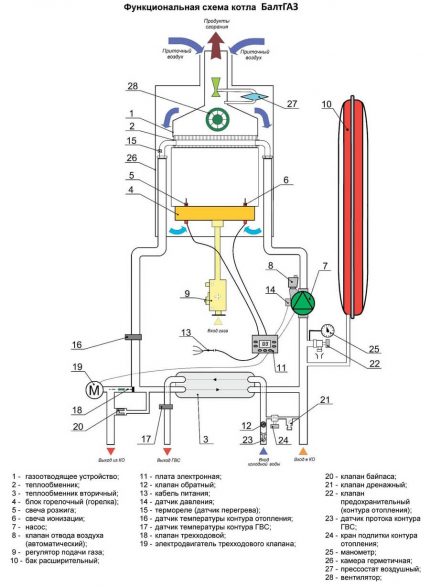

Errors of gas boilers Baltgaz: trouble codes and troubleshooting methods

BaltGaz is an exemplary brand producing comfort and premium gas appliances with a high reliability class. All of them are equipped with high-tech functions and protection, have a large number of accessories and spare parts. But just like any other devices of this type, Baltgaz boilers can exhibit malfunctions over time. Fortunately, for the convenience of diagnosing problems that arise, they have the function of automatically recognizing system weaknesses and errors of Baltgas gas boilers are displayed in the form of alphanumeric codes.

The programmed diagnostics with the help of sensors helps to quickly identify weak areas of devices and eliminate malfunctions immediately, as they arise.

Want to learn how to deal with these codes, which many seem completely incomprehensible to? We will help you and tell you what these letters are with numbers and how to correctly decrypt the codes of gas boilers BaltGaz.

The content of the article:

BaltGaz boiler errors

The interpretation of error codes for gas boilers “Baltgaz Turbo” is in any instruction manual. However, if your manual is lost, damaged or there is some other reason why you cannot look into it, use our recommendations.

Immediately, we note that only those errors that you can handle without disassembling the boiler and without changing the parts for it are subject to independent elimination.

Repair of gas-powered equipment is only authorized by an employee of the gas service or company with which maintenance contract gas equipment.

Problem number 1 - difficulties with ignition

If you see the display error E01 - this means that you have problems with the ignition of the boiler. The ionization sensor signals this, monitoring the ignition control.You already guessed that there is a malfunction when an attempt to ignite the device did not bring results. But with the help of an error, you can identify possible causes.

Fuel does not enter the burner at all. You should see if the shutoff valve is closed on the pipe, and if so, turn it to the “open” position. When starting up for the first time, remember to let the air out of the system first.

Pay attention to the recommended pressure of 18-20 mbar. If everything is OK on the line, test the nozzle pressure setting in accordance with the instructions for use of the device.

Another common reason is a gas valve breakdown and in case of such an accident, the element should be replaced.

E01 is often observed in violation of the operation of the ionization electrode, carrying out the ignition. It may be dirty (wipe and degrease) or malfunctioning.

When there are problems in the gas valve coils, this indicates a possible short circuit or open circuit requiring valve replacement. But also it can start to stick.

If the ignition power is unsatisfactory, use the settings to adjust it.

Clogging of the burner block requires cleaning, instructions for the implementation of which are usually found in the manual.

If the ignition transformer is faulty, you should consider replacing the electronic board. The same thing if it breaks. But if the board sees combustion, but actually it does not exist, you need to inspect the ionization electrode, or rather, its wiring, for damage or a possible break.

An element such as a thermal relay is also present in the boiler. This is an overheating sensor. In case of violation of its operation, ignition will not be possible, therefore, it is necessary to carefully check the electrical circuit and all contacts.

Error E01 is followed by K1. That is, after correcting the malfunction, it must be pressed. It has 2 functions - the choice of the information mode and the manual reset function (RESET) of the lock.

E02 signals that a false indication of combustion has been made due to blocking. The boiler does not work.

First of all, check the electrical circuit of the electrode and the contacts from its connection. If the element itself is malfunctioning, it is recommended to replace it.

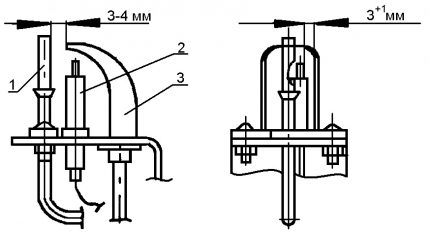

As with E01, an incorrect gap between the burner and the electrode can also cause an error on the display. To eliminate the actions are similar - it is necessary to set the gap (3 + 1 mm).

If the grounding is broken or a potential arises between the ground and zero, E02 will “tell you” about it. The correction is logical, correct the ground and remove the potential.

After performing repairs, also press K1.

Error with code F02 directly reported with the error E02 and also denotes a stray flame.

It downloads:

- violation in the chain message of the electrodes;

- faulty electrodes;

- incorrect setting of the clearance between the burner and the electrode;

- poor grounding and potential between ground and zero.

It is a prerequisite for the appearance of error E02.

