Connection diagrams of magnetic starter for 220 V and 380 V + features for independent connection

Magnetic starter - a device that is responsible for the uninterrupted and standards-compliant operation of equipment. With its help, the distribution of the supply voltage is carried out and the operation of the connected loads is controlled.

Most often, it is powered through electric motors. And through it, the engine is reversed, it is stopped. All these manipulations will allow the correct connection of the magnetic starter, which can be assembled independently.

In this material we will talk about the device and the principles of operation of the magnetic starter, as well as understand the intricacies of connecting the device.

The content of the article:

The difference between a magnetic starter and a contactor

Often, when selecting a switching device, confusion arises between magnetic starters (MP) and contactors. These devices, despite their similarities in many characteristics, are still different concepts. The magnetic starter combines a number of devices, they are connected in one control unit.

The MP can include several contactors, plus protective devices, special consoles, control elements. All this is enclosed in a housing that has some degree of moisture and dust protection. Using these devices, they mainly control the operation of induction motors.

Contactor is a one-piece device with a set of functions provided for by a specific design. While starters are used in rather complex circuits, contactors are mainly present in simple circuits.

Device design and purpose

Comparing the connection of the MP and the contactor, we can conclude that the first device differs from the second in that it is used to start the electric motor. You can even say that the MP is the same contactor that controls the electric motor.

The difference is so arbitrary that recently many manufacturers have called MP AC contactors, but with small dimensions. Yes, and continuous improvement of contactors made them universal, because they have become multifunctional.

The purpose of the magnetic starter

Embed MP and contactors in power networks that transport current with alternating or constant voltage. Their action is based on electromagnetic induction.

The device is equipped with signal contacts and those through which power is supplied. The first are called auxiliary, the second - workers.

MP remotely control electrical installations, including electric motors. Their role as protection is zero - only the voltage disappears or at least drops to a limit below 50%, the power contacts open.

After stopping the equipment, in the circuit of which the contactor is mounted, it will never turn on by itself. To do this, you must press the "Start" key.

For safety, this is a very important point, since accidents caused by spontaneous switching on of the electrical installation are completely excluded.

Starters in the circuit of which are included thermal relays, protect the electric motor or other installation from prolonged overloads. These relays can be bipolar (TRN) or unipolar (TRP). The operation occurs under the influence of the motor overload current flowing through them.

Design and function

For the MP to work correctly, it is necessary to adhere to certain installation rules, have an understanding of the basics of relay technology, and correctly choose the power supply circuit of the equipment.

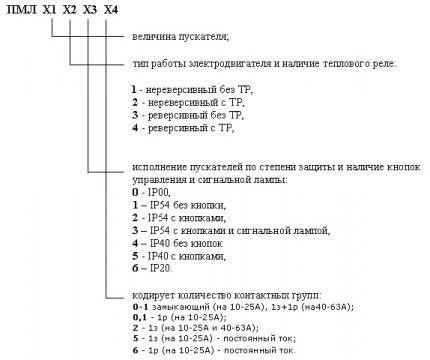

Since the devices are designed to operate over a short period of time, the most popular are MFs with normally open contacts. The greatest demand is for MP series PME, PAE.

The first are built into signal circuits for electric motors with a power of 0.27 - 10 kW. The second - with a capacity of 4 - 75 kW. They are designed for a voltage of 220, 380 V.

There are four options:

- open;

- protected;

- dustproof;

- dustproof.

PME starters include a two-phase TRN relay in their design. In the PAE series starter, the number of built-in relays depends on the value.

At a voltage of about 95% of the rated starter coil, it is capable of ensuring reliable operation.

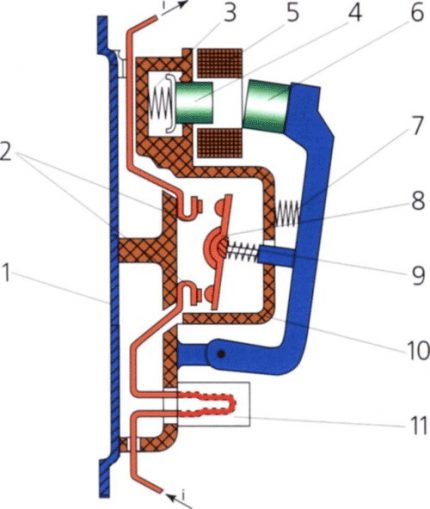

The MP consists of the following main nodes:

- core;

- electromagnetic coil;

- Anchors

- frame;

- mechanical sensors of work;

- Contactor groups - central and secondary.

