Gas cylinder ramp: device + DIY manufacturing example

The operation of autonomous household equipment, the principle of which involves the use of natural gas, can be made more rational. For example, gas boilers for a home heating system are more convenient to operate if there is a gas ramp for cylinders - a collector line where several gas vessels are connected at once.

The ramp design provides the functions necessary for the reliable operation of gas equipment. In this material we will tell you what a ramp for cylinders is and how, if necessary, do it yourself.

The content of the article:

What is a gas cylinder ramp?

A direct connection from a gas cylinder to the same hot water boiler is often accompanied by shortcomings, which can be expressed, for example, in the form of pressure drops. Such conditions adversely affect the operation of the gas burner. As a result, the boiler is unstable, interruptions in the supply of hot water, etc.

It is for pressure stabilization that it is first of all recommended to use a ramp for gas cylinderswhich you can do with your own hands.

However, in general, the device gives the user a number of operational advantages:

- safety of work in case of possible leaks;

- providing equipment with stable working pressure;

- disposal of gas cylinders from the effect of "freezing";

- the ability to significantly reduce the frequency of calls to the gas service.

The technological scheme of the gas ramp may include a collector for connecting a small number of vessels, and for using more than a dozen cylinders.

For domestic use, gas ramps for two or four cylinders are most often made.

The device and assembly diagram of the gas train

The collector design is an ordinary pipeline equipped with a gas shut-off valve, endowed with additional elements:

- gas distribution fittings;

- pressure control devices;

- gas flow filter;

- discharge pipelines (high pressure hoses).

The gas distribution distribution valves are, as a rule, valves with an electromagnetic actuator, but they are rarely installed in household circuits. With electric valves, all individual lines forming a collector group are switched, connecting or disconnecting individual cylinders.

The group of pressure monitoring and adjustment devices consists of classic devices - pressure gauges and gas reducers. The filter is also used standard - for gas systems.

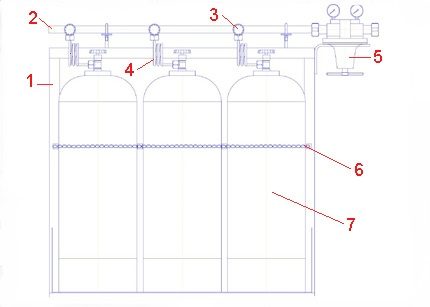

The assembly diagram of a simple classical ramp for gas cylinders is built as follows:

- A distribution manifold is created from a metal pipe.

- A filter is mounted at the collector input.

- After the filter, a gearbox is installed.

- Further along the collector, the installation of fittings for taps to the cylinders.

Industrial designs are usually complemented by a tightness control device. Its main purpose is tracking and closing / opening solenoid valves.

Meanwhile, the ramps supplying gas to equipment with a capacity of less than 1 kW can be built without a tightness control module. It is such equipment that is used in most cases in relation to the domestic sector.

General installation requirements

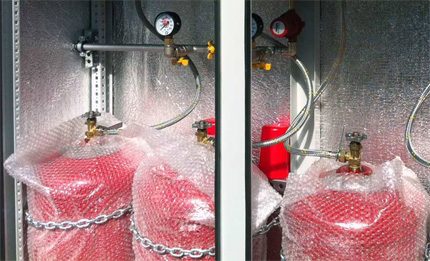

Ramps are allowed to be mounted inside separate (one-story) rooms. It is also allowed and recommended to install gas ramps for 2 cylinders, 4 cylinders or more, using metal cabinets for this.

If a system is arranged that involves technologically connecting no more than 40 cylinders, such ramps can be placed inside the annexes to production or utility rooms.

The bypass ramp, designed to connect and install no more than 6 gas cylinders, can be mounted directly inside the utility and production premises of the ground floor. At the same time, the volume of gas for each tank should not exceed the value - 100 m3. For the domestic sector, the conditions are somewhat different.

