Self-locking terminal blocks: types and scope + recommendations for customers

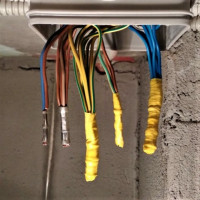

The rapid development of electricians was marked by a mass of innovations that affected even simple but extremely necessary connecting elements - terminals. Among the existing variety of such devices, self-clamping terminal blocks occupy a special place, due to which the wiring is greatly simplified.

You will learn all about the innovative form of connectors from our article. We will introduce the assortment currently presented to a novice electrician. Consider the most popular connectors of this kind, in high demand.

The content of the article:

The device of self-locking connectors

Technically, the design of self-clamping terminals does not stand out with special difficulties, despite the promising name.

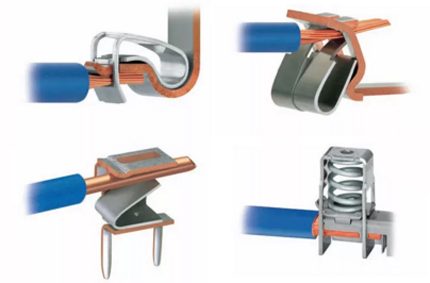

As a rule, the main working component of such products is the spring element. It is due to the spring action that the self-clamping property of the terminal is obtained.

The design of the terminal involves the concentration of force in a specific area, limited, for example, by the parameter of the wire section. Therefore, self-clamping connectors of various form factors are supplied to the market, providing the ability to work with various electrical wires.

The clamping element of the terminal block is traditionally made on the basis of a copper alloy having a sufficient level of rigidity. The contact area of the clamping element is treated with a tin-lead coating.

Such an approach to processing guarantees reliable protection against possible corrosion, ensures the durability of the product.

The self-clamping effect is ensured by a spring made on the basis of durable steel. The spring "supports" the clamping element with a calculated force that is almost equal to the force that the user must apply to the working lever before inserting the wire into the groove.

According to technical information, the self-clamping terminals are designed to work with conductors with a cross section of 0.08-95 mm at operating voltages up to 1000 volts. Operating current parameters are allowed in the range of 6-320A. The main area of application is household, but industrial products are also produced.

Varieties of self-locking terminals

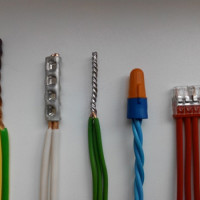

Actually, there are two varieties of products of this type:

- Lever

- Push.

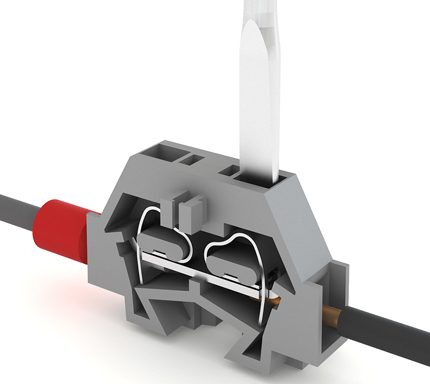

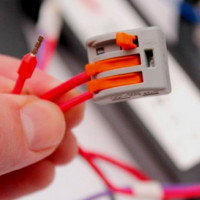

The first variety is a design where micro levers are used. A potential user raises or squeezes such a lever, and then inserts the wire end into the socket. After releasing the lever, the copper or aluminum core is firmly pressed by the spring-loaded plate.

The second variety usually involves an additional action with a screwdriver or similar tool. The screwdriver blade is inserted into an additional groove, usually located above the conductor entry groove, and light pressure is applied. Holding the screwdriver in this position, insert the wire end into the input hole until it stops.

Approximately in the same way, self-clamping push-in terminal blocks work, where the use of a screwdriver is not required. In this embodiment, the end of the conductor is simply inserted into the input window with some pressure until it stops. Usually this type of terminal is intended for single-core copper wires.

The noted two varieties are supplemented by a mass of subspecies, to some extent, modernized terminals.

A vivid example in this regard is demonstrated by the products of the well-known German company Wago. Connectors which are reliable, simple and easy to use. It is not surprising that most electricians choose these terminals. Get to know them closer.

Features of using various terminals

German manufacturer Wago offers an extensive range self-locking terminalsamong which, in terms of subspecies, the following stand out:

- cage clamp - flat configuration;

- fit clamp - mortise configuration;

- leaf spring configurations.