Also, the design can include, as additional elements, a protective relay, electric fuses, an additional set of terminals, a starting device.

In fact, this is a relay, but it turns off a much larger current. Since the electromagnets of this device are quite powerful, it has a high response speed.

An electromagnet in the form of a coil with a large number of turns is designed for a voltage of 24 - 660 V. Which is located on the core, a large power is needed to overcome the force of the spring.

The latter is designed to quickly disconnect the contacts, the speed of which depends on the magnitude of the electric arc. The faster the opening occurs, the smaller the arc and in the best condition the contacts themselves will be.

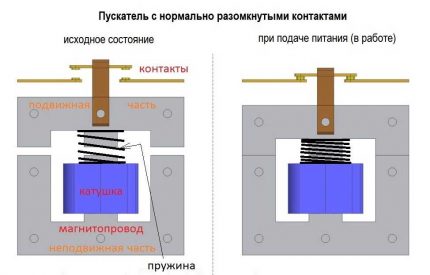

Normal state when contacts are open. At the same time, the spring holds the upper section of the magnetic circuit in a raised state.

When power is supplied to the magnetic starter, current flows through the coil and forms an electromagnetic field. It attracts the mobile part of the magnetic circuit by compressing the spring. The contacts are closed, power is supplied to the load, as a result, it is included in the work.

In case of power failure, the electromagnetic field disappears. Straightening, the spring makes a push, and the upper part of the magnetic circuit is at the top. As a result, the contacts diverge and the power to the load disappears.

Some starter models are equipped with surge arresters, which are used in semiconductor control systems.

The power supply to the control coil after connecting the magnetic starter is realized from alternating current, but the type of current does not matter for this device.

Starters, as a rule, are equipped with two types of contacts: power and blocking. Through the former, the load is connected, and the latter protect against incorrect actions when connected.

Power MP can be 3 or 4 pairs, it all depends on the design of the device. In each of the pairs there are both mobile and fixed contacts connected to the terminals located on the body by means of metal plates.

The first are different in that the load is constantly supplied with power. Decommissioning occurs only after the starter is activated.

Contactors with normally open contacts are energized exclusively during starter operation.

Normally closed differ in that the load is constantly supplied with power, and disconnection occurs only after the starter is activated. Contactors with normally open contacts are energized exclusively during starter operation.

Features of mounting the starter

Incorrect installation of the magnetic starter can have consequences in the form of false positives. To avoid this, it is impossible to select areas subject to vibration, shock, shock.

Structurally, the MP is designed so that it can be mounted in an electrical panel, but in compliance with the rules. The device will work reliably if the place of its installation is a straight, flat and vertical surface.

Thermal relays should not be heated from external heat sources, which will negatively affect the operation of the device. For this reason, they should not be placed in places subject to heat.

It is absolutely impossible to install a magnetic starter in a room where devices with a current of 150 A are mounted. Turning these devices on and off provokes a quick blow.

To prevent distortion of the spring washers located in the contact clamp of the starter, the end of the conductor is bent U-shaped or into a ring.When you need to connect 2 conductors to the clamp, it is necessary that their ends are straight and are located on two sides of the clamp screw.

The inclusion in the operation of the starter must be preceded by inspection, checking the health of all elements. Moving parts must be moved by hand. Electrical connections must be checked with the circuit.

Popular MP connection schemes

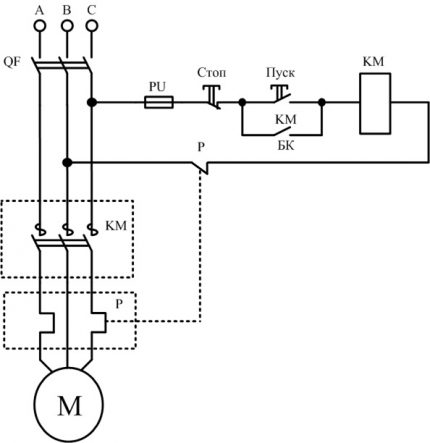

Most often use a wiring diagram with a single device. To connect its main elements use a 3-core cable and two open contacts in case the device is turned off.

Under normal circumstances, relay P is closed. When you press the Start key, the circuit closes. Pressing the “Stop” button parses the circuit. In the event of an overload, the thermal sensor P will trip and break contact P, the machine will stop.

