Laying a gas pipeline to a private house: methods, equipment, basic requirements

Designing and laying a gas pipeline is the prerogative of specialized gas services; you cannot do this work yourself. The owner of the gasified section is responsible for collecting the necessary documentation, obtaining permits for gas supply and putting the pipeline into operation.

Agree, for those who are faced with such a task for the first time, it is quite difficult to figure out where to start and where to turn. We suggest to sort everything out in order.

We will tell you which permits and design documents should be prepared, outline the main regulatory requirements, the algorithm of actions for laying and connecting the gas pipeline. In addition, we give tips on choosing a contractor and describe how the commissioning, launch and commissioning of the gas pipeline takes place.

The content of the article:

Package of permits

The list of such documents cannot be compiled without reference to a specific structure; its composition depends on many nuances. For example, when gas pipelines have to travel through neighbors, you will have to get permission from their owners.

A specific list can be clarified in the design organization, but in most cases it is required:

- Copies of the identity cards of all owners.

- Certificate confirming the ownership of land and buildings located on it.

- The act of checking the premises in which the installation is planned. Inspection is carried out by a representative of the Home Gas Equipment Service (SVDGO).

- A gasification permit confirming the technical feasibility of carrying out these actions. The document is drawn up by the Architectural and Design Department and certified by its head.

- Gasification Specifications houses that Gorgaz issues.

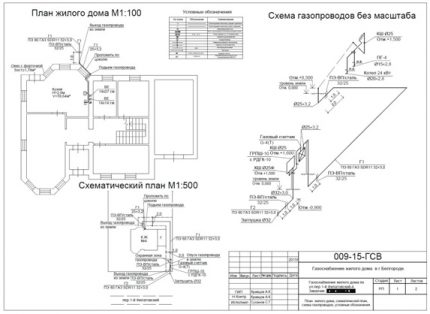

The listed documents must be accompanied by a data sheet from the Bureau of Technical Inventory along with a scaled map of the site with all the buildings that are planned to be gasified. You will also need a certified in the gas service, a diagram of all communications and the planned gas pipeline.

The prepared package is provided to employees of the selected design organization. On its basis, a gasification project is being developed taking into account all the features of the site and the buildings located on it.

What affects the preparation of the project

If there are no special skills, self-design is undesirable and hardly feasible. In the process project work many factors that are known only to specialists should be considered.

Among them are:

- groundwater depth, soil specifics, landscape and climatic features;

- the depth at which the central track runs;

- the distance from the pipeline to the building, taking into account the depth of the branch;

- SNiP requirements for equipment and connection points.

In addition to those listed in the project, they necessarily show the way of laying the trunk, gas pipe diameter, a necessary set of devices and accessories, materials used, features of joints and internal wiring.

Methods for arranging a gas pipeline

The main criterion for classification is considered working gas pressure. According to this characteristic, for household needs, low-pressure systems are of interest, where the maximum does not exceed 5 kPa.

Classification of gas piping systems

An important parameter is how to lay an individual gas pipeline from the main network transporting blue fuel to a private house / cottage.

He can be:

- underground;

- ground;

- underwater.

The latter option is relevant for the main gas pipeline, which meets lakes, rivers or seas on its way. For a private house, use the first 2 methods.

Depending on the location of the gas network, it can be external or internal. In practice, often there is a need for a combination of several laying options, since the tracing conditions from the main line can vary greatly.

For example, a branch from the central highway, passing over the road, will be above ground. Then it goes deeper into the ground and is brought to the structure in the underground version.

Underground laying method

The most time-consuming and costly option, which requires preliminary preparation of the trench for removal from the main highway. In this case, it is necessary to strictly adhere to the plan, which precisely determines at what depth the gas pipeline should be laid. Usually it is from 1.5-2 m.

The laying of communications can be significantly affected by such factors:

- groundwater;

- seismic activity;

- the abundance of corrosive elements in the soil;

- the presence of obstacles and pavement.

It is simpler and cheaper, in terms of the total costs of gasification, to use horizontal drilling. Estimated costs are reduced by 3 times.

In addition, the technology allows you to:

- reduce laying time;

- bypass the road surface and existing communications;

- minimize damage to the ecology of the site.

With a special device, a pilot well is drilled, which is then increased to the design dimensions. The walls are fixed with a solution, after fixing which a gas pipeline is pulled.

If there is a risk of electrical or mechanical damage, the pipes are protected with a steel case. This increases the cost, but makes the withdrawal more reliable and durable.

Overhead gas pipeline

This option of gasification involves laying on special supports. It is much cheaper, it allows you to save up to 60% of money in comparison with the previous method.

A significant drawback is the need to protect against a number of factors:

- deforming influences;

- mechanical loads;

- corrosive damage;

- temperature differences.

