Corrugation for electrical wiring: how to choose and install a corrugated sleeve for cable

Do you want to protect electrical wires by wearing a corrugated sleeve on them during installation? The cable must be protected from external damage, right? But you do not know how to mount a flexible corrugation for electrical wiring?

We will tell you how to install a corrugated sleeve. Here you will find out what types of flexible channels are used for these purposes. The article discusses their pros and cons, highlighted the intricacies of installing existing options for electrical pipes made of different materials.

The article is equipped with thematic photos, tips for choosing a corrugated sleeve and video recommendations for laying wires on your own are provided. Visual illustrations will greatly simplify installation and dismantling work.

The content of the article:

Why do I need a corrugated sleeve?

Installation of electrical wiring is a responsible and error-free business. The safety of staying in electrified rooms directly depends on its quality.

The benefits of civilization in the form of luminous bulbs and numerous household appliances, by definition, cannot work without being connected to the mains. And any electric cable under voltage is a source of damaging current, dangerous to humans.

The first protection against electric shock is the insulating braid of the cable itself. Regardless of the material of execution, it reliably protects a person from the current flowing through the veins.

However, insulation is not durable. These are aluminum or copper wires that can last 15–25 years, but the outer braid on them is often damaged 3-4 years after putting the wiring into operation.

The service life of the insulation of the electric wire is greatly reduced due to:

- high humidity (outdoor or indoor);

- overheating at high loads;

- ultraviolet and other factors.

As a result, breakdown, short circuit, fire and electric shock. To minimize risks, electricians also lay wires in hard cable channels or flexible corrugated hoses. On the one hand, it serves as an additional barrier between the electric current and the person, and on the other, it serves as a cable protection.

A cable laid in a corrugated pipe receives protection from:

- squeezing and other mechanical damage;

- ultraviolet radiation and precipitation (when laying wires on the street);

- exposure to moisture.

And the last one is fire safety. This quality is especially important when laying wiring in a wooden house. All corrugated hoses for electrical cables are made of non-combustible or self-extinguishing materials.

This reduces the likelihood of exposure to an open flame on the wire inside the corrugation, and also prevents the spread of fire during short circuits and fire cable braid made of plastic.

Types of corrugations for electric cables

Corrugated wiring for use with open wiring devicewhen laying lines on the street or in a channel formed in a wooden wall. Corrugated pipes are made from various plastics and metals. There are also composite versions of iron wrapped in a layer of PVC.

For the street, it is recommended to choose one sleeve, for laying in a screed or earth another, and for installation behind the interior cladding - the third.

All corrugations according to strength, wall thickness and structure are divided into:

- lungs (withstand loads up to 320 N / 5 cm2) - thin-walled, flexible and fragile, designed for laying under the skin on ceilings and walls;

- medium (rated for loads up to 750 N / 5 cm2) - recommended for installation in wall gates;

- heavy (withstand up to 1250 N / 5 cm2) - thick-walled and rigid, used when installing wires in cable ties on the floor;

- superheavy reinforced (designed for 4000 N / 5 cm2 and above) - sleeves made from a spiral twisted steel wire and plastic sheath, are needed for laying cables underground and on the streets by hanging.

The thinner the walls of the corrugation, the softer and more flexible it is. However, with increased flexibility, the corrugated sleeve decreases resistance to mechanical damage. At the same time, it is difficult to bend a pipe too thick at a right angle, it can simply break.

But such heavy corrugated hoses provide more reliable protection against moisture and dust. This is especially true when laying cables in the ground.

Type # 1 - Metal Hose

Metal in terms of strength when compared with plastics is obviously a more advantageous option. It perfectly protects the cable from the effects of chemistry, moisture, ultraviolet radiation, shock and compression. And in case of fire, the metal hose will last much longer than the plastic counterpart.

Metal corrugations for laying cables are divided into several types:

- RZ-Ts, RZ-TsH, RZ-TSA - made of galvanized steel.

