Hydraulic calculation of a gas pipeline: calculation methods and methods + calculation example

For safe and trouble-free operation of gas supply, it must be designed and calculated. It is important to perfectly select pipes for highways of all types of pressure, ensuring a stable supply of gas to the devices.

So that the selection of pipes, fittings and equipment is as accurate as possible, hydraulic calculation of the pipeline is performed. How to make it? Admit, you are not too versed in this matter, let's understand.

We offer to get acquainted with meticulously selected and thoroughly processed information about the options for the production of hydraulic calculation for gas pipeline systems. Using the data presented by us will ensure the supply of blue fuel to the devices with the required pressure parameters. Carefully verified data is based on the regulations of the regulatory documentation.

The article describes in detail the principles and schemes of computing. An example of performing calculations is given. As a useful informative addition used graphics applications and video instructions.

The content of the article:

The specifics of hydraulic calculation

Any hydraulic calculation performed is a determination of the parameters of the future gas pipeline. This procedure is mandatory, as well as one of the most important stages of preparation for construction. The correctness of the calculation determines whether the gas pipeline will function optimally.

During each hydraulic calculation, the following is determined:

- the necessary pipe diameterthat will ensure efficient and stable transportation of the right amount of gas;

- whether pressure losses when moving the required volume of blue fuel in pipes of a given diameter will be acceptable.

Pressure losses occur due to the fact that in any gas pipeline there is hydraulic resistance. With an incorrect calculation, it can lead to the fact that consumers will not have enough gas for normal operation in all modes or at the moments of its maximum consumption.

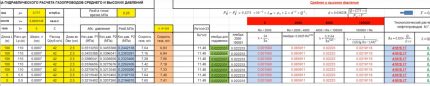

This table is the result of a hydraulic calculation carried out taking into account the setpoints. To perform the calculations, you will need to enter specific indicators in the columns.

| The beginning of the site | End of plot | Estimated consumption m³ / h | Gas pipeline length | Inner diameter cm | Initial pressure, Pa | Final pressure, Pa | Pressure drop, Pa |

| 1 | 2 | 31,34 | 120 | 9,74 | 2000,00 | 1979,33 | 20,67 |

| 2 | 3 | 31,34 | 150 | 9,74 | 1979,33 | 1953,48 | 25,84 |

| 3 | 4 | 31,34 | 180 | 7,96 | 1953,48 | 1872,52 | 80,96 |

| 4 | 5 | 29,46 | 90 | 7,96 | 1872,52 | 1836,2 | 36,32 |

| 5 | 6 | 19,68 | 120 | 8,2 | 1836,2 | 1815,45 | 20,75 |

| 6 | 7 | 5,8 | 100 | 8,2 | 1815,45 | 1813,95 | 1,5 |

| 4 | 8 | 9,14 | 140 | 5 | 1872,52 | 1806,38 | 66,14 |

| 6 | 9 | 4,13 | 70 | 5 | 1815,45 | 1809,83 | 5,62 |

Such an operation is a state-standardized procedure that is performed in accordance with the formulas, requirements set forth inSP 42-101-2003.

Calculations must be carried out by the developer. The basis is the data of the technical specifications of the pipeline, which can be obtained at your gas supply.

Gas pipelines requiring settlement

The state requires that hydraulic calculations be performed for all types of pipelines related to the gas supply system. Since the processes that occur during the movement of gas are always the same.

The following types of gas pipelines include:

- low pressure;

- medium, high pressure.

The former are designed to transport fuel to residential facilities, all kinds of public buildings, domestic enterprises. Moreover, in private, apartment buildings, cottages, gas pressure should not exceed 3 kPa, at household enterprises (non-production) this figure is higher and reaches 5 kPa.

The second type of pipelines is designed to power networks, all kinds of low, medium pressure through gas control points, as well as supplying gas to individual consumers.

This can be industrial, agricultural, various utilities and even freestanding, or attached to industrial buildings. But in the last two cases there will be significant pressure restrictions.

The types of gas pipelines listed above are conventionally divided into the following categories:

- house, in-shop, that is, transporting blue fuel inside any building and delivering it to individual units, devices;

- subscriber branchesused to supply gas from some distribution network to all available consumers;

- distributionused to supply gas to certain territories, for example, cities, their separate areas, industrial enterprises. Their configuration is different and depends on the features of the layout. The pressure inside the network can be any provided - low, medium, high.

In addition, hydraulic calculation is performed for gas networks with a different number of pressure stages, of which there are many varieties.

So, to meet the needs, two-stage networks can be used that work with gas transported at low, high pressure or low, medium. And also three-stage and various multi-stage networks have found application. That is, it all depends on the availability of consumers.

