Automation for gas heating boilers: device, principle of operation, manufacturers overview

Household heating appliances operating on liquefied or natural gas do not require constant attention and control from the owners. This task is performed by automation for gas heating boilers.

Electronic and mechanical control units integrated into the heat generator regulate combustion and help maintain the required temperature in the coolant.

The content of the article:

Varieties of automation for heating boilers

Automation works correctly, clearly and reliably, increases the efficiency of heating equipment, contributes to the rational consumption of energy resources and makes the operation of the heating system simple, comfortable and absolutely safe.

The automatic system protects heating systems from overloads and activates an emergency shutdown of the gas supply in case of sudden force majeure. In addition, the technique regulates the level of combustion intensity and current fuel consumption, allowing owners to save financial resources on space heating.

According to the basic principle of operation and design features, automation for gas-powered equipment is divided into:

- energy-dependent devices;

- energy independent appliances.

The systems of the first type are complex electronic units and for correct operation, which need an uninterrupted supply of electrics. The second types of devices are simplified mechanical structures that do not require energy recharge.

View # 1 - Volatile Products

Volatile module - This is a small electronic device that responds to the supply of a fuel resource.It turns on and off at the time of activation or closure of the main gas valve. It features a complex design and a large number of elements and microcircuits.

Allows owners to solve the following tasks:

- activation or shutdown of gas supply;

- starting the heating system in automatic mode;

- adjustment of the power level of the base burner (thanks to the presence of a thermostat);

- shutting down a working boiler both in emergency situations and within the limits of a user-defined mode;

- output of current indicators to the display (general level of air temperature in the room, mark to which the working coolant is warmed up, etc.).

More “sophisticated” modules have additional functionality and offer users unlimited and most convenient conditions for monitoring operation and controlling the unit. Electronic panels provide complete protection of heating equipment from malfunction three way valve and do not allow the boiler to freeze.

If the room temperature drops sharply, the “smart” system itself starts the heating equipment and turns it off when the house is filled with comfortable warm air.

The self-diagnosis option available for individual modules prevents malfunctions and contributes to the timely detection of defective parts and assemblies in the system. It makes it possible to notice a breakdown as early as possible and replace some small element even before it creates a real problem for the equipment.

Electronic automation, which is responsible for the safe operation of the equipment, ensures uninterrupted operation of the boiler, prevents the system from overheating and shuts off the gas supply in case of draft drop or flame attenuation in the burner.

The assortment line of volatile automation, presented on the market today, pleases with variety. Useful and necessary mini-units are produced by world famous brands and small companies, just trying to win their place in the sun.

Among the offered models there are both very simple products and more advanced units with the programming option.

On them, the user can choose the most suitable for themselves individual settings and program the system to work in day / night mode or, focusing on the weather forecast, set a certain level of heating of the house or apartment for a period of 1 to 7 days.

View # 2 - non-volatile units

Non-volatile automation more simple and practical. Management and adjustment are carried out manually using mechanical rotary toggle switches and are not difficult even for those who are far from technology. The device works absolutely autonomously and does not need to be connected to the central electrical system.

The product is marked with a digital scale with a list of values from minimum to maximum. To activate, the user selects the desired mark and in this way sets the appropriate operating temperature directly to the boiler.

After these manipulations is connected temperature regulator and takes control of the specified heating mode. The boiler works actively until the room warms up to the desired temperature. Then the temperature controller turns off the gas supply to the system and is activated again only when the room gets colder.

The principle of operation is based on the specific design of the device. The thermocouple of the gas boiler integrated in the heat exchanger is equipped with a special rod. It is made of a special iron-nickel alloy called Invar.

The physical characteristics of this progressive material give it the ability to almost immediately capture the minimum temperature fluctuations.

If the room becomes excessively hot or too cold, the size of the rod changes. The connecting valve responds to this and timely shuts off or activates the flow of gas into the burner.

Additionally, non-volatile type automation has sensitive traction and flame sensors. If the pressure suddenly drops in the pipe or the draft level in the chimney drops for some reason, the supply of the resource immediately stops and gas leaks can be avoided.

Correct operation of the flame sensor provides a special plate. With normal and proper functioning of the system, it is in a slightly bent state.

In this way, the part holds the shut-off valve in "Open". When the flame becomes smaller, the plate is aligned and the valve closes under its pressure.

Design and function

Automation controlling the work gas boiler, consists of many elements, conditionally divided into two subgroups. The first includes mechanisms to ensure the full and safe functioning of the boiler itself. The second includes devices that make it possible to operate the heating system in the most convenient and user-friendly mode.

Security system components

Several modules are responsible for the operational safety of the unit:

- Flame controller - consists of two main parts - the electromagnetic valve and the thermocouple. Timely and reliably shuts off gas and prevents leakage.