- RZ-SL and RZ-SL-X - from tinned steel tape (tinplate with tin spraying).

- RZ-CPU - with PVC insulation.

Letter "X" in the first two options indicates the presence of cotton, and "AND" asbestos-cement seal. "P" in the latter type of corrugation indicates the outer layer of PVC.

Also, metal hoses for wires exist with flanges at the ends and ends for welding. Plus there are variations of the high pressure hoses in explosion-proof design and under high pressure.

However, such corrugated pipes are more suitable for industrial conditions. For the installation of electrical wiring in the house they are not used because of the high price and the principle unnecessary.

Conventional metal hoses are made of steel tape by wrapping it with a spiral. At the same time, the resulting corrugation is not leakproof. With a strong press, the tape joints immediately diverge, the sleeve simply spreads to pieces.

If a metal sleeve is needed tight, then you should take a product with additional insulation from polyvinyl chloride. In this case, the top layer of self-extinguishing plastic will definitely not allow moisture and dust to the steel base.

Only such corrugations are recommended to be used in bathrooms and in outbuildings, where constant changes in humidity and temperature are the norm.

Type # 2 - Polyvinyl Chloride (PVC)

Gray electrotechnical corrugations made of PVC are of low cost and self-extinguishing. In a fire, they not only do not burn, but due to additives in plastic, they themselves die out.

The main disadvantage of any PVC products is the poor tolerance of UV rays. Under the influence of the sun, this material begins to “deteriorate”, which dramatically reduces their actual life.

Another disadvantage of PVC corrugation is intolerance to low and too high temperatures, as well as excessive humidity. When frozen, this plastic becomes brittle. In the cold, it collapses even from a mild blow.

And in extreme heat (and even if it is in the sun) the polyvinyl chloride corrugated sleeve begins to soften slightly and “leak”.This does not lead to its immediate destruction or damage, however, its service life is sharply reduced due to such operating conditions.

A similar situation with water. With constant exposure to moisture, the walls of such a corrugation begin to gradually collapse. This PVC pipe for water supply was originally designed for a similar effect, while the characteristics of corrugated pipes are somewhat different.

If the wiring must be laid in the bathroom or on the street in direct sunlight, it is better to look for another version of the cable channel for it.

Corrugated PVC pipes are ideal for mounting wires in dry, heated rooms. They are cheap and flexible, there should be no difficulties with laying. But their gray appearance is frankly not happy with presentability and aesthetics.

From above, such corrugations are best covered with finish (wall panels, gypsum with wallpaper on top or lining).

Type # 3 - polyethylene and polypropylene

Corrugations made of polyethylene PND (or LDPE) and polypropylene PPR are approximately equal in cost and characteristics. They are resistant to strong moisture, temperature extremes and ultraviolet rays. Such corrugated hoses are universal.

They can be used both in the house and in street installation. For example, when connecting a connection line heating cable, electrical panel when entering the site, outdoor lighting branches, activation of the irrigation system, etc.

Both versions of these electrical corrugated hoses calmly feel at air temperatures in the range -40 ... + 45 degrees Celsius. At the same time, PND is famous for its resistance to oils, acids and solvents.

It is recommended to use corrugated products from it in garages, utility rooms and on the streets - that is, wherever aggressive technical fluids can get on the wires.

The nuances of the choice and installation of corrugated channels

Plastic corrugations for cables are available in various colors. Gray ones are usually made of PVC, black ones from polyethylene, and blue ones from polypropylene. But strict rules in terms of color do not exist.

Each manufacturer adds dye to the polymer in the manufacture of corrugated pipes as they wish. However, there is an international standard for coloring such products and wires in them, which provides for the choice of color in accordance with the purpose of the cable route.

It is recommended to use white wires and corrugations for computer networks, gray and black for general purpose, green for telephone lines, and red - exclusively for outdoor street installation.

Following these recommendations greatly simplifies the life of electricians when they come to repair in an unfamiliar place. So the direction of each line is immediately clear.