With this circuit, the rated voltage of the coil is of great importance. When the force on it is 220 V, the engine is 380 V, if connected to a star, such a scheme is not suitable.

For this, a circuit with a neutral conductor is used. It is advisable to apply it in case of connecting the motor windings with a triangle.

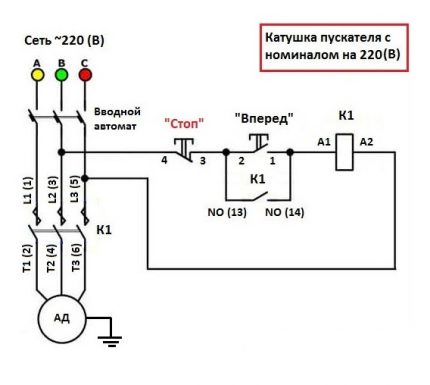

Subtleties of connecting a device to 220 V

Regardless of how it is decided to connect a magnetic starter, the project must have two circuits - power and signal. Voltage is supplied through the first, and equipment operation is controlled by the second.

Power circuit features

Power for the MP is connected through the contacts, usually indicated by the symbols A1 and A2. They get a voltage of 220 V, if the coil itself is designed for such a voltage.

It is more convenient to connect the “phase" to A2, although there is no fundamental difference in the connection. The power source is connected to the contacts below on the case.

The type of voltage does not matter, the main thing is that the rating does not go beyond 220 V.

The disadvantage of this connection option is the fact that you need to manipulate the plug to turn it on or off. The circuit can be improved by installing an automatic machine in front of the MP. With it, turn the power on and off.

Change control circuit

These changes do not concern the power circuit; in this case only the control circuit is modernized. The whole scheme as a whole is undergoing minor changes.

The keys are embedded sequentially in front of the MP. The first is “Start”, followed by “Stop”. The contacts of the magnetic starter are manipulated by means of a control pulse.

Its source is the pressed start button, which opens the way for supplying voltage to the control coil. The “start” does not have to be kept on.

It is supported by the principle of self-capture. It consists in the fact that in parallel with the "Start" button additional self-locking contacts are connected. They supply voltage to the coil.

After their closure, the coil self-energizes. The break of this circuit leads to the shutdown of the MP.

The stop key is usually red. The start button can have not only the inscription “Start”, but also “Forward”, “Back”. Most often it is green, although it may be black.

3-phase network connection

It is possible to connect a 3-phase power supply through an MP coil, operating from 220 V. Typically, the circuit is used with an induction motor. The signal circuit does not change.

The power circuit has differences, but not very significant. Three phases are fed to the inputs indicated on the plan as L1, L2, L3. The three-phase load is connected to T1, T2, T3.

Input to the thermal relay circuit

In the gap between the magnetic starter and the induction motor, a thermal relay is connected in series. Its selection is carried out depending on the type of motor.

Connect the relay to the terminal with a magnetic starter. The current in it passes to the motor sequentially, simultaneously heating the relay. The top of the relay is equipped with auxiliary contacts integrated with the coil.

Relay heaters rely on the limiting value of the current flowing through them. This is done so that when the engine is in danger due to overheating, the relay could turn off the starter.

We also recommend that you read our other article where we talked about how to choose and connect an electromagnetic starter for 380 V. More - go to the link.

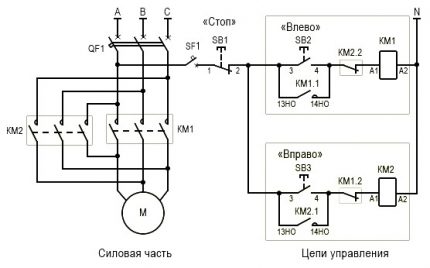

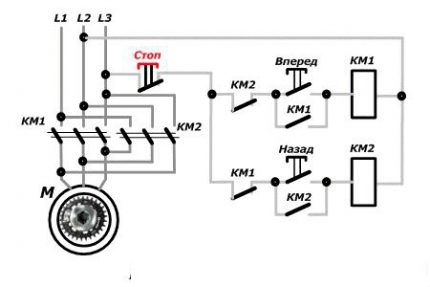

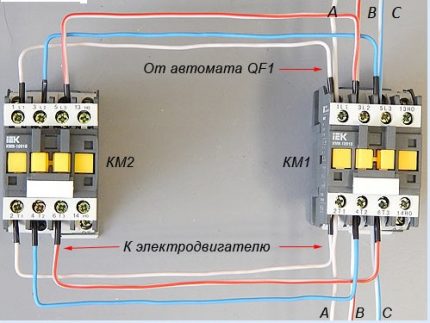

Starting the motor with reverse travel

For the functioning of a separate equipment, it is necessary that the engine can rotate both left and right.

