questions arise regarding the use of certain materials, as well as cable management technologies, you should rely on the rules and regulations for connection electricity in a wooden houseset forth in the EMP and SNiP.

For example, one of the requirements is to use only copper wires, the cross section of which is selected according to the network load. They are more expensive, but have better conductivity and mechanical strength, serve for a long time and are easy to install.

A few more requirements, the implementation of which will save the wooden house from harm:

- To protect against damage, condensation, dust contact, the cable is placed in metal pipes, metal flexible sleeves or plastic boxes.

- The joints of the protective pipes or ducts must be carefully sealed.

- It is forbidden to lay electrical wiring through ventilation shafts and channels.

- Before buying a cable, you must correctly calculate its cross-section, which should correspond to the current load.

- For closed wiring, it is recommended to use only metal pipes, flexible and self-extinguishing hoses are not suitable.

- One of the conditions for full protection is a well-assembled electrical panel with a kit circuit breakers and RCD.

It is also not recommended to save on materials and buy cheap products from unverified manufacturers. If there is no experience in the electrical installation of closed wiring, it is better to make an open wiring - there are many ways to safely install and decorate.

Step # 3 - preparing materials and tools

Before making an estimate, it is necessary to determine which tool is useful and how much installation material you need to purchase. This will help a pre-compiled diagram indicating all electrical installations and cable broaches.

For installation, both manual and power tools will be required:

- hammer;

- Screwdriver Set;

- voltage indicator (tester);

- pliers;

- construction knife.

A distinctive feature of tools for electrical work - insulated handles. In addition, protective gloves and rubber-soled shoes should be prepared. Materials are selected, taking into account the load, the installation method, the subsequent decorative finish. The main products will be based on the following products:

In addition, it is necessary to purchase insulation materials for wiring - a metal hose, duct or cable channels, mounting clips, self-tapping screws, aluminum tape for insulation, metal pipes for adapter sleeves. It is recommended to buy a cable with a margin of 10-15%.

After drawing up the project, calculations, coordination (if necessary) and preparation of materials, you can begin to work.

Stages of electrical installation in a wooden house

The process of equipping electrical networks includes not only the installation of wires, everything is important here: input of the power cable into the house, grounding device, filling the electrical panel. Some difficulties are associated with the planning and arrangement of hidden wiring. Any activities should be carried out in accordance with the norms and requirements of SNiP and PUE.

Stage # 1 - we bring electricity to the building

Over the past decades, electricity consumption has increased, and along with this, requirements for arranging the input of an electric line into a house.

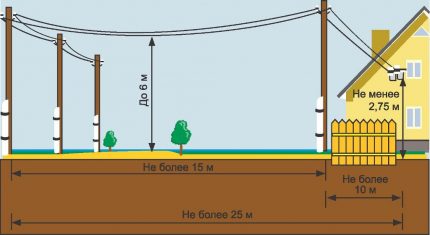

There are two ways to enter cables:

- aboveground or air, implemented using high supports;

- underground or trench.

The first method relates to the traditional ones - power communications are pulled from the power line directly to the house. To do this, use an insulated polyethylene wire SIP, which is called self-supporting. It does not require the installation of an additional cable and is supported by its own bearing capacity.

The underground way to enter the power line is more modern. The wires are laid in a trench with a depth of 0.8 m or more. The protection zone on the surface of the ground is marked with signs. Underground wires, additionally insulated and placed in a metal pipe, are protected as much as possible from moisture, damage and load.

The input of the wire into the wooden structure is carried out by means of a metal sleeve, which can be made from a piece of thick-walled pipe. The main purpose of the sleeve is to prevent contact between the cable and the wooden parts of the house.

Stage # 2 - install the ground loop

There is an old proven grounding device for a private home. Not far from the point of entry of the power cable into the house, a triangular pit 0.5 m deep is excavated in the ground. Metal rods are driven into the corners of the resulting triangle - pins, fittings, connected with thick wire or a corner.