- Thermostat - maintains the set temperature of the coolant and protects the system from overheating. When the coolant cools to minimum temperatures, the module starts the boiler to work, and after fixing the peak-high indicators, it turns it off, completely relieving the owners of the need to constantly pay attention to the system.

- Traction control sensor, is responsible for stopping the gas supply to the burner in case of a change in the base position of the bimetallic plate, thus preventing gas leakage.

- Safety valve - monitors the amount of coolant in the circuit.

In addition to all of the above useful qualities, automation has a number of additional functions that increase the comfort of using equipment.

The device performs auto-ignition of the gas burner, selects the most effective operating mode, contributes to the rational consumption of energy and conducts independent diagnostics, saving the owners from all these activities.

The principle of operation of security automation

Current regulatory documentation says that the safety system of gas boilers must be equipped with a device that stops the entire system and shuts off the gas supply in case of unexpected breakdown or any other force majeure circumstances.

To accomplish this task, automation should control such parameters as:

- gas pressure in the system;

- the presence of an optimal size flame in the burner;

- high-grade, high-quality traction;

- working fluid temperature level.

When in a non-volatile mechanical system the gas pressure drops to a critical level, the supply of the resource immediately stops. This happens automatically due to the presence of a valve mechanism tuned to a specific value.

Volatile electronic devices are designed somewhat differently. In them, the function described above is carried out by the minimum / maximum pressure switch.

As the number of atmospheres increases, the membrane with the rod bends, opening the power supply contacts of the boiler itself. Gas stops flowing and is not supplied until the pressure level is restored.

If the flame disappears in the burner, the thermocouple cools down and ceases to generate current. After that, the electromagnetic damper in the valve no longer functions, and gas stops flowing to the burner. When the thrust falls, the bimetallic plate heats up intensively, changes shape and acts on the valve, causing it to stop supplying fuel.

The temperature of the coolant is controlled by a thermostat. It provides maintenance of the user-selected warm-up mode, while preventing the system from overheating and failing.

The nuances of the functioning of the system

Volatile electronic automation in operation relies on information received from sensors. The microprocessor and internal controller analyze this data, process and give the system commands that are optimally suited for a particular situation.

Mechanics have a slightly different principle. When the boiler is turned off, the internal gas valve is completely shut off. At the time of starting the equipment, the washer on the valve is squeezed out and the passage for the fuel resource to the igniter is forced to open. Ignition stimulates the heating of the thermocouple and voltage generation occurs on it.

This resource uses an electromagnet to support the valve in the open position. By turning the washer manually, the user can adjust the level and power of his heating equipment without any effort.

Overview of popular models and manufacturers

In the market of progressive gas equipment and related components, automation is represented by both domestic and foreign manufacturers. By the principle of operation, all devices are absolutely identical, however, in terms of design, there are significant differences between them.

The cost of the modules varies in the widest range. Simple mechanical products with a minimum of functions belong to the budget class and are sold at the lowest price. Advanced electronic panels are valued much higher, but provide the user with more advanced features for individual settings and control of work.

Programmable electronic devices are considered luxury. They enable the owner to ask the equipment a work plan for a long period of time, taking into account seasonal weather conditions and the current air temperature in the street.

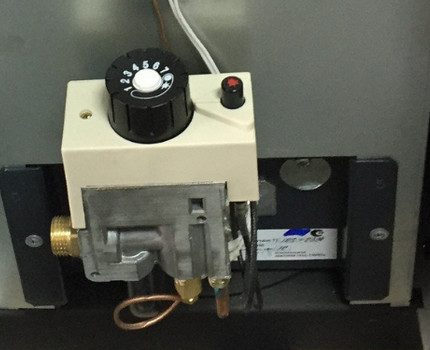

No. 1 - EUROSIT 630 automation

The automatic non-volatile EUROSIT 630 block of production of the Italian company Sit Group (Eurosit) In sales, it occupies a leading position in the market.

It is considered universal and works effectively with parapet and floor boilers power from 7 to 24 kW. Switching on / off, ignition of the ignition burner and setting the desired temperature are carried out using one knob with a button.

The product has a high level of reliability, withstands significant operational loads and has extensive functionality. Structural elements are “hidden” in the housing to which the sensor cables and other connecting tubes are connected.

Inside the unit are a shut-off valve, a spring valve and a pressure regulator. Gas is supplied from below or from the side according to the wishes of the user. At cost, the unit is included in the category of budget.

No. 2 - Honeywell 5474 module

Honeywell 5474 manufactured by a German concern Honeywell, more than a hundred years specializing in the development and sale of various types of automation. Works correctly with household gas boilers power up to 32 kW.

