How to design a gas pipeline: designing a gas supply system for a private house

The organization of gas supply is the most important moment in arranging comfortable housing. Practice shows that most often this type of fuel is chosen to ensure the operation of household appliances, but the gas mixture is among the potentially dangerous substances. For the system to work efficiently and without problems, it will be necessary to properly equip it.

We will tell you how to design a gas pipeline, show you how to choose the right person for the project. In the article we presented, the preparation procedure is described in detail, the documents that are required by the customer are given. Based on our advice, you can reduce the time and cost of order execution.

The content of the article:

Gasification project: what is it?

A gasification project is understood to mean a scheme for introducing power equipment at an object. It is developed in strict accordance with all applicable requirements and instructions, taking into account the wishes of the customer.

The project includes calculations and energy efficiency indicators of the facility, detailed specifications for the supply equipment and material, the rationale for the solutions for the installation of underground or elevated gas pipelines, etc.

Actually, the gasification project is understood as a collection of documents, which includes:

- Drawing of the location of gas pipelines, aboveground and underground.

- Drawing of the placement of gas equipment.

- A drawing of the location of all ventilation and smoke channels.

- Specifications for gas supply.

- Inspection acts of all ventilation ducts and chimneys.

- All necessary executive documentation for the gas main to which the connection will be made.

- Passports and certificates for each of the installed gas appliances.

- Explanatory note.

Legislation requires that any conversion or construction of a gas supply line, installation of gas equipment be carried out only after the preliminary implementation of the project.

Only with its help can one correctly select gas equipment, determine the price of installation work and the necessary materials, choose and equip the premises for the installation of gas appliances correctly. In addition, the availability of the project allows for the necessary coordination in the relevant authorities.

How to choose a project executor?

It is impossible to carry out the gasification project on one’s own. And save on its development too. This is a mandatory document that is developed taking into account many requirements. They are indicated in special technical literature, reference books and codes of practice, as well as in state standards.

All these requirements are known to professional designers, who should be engaged in design. And it should be employees of special design departments, and not just specialists offering their services.

As a rule, in your city you can find several organizations involved in the implementation of housing gasification projects. Most often, trustworthy organizations are members of SROs. This abbreviation means "Self-regulatory organizations."

It is best for the customer to deal specifically with such companies. In this case, he can be sure that the work will be done efficiently, competently and on time.

Otherwise, organizations face serious troubles associated with problems with reputation and financial losses. Non-SRO companies are limited in their choice of clients. They cannot count on serious orders and cannot take part in tenders.

To join the SRO, an organization must exactly meet certain requirements. They should have at least two professional design engineers on a permanent basis.

Every three years they are required to undergo a test, thereby confirming their qualifications and knowledge. The inspection is carried out by a special commission, according to its results, certificates are issued or not issued to specialists.

In addition, only an organization licensed to conduct this type of activity can develop a project. This point must be clarified before concluding an agreement on a gasification project.

Also, when concluding it, it is important to clarify that the contractor assumes responsibility for the coordination and approval of documents, field trips and visits to gas services. Such a clause in the contract enables the customer to take minimal participation in the design process.

Where to start?

You need to know that work on the design of gas supply can only begin after technical specifications are agreed upon and received, or as they are also called specifications for gas supply to the facility.

This is a significant special document; only a gas distribution organization is entitled to issue it. Obtaining technical specifications gives the owner of the site the opportunity to order the development of the project.

For receiving technical conditions The following documentation package must be submitted to the local gas service:

- Application for obtaining technical specifications. It can be written only by the owner of the land plot, which is reserved for construction, or the landlord, if the building has already been erected.

- A copy of a document that can verify the identity of the applicant. This is usually a passport.

- Original documents confirming the applicant’s ownership of the house.You will also need a document that confirms the legality of the building. This may be a contract of sale / purchase, as well as an act of acceptance of the building into operation or a technical passport from BTI.