Despite the wide variety of gas pipeline options, the hydraulic calculation is similar in any case. Since structural elements with similar materials are used for manufacturing, and the same processes occur inside the pipes.

Hydraulic resistance and its role

As indicated above, the basis for the calculation is the presence of hydraulic resistance in each gas pipeline.

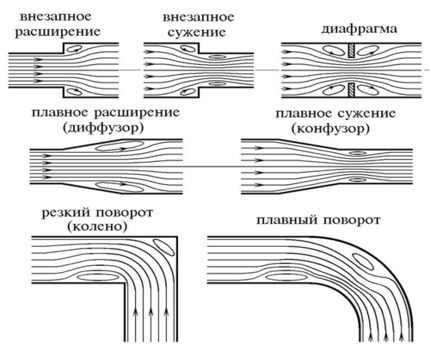

It acts on the entire pipeline construction, as well as on its individual parts, nodes - tees, places for a significant reduction in the diameter of the pipes, valves, various valves. This leads to pressure loss by the transported gas.

Hydraulic resistance is always the sum of:

- linear resistance, that is, acting along the entire length of the structure;

- local resistances acting at each component of the structure, where there is a change in the speed of gas transportation.

The listed parameters constantly and significantly affect the performance of each gas pipeline. Therefore, as a result of incorrect calculation, additional and impressive financial losses will occur due to the fact that the project will have to be redone.

Calculation Rules

It was indicated above that the procedure for any hydraulic calculation is regulated by the relevant Code of Rules with a number42-101–2003.

The document indicates that the main way of calculus is to use a computer with special programs for this purpose, which allows you to calculate the planned pressure loss between sections of the future gas pipeline or the desired pipe diameter.

If there are no such programs or a person believes that their use is inappropriate, then you can apply other methods permitted by the Code of Practice.

Which include:

- calculation according to the formulas given in the joint venture is the most difficult method of calculation;

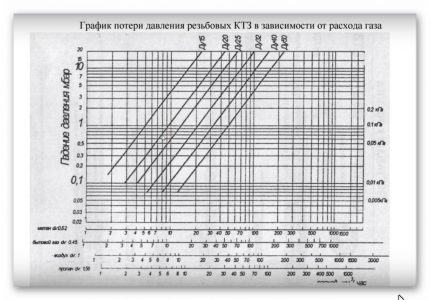

- Calculation by so-called nomograms is a simpler option than using formulas, because you don’t have to make any calculations, because the necessary data are listed in a special table and are given in the Code of Rules, and you just need to select them.

Any of the calculation methods leads to the same results. Therefore, the newly built gas pipeline will be able to provide timely, uninterrupted supply of the planned amount of fuel even during its maximum use.

PC computing option

Performing a calculus using a computer is the least time-consuming - all that is required of a person is to insert the necessary data into the appropriate columns.

Therefore, hydraulic calculation is done in a few minutes, and for this operation does not require a large stock of knowledge, which is necessary when using formulas.

For its correct implementation, it is necessary to take the following data from the technical conditions:

- gas density;

- kinetic viscosity coefficient;

- gas temperature in your region.

The necessary technical conditions are obtained at the gas station of the settlement in which the gas pipeline will be built. Actually, with the receipt of this document, the design of any pipeline begins, because it contains all the basic requirements for its design.

Next, the developer needs to know the gas flow for each device that is planned to be connected to the gas pipeline. For example, if the fuel will be transported to a private house, then there are most often used stoves for cooking, all kinds of heating boilers, and their numbers always contain the necessary numbers.

In addition, you need to know the number of burners for each stove, which will be connected to the pipe.

At the next stage of collecting the necessary data, information is collected on the pressure drop at the installation sites of any equipment - this may be a meter, a shut-off valve, a thermal shut-off valve, a filter, and other elements.

In this case, the required numbers are easy to find - they are contained in a special table attached to the passport of each product. The designer should pay attention to the fact that the pressure drop should be indicated at maximum gas consumption.

At the next stage, it is recommended to find out what the pressure of the blue fuel will be at the insertion point. Such information may contain the technical conditions of its gas, the previously drawn up scheme of the future gas pipeline.

If the network will consist of several sections, then they must be numbered and indicate the actual length. In addition, each variable should be registered separately - this is the total consumption of any device that will be used, pressure drop, other values.

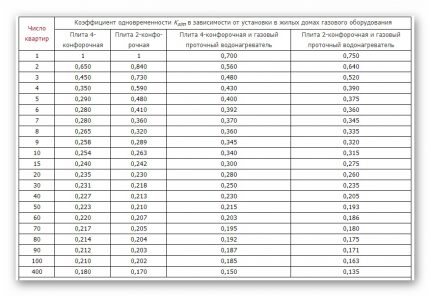

Without fail, a simultaneity factor will be needed. It takes into account the possibility of joint work of all gas consumers connected to the network. For example, all heating equipment located in an apartment building or a private house.