It should be remembered that gas ramps of 2 cylinders and more are allowed to be placed outside the boundaries of domestic premises, in places that are reliably protected from sources of open flame, heat, including solar radiation.

The installation location should be selected remote from the basement and technical communications. The design of the gas ramp must be protected from possible break-ins, mechanical stress, etc.

Do-it-yourself ramp making

It is not difficult to make a design for storage and operation of gas cylinders.

To do it yourself do:

- Sheet steel 2-3 mm thick.

- Steel angle No. 45 or profile pipe 40 x 25 mm.

- Metal pipe under the collector (the length is selected according to the number of cylinders).

- Small metal chain for fixing the cylinders.

In addition to this material support, the skills of a welder, a locksmith, tools and equipment (a welding machine) will be required. However, welding work can be performed on request.

Initially, it is necessary to determine the number of gas cylinders that will be installed in the ramp. For example, 3 cylinders. Based on the size of the diameter of the cylinders, get the initial size of the width of the ramp structure and increase it by 150-200 mm. The height size will be determined taking into account the height of the gas cylinders, plus 150-200 mm to the installation horizon of the collector.

Based on these calculations, a support frame is made of a steel corner or a profile pipe. The support frame can be assembled by welding or the mechanical method of fixing the corners (pipes) with a bolted connection can be applied. The assembled frame has the form of the letter "P".

Next, brackets for the collector are placed on the upper jumper of the frame and the frame is fixed to the rear wall inside a metal box previously made of steel sheets.

Mounting the gas manifold

Now it’s up to the manufacture of the collector, its installation and the addition of all the necessary accessories. A metal pipe (d = 32-50 mm) is measured along a length equal to the size of the length of the jumper of the support frame and points are marked on the pipe body for fittings (3 pcs).

Gently weld the bends for the fittings into the pipe body and install these parts together with the valves. A plug is placed at one end of the pipe, and a fitting for connecting the gearbox is at the other end. After completing these works, lay the collector on the brackets previously mounted on the upper side of the bridge of the support frame.

The installation of the collector should be carried out taking into account the indentation above the level of the valves of the cylinders by 150-170 mm. The collector should be set as accurately as possible horizontally and secured with clamps on the brackets, laying under the hoops of the clamps gaskets made of sheet technical rubber.

Then you need to install a gas reducer equipped with a filter on the open end of the manifold and supplement it with a shut-off valve.

The next step is the manufacture of liners for cylinders. They can and preferably be made from a copper tube in order to obtain an expansion compensation effect. But also allowed high pressure hoses.

The inlets are screwed at one end to the manifold valves, the other end of the tube will connect to cylinder valves.

Final assembly and connection

At the end of the assembly process of the ramp for gas cylinders with their own hands on the racks of the support frame, at a distance of 2/3 of the height of the cylinders, make a chain shutter.

To do this, perform the following actions:

- Take a metal chain.

- Measure along the length of the cylinder.

- Cut and fasten the resulting chain segment at one end to the frame rack.

The second end of the metal chain remains free. It will be mounted with a locking device on the second rack after the gas cylinders are loaded into the ramp. Of course, it is not at all necessary to use a metal chain as a fixer. You can use other suitable, but always reliable mounts.

At the last stage of work, a gas pipe is supplied from consumers to the collector gearbox. Technically, it remains only to load gas cylinders onto the ramp, connect them with branch pipes (hoses) to the collector, and that’s all - the device is ready for the stable supply of domestic equipment with gas.

But there are still some mounting details. It is necessary to equip the doors of the steel cabinet where the ramp is installed. In the future, when the system will be operated, it is necessary to equip the drawer doors with a reliable lock and restrict access to it for children.

The order of launching the structure into operation

Before starting the system, it is recommended to purge the gas line from the consumer point to the point of its connection to the collector gearbox. After purging, the line is connected to the input fitting of the gearbox.

Then, the following actions are performed sequentially:

- 3 cylinders with propane are loaded onto a ramp.

- Fix the cylinders with a safety chain.

- Connect diversion tubes to the valves of the cylinders.