Then a metal conductor is drawn from the circuit to the pole or wall, the end of which is connected to the grounding bus in the electrical panel. The lightning rod is also included in the circuit. The underground structure is covered with soil.

Stage # 3 - equip the electrical panel

The switchboard of a wooden house is the “brain” of the power grid, on which the system’s operation and the safety of residents depend.

In order for it to function correctly, it is necessary to observe a number of important rules:

- shield sizes are selected by quantity RCD and automatic machinesbut with a margin - free places on DIN rails;

- in addition to automatic machines and RCDs, it is necessary to allocate places for the electric meter, grounding and zero buses, connected wires;

- if the shield is placed on the street, it is necessary to ensure its protection from precipitation;

- installation height - at least 1.5 m, so that children or animals do not have access.

Rating of machines, like wire cross sectiondepends on the current load. The parameters of the input machine are focused on the limit of e / energy from the supplier.

To connect or connect wires, it is recommended to use more efficient and replaceable terminals, twisting is not suitable, and soldering takes a lot of time and requires proven skills.

Stage # 4 - wiring correctly

Option 1. Installation of concealed wiring. Before starting installation work, you should determine the type of wiring. The fact is that without protection it is impossible to fix the cable inside wooden elements: timber, logs, etc.

According to PUE-6, there is the possibility of wiring covert wiring, but using a metal pipe.

Hidden wiring is risky and difficult for independent execution: each wire will have to be placed inside a metal pipe, and the joints of the two pipes should be hermetically fastened together.

Firefighters do not recommend using this method, but if it is still important for the house owners to disguise the wires under the cladding, you must follow the instructions below:

- Prepare strobes in logs / timber.

- Install junction boxes so that they are accessible after finishing work.

- Drill holes in walls and partitions and insert bushing sleeves with machined edges into them.

- In places of fastening of switches and sockets also install metal mounting "glasses".

- Choose pipes by diameter so that the wires occupy no more than 40-50% of the internal space.

- Sand the ends of the pipes, as well as the sleeves, or secure them with plastic rims so that the wires do not bend or break.

- Fix pipes on the ceiling or walls with clamps, to metal sleeves - by means of flaring.

- Route the wires according to the diagram inside the pipes.

- Connect the wires in the junction boxes, connect them to the electrical installations and the electrical panel.

After that, it is possible to clad wooden surfaces with clapboard, drywall or other material.

To protect the metal from corrosion, galvanized or stainless steel pipes are chosen. Plain steel is coated with anti-corrosion paint. If increased humidity is noticed, the pipes are laid at an angle - to drain the condensate.

Option # 2. Installation of open wiring. Open wiring is in sight, mounted on top of wooden surfaces, so it should look attractive.

For disguise use corrugated pipes, rigid plastic boxes and baseboards made of non-combustible material. But many do not like the "office" design, and they use retro wiring specifically designed to create an internal electrical network of a wooden house.

If the budget is small and retro wiring is not affordable, boxes made of self-extinguishing plastic are suitable. You can choose the color that is most suitable for wall cladding: white, brown, beige, “wood like”.

Installation Instructions:

- Select cable channels and skirting boards corresponding to the diameter of the wires.

- Remove the upper part - the cover, and fix the base on a wooden surface with self-tapping screws.

- At the joints, in the corners, install junction boxes for connecting wires.

- Install, in accordance with the rules for installing electrical installations in wooden houses, sockets, switches.

- Place the wires in the cable ducts.

- Make a connection on all lines.

- Attach the upper parts - covers, snap in.

Full protection is considered to be where the wires never come into contact with a wooden surface and do not protrude outward.

Stage # 5 - install switches and sockets

Installation overhead electric points is carried out according to general rules, with one exception - an insulating non-combustible material, for example, aluminum or asbestos, is additionally placed under each device.

Switches are mounted on the same principle as sockets.

For accurate installation often use the linings and inserts made of wood. To reduce the risk, they must be treated with a flame retardant - additional protection does not hurt.