The disadvantages include the probability of an arbitrary tie-in to the trunk, which requires regular inspection of it on the integrity of the structure and the absence of violations.

Such a threat is reduced to zero when the pipes are laid on the territory of their own site, access to which by outsiders is as limited as possible.

External and internal network

The internal type of installation is carried out in a specially adapted room. In this case, it is necessary to provide access to the wiring, which cannot be hidden in the walls, covered with any overlays.

The opposite connection option involves laying pipes on special brackets that are securely fixed to the entrance.

The basic requirement is maximum protection against outsiders.

Protection against unauthorized access and natural influences is provided by a box with a door that closes with a key. It is usually installed when installing a gas meter outside the building.

Which option is better to use?

Each of the gas pipeline laying methods has its own list of advantages and disadvantages. But when designing a gas pipeline, they are taken into account or ignored on the basis of the conditions of a particular section where tracing will be performed.

For example, an elevated version will be preferred when the following conditions are true:

- the soil is saturated with corrosive elements that can destroy the metal during use;

- the branch passes through the territory of the neighboring section;

- the main pipe is separated from the site by the road surface.

If tracing is carried out under high-voltage lines, it is recommended to choose an underground option that will provide protection against high voltage.

Gas lines made of polymers

For above-ground gasification options, it is recommended to use pipes from low alloy steel alloys that are resistant to external influences.

Features of plastic structures

Underground installation allows the use of polypropylene pipes, which saves on installation costs and provides a number of other advantages.

The advantages are primarily due to the properties of the material:

- high corrosion resistance, which positively affects not only the cost of installation, but also reduces operating costs;

- ease of processing - the material is well cut, amenable to welding, which simplifies installation;

- perfectly flat inner cavity provides good throughput properties; material features allow avoiding their reduction during use;

- lack of sensitivity to electric currentsthat provides high security, eliminates the need for additional protection.

In addition to these advantages, such pipes have a high level of flexibility, which allows them to be used for horizontal drilling.

To this should be added a small mass, which is several times lower than the steel counterpart. An important advantage is a service life of around 50 years. All this time, the system works without losing the specified characteristics.

Pipe restrictions

Despite the high resistance to external influences, such pipes can not always be used. There are a number of restrictions under which their installation is not allowed.

These include:

- climatic conditions under which the temperature drops below 45 ° C, which leads to freezing of the soil and walls of the branch;

- the use of liquefied hydrocarbon options;

- high seismic activity with a magnitude of more than 7 points, when there is no possibility for ultrasonic monitoring of the integrity of suture joints.

In addition, polypropylene materials cannot be used to create overhead communications of all kinds, including bypass sections through barriers of a natural or man-made nature.

Their laying through tunnels, collectors, channels is excluded. For entering the system into the house and wiring on it apply only steel counterparts.

Additional recommendations for choosing pipes for laying a gas pipeline are given in the article - Gas pipes: a comparative overview of all types of gas pipes + how to choose the best option

General gasification requirements

Gas heating refers to communications with a high level of potential danger. For this reason, there is a whole range of requirements that must be observed regardless of the material used and the chosen method of laying the system.

The basic rules include the following:

- The possibility of constant and free access to all connecting elements of the gas pipeline system, such nodes cannot be walled into the walls.

- Lack of contact with flammable elements of the building, which include door frames, window frames, partitions made of combustible materials, and other similar structures.

- Wiring without bevels inside and outside the house. Strictly vertical laying is mandatory, and with the horizontal version, a slope of 2 to 5 mm with a distance of a meter to the instrument devices is allowed.

- Placement of the riser outside the inhabited premises. In the absence of a suitable interior, it can be let out on the facade, the allowable slope cannot exceed 2 mm.

When designing the installation, it is recommended that you pay particular attention to the installation of cranes. In any case, their center line should be parallel to the wall.

Without observing these and other requirements of SNiPs, the gas pipeline will not be accepted for operation. The additional cost of eliminating such violations is the smallest of troubles. Commissioning with such deficiencies can have more serious consequences.

When the gasification project is ready

A prerequisite for the transition from the design phase to the construction and installation work is the coordination of the project with the technical department of the gas service. Usually this procedure is performed within 2 weeks.

Contractor selection and contract conclusion

After approval, the following must be attached to the project:

- estimate for the performance of work provided for by the project;

- technical supervision agreement;

- Act on inspection of smoke ventilation channels, drawn up and signed by a representative of the VDPO service.

When the entire list of necessary documents is on hand, you can proceed to the arrangement. As a rule, any design organization has a license for construction and installation works.If such a license is not available, you will have to worry about finding a contractor.