The following gallery of step-by-step photos will familiarize you with the procedure for laying the cable in the corrugated pipe:

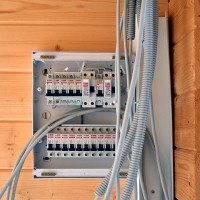

After pulling the cable into the corrugated channel, we proceed to fastening the lines to the building structures:

For a cable wiring device with a cross-section of 3 × 2.5 mm², a corrugated pipe with a diameter of 16 mm and mounting clips of the appropriate size are usually purchased.

Installation of corrugations and wiring in them is carried out in five stages:

- Corrugated sleeve and cable are cut into pieces of the desired length.

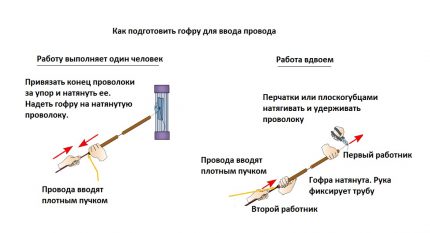

- With the help of a cable stocking, a built-in broach, or simply inserted into the pipe, the wire is drawn into the corrugation.

- Sleeves with a cable inside are fixed in a strob, on a floor or a wall.

- The laid and fixed corrugations are connected to the input holes on the cases of boxes, shields and socket boxes, or simply inserted into them, and the wires are brought out.

- Next - the usual wiring of devices connected to the mains.

To simplify myself electrical wiring, on sale a corrugated sleeve should be sought with a special plait (broach) inside. This is an ordinary wire that was previously pulled through a corrugated pipe in a factory.

Only when cutting the corrugation, you need to be careful so that this broach does not go inside. The cable on it for pulling into the sleeve is attached using conventional electrical tape.

Metal corrugation must be grounded. And to do this is on both sides of the sleeve. The inner diameter of the corrugated pipe is selected by doubling the total cross-section of all cables laid in it. This is necessary both to simplify installation and to prevent overheating of wires inside.

The corrugation must enter the body of the outlet, switch or flap flush. Any “peeping” of the cable or gaps between the end of the pipe and the housing of the installation or switchgear are not allowed.

In this case, you can forget about protecting the wiring with a corrugated sleeve. Such improper installation will only take time and money, there will be zero sense from it.

Conclusions and useful video on the topic

So that you can understand all the nuances of the types of corrugations for low-current and electric cables, we have made a selection of video materials for you on this topic.

After reviewing the following reviews and descriptions of the installation, you definitely will not have any questions about the need, types and characteristics of the implementation of electrical work using corrugated hoses.

Video # 1. The importance of installing additional insulation on the wiring in the form of a special corrugation:

Video # 2. Wire pulling through corrugated hoses in detail:

Video # 3. Overview of different types of electrical corrugations:

Cable channels in the form of corrugated hoses are extremely easy to install. They are inexpensive, and the benefits of such additional protection for wiring are enormous.

The cost of repairs in the event of a fire from a short circuit will obviously be higher. The pull through the wiring sleeve of the cable only at first glance looks complicated. Everything can be done independently.

Please write comments in the block below. Tell us about how you built or repaired the wiring using the corrugation as a cable channel. Perhaps you have questions, have useful information and photos on the topic of the article?

Installation of open wiring: a review of the technology of work + analysis of the main errors

Installation of open wiring: a review of the technology of work + analysis of the main errors  Cable channel for electrical wiring: types of structures and their classification

Cable channel for electrical wiring: types of structures and their classification  Wiring in the apartment: an overview of the main schemes and the procedure for performing work

Wiring in the apartment: an overview of the main schemes and the procedure for performing work  Wiring diagram in the apartment: electrical wiring for different rooms

Wiring diagram in the apartment: electrical wiring for different rooms  DIY wiring: how to properly perform electrical work

DIY wiring: how to properly perform electrical work  Calculation of cable cross-section by power and current: how to calculate wiring correctly

