Methods of connecting gas pipes and methods of sealing compounds

Have you noticed how many different ways experienced craftsmen can offer to solve the same problem? The installation of the gas pipeline is no exception. So, the connection of gas pipes by professional gas workers is performed using different materials and techniques. In the arsenal of masters, carving and welding, soldering and flanges. They actively use proven techniques for decades and recently appeared.

Knowing the basic methods, understanding the tools and modern materials, it is easier to track the correctness of the work, to monitor the actions of the invited specialists.

In this article, we described the main options for fastening gas pipes, methods of sealing joints. After reading it, you will understand the types of pipes, features of materials, technologies for working with them. We paid special attention to methods for checking already completed connections, since the operation safety of domestic gas equipment depends on their correctness.

The content of the article:

Features of connecting gas pipes

For a long time, the gas pipeline consisted exclusively of metal pipes of different diameters. The material was appreciated for the ability to create a seamless line capable of maintaining absolute tightness under high pressure.

The search for other options was made by a significant drawback of the metal alloy - under the influence of moisture, after several years of operation, it began to rust, jeopardizing the integrity of the pipeline.

Then pipes from other materials began to appear:

- Copper, the advantage of which is corrosion resistance, the negative is the ability to maintain integrity at low pressure not exceeding 5 kPa.

- Mild steelnot affected by rust. Its disadvantage is the difficulty in processing and high cost. Therefore, PVC pipes with a steel outer braid are used to equip gas pipelines.

- Polyethylene. Flexible and lightweight, this material does not conduct electricity, is cheaper than other analogues and can withstand strong transformations without loss of integrity.

More information about the different types of gas pipes and the features of their choice can be found in this stuff.

Elements connecting the highway and the layering leading to the consumer began to be made of rubber. For such compounds, heat-resistant rubber is selected that is not prone to drying out with excessive insolation.

The choice of material is determined gas pressurerequired throughput and calculated by specialists.

The same goes for connections. Only a professional can determine the appropriate type of fastening, correctly correlate it with the pipe material, technical operating conditions.

Gas pipe connection options

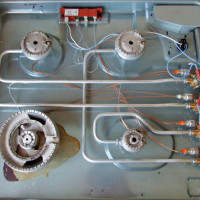

Today, masters distinguish 5 types of connections when installing a gas pipeline. This is welding used for metal pipes, soldering used for copper and PVC, inset, threaded and flange connections.

Option number 1 - weld

Steel pipes are treated using an inverter apparatus or gas welding equipment. The ends to be connected are located at a distance of 1.5-2 mm from each other, thoroughly fixed.

In the process of metal melting, the welder makes two seams: the main and the secondary one.

The polyethylene elements are joined by a device that controls the temperature reached by heating. For connection, a fitting with a melting element is used. By heating the surrounding material, it turns the mixture into a homogeneous mass. The result is a sealed, durable seam.

Option number 2 - soldering pipes

Butt brazing is suitable for both metal pipes and thermoplastic polymer products. The work is carried out on a modular unit, including a hydraulic unit, a centralizer, a soldering iron and an integrated torch.

The algorithm is as follows:

- The ends of the elements to be soldered are cleaned of chips, dust, foreign particles. Degreased.

- With help soldering iron for polypropylene pipes the parts are heated and come together until an influx of 1 mm thick appears on the junction surface.

At the end of work, the connection is left in the unit until it cools completely. Any movement during a decrease in temperature can cause fistulas.

Option number 3 - insert into the pipe

The box is a method that requires special qualifications. It can be performed in a hot way, in which an arc welding unit is used, and cold, when drilling equipment is the main tool.

The meaning of manipulation is to organize a tight branch from the whole pipe.

The insert by the first method is permissible only when the pressure in the gas pipeline is reduced to a value of 40-50 kg per square meter. see. The second can be implemented without lowering the pressure. In both cases, permission from the supervisor is required.

Read more about how to crash into a gas pipeline Further.

Option number 4 - the use of threaded connections

Threaded connections are used throughout the gas pipeline: from end elements to different types of branches. If flexible rubber eyeliners are already equipped with appropriate nozzles, then metal pipes often have to be cut.

It is performed in the following way: the surface of the future thread is cleaned, filed, lubricated with machine oil. Then, with the help of a pipe hob, cutting is performed.

If it is supposed to join two fixed sections of the gas pipeline, the gas pipes are connected by means of a coupling. This is a separate metal element with internal thread. The imposition of it on the external thread of the pipe ends makes it possible to ensure a tight fit.

Even perfectly crafted threads do not provide perfect joint integrity. Therefore, additional materials are always used to seal gas threaded connections.

Option No. 5 - flange connections

This method is suitable for pipes made of copper, steel, polyethylene. Used only in low pressure areas.

A flange is a flat part with holes made in it. The part itself serves as a connecting element. The holes in it are for studs and bolts.

For PVC pipes use special fittingwhich are connected by welding. In the case of metal elements, you can do without heating. They use bolts to fix the flanges.

Joint sealing materials

Threaded and flange connections need additional sealing.

The choice of material for the gasket is based on the fact that it should:

- withstand the loads specified by the project, including pressure drops;

- to level defects of the condensed surface;

- fill the space between connected elements.

That is, the gasket must be flexible, strong and dense. The most famous material that meets these requirements is flax. Linen strand is actively used to seal joints of gas and water pipes.