- If construction is still underway, it is necessary to provide documentation confirming the applicant’s ownership of the site. This may be a lease or purchase / sale of the land, as well as a certificate confirming the registration of ownership.

- Explication of the structure on the ground.

It must be understood that the proposed connection to the gas main will be allowed only if the area where the house is built is included in the gasification plan.

It is important that there is technical connectivity. This assumes that the volume of gas in the existing line allows you to add another point of consumption.

On time, the preparation of technical specifications takes about a month. When connecting to a gas main, some requirements must be observed. For example, a building can be removed from the gas pipeline by no more than 200 m.

Moreover, the design area of the building should not be more than 250 square meters. m. Such houses belong to the first group of gas consumers. They have the right to consume gas at a speed of not more than 5 cubic meters per hour.

If the area of the house is larger, connection is also possible, but obtaining the technical specifications will be much more complicated, since it will be necessary to coordinate the transfer of the consumer from the second group to the first.

To obtain technical conditions, you can use the services of special companies, but it will cost a lot. Therefore, it makes sense to do paperwork yourself.

Features to consider in the project

Each project is designed for specific operating conditions, which are always reflected in it. Let us consider in detail several important points.

Type of gas supply used

The easiest option to provide gas to your home is to connect to a centralized highway. For its implementation, permission is required from gas services and the availability of the necessary technical conditions.

In addition, consent from neighbors is also needed if a gas pipeline passes through their section. In practice, most often such permission is taken in the gas service, which in the vast majority of cases will be the owner of the gas main.

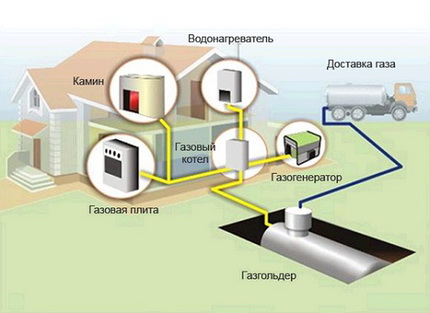

Unfortunately, connection to a centralized gas pipeline far from always possible. In such cases, it is possible to equip an autonomous gas supply, which involves the installation of special tanks from which gas will be supplied to the house.

Such a system can be designed as a primary or as a backup fuel source. In the second version, it is used in case of an accident on the highway or when the gas supply is turned off.

Well established as the main source of gas in the absence of the ability to connect to the gas pipeline autonomous gas supply options.

They have significant advantages, which include the ability to control the volume of gas used in the house and the durability of the system. Subject to competent design and gas holder installation an independent system will last an average of about 40-50 years.

Arrangement of an external gas pipeline

Structurally, the external gas supply system can be performed in two ways: aboveground and underground. Let's consider them in detail. The underground installation method is considered the most optimal for the installation of gas pipes.

He suggests that gas pipeline in trenches, the depth of which is calculated during the design process.Recently, however, this installation method has been supplanted by more modern trenchless installation.

This is due to the lower cost of the latter. The trenchless method allows cheaper gasification by two, or even three times. In addition, it has other significant advantages. Pipe laying works are carried out in the shortest possible time.

The trenchless method is recognized as the most sparing. If necessary, it makes it possible to preserve the integrity of artificial and natural objects, road surfaces encountered on the gas pipeline path.

Actually, the trenchless laying procedure is quite simple. First, a pilot well is performed, then a trunk for laying communications is formed by the method of horizontal drilling or directional puncture. The walls of the excavation are reinforced with casing or a soil stabilizing solution.

After it hardens, the gas pipes are fed into the well and laid in it. A special case can be used to protect the gas pipe. This is necessary if communications can suffer from stray currents or from mechanical damage.

The latter are quite likely when the highway intersects with the pipes of the water supply system or heating system, and also passes under the road. It is recommended to protect the gas pipeline with a case at the entrance to the building and at its exit from the ground. As a case, a steel pipe is usually used.