Wago products are divided into series for ease of selection and configuration. Consider what serial modifications of self-clamping terminals exist.

Subtype # 1 - 222 Series Stranded Wire

Products in this series represent a lever-type construction. As a rule, these are painted wire terminals bright orange color, which allows you to quickly detect the connection object in conditions of mass wiring.

Despite its specific purpose, the 222 series is just as well used for connecting single-core conductors. The rated operating voltage is limited by the parameter 380 volts at a maximum permissible current of 32A.

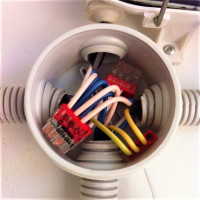

222 Series self-clamping terminal blocks are used to create connections inside junction boxes.At the household level, they are often used in the installation of lighting networks.

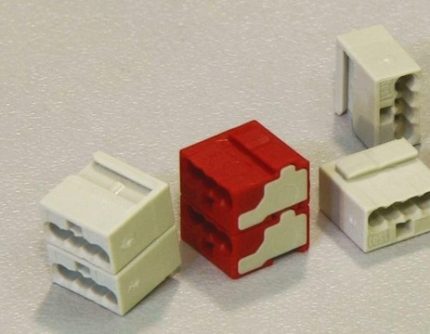

Subtype # 2 - 243 Series for Micro-Clamp

Given the micro-performance of this series of products, the rated voltage for the connection is allowed no higher than 100 volts at a rated current of 6A. The manufacturer claims the use of this type wire clamps only for solid wire. Conductors on both copper and aluminum are supported.

This is one of the subspecies of the self-locking terminal blocks, where the use of auxiliary levers is not provided.

The standard version of the 243 series terminal block is a rectangular module for placing four conductors inside four contact holes. Products in this series are usually painted in dark gray tones. They are used in the installation of video surveillance systems and in the assembly of other systems and networks where miniature connectors are required.

Subtype # 3 - 2273 series for lighting installation

2273 or Compact is a kind of self-clamping specialized terminal blocks, that is, designed for use in the construction of a lighting network circuit. True, the manufacturer does not make severe restrictions. As the documentation indicates - it is allowed to work with conductors with a size of 0.5-2.5 mm2 by section.

The peculiarity of this series is the presence of products containing paste and not containing inside. As a rule, a special conductive paste is used on the installation of aluminum wires in order to create optimal conditions against the appearance of metal oxides on clamped conductors and terminal blocks themselves.

Subtype # 4 - 773 Series for Junction Boxes

The main purpose of this series of terminal blocks is to work with conductors on a copper base (single-core / multi-core) of the 3rd class of flexibility.

The insertion of veins with a section of 1-6 mm is allowed2 depending on the configuration of the structure for a particular section. Terminals belong to the category of vibration-resistant products. Operating current 25-40A.

The body of such Wago products is made of transparent insulating material, which allows you to control the depth of penetration of the core into the contact groove. Also on the case there is a "control" contact - points where it is possible to connect probes of measuring instruments.

Subspecies # 5 - 862 Series with Presser Foot

This series provides connection of single-core and multi-core wires. In this case, up to 4 wires of both types with a diameter of not more than 4 mm can be connected to one terminal. The 862 series terminals are designed for use with voltages up to 500 volts.

Product uniqueness - there is no need to use an electric tool when making a connection. The design has a special button - a fixing foot, thanks to which it is easy and simple to connect / disconnect the conductor manually or with a screwdriver.

The design also differs by the presence of a fixing leg for attaching this connector.

Rules for choosing self-locking terminals

The main rule of a potential buyer of self-locking terminal blocks, perhaps, is to highlight the mandatory verification of goods for authenticity. On the commercial market there is a mass of fake goods marked with a German brand - manufacturer Wago warns about this.

The cost of such products is reduced, which naturally attracts the buyer. However, this kind of savings can turn into troubles when operating the assembled circuits.

Meanwhile, without unnecessary warnings, it should be obvious that a forged product is a significant decrease in quality. How to choose the right wire connectorswithout fear of getting a fake? In principle, everything is quite simple. You only need to be more careful when choosing self-clamping terminals for installation.

The branded product traditionally has the Wago logo, printed in clear print, usually on the top or side of the case. Also, the main parameters are applied on the side - voltage and current.

The color of the insulating material of the branded products is monotonous clear color. On the back / side of the terminal block is a mini-briefing of the connection.