Such data is used by the program that performs the hydraulic calculation to determine the maximum load on any section or in the entire gas pipeline.

For each individual apartment or house, the specified coefficient does not need to be calculated, since its values are known and are indicated in the table below:

If at some facility it is planned to use more than two heating boilers, furnaces, and storage water heaters, then the simultaneity index will always be 0.85. Which will need to be indicated in the corresponding column used for the calculation of the program.

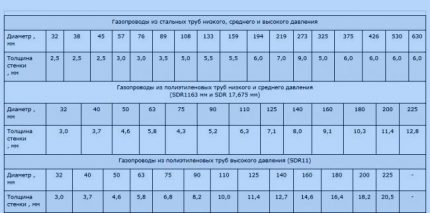

Next should indicate pipe diameter, and you will also need their roughness coefficients, which will be used in the construction of the pipeline. These values are standard and can easily be found in the Code of Conduct.

The influence of pipe material on the calculation

For the construction of gas pipelines, pipes made only of certain materials can be used: steel, polyethylene. In some cases, copper products are used. Coming soon metal-plastic constructions.

Today, the necessary information can be obtained only for steel and polyethylene pipes. As a result, design and hydraulic calculation can be performed only taking into account their characteristics, which is required by the relevant Code of Practice. And also in the document the data necessary for calculation are indicated.

The roughness coefficient is always equal to the following values:

- for all polyethylene pipes, whether new or not, new - 0.007 cm;

- for steel products already used - 0.1 cm;

- for new steel structures - 0.01 cm.

For any other types of pipes this indicator is not indicated in the Code of Practice. Therefore, they should not be used for the construction of a new gas pipeline, as Gorgaz specialists may require adjustments. And this is again an additional cost.

Calculation of flow in a limited area

If the gas pipeline consists of separate sections, then the calculation of the total flow rate for each of them will have to be performed separately. But this is not difficult, since calculations will require already known figures.

Definition of data using a program

Knowing the initial indicators, having access to the simultaneity table and to the technical data sheets of stoves and boilers, you can proceed to the calculation.

To do this, the following actions are performed (an example is given for an intra-house gas pipeline of exactly low pressure):

- The number of boilers is multiplied by the performance of each of them.

- The obtained value is multiplied by the coefficient of simultaneity specified by a special table for this type of consumer.

- The number of stoves intended for cooking is multiplied by the productivity of each of them.

- The value obtained after the previous operation is multiplied by the simultaneity coefficient taken from a special table.

- The amounts received for boilers and stoves are summarized.

Similar manipulations are carried out for all sections of the pipeline. The data obtained are entered into the corresponding columns of the program with which the calculus is performed. Electronics does everything else.

Calculation using formulas

This type of hydraulic calculation is similar to that described above, that is, the same data will be required, but the procedure will be lengthy. Since everything will have to be done manually, in addition, the designer will need to carry out a number of intermediate operations in order to use the obtained values for the final calculation.

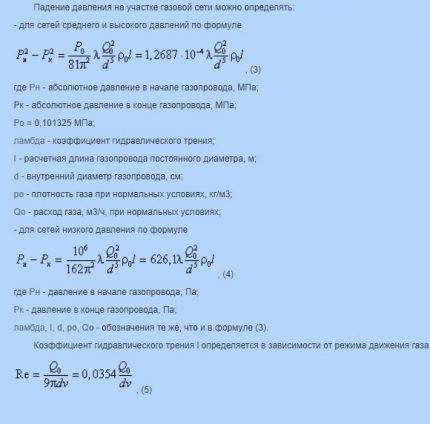

And also you will have to devote a lot of time to understand many concepts, issues that a person does not meet when using a special program. You can verify the validity of the foregoing by reading the formulas to be used.

In the application of the formulas, as in the case with hydraulic calculation using a special program, there are features for low, medium and, of course, gas pipelines high pressure. And this is worth remembering, since a mistake is fraught with, and always, impressive financial costs.

Nomogram Calculations

Any special nomogram is a table where a series of values are indicated, having studied which you can get the necessary indicators without performing calculations. In the case of hydraulic calculation, the diameter of the pipe and the thickness of its walls.

There are separate nomograms for polyethylene and steel products. When calculating them, standard data were used, for example, the roughness of the inner walls. Therefore, you can not worry about the accuracy of the information.