Since it is the installation organization that will be responsible for the construction and commissioning of the gas pipeline, it is desirable:

- check the license for gasification;

- see other permits;

- Ensure that employees have appropriate approvals.

Before concluding the contract, it is necessary to agree and approve the installation dates, which should be fixed in the contract.

In the agreement for the performance of work, among other obligations, the following conditions must be fixed:

- the employees of the organization working at the facility have a protective screen protecting the walls from heating and all necessary fire extinguishing means;

- the issuance of executive technical documents to the customer immediately after settlement of the work provided for in the project;

- the contractor’s obligation to complete installation on time, in accordance with established standards and the necessary level of quality;

- the contractor’s duty to compile all the envisaged technical documentation in a timely manner.

The contractor must provide the customer with the specified documents, after installation, before visiting the commission for acceptance and commissioning of the facility.

Gas pipeline commissioning

The delivery of the finished gas pipeline is carried out in the presence of a commission, which includes representatives of the contractor, gas service and the customer himself. During the acceptance process, it is necessary to check the availability of all equipment provided by the project, the correctness of its installation and connection.

The commission accepts work from 2 weeks to a month. If no shortcomings have been identified, the representative of the gas service issues a receipt for payment, which the customer pays, and transfers a copy of the document to the contractor.

The contractor transfers to the gas service all the technical documentation, where it is stored for the entire period of operation. Based on the results of the commission’s work, the gas service must seal the meter within 3 weeks, after which the system is considered ready for gas supply.

The agreement with Gorgaz regulates the maintenance of the system, for which this service will be responsible. It is the basis for the supply of gas.

In addition to concluding a contract, you will need to undergo safety training. It is carried out at the office of the company or at the place of residence by a specialist with the appropriate admission. In any case, after the briefing, the customer must confirm the briefing with a signature in the accounting journal.

System startup and setup

The insert is carried out by the appropriate service, the procedure is paid, it is carried out in a predetermined time when all the equipment has passed the acceptance and is recognized as functional.

After this is carried out test runChecking instrumentation and meter for leaks.

The final equipment debugging and start-up is carried out by the equipment supplier organization with which there is a service agreement:

- the system starts up;

- it is tuned to the optimal mode of operation;

- a company representative must explain all the nuances of the equipment, the rules for its operation.

In cases where malfunctions and other malfunctions are noticed, the launch is suspended until they are eliminated.

If everything is in order and the launch is successful, a bilateral act is signed confirming the completion of the work.

Read about the rates for connecting gas to a private house and the financial costs of putting the system into operation in this article.

Conclusions and useful video on the topic

Video about the collection of documents, requirements, equipment and its maintenance:

The video will tell you about the necessary documents, indicative prices, equipment purchase, connection problems and the main stages of the process:

Using natural gas for heating is one of the most economical ways. All gasification costs pay off relatively quickly. The only drawback is the increased danger. But proper installation, timely maintenance and operation without any violations minimize all risks.

Have something to supplement, or have questions about the gasification of a private house? You can leave comments on the publication, participate in discussions and share your own experience in laying the gas pipeline. The contact form is located in the lower block.

Requirements for laying a gas pipeline in settlements: depth and rules for laying an elevated and underground pipeline

Requirements for laying a gas pipeline in settlements: depth and rules for laying an elevated and underground pipeline  Hydraulic calculation of a gas pipeline: calculation methods and methods + calculation example

Hydraulic calculation of a gas pipeline: calculation methods and methods + calculation example  Gas pipeline looping: its functions and features of arrangement for a gas pipeline

Gas pipeline looping: its functions and features of arrangement for a gas pipeline  Is it possible to connect gas to an unregistered house: features of the connection and design of “unfinished”

Is it possible to connect gas to an unregistered house: features of the connection and design of “unfinished”  Is it possible to close a gas pipe with siding: the rules and subtleties of masking a gas pipeline

Is it possible to close a gas pipe with siding: the rules and subtleties of masking a gas pipeline  Requirements for installing a gas boiler in a private house: installation tips and rules for safe operation

Requirements for installing a gas boiler in a private house: installation tips and rules for safe operation  How much does it cost to connect gas to a private house: the price of organizing gas supply

How much does it cost to connect gas to a private house: the price of organizing gas supply  The best washing machines with dryer: model rating and customer tips

The best washing machines with dryer: model rating and customer tips  What is the color temperature of light and the nuances of choosing the temperature of the lamps to suit your needs

What is the color temperature of light and the nuances of choosing the temperature of the lamps to suit your needs  Replacement of a geyser in an apartment: replacement paperwork + basic norms and requirements

Replacement of a geyser in an apartment: replacement paperwork + basic norms and requirements

We are faced with this situation: we bought a house, we didn’t know about the fact that once there was a detour around the district and we collected lists and money for adding houses to the gas connection project. Our previous owners refused. And here we are, buying a house, after 2 months they are already starting to lay pipes. We are trying to get into the project, so that at least the pipe is brought out to the site - no way! This is some kind of nightmare!