The Honeywell 5474 automation system is equipped with a basic set of monitoring functions that guarantee efficient boiler operation with absolute safety for users.

The product in auto mode maintains the specified coolant temperature (from 40 to 90 degrees), turns off the boiler in the event of a fuel cut, lack of draft at the desired level in the chimney, back draft or burner attenuation.

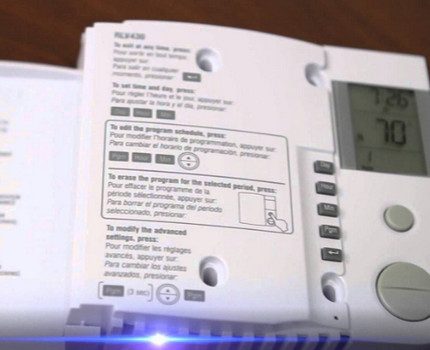

No. 3 - Honeywell Premium Automation

In addition to inexpensive budget models, the company Honeywell It also produces other types of automatic equipment, for example, luxury premium series chronothermostats ST or programmed Honeywell YRLV430A1005 / U thermostats.

These electronic panels allow you to set the heating equipment with the most detailed and precise settings, up to changing the temperature several times a day depending on the time of day, weather conditions and personal wishes.

No. 4 - Orion device

Automatic device Orion It is made in Russia. The complete set of the device includes piezoelectric ignition and traction sensor.

The device turns off the gas in the event of an arbitrary attenuation of the burner or the absence of the required draft. When the room temperature drops, the thermostat activates the fuel supply and the boiler resumes operation.

The transition to the flame reduction mode when a certain temperature (set by the user) is reached is automatic and saves fuel resource.

Conclusions and useful video on the topic

A detailed description of the principle of operation of automation designed for a gas boiler. Interesting features and nuances of monitoring equipment:

How does the automation of a gas heating boiler work? A visual demonstration of the process of igniting a gas unit:

A detailed description of one of the most popular automation models designed to control and adjust a gas boiler:

Automated gas heating system is a practical and cost-effective option for home heating equipment.

The mechanical controller is notable for its low price, reliability and elementary control method. The electronic panel is more expensive, but has advanced functionality that allows you to create the most comfortable conditions in the room.

It is better to purchase mini-units in company stores where certified products are sold that meet all the requirements for elements of heating systems that run on gas.

Do you know the intricacies of the automation of gas equipment that are not noted in the article? Having questions while reviewing the material? Please write comments, share your own opinion and photos on the topic of the article.

Sensors for gas boilers: types, principle of operation, characteristics

Sensors for gas boilers: types, principle of operation, characteristics  Pyrolysis heating boilers: principle of operation and types of boilers for long burning

Pyrolysis heating boilers: principle of operation and types of boilers for long burning  Gas boiler with an electric generator: device, principle of operation, an overview of the best brands

Gas boiler with an electric generator: device, principle of operation, an overview of the best brands  Hydrogen heating boiler: device + principle of operation + selection criteria

Hydrogen heating boiler: device + principle of operation + selection criteria  Adjustment of gas boiler automation: device, principle of operation, tuning tips

Adjustment of gas boiler automation: device, principle of operation, tuning tips  The principle of operation of a dual-circuit gas heating boiler and features of its connection

The principle of operation of a dual-circuit gas heating boiler and features of its connection  How much does it cost to connect gas to a private house: the price of organizing gas supply

How much does it cost to connect gas to a private house: the price of organizing gas supply  The best washing machines with dryer: model rating and customer tips

The best washing machines with dryer: model rating and customer tips  What is the color temperature of light and the nuances of choosing the temperature of the lamps to suit your needs

What is the color temperature of light and the nuances of choosing the temperature of the lamps to suit your needs  Replacement of a geyser in an apartment: replacement paperwork + basic norms and requirements

Replacement of a geyser in an apartment: replacement paperwork + basic norms and requirements

I have a double-circuit wall mantlet, and automatic safety for flame attenuation, lack of gas, pressure loss, and other force majeure is built inside. The display shows two letters, by which you can understand why the boiler turned off.

And there is also an automatic thermostat, programmable, so it controls the boiler according to the room temperature, and according to the settings of working days and days off. This is in order to feel comfortable and at the same time save (for example, when nobody is at home all day, he is turned off, and turns on and warms up the apartment an hour before arrival).

Automation is, of course, cool, but for some time now I prefer mechanics. It may be a step backward in terms of progress, but it’s more convenient for me. The fact is that somehow there was a thunderstorm, lightning got close somewhere, and all my automation burned out. Rather, an electronic board, but it costs a lot, half the cost of the device itself. Maybe, of course, someone was luckier, but it was very convenient to use.