Double-circuit gas boilers: types, principle of operation, selection criteria + overview of the best brands

For heating private houses and preparing hot water, double-circuit gas boilers are perfectly suited. They work on the basis of transferring energy to the coolant arising from the combustion of the most affordable and demanded type of fuel. However, due to the wide range of equipment, it can be difficult to choose. Do you agree?

We will talk about how to decide on the most suitable model of a gas boiler. The article we have proposed gives all the guidelines for choosing an aggregate with the highest possible efficiency that can withstand intense operating load. Market leading models and trustworthy manufacturers are listed.

The content of the article:

- Unit design features

- What to consider when choosing?

- Location classification

- Differences in power models

- Types of working gas burners

- Varieties of ignition function

- Equipment traction options

- Distinctive features of heat exchangers

- Advantages and disadvantages of gas systems

- Overview of popular manufacturers and models

- Conclusions and useful video on the topic

Unit design features

The household gas appliance consists of a housing, two communication circuits, an integrated burner, a heat exchanger, an expansion tank, a flue gas removal unit, a gas valve and a control unit.

The main circuit is connected to a common heating system in a closed circuit. With the active operation of the unit in heating mode, the coolant circulates through the pipes of the primary circuit, but does not enter the hot water supply (DHW) communications system, since a special valve blocks the way there.

When the user turns a hot faucet in the kitchen or in the bathroom, the valve is activated, closes the entrance to the heating pipes and directs the heat carrier to the DHW circuit to warm the water in the heat exchanger.

From there, the liquid enters the tap and is used for its intended purpose. When the need for hot water disappears and the valve closes, a reverse switch occurs and the valve again redirects the coolant to the heating circuit.

What to consider when choosing?

All double-circuit gas boilers perform the same complex of basic tasks, but differ from each other in such parameters as:

- location;

- power level;

- type of burner;

- ignition principle;

- type of traction;

- heat exchanger material.

All of the above criteria are equivalent in importance and require mandatory consideration when choosing and buying heating equipment.

Location classification

According to the principle of installation, boilers serving two communication circuits are floor, wall and parapet. Each of the options has its own special characteristics.

Focusing on them, the client can choose the most suitable installation method for themselves, in which the equipment will be located conveniently, will not “eat” the useful area and will not cause problems during operation.

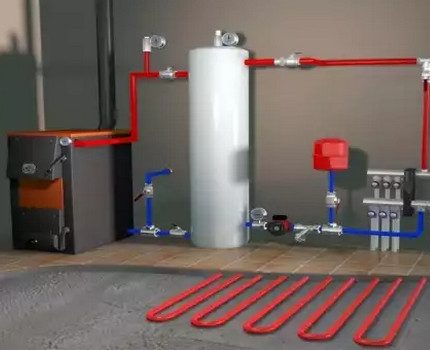

Floor standing boilers

Floor units are high-power devices that can heat and provide with hot water not only a standard apartment or apartment building, but also a large-sized industrial building, public building or structure.

Due to the large size and solid weight (up to 100 kg on some models) floor gas boilers they don’t put it in the kitchen, but place it in a separate room directly on the foundation or on the floor.

Features of wall equipment

The hinged device is a progressive type of household heating equipment. Due to compact size gas column installation can be made in the kitchen or in other small rooms. It is combined with an interior solution of any type and fits seamlessly into the overall design.

Despite the small size, wall boiler It has the same functionality as a floor device, but has less power. It consists of a burner, expansion tank, pump for forced movement of the coolant, pressure gauge and automatic sensorsgiving the opportunity to use the fuel resource with maximum efficiency.

All communication elements “hide” under a beautiful, modern case and do not spoil the appearance of the product.

The automatic control unit allows you to set the instrument to any operation parameters that are most suitable for the user. It is possible to set your own temperature conditions for different times of the day, thus ensuring economical fuel consumption.

