Control pipe on the gas pipeline: purpose + installation rules on the case

Underground gas pipelines have many advantages. They do not spoil the exterior of urban buildings and the countryside, do not interfere with the movement of vehicles, do not force the existing buildings to be displaced. But they have a significant drawback - this is the complexity of monitoring both the pipe itself and the medium moved through it.

We will tell you how the control pipe on the gas pipeline helps to monitor the status of the system. We will introduce you to the design features of this device. We will analyze the location options and installation rules.

From our article you will find out where and in what sequence the control tubes are installed on the gas pipeline system. Get acquainted with the features of mounting them on the cases and on the semicircular casings. Understand how much it is necessary to monitor the technical condition of the underground pipeline.

The content of the article:

The purpose of monitoring the status of the underground gas pipeline

The gas pipelines laid in trenches need regular inspection no less than land routes. Of course, they are not threatened with purely mechanical damage, as happens with openly arranged communications. However, gas workers have no less reasons to worry about their condition.

If the blue fuel pipe is submerged:

- It is difficult to monitor the mechanical condition of the gas pipeline, but its walls are affected by soil pressure, the weight of structures and pedestrians, as well as passing vehicles if the highway passes under the highway or railway line.

- It is not possible to detect corrosion in a timely manner. It is caused by aggressive groundwater, directly the soil, which contains active ingredients. The loss of initial technical characteristics is facilitated by technical fluids that penetrate to the depth of the route.

- It is difficult to determine the loss of tightness caused by a violation of the integrity of the pipe or weldment.The reason for the loss of tightness is usually the oxidation and rusting of metal pipelines, commonplace wear of polymer structures or violation of assembly technology.

Despite the fact that the laying of gas pipelines in trenches provides for the complete replacement of aggressive soil with soil with neutral properties, and the device in places of possible spillage of technical fluids is completely prohibited, without special devices they cannot be considered completely protected from chemical aggression.

As a result of the loss of tightness, a gas leak occurs, which, as expected for all gaseous substances, rushes up. Penetrating through pores in the ground, a gaseous toxic substance comes to the surface and creates negative effects for the entire living area above the gas pipeline.

A gas leak can easily become a cause of a serious catastrophe if the blue fuel that has left the pipe "finds" in the ground any cavity for accumulation. When heated, for example, by the elementary exposure to sunlight during a hot summer period, an explosion of accumulated gaseous fuel is almost inevitable.

In addition, a gas leak entails considerable financial losses for the gas producing and gas transportation organization. Moreover, disagreements may arise between them, which you should not even go to court if a control pipe for monitoring has not been installed on the gas pipeline case.

Why is a gas pipeline case?

In the device of underground gas utilities are usually used steel or polyethylene gas pipesable to withstand the pressure of the medium passing through them. Their strength characteristics are designed for the load created by the thickness of the soil up to 2.0-2.2 m. However, standard pipe rolling is not designed for a possible transport load from above, i.e. over the gas main.

It is also not taken into account that pipelines through which gas is transported to the consumer are undesirable to pass under other communication lines. There are still geological and hydrogeological restrictions, in accordance with which the gas main has to be laid above established standards.

If it is not possible to find a laying route that does not cross other engineering structures, in accordance with the requirements of SNiP 42-01-2002, a safe vertical distance must be ensured between the pipelines. This is 0.2 and more meters, which as a result changes the depth of the gas pipeline.

The depth of the gas pipe is also changed if rock formations or an unstable groundwater level interfere with laying at the standard depth mark.

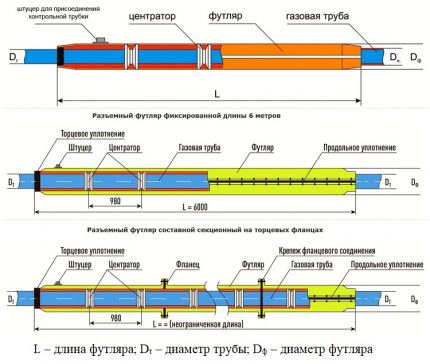

How to protect the gas pipeline if additional load on the line is inevitable? In all these cases, cases are used, which are a rigid round or semicircular section of a casing made of steel alloy, polyethylene or fiberglass. It is he who protects the path of blue fuel from possible damage.

