Gas valves: varieties, basic characteristics + selection criteria

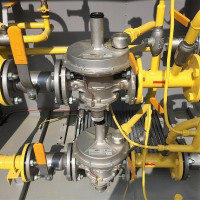

All pipes that supply gas to the boiler or stove, without fail, have gas taps that serve to shut off or supply natural fuel to the facilities. Gas valves also serve to stop the gas supply, if there is a suspicion of a gas leak or other malfunction of the gas appliance.

It is worth noting that for such purposes, ball valves are most often used. Although the type of valve is not so important, the main thing is that it is reliable and serviceable. Next, we will talk in detail about the types of gas valves and outline the main criteria for their selection.

The content of the article:

Classification of gas taps

From childhood we were taught that you can’t joke with gas. Yes, and now every schoolchild knows the gas service telephone number: 104. At school, from early childhood they explain where to call if there is a smell of gas in the house.

Pipes, valves and other constituent materials for the supply of gas must be of special quality. These structural elements must serve a person for at least ten years, and they should be checked periodically, and replaced if necessary.

However, the owner of the room will have to purchase gas equipment. Choosing it is not difficult if you study what requirements it should meet. So, the main characteristics of gas valves are almost all reduced to the reliability of the valves. Dimensions depend on pipe diameter. That is why the diameters of gas valves must match the size of the pipe.

Most often it is 24, 27 mm. Manufacturers produce gas valves and valves, the thread size of gas valves can be of three types. If you look at the product labeling, then there must be specified in accordance with GOST the following information: type of product and type of crane

According to the principle of action

Next, consider what types of gas valves are. Judging by the principle of action, they can be divided into cork and ball.

Cork gas taps - their principle of operation is based on the work of the cork mechanism. The principle is quite simple: just turn the handle of the crane and the plug will also turn inside the case. And there is a hollow structure, thanks to this gas can safely pass inside the body through the pipe to its destination.

When the handle of the tap is turned back, then there will already be a closed space and therefore the gas will no longer pass through the obstacle. The only thing is that the body of the crane and the plug should be tightly adjacent to each other. The role of the sealant is performed by the valve seal.

Ball Valves somewhat different from cork in that there is a ball inside, which plays the role of a locking system. If the ball is turned in one direction, then gas will pass through the hole in it, thus, the valve will open. If in the other direction, then the closed surface will not allow gas flows. Usually such a ball is made metallic. Moreover, the material is used durable.

The product serves for a long time and special care for the ball valve is not necessary, unlike the cork valve, which needs to be serviced periodically. Ball constructions appeared on the markets not so long ago, but they are especially popular, because they have their own advantages. In particular - low cost of the product, ease of use, strength and reliability, long service life.

Also, these cranes can be operated at low and high temperatures, more precisely in the range from -55 to +75 degrees Celsius. That's why experts advise to use just such gas taps for domestic purposes.

According to the method of connection with pipes

If you look at the method of connecting cranes with pipes, then they can be divided into the following types:

- threaded taps - they are connected to the pipe by scrolling to full contact. To prevent gas poisoning, special gaskets are used;

- flange mounted cranes - connect with special flanges, which are metal disks, but they are already bolted;

- weld-on taps - such locking mechanisms are simply installed with a welding machine, without any threads and flange auxiliary discs and bolts.

The cranes of the first two mounting methods (threaded and flanged) can be used reusable, they can be removed from the pipes, then fixed back. But the welded mechanisms are used only once, repeated application is impossible.

According to the material of the product

When buying a gas valve, it is imperative to pay attention to the material of the product. This is an important component, because the stronger the material from which the locking mechanisms are made, the longer its service life. And for gas pipes, taps must be of the highest quality.

It is from the raw materials from which the cranes are made that they got their names. Brass tapsPerhaps the most common products on the market.

True, there are some drawbacks to these designs. If you need a faucet for supplying gas to the stove, boiler, then yes, you will find such taps from this material. For pipes of small diameter, there is a small selection of products, and then not for everyone. Brass also responds to high temperatures. If the product is heated above 200 ° C, then after that it will be impossible to use it. Also, brass is not used in the petrochemical industry.

In addition, many manufacturers have recently replaced brass with silumin for the sake of economy and do not always warn about it, so the buyer should be careful about the product, choosing it in those places where there is no product certification. Siluminovye cranes during repairs, they can leak gas due to microcracks, this is unacceptable and unsafe.

In the USSR, more often than others used cast iron gas taps. The quality of these products was at their best, but now manufacturers have stopped making them, because this industry does not stand still, but is developing. New types of steel are appearing, which are not as expensive as cast iron, but have properties similar to it. Therefore, they do not already make cast-iron mechanisms for controlling the gas supply.

Now, in addition to brass products, the following are often found:

- Carbon valves - they have a huge variety of diameters, but they are most often used for water, they are not suitable for feeding evenslightly aggressive wednesday Also, if the temperature is minus forty, then the material loses its properties, is not suitable for use.

- Alloy Cranes - They are quite similar to carbon ones in type of application, their only difference is that they withstand temperatures up to - 60 ° С.

- Stainless taps - more often used in large industries. They are resistant to different temperature extremes, are not afraid of aggressive environments, do not rust.

Particular attention should be paid to the valve shutter. It must be smooth. After all, manufacturers use diamond cutting technologies to reduce friction between parts, thereby minimizing the risk of leaks.

Good quality gas taps are made with brass valves. And on top of the material is also coated with nickel or chrome. This extends the life of the locking mechanism. Those cranes that are lower in cost are made of metal. It is good, while new, but over time, the metal begins to rust.