The nuances of parapet devices

The parapet boiler is a cross between a floor and a wall unit. It has a closed combustion chamber and does not create harmful emissions. Does not require the installation of an additional chimney. The removal of combustion products is carried out through coaxial chimneylaid in the outer wall.

The device is mainly used to provide hot water and full heating to small houses and apartments in high-rise buildings, where it is not possible to mount a classic vertical chimney. The base power ranges from 7 to 15 kW, but, despite such low indicators, the unit successfully copes with the tasks.

The main advantage of the parapet equipment is the ability to connect heating and water supply lines to the central gas system and pipelines from any user-friendly side.

Differences in power models

Double-circuit type boilers are divided in power into single-stage and two-stage. Single-stage devices always operate at a constant power level and use the same amount of fuel resource year-round.

This is not effective and entails gas overruns, because high-quality heating is required for a house or apartment for no more than 5 months a year. For the rest of the time, “driving” equipment at full capacity is neither reasonable nor economically viable.

The functionality of two-stage devices is wider.

Using it you can:

- regulate the regime of gas intake and rationally consume fuel;

- reduce the number of on / off, thus reducing equipment wear and extend its life;

- Minimize harmful air emissions.

In addition, the device is equipped with a smooth switching module, which reduces energy consumption and allows you to simultaneously operate the boiler and boiler of any capacity, installed separately.

Types of working gas burners

A gas burner is either atmospheric or supercharged. The first type has an elementary design and does not produce any noise during operation. The module is cheap and, as a rule, is included in the basic package of the boiler.

The principle of operation of an atmospheric type burner resembles the operation of industrial hearth models. The fuel resource is fed through the ejector and draws air from the surrounding atmosphere due to traction. Through a special hole, the mixture enters the combustion chamber and immediately ignites.

As a result, fiery flames of flame with a very low actual temperature appear above the outlet openings, the task of which is to heat the coolant to the desired level.

Supercharged (mounted) burners demonstrate a high level of efficiency; they constantly maintain the set temperature both in the coolant itself and in the hot water supply system, but they are much more expensive than atmospheric analogues.

However, these costs are justified, since the modules have advanced functionality and make it possible to spend the fuel resource as wisely as possible, without reducing the level of comfort of the home.

When fully operating in pressurized burners, the air supply is forced, and its volume is very clearly controlled by internal automation.The module is placed in devices equipped with a closed combustion chamber, working with supercharging.

Fuel and air are not mixed inside the system, but at the outlet. The process of the device is almost completely automated and does not require human control.

Atmospheric burners are installed in heating dual-circuit appliances with power up to 80 kW. Supercharged (mounted) modules are introduced into large-sized units, with a capacity of up to several thousand.

Varieties of ignition function

The launch of a household double-circuit boiler is carried out manually (using matches or a lighter) or by means of built-in elements (electric ignition or piezo ignition). The first method is the most simple and accessible. The second makes it possible to save blue fuel, without leaving the wick in the igniter to burn continuously.

The disadvantage of this option is only one - the dependence on the availability of electricity in the network. If, for some reason, the energy ceases to flow, the equipment immediately turns off and automatically activates again when the power supply resumes.

Piezo ignition is absolutely safe and allows you to turn on the boiler by pressing just one button. The element does not depend on current supply and it is possible to use equipment even in the absence of electricity.

Equipment traction options

During operation of the unit, fuel burns and flue gases are generated. To remove them from the living room, natural or forced draft is required. It will ensure timely removal from the apartment or house of all combustion products and released harmful substances.

Natural draft modules

Natural draft boilers have a simple design and take the necessary air for full combustion from the room in which they are located. During intensive use, a certain amount of steam and various chemicals are released. Emissions are removed through a vertical chimney.

In general, devices with natural draft are convenient and good, however, when the pressure in the gas pipeline drops, the quality of their work decreases significantly. At the same time, the risk of rapid burnout of the burner increases, since the fire extinguishes or goes inside the burner at a reduced pressure level.

Uneven pressure in the trunk networks provokes a serious overspending of fuel, which entails an increase in the size of utility bills.

