How to change and remodel the outlet: step-by-step instructions on how to replace

The situation when an electrical outlet fails is a common phenomenon that requires professional intervention by a master. But with a competent approach to resolving the issue, it is not at all necessary to resort to the help of specialists.

What nuances to consider when replacing an old connection point with a new one and how to change the outlet on our own will be considered in more detail.

The content of the article:

The principle of replacing outlets

Usually those sockets that are most often used fail.

There may be many reasons for remaking the outlet. It:

- violation of the operability of the connection point, for example, when the device body is melted or the socket falls out of the wall;

- in order to improve electrical equipment;

- when changing designs from a banal aesthetic point of view.

In any case, the replacement of the outlet should be carried out in strict accordance with the rules of SNiP.

Regardless of the reason, when choosing a feeding device, it is important to consider a number of key factors:

- Correspondence of connection point parameters. The operational characteristics of the installed outlet must exactly meet the requirements for a particular room. So, to "power" the kitchens and bathrooms, you need to use devices that have a high degree of protection of the housing. Read how to choose such a socket Further.

- Wiring Method. When installing outlets, both open and closed installation methods are used. To implement each of these options on the radio market, a wide range of embedded sockets and overhead execution.

- Aesthetic qualities. A large selection of equipment, available in a wide color palette, allows you to organically fit the connection points into any stylistic interior solution.

When choosing and installing the outlet should focus on the type of network.So in a three-wire network, a conventional design can not do without grounding contact.

But even if a two-wire network is laid in the house, electricians still recommend using sockets equipped with grounding terminals. The main argument of this decision is the fact that metal inserts will strengthen the strength not only of the connection point, but also of the plug itself, thereby extending the life of the product.

Step-by-step dismantling instruction

Working with electricity requires attention and caution. When dismantling and replacing the outlet, it is important to observe safety precautions. In this article, we will talk about replacing a wall outlet in a two-wire network. But if you need to replace the ground outlet, we recommend that you familiarize yourself with this stuff.

In multi-storey buildings, shields with batch switches that cut off the supply of electricity to apartments are located on landings. It is necessary to determine the appropriate bag on the shield, and then transfer it to the upper “off” position.

If desired, only one room can be de-energized, in which a replacement will occur. But for this it is necessary to clearly know which of the machines is responsible for the corresponding line.

Since when you turn off the power supply, you temporarily lose lighting, when replacing the outlet in a dark room or at dusk, you should worry about an alternative light source in advance. It is convenient to use a flashlight on batteries or a lamp connected to another powered line as a backlight.

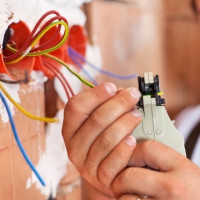

The wires at the connection point are separated into phase and zero threads. The indicator alternately touches the phase and zero wire of the outlet. If it is energized, the lamp on the screwdriver will light up. Without fear, you can replace the connection point only if the indicator does not react when the probe comes into contact with the bare ends.

Dismantling the outlet is performed in the following sequence:

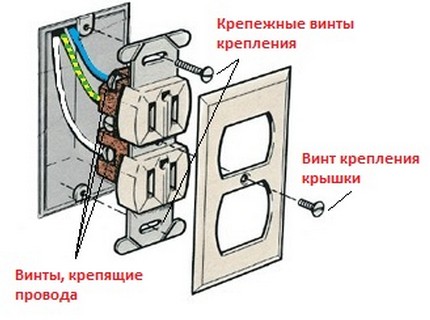

- Remove the case of the old device. To unscrew the fixing central bolt located on the cover, you will need a Phillips or flat head screwdriver. Under the removed cover you will see a working mechanism.

- After making sure that there is no voltage in the network, proceed to the removal of the internal unit of the device. To do this, special spacer tabs are opened on the sides of the working board. In some models, the metal plate of the mechanism is fixed with two screws. They must be unscrewed.

- Having removed the socket from the socket, as far as the wires allow, unscrew the clamping screws that secure the power cables. In the block, conductive conductors are sequentially disconnected.