Note that when protecting the pipeline, monitoring the condition of the pipe laid in the case is even more difficult. To facilitate the difficult work of lineman, employees of the extractive industry and gas supply structures, a control tube is installed on the gas pipeline.

We list all the possible prerequisites for the installation of cases with control devices over gas pipelines:

- The proximity of the underground gas pipeline to a residential building or public building.

- Laying a gas pipeline at shallow depth.

- The device under the transport routes: road, tram, railway.

- The presence of a threaded joint or weld on electric-welded metal pipes and polyethylene analogues.

- "Intersection", i.e. Passage 0.2 m higher or lower than the heating network and other communication lines.

- Enter gas supply pipe to the house through the load-bearing wall and the vertical intersection of the floors.

- The construction of a test point with a protective carpet. They are installed along the entire route every 200 m within the cities and other settlements. In a free area they arrange after 500 m.

All of the above options except for the intersection of the gas pipe floors, as well as arrangement of the entrance and underground line exit on the surface provide installation on one of the edges of the case of the control tube.

Even in the case of installation above a problem weld, it is allowed to use not cases as the basis for fastening the tube, but a semicircular metal casing.

The control tube is placed in a convenient place for monitoring. Those. on the other hand, with which a gasman’s approach to monitoring operations is possible, safe and does not require permits.

If two gas pipelines are laid in one trench, which is allowed by construction standards, then the arrangement of the cases with the pipes connected to them should ensure the tracking of both systems.

Cases are installed both on newly laid gas pipeline lines, and on existing branches by puncture or pressing soil. They should go beyond the boundaries of the highway, highways, load-bearing walls and other structures at 2 m from both edges.

Control tube design

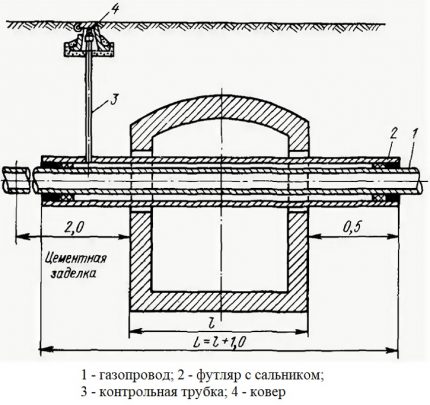

According to the standards, the minimum distance from the top of the case to the day surface is 0.8 m, and the maximum is 3.0 m. In places where no transport load is planned, the minimum soil power above the case can be reduced to 0.6 m. The intersected soil thickness determines the height of the control tube that should go to the surface.

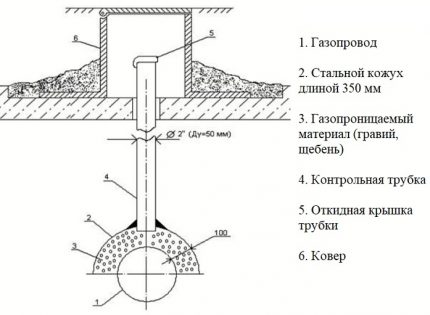

Structurally, this control device is in the literal sense a tube fixed with one end on a case or a semicircular casing of a gas pipeline. The second is brought to the surface and equipped with either a clapper cap or a sleeve with a tightly screwed threaded plug.

The diameter of the control tubes, which are installed on the case or casing of the gas pipeline, is 32 and 57 mm, according to technical standards. However, they can be produced according to the size required by customers. In this case, to produce a series of tubes, a project is developed and TU is approved with quality requirements.

Rules for installing and fixing the tube

The control tube is fastened to the case or semicircular casing of the gas pipeline in accordance with the pipe material and the protective system.