The underground gas pipeline in any design is reliable, but has a high cost. A more budgetary option is overhead laying of the pipeline. It can be cheaper than the underground by an average of 60%. In this case, the gas pipes are laid on special supports installed in accordance with the laying path. A trunk laid above ground is extremely vulnerable.

Therefore, it should be provided with reliable protection against load, mechanical damage, sudden temperature drops, and corrosion. Elevated pipelines require protection to exclude the possibility of unauthorized tapping or intentional damage.

Therefore, they are usually positioned in such a way as to limit as much as possible the access of outsiders. One option is to place the pipes at a certain height. You must understand that both methods of laying gas pipelines are viable. Which one to use for the implementation of the gasification project is decided by the design engineer.

He does this on the basis of analysis of a complex of data, which include the characteristics of local climatic conditions and landscape, the location of groundwater, chemical analysis of soils, and more. In some cases, a combined styling method may be chosen.

It consists in the fact that part of the gas pipeline is mounted above ground, and part underground. For example, if the track passes under the roadway, it should be laid only underground, but before this section it may well be mounted above the ground. You need to know that only the designer decides on the method of laying the pipeline, the opinion of the customer is taken into account, if possible, but is not decisive.

Project Creation Procedure

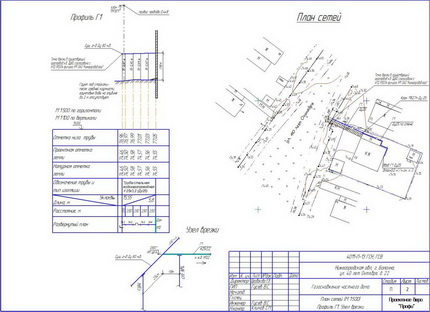

Work on the gas supply project of a private house begins with calculations that will determine the amount of gas required for the uninterrupted supply of all devices using it. After which the engineer proceeds to the planning of the gas route.

It is carried out taking into account all the recommendations and requirements of building codes. A pipeline connects the building to a gas pipeline or to an underground reservoir. In any case, a valve should be installed on the side of the inset to shut off the gas supply, and a meter should be installed at the entrance to the building.

The important point is gas equipment selection. This should be done by the design engineer taking into account the wishes of the customer. The specialist will be able to select equipment models whose characteristics are optimally suited for operation in existing conditions.

To purchase the selected device should only be in specialized stores. That will make it possible to exclude the likelihood of acquiring low-quality or non-certified products.

Each of the gas appliances used must have a special technical passport and certificate with corresponding marks. This documentation is subsequently provided to a gas service representative who will issue a permit to commission the system.

The designer implements a plan for the placement of gas equipment and internal piping. After it is ready, a hydraulic calculation of the designed gas pipeline is performed.

This is necessary to determine the exact size of the pipes in all sections of the pipeline. In addition, the hydraulic calculation determines the pressure loss in the pipeline and confirms the operability of the designed gas network. Only then can we start compiling the specification.

The result of the work are:

- Gas network diagrams from the tie-in section to the equipment installation section.

- Sectional views of the building and floor plans, which indicate the layout of the gas pipeline and the installation site.

- Detailed assembly diagrams with explanations and recommendations for their construction.

- Specification of equipment and materials.

- Description of measures necessary to protect the system from various negative influences.

- Recommendations regarding the operation and maintenance of the designed gas system.

At the end of all work on the project, it is submitted for approval to the technical department of the service, which previously issued the technical specifications.Specialists will carefully check the project for safety and compliance with all applicable standards. At the end of the audit, a decision is issued on the coordination of the approval of the project or it can be returned for revision.

Subsequent installation of equipment and laying of the gas pipeline should be carried out in strict accordance with the agreed project. If any changes are planned during the construction, they should again be agreed with the technical department and wait for the decision of specialists. Otherwise, the system cannot be put into operation.