When dismantling an outlet for external wiring, keep in mind that there are devices with a mechanism that is separated from the socket and models, the mechanisms of which are combined with the overlaid socket. Both are subject to analysis. Only in the first option, you must first remove the housing, and only then disconnect the working body, and in the models of the second type - only remove the housing.

If during dismantling of the socket for concealed wiring it is not possible to unscrew the screw fixing the cover, you can go to extreme measures - use an accurate, but not very strong hammer blow to break it. The socket itself should be removed very carefully so as not to damage the cables leading to it.

After dismantling the outlet, it is necessary to inspect the insulation of the wires.If the braid is melted or damaged, the wire should be cut to intact insulation. For the future, keep in mind that one of the main causes of melting insulation is the incorrectly selected fuse or circuit breaker rating, which led to a malfunction of the protection device.

In the houses of the old building, there are often situations when, after dismantling the outlet, it is found that the socket is absent in the niche, and the “core” itself is attached directly to its walls. Do not install the outlet in this way: the mounting of the device will be unreliable. In this case, you will have to install a new plastic socket.

Setting a new connection point

The electrical outlets are similar in almost all models. Therefore, there should be no problems with installing a new connection point.

Stages of work with an external device

The steps for installing overhead and hidden outlets are similar. However, it is better for a novice electrician to start with the overhead option:

When disassembling the outlet, we remember the sequence of actions and the parties, according to which the parts were connected into an integral device. Assembly will need to be done in the reverse order.

Selection of required materials

To replace the outlet, you must prepare:

- mounting knife for cutting the cable;

- Phillips or straight screwdriver

- pliers;

- heat shrink tubes;

- dielectric gloves;

- self-tapping screws.

It is also worthwhile to prepare a multimeter or voltage indicator in advance.

If a situation arises when the length of the wire is not enough, it can always be increased by attaching small segments.

But when building, you should consider:

- The extension of aluminum wires is carried out using terminal block.

- Copper wires are lengthened by twisting the pieces, followed by insulating or sealing the connection.

When building or replacing the wire, it is important to comply with the cable cross-sections. So, to connect the same washing machine, the power of which does not exceed 2 kW, a copper three-core cable of the VVGng brand with a cross section of 3X1.5 mm is enough2. An automatic machine with a rated current of 10A is enough at the input to protect such a cable.

When planning to use a socket to power the same iron or hair dryer, it is worth considering the option of replacing the wire with a three-core copper cable, but with a cross section of 3x2.5 mm2. But such a line will have to be replaced at the input with a 16A automatic machine.

Replacing or mounting a socket

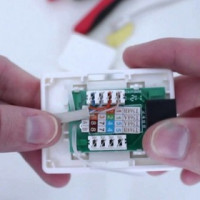

First of all, they disassemble the case of the new device by removing the front panel from it. The task of the master is to fix the metal frame with the built-in working mechanism to the old place and connect the conductors with terminals.

When replacing an old-style outlet, be prepared for the size of the socket to be slightly larger than the diameter of the plastic cup used in modern devices.

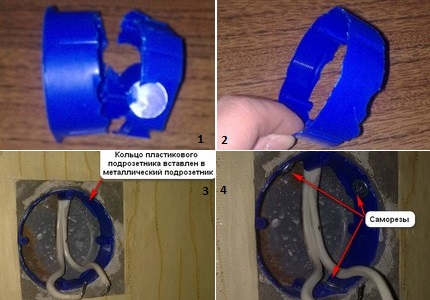

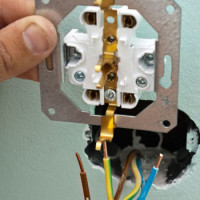

In the plastic specimen of the new sample, the problem of weak fixing of the stops of the "core" of the device is absent. Therefore, when remaking the outlet, it is advisable to remove the metal old socket, and install a new plastic box in its place.

Plastic sockets designed for installation in drywall differ from analogues for installation in concrete and brick walls by the presence of two ears. With their help, the box is easy to fix on the back of the drywall sheet.

If desired, you can also upgrade the metal socket. This solution avoids the "dirty" work and the "wet" procedures associated with plaster. In addition, this method is good in that it allows the outlet to "dead" sit in its place. Improve the design using a standard socket for concrete.