- Open the valves on the manifold and on the cylinders.

- Check the tightness of all connections.

- The desired value of the working pressure is set by the regulator of the gearbox.

When the time comes to replace the empty gas cylinders with filled vessels, it is enough to simply close the valves on the vessels and on the manifold in order to quickly and safely replace them.

Periodically it is recommended to check the system for leaks. This work should be done at least once a quarter. Actually, such a service schedule is prescribed by the rules and requirements from among those that are used in the gas sector.

It should be remembered: such facilities as gas ramps are allowed to be serviced only by persons who have passed the relevant technical minimum. Devices of this type should be kept clean.

It is strictly forbidden to store technical oils and liquids, flammable components near the ramp. Naturally, smoking or working with fire on an existing ramp is unacceptable.

Conclusions and useful video on the topic

How is the combination of gas cylinders using a ramp:

Designs for loading, storage, operation of several vessels at once are made not only for propane-butane, but also for acetylene, oxygen, carbon dioxide and others. True, for the domestic sphere, natural gas still remains the main consumer product. Most often, gas ramps are made for this type of product.

Whatever the purpose of the design, it basically changes the operating conditions of the equipment - makes them more convenient for users, safe for others.

Have questions about the topic of the article? Or maybe there is valuable information which you can share with our readers? Please leave comments, ask questions, share experiences in the block below.

Do-it-yourself gas burner for a sauna stove: how to make a home-made device

Do-it-yourself gas burner for a sauna stove: how to make a home-made device  Do-it-yourself gas cans for burners: instructions for different types of cylinders

Do-it-yourself gas cans for burners: instructions for different types of cylinders  DIY gas stove: the best options for homemade tiles from improvised materials

DIY gas stove: the best options for homemade tiles from improvised materials  DIY propane gas burner: step-by-step instructions for assembling home-made burners

DIY propane gas burner: step-by-step instructions for assembling home-made burners  DIY gas torch from a blowtorch: a manual for the manufacture and operation

DIY gas torch from a blowtorch: a manual for the manufacture and operation  Gas cylinder cabinet: cylinder storage requirements + cabinet selection and installation tips

Gas cylinder cabinet: cylinder storage requirements + cabinet selection and installation tips  How much does it cost to connect gas to a private house: the price of organizing gas supply

How much does it cost to connect gas to a private house: the price of organizing gas supply  The best washing machines with dryer: model rating and customer tips

The best washing machines with dryer: model rating and customer tips  What is the color temperature of light and the nuances of choosing the temperature of the lamps to suit your needs

What is the color temperature of light and the nuances of choosing the temperature of the lamps to suit your needs  Replacement of a geyser in an apartment: replacement paperwork + basic norms and requirements

Replacement of a geyser in an apartment: replacement paperwork + basic norms and requirements

I read it with interest, I agree with everything, I will say more: during the Union, when there were big problems with the gasification of private houses, my father did something similar. Of course, simpler and structurally primitive, but these devices really worked. But now, for example, our cylinders are filled with gas, which is frankly ugly in quality, there are a lot of impurities. Should I bother with the manufacture? Will it pull? And one more question. We have rather cold winters, if this unit will stand on the street, at what minimum temperature can problems begin?

The minimum temperature at which the unit will work depends on whether the mixture is pumped into cylinders - winter or summer. There is more propane in the winter mixture and it will work up to 30 degrees if the bottle is in a closed box. With the summer mixture, which has more butane, problems will arise much earlier.

Good afternoon. I would like to know, but I could not find an answer anywhere.

Please tell me, two cylinders are connected, working in pairs at the same time through a tee to the heating boiler. The question is - can gas be transferred from one cylinder to another, or is there a check valve on the gearbox? For example, if you connect one empty and one full cylinder, as a result, the gas in both cylinders compares? Or not?

Hello, the minimum temperature operation of winter gas based on propane is minus 44 degrees Celsius, summer temperature based on butane is minus 0.5-3 degrees, depending on the concentration.