Calculation example

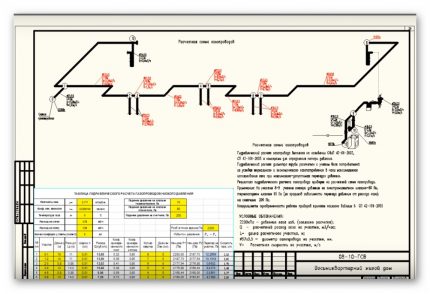

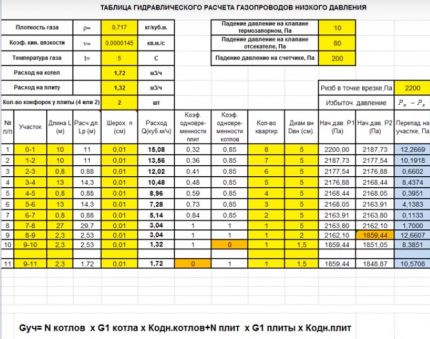

An example of performing hydraulic calculation using the program for low pressure gas pipelines is given. In the proposed table, all the data that the designer must enter independently are highlighted in yellow.

They are listed in the paragraph on computer-aided hydraulic calculation above. These are gas temperature, kinetic viscosity coefficient, density.

In this case, the calculation is carried out for boilers and stoves, therefore, it is necessary to prescribe the exact number of burners, which can be 2 or 4. Accuracy is important, because the program will automatically select the simultaneity factor.

It is worth paying attention to the numbering of plots - it is not invented independently, but taken from a previously drawn up scheme, where similar numbers are indicated.

Next, the actual length of the pipeline and the so-called estimated, which is greater, are prescribed. This happens because in all areas where there is local resistance, it is necessary to increase the length by 5-10%. This is done in order to exclude insufficient gas pressure from consumers.The program performs the calculation on its own.

The total flow in cubic meters, for which a separate column is provided, is calculated in advance for each section. If the house is multi-unit, then the number of housing must be indicated, and starting with the maximum value, as can be seen in the corresponding column.

Without fail, all elements of the gas pipeline are entered into the table, during the passage of which pressure is lost. The example shows a thermal shut-off valve, shut-off valve and counter. The loss value in each case was taken in the product passport.

The inner diameter of the pipe is indicated according to the technical specifications, if the gas has any requirements, or from a previously drawn up scheme. In this case, it is prescribed in the amount of 5 cm in most sections, because most of the gas pipeline runs along the facade, and the local gas pipeline requires that the diameter be no less.

Even if you look superficially with the given example of performing hydraulic calculation, it is easy to notice that, in addition to the values entered by a person, there are a large number of others. This is all the result of the program, because after entering the numbers in the specific columns highlighted in yellow, the calculation work is finished for the person.

That is, the calculation itself takes place rather quickly, after which the data can be sent for approval to the city gas department.

Conclusions and useful video on the topic

This video makes it possible to understand where the hydraulic calculation begins, where the designers get the necessary data from:

The following video shows an example of one of the types of computer calculation:

Further, you can see an example of calculation using a computer program:

To perform hydraulic calculation using a computer, as the specialized Code of Practice allows, it is enough to spend a little time familiarizing yourself with the program and collecting the necessary data.

But all this does not have practical significance, since the preparation of the project is a much more lengthy procedure and includes many other issues. In view of this, most citizens will have to turn to specialists for help.

Have questions, find bugs or can you add valuable information to our material? Leave your comments, ask questions, share experiences in the block below.

Gas pipeline looping: its functions and features of arrangement for a gas pipeline

Gas pipeline looping: its functions and features of arrangement for a gas pipeline  Laying a gas pipeline to a private house: methods, equipment, basic requirements

Laying a gas pipeline to a private house: methods, equipment, basic requirements  Is it possible to close a gas pipe with siding: the rules and subtleties of masking a gas pipeline

Is it possible to close a gas pipe with siding: the rules and subtleties of masking a gas pipeline  Requirements for laying a gas pipeline in settlements: depth and rules for laying an elevated and underground pipeline

Requirements for laying a gas pipeline in settlements: depth and rules for laying an elevated and underground pipeline  Amount of air for burning natural gas: formulas and calculation examples

Amount of air for burning natural gas: formulas and calculation examples  Registration of gas documents: the procedure for concluding a gasification agreement

Registration of gas documents: the procedure for concluding a gasification agreement  How much does it cost to connect gas to a private house: the price of organizing gas supply

How much does it cost to connect gas to a private house: the price of organizing gas supply  The best washing machines with dryer: model rating and customer tips

The best washing machines with dryer: model rating and customer tips  What is the color temperature of light and the nuances of choosing the temperature of the lamps to suit your needs

What is the color temperature of light and the nuances of choosing the temperature of the lamps to suit your needs  Replacement of a geyser in an apartment: replacement paperwork + basic norms and requirements

Replacement of a geyser in an apartment: replacement paperwork + basic norms and requirements

And where can I download this table for the hydraulic calculation of low pressure gas pipelines? I would be grateful for the answer.