The resulting blank in the form of a ring is inserted into the old metal socket, placing it so that the mounting of the socket coincides with the holes where everything is screwed. For fastening plastic with metal, small “bugs” screws are used. They are screwed diagonally.

When replacing a metal podrozetnika with a plastic analogue, keep in mind that the "glass" should be completely buried in a niche. Deformation of the structure is unacceptable.

If the undergrowth does not fully enter the hole, the issue is solved in two ways:

- cut off the back of the socket, shortening it to the depth of the hole;

- expand and deepen the hole in the wall itself.

To securely fix the podrozetnik, use a solution of gypsum or alabaster. For this, the walls of the hole are niche moistened with water, and covered with a layer of gypsum solution. The same manipulations are performed with the outer walls of the plastic socket, after which they are inserted into the hole in the wall.

To obtain a solution of the desired consistency of thick sour cream in a container of water, the powder is gradually diluted in small portions. To obtain a homogeneous mixture without lumps, gypsum is added to water, but not vice versa.

When working with alabaster, keep in mind that its hardening time varies within a few minutes. Therefore, the work should be done carefully, but quickly.

If desired, a cement-based mixture can also be used for fixation. But working with her will be a little more difficult.

The socket should not protrude beyond the wall, otherwise the socket installed in it will stick out strongly, which will be extremely unsafe and also ugly. Two holes located on the outer edge of the "glass" should be set strictly horizontally.

A hole is made in the socket from the input side of the electrical wires.

Using a narrow spatula with a solution, the voids and the joints of the end part of the structure with the surface of the wall are smeared. After the solution hardens and gains the necessary strength, pass through the wires and proceed with the installation of the indoor unit. We also recommend that you read our other article, which describes the technology in more detail. installation of sockets.

The connection of the mechanism to the veins

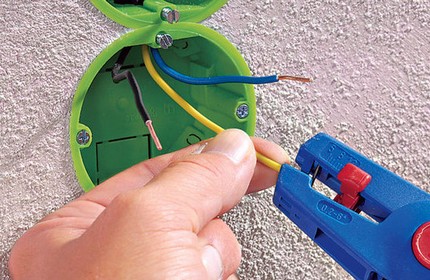

The outlet mechanism is connected to the cores by inserting the ends into special terminals. Since the wires of the “phase”, “zero” and “earth” inside the box must lie separately, but at the same time they have one common insulation in the cable, the first thing to do is to remove the flexible tube wrapping around them.

To do this, remove the insulation from the wires of the failed wire and “bite off” the excess ends. But still experienced craftsmen recommend not to “bite off” the excess wire, but to leave a “margin” of 20 cm and hide it in the walls of the socket.

Work should be done as carefully as possible so as not to damage the fragile cores. For lack of a special knife for stripping, you can use a sharpened kitchen or office knife. Some craftsmen recommend warming it up with a lighter before removing the braid.

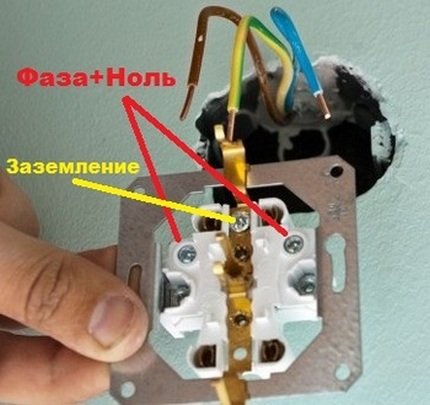

In the regulatory document of the PUE it is clearly indicated that the identification of the core wires by digital designations or colors is carried out in accordance with the current GOST 50462-92.

So the color coding for wires up to 1000 V looks like this:

- "Phase" - a white braid (less often gray, red or black);

- zero working "N" - blue (rarely blue) color of the braid;

- protective conductor "earth PE" - yellow-green insulation.

When connecting wires to a new point, as well as performing any electrical work, these requirements should be strictly observed.