Forced traction devices

Boilers with forced draft are sometimes called supercharged or ventilated. They take air not from the room where they are located, but from the street. Closed combustion chambers are installed in the modules, and the exhaust is discharged through a horizontal coaxial exhaust using a powerful fan integrated in the system.

Products with forced draft are easy to install, do not make complaints about the location, do not “eat” oxygen in residential premises, work stably and clearly even with reduced gas pressure in the central main networks and do not need to install an additional vertical chimney.

The appliances are reproached by the noisy operation of the fan elements, a higher cost and dependence on power supply.

Distinctive features of heat exchangers

The heat exchange unit of the heating device is cast iron, steel or copper. The cast-iron version retains heat for a long time, almost does not undergo corrosion due to the high wall thickness and is resistant to aggressive coolants.It has a large weight and therefore is mainly integrated into floor boilers.

It requires great accuracy during installation, since any impact violates the structural integrity of the material and leads to the formation of microcracks.

The steel structure weighs little, is not afraid of mechanical impact, quietly tolerates temperature differences of the coolant, is easily transported and mounted. It has some tendency to corrosion. The boiler control system helps to avoid it, which prevents the coolant temperature from falling below a critical point.

Copper elements are much more expensive than cast iron and steel counterparts, but compensate for the solid cost with a large number of advantages. Inside the copper heat exchanger, sediment and scale are formed to a minimum and do not interfere with the normal circulation of the working fluid. The walls of the device warm evenly and do not cause local overheating of the coolant.

Advantages and disadvantages of gas systems

In places where central gas communications are laid, double-circuit boilers are very popular. They are bought for heating and uninterrupted supply of hot water for apartments, houses and country cottages.

The main advantages of devices

The gas system demonstrates a high level of efficiency, gives several times more energy than it consumes, serves for a long time and runs smoothly. In constant monitoring by the person does not need.

The fuel resource is supplied to the installation continuously, and the built-in controller independently monitors the presence of fire on the burner. If the flame is extinguished, the sensor sends a signal to the ignition unit and the automatic supply of a spark instantly restores fire. The boiler is controlled elementarily and is not difficult.

The disadvantages of dual-circuit equipment

The main disadvantages are associated not so much with the device itself as with the process of legalizing and installing it. You can’t just buy a boiler, bring it home and install it yourself according to wiring diagram. First, you will have to observe a lot of technical nuances, draw up documentation and coordinate all subsequent actions with the local gas supply company.

There you will need to provide:

- project equipment installation, drawn up in accordance with the norms adopted by law;

- installation contract with a specialized organization;

- copy of the license of the profile organization, confirming the right to work.

In addition, it will be necessary to organize the removal of exhaust gas from the living room, lay an additional chimney for this, or use the existing one, and install additional equipment to monitor the potential gas leak.

The main installation activities can only be started when the project documentation for organization of gas heating it will go through all stages of coordination and the client will receive a certified seal on the hands of the system.

Overview of popular manufacturers and models

The market of modern gas equipment offers its customers a large number of high-quality appliances designed for heating residential premises and supplying hot water.

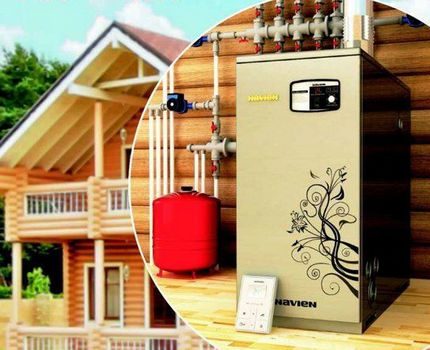

Among the mounted units, the most popular are:

- Navien DELUXE 24K (South Korea) - efficiency, good functionality and reasonable cost;

- Baxi MAIN 5 24 F (Italy) - budget price, high level of efficiency, long service life;

- Vaillant turboTEC pro VUW 242 / 5-3 (Germany) - reliability, high-quality heat transfer.