Calculation of cable cross-section by power and current: how to calculate wiring correctly  How much does it cost to connect gas to a private house: the price of organizing gas supply

How much does it cost to connect gas to a private house: the price of organizing gas supply  The best washing machines with dryer: model rating and customer tips

The best washing machines with dryer: model rating and customer tips  What is the color temperature of light and the nuances of choosing the temperature of the lamps to suit your needs

What is the color temperature of light and the nuances of choosing the temperature of the lamps to suit your needs  Replacement of a geyser in an apartment: replacement paperwork + basic norms and requirements

Replacement of a geyser in an apartment: replacement paperwork + basic norms and requirements

It is clear that for a long time no one has laid cables into the wall without corrugations. It’s really worth getting rid of metal corrugations, but PVC are excellent not only for heated rooms. They themselves were mounted in the basements. At the same time, their service life is quite satisfied. For outdoor work, it is necessary to take not PVC, but polypropylene or polyethylene corrugations precisely because of their resistance to the effects of the atmosphere.

I decided to replace the wiring in the house, since the house-building is from the old housing stock, the wiring is all made of aluminum. I was looking for help on the network - I myself am not an electrician and I don’t understand this very well.Well, I read and understood how to use the corrugation correctly, how to choose the suitable option for arranging the line. It turned out very well. It is convenient that I have learned all the information on the topic of correct installation: now I am boldly working with corrugation.

Corrugation allows you to lay cables on any building materials that have different thermal resistance, while maintaining the rated current of the cable. However, the cable sheath, in comparison with a wire in single insulation, reduces the rated current of the cable even when it is laid open by about 10%.

When laying the cable in the pipe (and the corrugation is a flexible PVC pipe), the influence of the cable sheath on its rated current is even stronger. The rated current of the cable when it is laid in the corrugation is reduced by 22%, and the single-core wire in single insulation only by 10%.

In general, a cable in a corrugation has a rated current of 22% less than a single-core wire in single insulation with equal cross-sections of cable and wire cores. That is, the cable sheath and the proximity of the cores in the cable due to the thermal resistance of its sheath lead to a decrease in net power transmitted through the cable by about 1.3 kilowatts.

In addition, at the same time there is also a rise in the cost of wiring by about 27%. So the cables must be used for their intended purpose - for open or hidden wiring. And in the corrugation, it is necessary to pull single-core copper wires in single insulation. But the cables are also not suitable for stucco gates, of course, if you lay them on reinforced concrete, under a layer of sand-cement plaster, then, according to the PUE, such a scheme is allowed, but you can not lay cables in gates in materials with high thermal resistance.

In these cases, wiring should only be done in the corrugation. For example, for lightweight aerated concrete or foam concrete in gates under a layer of gypsum plaster, the rated current of the cable is already reduced by about half compared with its laying in the corrugation. And this rated current is approximately 2.7 times less than the current of single-core wires in single insulation of the same cross-section when laying single-core wires in single insulation in corrugation in the same strobes in aerated concrete under a layer of gypsum plaster. Of course, we are talking exclusively about the copper conductors of cables and wires, while their rated currents are taken from the PUE tables.

Thanks for the info!

Good afternoon, Anatoly. I will analyze your comment in paragraphs.

The first paragraph - let's say entry into the house is done through the basement. There it is more expedient to forward the route along cable shelves. They retain the current carrying capacity of the cable better than corrugation.

The second paragraph - the pipe does not affect the cable sheath. Corrugation - too. They degrade the cable-environment heat transfer.

The third paragraph is incorrect to compare a four-core cable with a single wire.

The fourth paragraph - here you, having finished the general reasoning, answer for yourself when to use wires, when cables. PUE 2.1.4, of course, allows laying a cable under the plaster, but this option is in fifth place, as appropriate.

The fifth paragraph - the exclusivity of the corrugation proclaimed by you, contradicts paragraph 2.1.4 of the PUE.

Conclusion - your calculations do not bear practical value - engineers are guided by the conditions in which wires and cables will be operated.