You need to know that all the executive documentation illustrating the work performed is in the archive of the gas service. Therefore, it will not be possible to prove the legitimacy of arbitrary changes to the project.

Available options for saving on the project

The issue of project cost excites many customers. The company-designer does not always clearly answer this question, often gives approximate figures, motivating it with the varying complexity of work in each case. However, a general idea of the amount can be obtained.

Practice shows that the minimum cost of design will be for state-owned companies. For example, the same Gorgaz can provide such a service.

But in this case, you need to be prepared for the fact that the execution time of the order can be significantly delayed. Sometimes up to six months. Those who do not want or cannot wait for so long need to contact private companies that work more quickly.

But the cost of their services will be much higher. It is very important not to make a mistake in choosing the organization that will carry out the design.

The finished project must exactly meet all regulatory requirements. Competent and experienced specialists are well versed in the many subtleties of regulatory documentation and are able to work with it.

Each new project requires a thorough study of the rules and regulations. Professional designers know that the requirements for gas systems may vary depending on the method of laying the pipeline, construction conditions, the type of equipment selected and many other factors.

If at least one of the current rules is not fulfilled, the project returns for revision. Gas services very carefully check all the documentation provided to them, and there is no reason to hope for their carelessness.

Each of these improvements significantly delays gasification. Therefore, it is worth entrusting the design to competent specialists in order to get a quality project in the shortest possible time.

All cost items associated with connecting gas to a country house are given in next article, which we advise you to familiarize yourself with.

Conclusions and useful video on the topic

Video # 1. Consider all the stages of gasification of a private house:

Video # 2. What happens if the gasification project is violated:

Video # 3. Advantages of autonomous gas supply:

Gasification at home is impossible without a competent project. This is a defining document, which indicates all the features of specific gas networks, wiring and equipment.

Based on the project, the system is subsequently installed and a permit is issued for its further operation. It is imperative that the project is completed correctly, so order it only from competent professionals.

Please write comments in the block below. Tell us about how you designed the gas pipeline, as well as how much time has passed between the issuance of the project and the connection of the house to the highway. Share useful information and photos on the topic of the article, ask questions.

How to turn off gas in the apartment: the procedure for refusing gas supply

How to turn off gas in the apartment: the procedure for refusing gas supply  Suspension of gas supply: reasons for disconnecting from gas supply in an apartment building

Suspension of gas supply: reasons for disconnecting from gas supply in an apartment building  Is it possible to connect gas to an unregistered house: features of the connection and design of “unfinished”

Is it possible to connect gas to an unregistered house: features of the connection and design of “unfinished”  Technical conditions for gas connection: the procedure for obtaining the necessary documentation

Technical conditions for gas connection: the procedure for obtaining the necessary documentation  Gas on the border of the site - what does it mean? Features of connecting to an existing gas pipeline

Gas on the border of the site - what does it mean? Features of connecting to an existing gas pipeline  Laying a gas pipeline to a private house: methods, equipment, basic requirements

Laying a gas pipeline to a private house: methods, equipment, basic requirements  How much does it cost to connect gas to a private house: the price of organizing gas supply

How much does it cost to connect gas to a private house: the price of organizing gas supply  The best washing machines with dryer: model rating and customer tips

The best washing machines with dryer: model rating and customer tips  What is the color temperature of light and the nuances of choosing the temperature of the lamps to suit your needs

What is the color temperature of light and the nuances of choosing the temperature of the lamps to suit your needs  Replacement of a geyser in an apartment: replacement paperwork + basic norms and requirements

Replacement of a geyser in an apartment: replacement paperwork + basic norms and requirements

At one time we were running around with a gas pipeline. A pile of paperwork, hiking from one office to another. And the gas pipeline project was done for us for a very long time, several times it was sent for revision. In general, I do not recommend saving on this matter, it is better to immediately contact a normal office. By overpaying a small amount, you will save a large number of your nerves.