Basic equipment selection criteria

If there is a question about replacing a gas valve, then doing it yourself is not recommended. Only specialists have the right to engage in such work, and they must have a license for these types of work. Do gas pipe replacement, cranes to yourself is simply not permissible. You can endanger not only your life, but also the life of your family and neighbors.

This information should be known to any homeowner and tenant. It is gas workers who conduct periodic inspections of the state of gas equipment or, in case of malfunctions, the landlord calls the gas emergency service. They, in turn, establish what is out of order, and residents buy everything they need to fix the breakdowns. In this case, we find out by what criteria it is better to choose a gas valve.

As previously mentioned, ball valves are popular, although experts in this industry say that cork valves serve more - their service life is about 20 years. But they need to be serviced and sometimes lubricated. But ball - no.

So when choosing, you should pay attention to all the little things, even the appearance of the product and take into account the following circumstances:

- The diameter of the gas valve must necessarily coincide with the diameter of the pipe. Of course, valves of a smaller, larger diameter are simply not suitable for work.

- Thread pitch. If you take a threaded locking mechanism, then it must correspond to the thread pitch on the gas pipe.So you do not have to buy any adapters that will pile up the design.

- Pay attention to the material of the product. Nevertheless, it is better to use brass taps for gas. This is time-tested material. He will serve you for a long time and without problems. Brass has a yellowish tone and a brass faucet is heavier than that of various types of steel.

- Look carefully at the look. The product must be free of scratches, cracks, chips. There should be no defects either on the surface or inside. Do not hesitate to carefully examine the gas valve, you do not want to change it often. You should also not save on buying.

Choose cranes from well-known companies, as these manufacturers are responsible for their products because they do not want to lose customers. And for them the reputation of their company is important. These manufacturers include a German company Dungs, Italian company Bugatti.

Tips for replacing gas valves

In apartments or houses gas communications serve for many years. The only thing that they require periodic inspections and maintenance (pipe painting). The most vulnerable parts of such structures are gas taps. Still, they are used several times a day, or even more. Because of the heavy loads, gas taps break. Especially often breakdowns of gas valves from poor quality raw materials occur. Plastic products fail faster than others.

Not everyone knows when a crane needs to be replaced. The answer is simple - when you feel the unpleasant aroma characteristic of gas, you need to check where the smell is more saturated. If there is a leak in the area of the gas valve, then it should be replaced.

Inspect the product, you may notice cracks or other damage on it. Maybe the crane turns tight or vice versa - it rotates too freely, then we can safely say that the device is out of order. But you cannot replace the locking device yourself. Do not tempt fate - call a gas worker.

He is free to you will replace the gas cockYour task is only to buy the right mechanism that fits your gas pipes and lasts for many years. About the selection rules we described above.

If you need to change the device, do the following:

- To get started, dial the gas economy number, report your problem to the dispatcher.

- Buy a suitable tap, consider the diameter of the pipes, thread pitch, other nuances. Choose the cheapest product.

- Prepare documentation for gas specialists. Most likely you will need: technical passport, gas supply documentation.

- When the employee arrives, he will ask to light the burner, close the valve that controls the gas supply. So the fuel comes out of the pipe.

- All work on the replacement or repair of gas equipment should be carried out in a well-ventilated area.

- The master will replace the faucet and check its operation, he must also check for gas leaks.

- When the repair of gas communications is completed, the specialist will ask for a technical passport and make a record of the work done.

The detection of fossil fuel leaks is done by using soap suds. Foam is applied to the joints and the tap, and then carefully monitor the foam. If there is a gas leak, then bubbles begin to form in this area.

Conclusions and useful video on the topic

As you can see, selecting and replacing a gas tap is not such a difficult job. And in order not to endanger themselves and their neighbors, the process should be treated with responsibility. Even such a small detail as a gas pipe faucet in an apartment plays an important role in general gas utilities.

How to choose a high-quality gas valve will be discussed in the following video:

Please tell other visitors to our site if you have encountered the choice and replacement of gas valves. Perhaps there are subtleties that we did not mention in this material? Leave your comments, share experiences, ask questions - the communication block is located under the article.

Gas burners for spray can: varieties and principle of operation + nuances of choice and use

Gas burners for spray can: varieties and principle of operation + nuances of choice and use  Gas hoses for gas stoves: varieties, how to choose and connect

Gas hoses for gas stoves: varieties, how to choose and connect  Gas fittings and equipment: varieties + features of choice

Gas fittings and equipment: varieties + features of choice  Garage gas heaters: selection criteria for a practical and safe option

Garage gas heaters: selection criteria for a practical and safe option  Gas filters: types, device, purpose and features of the choice of filter for gas

Gas filters: types, device, purpose and features of the choice of filter for gas  Gas pressure relief valve: types of devices + selection guidelines

Gas pressure relief valve: types of devices + selection guidelines  How much does it cost to connect gas to a private house: the price of organizing gas supply

How much does it cost to connect gas to a private house: the price of organizing gas supply  The best washing machines with dryer: model rating and customer tips

The best washing machines with dryer: model rating and customer tips  What is the color temperature of light and the nuances of choosing the temperature of the lamps to suit your needs

What is the color temperature of light and the nuances of choosing the temperature of the lamps to suit your needs  Replacement of a geyser in an apartment: replacement paperwork + basic norms and requirements

Replacement of a geyser in an apartment: replacement paperwork + basic norms and requirements

Outdoor balloon, home heater. There is no tap on the heater (turn off the tap on the cylinder). Connection by a hose of 9 mm. I want to put a tap in the house so as not to run outside. Is there a tap in the hose break (with exits for clamps), or only fittings with a transition to 1/2 and have a tap to them?