In addition to the above listed qualities, the models are distinguished by their attractive appearance, compact dimensions, fit into a variety of interiors and are freely placed even in small rooms of complex layout.

Of the floor units, the most demanded are the high-power (30 kW) ATON Atmo 30E, the practical Lemax Premium-25B and the more expensive, but very functional Navien GA 17KN.

Baxi SLIM 2.300 Fi and Protherm Bear 40 KLZ are part of the premium technology line. They have advanced functionality and reliably serve for many years. By all parameters and physical characteristics, they comply with the most stringent European standards (confirmed by CSQ certification certificate and UNI EN ISO 9001).

Weak units simply can not provide an apartment or a large house with full heating.

Buy floor gas boilers and wall models only needed in company stores or official representatives of manufacturing companies. There, the client will be told in detail about the principles of operation of a particular unit and will help to make the optimal choice.

Conclusions and useful video on the topic

A simple and understandable description of the basic principles of operation of household double-circuit gas boilers. Overview of the “quick start” and “pump run-down” functions:

Expert opinion and a few interesting points that you should pay attention to when choosing a boiler:

How are wall-mounted boilers arranged and by what principle do they work:

The targeted choice of a dual-circuit domestic gas boiler for heating and hot water supply is an important, crucial moment. There is no need to rush here. It’s better to think things over in advance, decide on the brand and type of equipment, and calculate the running costs.

It is necessary to take into account the costs of acquisition and installation activities, and then make a purchase in a specialized store. The manager will issue guarantee papers, and at the same time he will give detailed advice to the client regarding the principle of operation of the device and the rules for safe operation.

Please write comments in the block below, ask questions, publish photos on the topic of the article. Tell us about how to choose a model of a gas boiler for installation in your own house or in the country. Share useful information and selection guidelines that are useful to site visitors.

Floor gas heating boilers: types, how to choose, an overview of the best brands

Floor gas heating boilers: types, how to choose, an overview of the best brands  Wall-mounted gas heating boilers: types, how to choose, an overview of the best models on the market

Wall-mounted gas heating boilers: types, how to choose, an overview of the best models on the market  Solid fuel boilers: main types and criteria for choosing the best unit

Solid fuel boilers: main types and criteria for choosing the best unit  Atmospheric gas boilers: TOP-15 rating of the best models and selection tips

Atmospheric gas boilers: TOP-15 rating of the best models and selection tips  Combined boilers for heating a house: types, description of the principle of operation + selection tips

Combined boilers for heating a house: types, description of the principle of operation + selection tips  Pellet heating boilers: types, advantages and rules for choosing the best boiler

Pellet heating boilers: types, advantages and rules for choosing the best boiler  How much does it cost to connect gas to a private house: the price of organizing gas supply

How much does it cost to connect gas to a private house: the price of organizing gas supply  The best washing machines with dryer: model rating and customer tips

The best washing machines with dryer: model rating and customer tips  What is the color temperature of light and the nuances of choosing the temperature of the lamps to suit your needs

What is the color temperature of light and the nuances of choosing the temperature of the lamps to suit your needs  Replacement of a geyser in an apartment: replacement paperwork + basic norms and requirements

Replacement of a geyser in an apartment: replacement paperwork + basic norms and requirements

I think that the best option for your country house would be wall equipment. Now many people put gas boilers in their homes, of course, the whole system is not cheap, but it will last for many decades. It is also necessary to consult an experienced specialist, well, so that everything is correctly carried out. If everything is well done, then the system has more pluses than minuses.

Denis, this does not always work.Whoever has a house up to 240 m2, that can be put on a wall-mounted gas boiler, should be enough.

But, if the hut is 300 meters, several bathrooms, plus a garage, non-residential premises, then the wall will not pull, I have not seen such powerful ones, in my opinion, the maximum is 36 kW.

A floor boiler will be better, it has many advantages, and some power reserve will not hurt. For him, a full boiler room needs to be done, and a generator is desirable. But for a big house, it’s not a problem to carve out such a room.