More modern materials - pastes, threads, sealants, FUM tape are used a little less often: due to the higher cost and some conservatism of experienced specialists.

Pros and cons of linen ribbon

Linen tape is wound tightly on the thread, creating a dense layer. The advantages of the method are low cost, high adhesion, strength of the fixed joint.

Cons - the destruction of flax over time, the complexity of dismantling, high requirements for the experience of a specialist.

If the gas pipe connection on the laid flax thread is made with too much force, the gasket may break. Such a joint will not be airtight. Therefore, it is better if the manipulation is entrusted to an experienced master.

Pastes based on oils and resins

Oil and resin compositions do not harden. The substance applied to the joint remains viscous for a long time, effectively resists the penetration of gas into the external environment.

A big plus is easy application, which even a beginner locksmith can handle.Cons - lack of fixed fixation, low resistance to pressure.

With increasing pressure in the gas pipeline, the paste is gradually squeezed out of the compound.

Drying Sealants

The basis of these compounds are solvents. After application, the substance dries, provides a firm hold. It can be used alone or paired with linen winding for gas connections.

Experts attribute the strengths of drying sealing pastes to the strength of the compounds obtained. In addition, the composition is easy to apply: during processing, it acts as a lubricant, and begins to dry, already being in the threaded gap. Of the shortcomings, a tendency to shrink is distinguished.

Anaerobic adhesives

Viscous, polymerizable, non-shrink adhesive is the best sealant for threaded and flanged gas connections. Filling the space at the joints, it freezes only there, remaining fluid and viscous from the outside.

Excess glue can be easily removed from the surface, and the dose that gets inside will remain in place and quickly polymerize.

The only drawback of anaerobic adhesive is the inability to use it at low temperatures. With a strong minus, the polymerization time sharply increases. And in some situations, it may not come at all.

Nylon Seal

The principle of using a nylon thread is similar to the method of using flax fiber: the material is wound on the external thread of one element, and then pressed against the internal thread of another.

The benefits include:

- low cost;

- wide temperature range, the upper limit of which is fixed at around 130 degrees;

- possibility of use in conditions of high humidity;

- reliability of the processed compound.

Among the disadvantages, the need to roughen the thread is highlighted - it is extremely difficult to hold the material on smooth metal. In addition, the nylon thread is not suitable for sealing pipe joints with a diameter of more than 80 mm.

Teflon tape

FUM tape is a relatively new type of sealant, but quite popular. Its main advantages are elasticity, chemical resistance and heat resistance.

The tape is easy to wind, it has a long service life, suitable for metal and polyethylene pipes.

However, there are also disadvantages. This is a low level of sealing compounds of large diameters and sensitivity to irregularities - roughness, nicks, metal shavings can easily violate the integrity of the tape.

Methods for checking the tightness of joints

The tightness of the gas pipeline is checked by sections. In the situation with apartment buildings, a segment is selected from the place where the fuel is introduced into the building to the taps of household equipment.

At the ends of the plot are placed stubs. In the pipes, pressure is increased, exceeding the standard indicators by 25%. A drop in pressure is the reason for checking the connections.

The integrity of the joints, branches and connection points of equipment is checked in two ways:

- Using a gas leak indicator.

- By applying a soap solution, emulsion.

In the first case, a digital, sound or color signal of the device will notify about the danger. In the second, you must monitor the appearance of bubbles. Their presence indicates a violation of the integrity of the connection.

Conclusions and useful video on the topic

Three methods of sealing standard threaded connections are shown in the video:

Having got an idea of the materials from which the pipes for the gas pipeline are made, the types of joints and sealing methods, it becomes clear that it is better to entrust all the work to professionals. An experienced master will be able to choose the best joining method, a suitable sealant, and correctly check the integrity of the connection.

If you have experience in sealing compounds, you are in the know about the novelties in the market of sealing compounds, write. Both novices and those who have something to share visit our site. Share experience, knowledge, ask questions. The form below allows you to accompany the comment with photos, diagrams, drafts.

Gas pipes: a comparative overview of all types of gas pipes + how to choose the best option

Gas pipes: a comparative overview of all types of gas pipes + how to choose the best option  Repair of gas stoves Hephaestus: the most common breakdowns and methods for their elimination

Repair of gas stoves Hephaestus: the most common breakdowns and methods for their elimination  Dielectric insert for gas: varieties of gas couplings and installation tips

Dielectric insert for gas: varieties of gas couplings and installation tips  Insulation of steel gas pipelines: materials for insulation and methods of their application

Insulation of steel gas pipelines: materials for insulation and methods of their application  Repair of gas ovens: an overview of the main breakdowns of gas ovens and recommendations for repair

Repair of gas ovens: an overview of the main breakdowns of gas ovens and recommendations for repair  What to do if the gas meter creaks during operation: the main causes of noise and methods for eliminating them

What to do if the gas meter creaks during operation: the main causes of noise and methods for eliminating them  How much does it cost to connect gas to a private house: the price of organizing gas supply

How much does it cost to connect gas to a private house: the price of organizing gas supply  The best washing machines with dryer: model rating and customer tips

The best washing machines with dryer: model rating and customer tips  What is the color temperature of light and the nuances of choosing the temperature of the lamps to suit your needs

What is the color temperature of light and the nuances of choosing the temperature of the lamps to suit your needs  Replacement of a geyser in an apartment: replacement paperwork + basic norms and requirements

Replacement of a geyser in an apartment: replacement paperwork + basic norms and requirements