Conclusions and useful video on the topic

Video # 1. Risks of improper installation and recommendations for proper arrangement:

Video # 2. General rules for wiring devices:

Video # 3. Overview of the electrical installation in a log house:

Even knowing the basics of electrical work, do not start self-laying wiring in a wooden house without the appropriate education, skills and experience. There are a number of nuances and rules known only to qualified installers.

Please write comments in the block below. Ask questions on obscure and interesting points, post photos on the topic of the article. Share useful information that may be useful to site visitors.

Electrician in a wooden house: diagrams + installation instructions

Electrician in a wooden house: diagrams + installation instructions  Do-it-yourself wiring in the kitchen: wiring diagrams + features of the electrical work

Do-it-yourself wiring in the kitchen: wiring diagrams + features of the electrical work  Installation of open wiring: a review of the technology of work + analysis of the main errors

Installation of open wiring: a review of the technology of work + analysis of the main errors  DIY wiring: how to properly perform electrical work

DIY wiring: how to properly perform electrical work  How to conduct wiring in the apartment with your own hands from the shield: basic schemes and rules + installation steps

How to conduct wiring in the apartment with your own hands from the shield: basic schemes and rules + installation steps  Which wire to use for wiring in the house: recommendations for selection

Which wire to use for wiring in the house: recommendations for selection  How much does it cost to connect gas to a private house: the price of organizing gas supply

How much does it cost to connect gas to a private house: the price of organizing gas supply  The best washing machines with dryer: model rating and customer tips

The best washing machines with dryer: model rating and customer tips  What is the color temperature of light and the nuances of choosing the temperature of the lamps to suit your needs

What is the color temperature of light and the nuances of choosing the temperature of the lamps to suit your needs  Replacement of a geyser in an apartment: replacement paperwork + basic norms and requirements

Replacement of a geyser in an apartment: replacement paperwork + basic norms and requirements

In a wooden house, the main attention should be paid to security. It is necessary to correctly calculate all cable cross sections and correctly choose protective equipment. Safe electrics are, first and foremost, a balanced system where each element matches a different one. The cross section of the wires should correspond to the power consumption. Cables and circuit breakers need to be taken good, from well-known manufacturers, you should not save on this. And of course it is necessary to avoid various kinds of twists wrapped in electrical tape and other unsafe connections.

I completely agree with the opinion of Ivan. The most important thing in a wooden house is fire safety. According to statistics, most of the fires of buildings made of wood occurs due to a fault in the wiring. Experts categorically do not recommend laying wires in PVC pipes, as they are flammable material.

I'm going to mount wiring in a new country house from a bar. Unfortunately, it is difficult to verify the long qualifications of an electrician found in a specialized company via the Internet. What questions should he be asked to understand how competent he is? And I can’t imagine and nowhere can I find how the place for entering the wiring into the house should look like from the outside. From the pillar is the wire extended to the house, and then? How should it be docked with the inside? What is used for this and how to do it right? Since I did not find such information, I ask for your professional help. Thanks in advance for your reply.

I found information, remove the question.

It is good that you found the answers to your questions, but it was nice to share such useful information with other readers.I think that many of these data will be useful, so I will write about the main points. Call an electrician from a trusted company, which gives a guarantee on the work done and the relevant documents after.

Further. At the moment, there are several ways to conduct electricity from a pillar to a house:

- by air;

- underground.

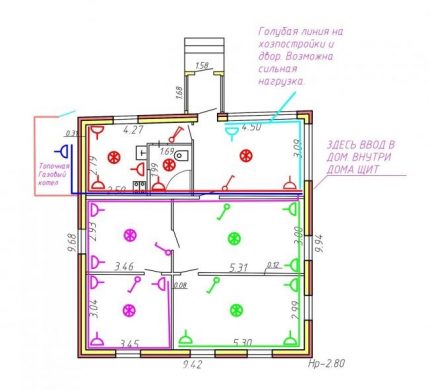

Here, the choice of method already depends on the current connection and the wiring project in the house as a whole. For clarity, I am enclosing a general view of the connection and a real wiring project for a residential building.