The connection diagram for this option contains two MPs, a button post or three separate keys - two start “Forward”, “Back” and “Stop”.

From short the power circuit is protected by normally closed contacts KM1.2, KM2.2.

The preparation of the circuit for work is as follows:

- Include AB QF1.

- Phase A, B, C flows to the power contacts of the MP KM1, KM2

- The phase that supplies the control circuit (A) through SF1 (signal circuit breaker) and the SB1 stop key is applied to pin 3 (keys SB2, SB3), pin 13NO (MP KM1, KM2).

Further, the circuit operates according to an algorithm that depends on the direction of rotation of the motor.

Engine reverse control

The rotation starts when the SB2 key is pressed. In this case, phase A is fed through KM2.2 to the MP coil KM1. The start of the starter starts with the closure of normally open contacts and the opening of normally closed.

Closing KM1.1 provokes self-locking, and closing contacts KM1 is followed by the supply of phases A, B, C to the identical contacts of the motor windings and it starts rotation.

The action taken will disconnect the circuit, the control phase A will no longer be fed to the inductor KM1, and the core with the contacts, by means of the return spring, will be restored to its original position.

The contacts will disconnect, the voltage will be cut off to the motor M. The circuit will be in standby mode.

Start it by pressing the SB3 button. Phase A through KM1.2 will arrive at KM2, MP, will work and through KM2.1 will be on self-pickup.

Further, the MP through contacts KM2 will change phases. As a result, the motor M will change the direction of rotation. At this time, the connection KM2.2, located in the circuit supplying the MP KM1, will disconnect, preventing the inclusion of KM1 while KM2 is functioning.

Power circuit operation

Responsibility for phase switching to redirect engine rotation lies with the power circuit.

When the contacts of the MP KM1 are activated, phase A enters the first winding, phase B enters the second winding, and phase C enters the third winding. The motor rotates to the left.

When KM2 is triggered, phases B and C are relocated. The first falls on the third winding, the second on the second. Phase A changes do not occur. The engine will begin to rotate to the right.

Conclusions and useful video on the topic

Details on the device and connection of the contactor:

Practical help in connecting the MP:

According to the above diagrams, you can connect a magnetic starter with your own hands to both 220 and 380 V.

It must be remembered that the assembly is not difficult, but for a reverse circuit, the presence of two-way protection is important, making it impossible to turn on. In this case, the blocking can be both mechanical and by means of blocking contacts.

If you have questions about the topic of the article, please leave your comments in the block below. There you can provide interesting information or give advice on connecting magnetic starters to visitors to our site.

Solid State Relays: Types, Practical Applications, Wiring Diagrams

Solid State Relays: Types, Practical Applications, Wiring Diagrams  380V electromagnetic starter: device, connection rules and selection recommendations

380V electromagnetic starter: device, connection rules and selection recommendations  Intermediate relay: how it works, labeling and types, nuances of adjustment and connection

Intermediate relay: how it works, labeling and types, nuances of adjustment and connection  Thermal relay: operating principle, types, connection diagram + adjustment and marking

Thermal relay: operating principle, types, connection diagram + adjustment and marking  Time relay: operating principle, wiring diagram and tuning recommendations

Time relay: operating principle, wiring diagram and tuning recommendations  Electromagnetic relay: device, marking, types + subtleties of connection and adjustment

Electromagnetic relay: device, marking, types + subtleties of connection and adjustment  How much does it cost to connect gas to a private house: the price of organizing gas supply

How much does it cost to connect gas to a private house: the price of organizing gas supply  The best washing machines with dryer: model rating and customer tips

The best washing machines with dryer: model rating and customer tips  What is the color temperature of light and the nuances of choosing the temperature of the lamps to suit your needs

What is the color temperature of light and the nuances of choosing the temperature of the lamps to suit your needs  Replacement of a geyser in an apartment: replacement paperwork + basic norms and requirements

Replacement of a geyser in an apartment: replacement paperwork + basic norms and requirements