Compared to Chinese counterfeit goods, terminal blocks, as a rule, have none of the above differences. In addition, the fake immediately differs in the diffuse color of the insulator, often in different colors.

Of course, the main points of choice are the purely technical parameters of the self-clamping terminal blocks. In particular, working voltage and allowable conductive current.

If the mounted circuits are designed for operating voltages that exceed the capabilities of the terminal blocks, respectively, the application becomes inappropriate and, moreover, dangerous.

You will learn about what color the connected wires are marked with next article, the contents of which we advise you to read.

Conclusions and useful video on the topic

The video below demonstrates a comparative analysis of branded terminal blocks with products that are completely fake and quite widely presented on the market.

The moment is considered - how to distinguish a branded self-clamping terminal from a fake:

Self-locking devices with which an electrical connection is arranged are convenient and practical. But with all the advantages of such accessories, their use is somewhat limited by technical and operational parameters.

But the development of such devices is actively continuing. It is not surprising if in the near future there will appear a kind of universal terminals for working in different conditions.

Tell us about how to repair or upgrade the power grid using clamp connectors. Share the technological nuances that beginner electricians should use. Please leave comments in the block below, post photos and ask questions about the topic of the article.

Terminals for connecting wires: which terminal blocks are better and how to work with them

Terminals for connecting wires: which terminal blocks are better and how to work with them  Wago terminal blocks: varieties and their characteristics + subtleties of connecting wires with Vago terminal blocks

Wago terminal blocks: varieties and their characteristics + subtleties of connecting wires with Vago terminal blocks  How to connect wires without soldering: the best ways and their features + installation recommendations

How to connect wires without soldering: the best ways and their features + installation recommendations  Wire connectors: the best types of connectors + what to look at when choosing a connector

Wire connectors: the best types of connectors + what to look at when choosing a connector  Methods of connecting electrical wires: types of connections + technical nuances

Methods of connecting electrical wires: types of connections + technical nuances  Junction box for indoor and outdoor wiring: types, classification + installation instructions

Junction box for indoor and outdoor wiring: types, classification + installation instructions  How much does it cost to connect gas to a private house: the price of organizing gas supply

How much does it cost to connect gas to a private house: the price of organizing gas supply  The best washing machines with dryer: model rating and customer tips

The best washing machines with dryer: model rating and customer tips  What is the color temperature of light and the nuances of choosing the temperature of the lamps to suit your needs

What is the color temperature of light and the nuances of choosing the temperature of the lamps to suit your needs  Replacement of a geyser in an apartment: replacement paperwork + basic norms and requirements

Replacement of a geyser in an apartment: replacement paperwork + basic norms and requirements

Self-locking terminal blocks are a very useful invention. Finally, there is a chance that thanks to them there will be fewer unfortunate electricians who leave behind fire-hazardous twists. Terminal blocks cost a penny, are easy to use and must be in the arsenal of any professional. I am glad that the terminal blocks are practically devoid of minuses.I myself can recommend products from the company WAGO, because I had to work with them.

Of course, if you use self-clamping terminal blocks, it is best to choose VAGO, but personally, I practically do not use them anywhere, since they have one very big minus. Stranded wires cannot be connected with these terminals, namely stranded wires are used in 90% of internal wiring.

In addition, there is still no information on how the terminal block will behave after 10 or 20 years of operation. But everyone is well aware that a well-soldered twist can last 50 years or more and burnout is extremely rare.

This is where it is interesting 90% use a multicore? For example, I have all mono-core wiring and I recommend everyone to use a mono-core, since it is much more reliable - there is more trouble, but the quality is higher. And why can not stranded wire be used in self-clamping terminals? Twisted well and forward.

As I understand it, self-clamping terminal blocks are generally not suitable for stranded wires. No WAGO, no others.

Good afternoon, Anton.

If you go to the official WAGO website, you will see that some models are suitable for single-core, others for multi-core, others connect both wire formats. For multicore copper, for example, WAGO 222-415 are designed - they have five connectors designed for conductors with a cross section of 0.08 ~ 4 mm2. The rated voltage is 380 volts, the current is 32 amperes. Under aluminum wires filling is provided - conductive paste Alu-Plus. For persuasiveness, I attached a screenshot of part of the passport data.

Why you can not use wires with multi-wire cores - you can read here.

Regarding the “well-soldered twist”, I recall - in paragraph 2.1.21 of the PUE this type of connection is in third place. About 50 years of wiring service - read the screenshot. There, full wear takes 40 years.