I want to say one thing - we live in Russia! Those. it turns out that gas was laid all over the street and those who were part of the project brought the pipes to the site or to the foundation of the house, whoever they wanted. But they bypassed us, and the pipe was not left for the future.

We found a contractor, tried to calculate how much we need to pay, so that they immediately bring us everything. So we counted more than 150 thousand for some 10 meters from the road to the site. What kind of arbitrariness? We live in such a rich country, everyone is given this gas from left to right, but not to their own! They also told us that we, it turns out, have not enough gas, so such harsh conditions! And the most interesting thing is that if you want to connect gas, for example, in a year, the price will increase by about 2 times. Where is the conscience of the people! In a word - Russia! Maybe someone was in a similar situation? Tell me what to do in this case? Stupidly give heavenly sums? Or is there some kind of government?

Inga, you answered your own question.

Regarding whether there is any kind of government - you can see the legal documents. For example, in the Decree of the Government of the Russian Federation of 29.12.2000 N 1021 26 (22):

“Fee for technological connection of gas-powered equipment with a maximum gas flow not exceeding 15 cubic meters. meters per hour, taking into account the gas flow rate previously connected at the connection point of the applicant’s gas-using equipment (for applicants intending to use gas for entrepreneurial (commercial) activities), or 5 cubic meters. meters per hour, taking into account the gas flow rate previously connected at the connection point of the applicant’s gas-using equipment (for other applicants), is set at not less than 20 thousand rubles and not more than 50 thousand rubles (with value-added tax if the applicant is an individual, and in other cases without value-added tax) provided that the distance from the gas-using equipment to the gas distribution network of the gas distribution organization to which the application is submitted, with a design working pressure of not more than 0, 3 MPa, measured in a straight line (smallest distance), is no more than 200 meters and the events themselves envisage the construction of only gas pipelines (without the need to take measures to lay gas pipelines in a trenchless manner and set up a gas reduction point) in accordance with the regional (interregional) gasification program for housing and communal services, industrial and other organizations approved in the established manner, including the scheme location of gas supply facilities used to provide gas to the population.

Starting from 2015, the indicated minimum and maximum levels of payment for technological connection are indexed annually at the forecast average annual inflation rate determined by the forecast of socio-economic development of the Russian Federation for the same period for which the payment for technological connection is established. The specified fee for the technological connection of gas-powered equipment does not include the costs of activities within the boundaries of the land owned by the right of ownership or on any other legal basis to an individual or legal entity. ”

Inga, hello. Sorry, I didn’t understand something about “there isn’t enough gas”. If it weren’t enough, you wouldn’t be offered 10 meters from the common fund. And then there is not enough gas ... But is it possible to agree with a neighbor on a subcut to his line? And what kind of contractor is this, have you tried to go to the organization of the supplier for the technical specifications?

I have a similar story. On the completed project of supplying the gas pipeline to the house, the pipe comes from the gas pipeline to the near corner of my possession, they don’t want to bring it to the house. In the laid two hundred meters I fit. Offer to lay for their money along the fence on the backwater. And this is about forty meters. I don’t understand why they draw only to the near border of possession, and not to the house itself?

Hello. Unfortunately, these are 2 different projects - gasification of the street and the house. In this case, a distinction is made between the balance sheet and operational accessories.

Hello! Please help with advice. A low-pressure pipe runs along the street, more precisely from the opposite edge, to the boundary of the section from the pipe 3 m.

Mosoblgaz writes in technical conditions it is required to lay 3 m of pipe in a trenchless manner, respectively, the connection does not fall into the first category and the cost of laying 3 m of pipe to the site and the connection is 250 thousand rubles.

Does Mosoblgaz rightfully require laying in a trenchless manner? This is a village road, individual housing construction, without asphalt, but put on the cadastre. The cadastral value of this road is 75 thousand rubles.

Hello. As I understand it, it bothers you that because of this you do not fall into category 1 and, accordingly, you cannot use the benefit of clause 26.22 of the Basic Provisions for Regulation of Gas Prices, approved by Decree of the Government of the Russian Federation of 29.12.2000 No. 1021?

Unfortunately, you will have to obey most likely. Everything is right here, the road is on the balance sheet and if there is no other way to connect, the cost of the road here does not matter at all. Mosoblgaz is not obliged to calculate for you how it is more profitable for you, here geo-surveys and complex engineering calculations are carried out that do not affect the interests of third parties.