When working with old wiring, in which only wires with a white or black braid are involved, it is advisable to check the supply wire before connecting it to the outlet. To prevent an error when connecting the contacts, the phase wire is marked with a marker.

In order to prevent distortion of the core, the screws are first baited, and then they are tightened one by one until they are firmly fixed. To give elasticity to the structure and at the same time prevent its loosening, a bolt is screwed in the center of the core.

At the final stage, it remains only to install the panel. The cover is fixed with a central bolt, being careful not to overtighten the mount so as not to “tear” the hole and not damage the fragile material of the protective cover.

To check the reliability of fixing the outlet, the plug of one of the electrical appliances is inserted into it. If the socket in the box is loose, you will have to remove the decorative panel again, and tighten the bolts of the spacers a little harder.

By reinstalling the cover, you can connect power to the shield. After the connection is completed, the correct connections in the installed outlet are checked by the indicator.

Also on our website there are several articles that detail the process of repairing and connecting various types of outlets:

- How to transfer the outlet: instructions for moving the outlet to another location

- Common Outlet Malfunctions: How to Fix an Outlet Do It Yourself

- How to make two from one outlet and how to properly conduct an outlet from an outlet

- How to connect a double outlet: installing a double outlet in one socket

Conclusions and useful video on the topic

A video with a visual demonstration and a detailed explanation of how to properly remodel the outlet:

Guide on how to change the outlet:

Even an aspiring master can change the outlet independently. The main thing is to observe safety precautions and strictly adhere to the above actions.

If you had to change or remodel the outlet yourself, please share your experience with our readers, tell us about the nuances that you need to know for those who are faced with such work for the first time. Write comments, ask questions about the topic of the article in the block below.

How to transfer the outlet: instructions for moving the outlet to another location

How to transfer the outlet: instructions for moving the outlet to another location  How to install a socket in drywall: installation rules and tips for installing a socket

How to install a socket in drywall: installation rules and tips for installing a socket  How to connect a double outlet: installing a double outlet in one socket

How to connect a double outlet: installing a double outlet in one socket  How to connect a telephone socket: connection diagram and installation rules

How to connect a telephone socket: connection diagram and installation rules  How to install and connect an outlet with grounding: learn to ground the outlet

How to install and connect an outlet with grounding: learn to ground the outlet  How to make two from one outlet and how to properly conduct an outlet from an outlet

How to make two from one outlet and how to properly conduct an outlet from an outlet  How much does it cost to connect gas to a private house: the price of organizing gas supply

How much does it cost to connect gas to a private house: the price of organizing gas supply  The best washing machines with dryer: model rating and customer tips

The best washing machines with dryer: model rating and customer tips  What is the color temperature of light and the nuances of choosing the temperature of the lamps to suit your needs

What is the color temperature of light and the nuances of choosing the temperature of the lamps to suit your needs  Replacement of a geyser in an apartment: replacement paperwork + basic norms and requirements

Replacement of a geyser in an apartment: replacement paperwork + basic norms and requirements

When replacing the outlet, I had most of the problems with replacing the socket — the apartment was old, the socket was metal, and old cement sprinkled after extraction. When I inserted a new one, I was so tormented with cementing around that I tore the polystyrene into pieces and in small pieces in the cement I was able to fix a new undergrowth in the center. Experienced electricians will probably laugh. Everything else has already gone fine. In general, not everything is as scary as it seems, eyes are afraid, and hands are doing, the main thing is to observe safety precautions.

Periodically I came across the fact that the sockets in the apartment after a while begin to "stagger". It was necessary to somehow solve the problem. I found these recommendations and realized - this is just what you need. I have metal sockets in the walls, so I did not want to mess with their replacement. I picked up the plastic in diameter, adjusted in size (I had to cut and fit in depth), assembled the structure. Now the sockets are sitting tight and, I hope, for a long time you will not have to re-mount them.

To change the outlet, it was not at all necessary to be an electrician or call him. If the hands grow from the right place, then everything is within reach. Many people make the mistake of naively believing that they have de-energized the power grid, and then receive a discharge of current. You need to check not only the phase, but also zero. Well, and when replacing the wiring, think in advance where the sockets and switches will be located. He himself remade his errors more than once.