In the installation, three main methods are used:

- Installation of the control tube together with a semicircular metal casing welded to its base. They put it as an ordinary control point on the pipeline route without a case after laying a steel or polyethylene pipe and partially backfilling it with sand up to 0.2 m.

- Fastening to a polyethylene case using a saddle branch and an adapter from polymer to steel. The hole for fixing the control tube is drilled before installing the case.

- Welding the base of the tube to the steel case. A welded assembly is arranged along a hole pre-drilled in a gas pipe.

If the tube is not directly welded to the gas pipeline, then a layer of sand is necessarily located between its base and the pipe. The tube itself is wrapped with plastic wrap or coated with a waterproofing primer.

In the new generation cases made of fiberglass, the mounting point of the control tube is laid in the manufacturing process. This solution greatly facilitates the installation process. The tube is screwed before installation and the joint is sealed, after which the foundation pit with the gas pipeline is filled with soil.

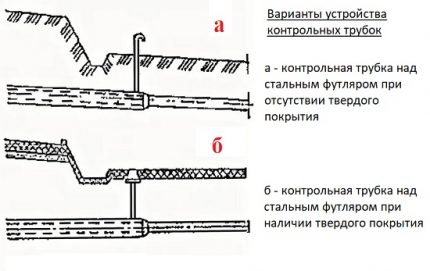

The design and arrangement of the top of the control tube is made in accordance with the type of surface through which it is discharged. In the presence of a hard coating (concrete slab, asphalt), a protective cap and carpet are placed above the top. In the absence of a hard coating, the tube is led out 0.5 m above the ground and gradually bent 180º.

Through the control tube, the lineman, who is obliged to monitor the technical condition of the gas pipe and the density of the transported gas, introduces the gas analyzer hose or pressure gauge sensor and takes the readings of the instruments. The data he collected is recorded in the survey log.

Conclusions and useful video on the topic

The following video will familiarize you with all types of structures and devices designed to service the gas pipeline and monitor its technical condition:

Information on the nuances of laying and arranging gas pipelines will be useful to owners of suburban areas who want to connect the property to a centralized gas supply.

Of course, the information will be extremely useful for those who intend to organize an autonomous network with a gas tank and pipes laid from it. With the installation of a control tube, monitoring the status of the underground system will be much easier.

Please leave comments in the block form under the text of the article, ask questions, post a photo on the topic. Tell us about your experience in arranging control devices for monitoring the operation of the gas pipeline in your own area. Share useful information that may be useful to site visitors.

Gas condensate collectors on the gas pipeline: structure and purpose of the condensate collector + nuances of installation and maintenance

Gas condensate collectors on the gas pipeline: structure and purpose of the condensate collector + nuances of installation and maintenance  Thermal shut-off valve on the gas pipeline: purpose, device and types + installation requirements

Thermal shut-off valve on the gas pipeline: purpose, device and types + installation requirements  Connecting a gas stove with an electric oven: installation procedure + norms and rules for connection

Connecting a gas stove with an electric oven: installation procedure + norms and rules for connection  Replacing the nozzles in a gas stove: purpose, structure and detailed instructions for replacing nozzles

Replacing the nozzles in a gas stove: purpose, structure and detailed instructions for replacing nozzles  Underground gas ball valve: design and operational features

Underground gas ball valve: design and operational features  Gas filters: types, device, purpose and features of the choice of filter for gas

Gas filters: types, device, purpose and features of the choice of filter for gas  How much does it cost to connect gas to a private house: the price of organizing gas supply

How much does it cost to connect gas to a private house: the price of organizing gas supply  The best washing machines with dryer: model rating and customer tips

The best washing machines with dryer: model rating and customer tips  What is the color temperature of light and the nuances of choosing the temperature of the lamps to suit your needs

What is the color temperature of light and the nuances of choosing the temperature of the lamps to suit your needs  Replacement of a geyser in an apartment: replacement paperwork + basic norms and requirements

Replacement of a geyser in an apartment: replacement paperwork + basic norms and requirements