At E08By the way, K1 is not required to be pressed. But the error is no less important in its significance. Consider what it signals and how to fix it. When this code occurs, the flame circuit fails, that is, its level goes beyond normal limits.

We look at the electronic board. The reason may be hiding in its malfunction.

As always, first of all, we check all the contacts and the electric circuit of the electrode, as well as the element itself and, if necessary, change or clean it.

Then, you should check the gap between the burner and the electrode and, if necessary, set it to the optimal values according to the passport (3 + 1 mm).

Error withcode E09 indicates that the gas regulator feedback does not fit the commands coming from the device’s electronic board.

There may be 3 reasons:

- Violations in the contacts and the electrical circuit of the regulator.

- Problems with the electronic board.

- Damage to the regulator itself.

If you yourself cannot diagnose and correct the breakdown, call a service technician.

Error E82 indicates frequent flame attenuation. This usually happens in a row with short breaks. The problem may be in the failure of the electronic control board, as well as in many other cases.

What can be done:

- completely replace the electronic board with a new one;

- try contacting a repair service;

- restart your heating unit, sometimes such problems are one-time and resolve themselves.

There is another possible reason, and it lies in the settings when the minimum boiler power is set incorrectly.

Here it is even easier to correct the situation, just look at the manual and set up the boiler according to the manufacturer's recommendations. If you have not saved your passport, you can download almost any instruction via the Internet.

Problem number 2 - failures in the heat exchanger

Error with code E03 will not let the boiler work. Such malfunctions of Baltgas gas boilers mean overheating of the coolant. This arises for a number of possible reasons. In general, it looks something like this.

A safety thermostat typically has a temperature of 105 degrees. The nozzle goes out as a result of increasing temperature, but the heat exchanger continues to heat up. If after 10 seconds the temperature rises in 105 degrees, the boiler will stop for a short time.

The superheat thermostat located on the outlet pipe of the primary heat exchanger will show its functions and send a signal to the control board. Therefore, in the absence of effectiveness and lowering the temperature to 100 degrees, an error will appear.

For example, you will see such a code when blockages appear in the heating system or filter, which must be cleaned to eliminate the error.

Do not forget to check the thermal relay, and if necessary, replace it or ensure its high-quality contact with the control board.

Still not found a reason? Then pay attention tobypass valvewhich may be faulty or improperly installed. It must be replaced, as well as the need to change the pump or the vent valve, if the cause is their failure.

Failure and malfunction of the electronic control board are suitable for many errors. Including this one. Accordingly, the board is usually changed, it can be repaired in rare cases.

As in error E01, there may be an open circuit of the overheating sensor. Pay attention to this probability and carefully examine everything. And, of course, do not forget about the K1 button. In this case, it is also relevant.

Error E70 also leads to a blockage of operation, and requires a subsequent reset to K1.

Error means recognition of freezing of the heat exchanger, which occurs mainly with a prolonged absence of power supply. The error is easily prevented by the presence of uninterruptible power supplybut if you don’t have it, you will have to turn off the power supply of the device, shut off the gas supply on the pipe and then defrost the element.

When propylene glycol is used as a coolant, it is necessary to set the value to zero on this function, according to the recommendations in the device certificate.

Error with code F37 helps to determine that the coolant pressure in the system is too low. And first of all, you need to measure it and fix it to the recommended value.

The pressure switch monitors the minimum pressure of the coolant and eliminates air in the heating system. If it breaks or the connection fails, error F37 may occur on the display.

Other possible reasons:

- air traffic jams;

- a problem with the pressure sensor;

- The electrical circuit leading from the pressure sensor to the board is faulty.

As always, we check all the given parameters and troubleshoot.

Problem number 3 - incorrect traction

Errors withcode E04 and E05result from blocking F23 and mean that you have bad traction. For the boiler to work correctly, as you know, it needs to provide good traction that contributes to the removal of flue gases.

If they exit poorly, carbon monoxide will enter the room, which is very dangerous. In modern boilers, special traction sensors and if it is not enough, they will send a signal to the board and the unit will automatically shut down.

First of all, the reason for this error in the chimney. If its diameter is unacceptable, or the device is not mounted correctly, clogged or ice has formed in it, of course, the traction will not be good. It also affects the length of the chimney.

Of course, the solution here is obvious - replacing the chimney if necessary or his cleaning, and deflector installation. But this is not all the possible reasons.

Also, this error indicates problems with the pressure switch, most often, the closure of its contacts, which must be checked and, if necessary, replaced the pressure switch or connected correctly. If tightness is broken on the pressure switch tubes, change them. Do not forget to inspect the electrical circuit.

In case of malfunctions of elements such as a fan and an electronic board, most likely, a replacement will also be required.

Errors E04 and E05 differ in that in the first case, the closure of the pressostat is usually observed, and in the second it is jammed. And with E05, do not forget about the lock, which must be removed by pressing K1 RESET.

E06 value very similar due to blocking with E04 and E05. That is, there is also no traction.

The troubleshooting steps are the same:

- check the electrical circuit and contacts (replace if necessary);

- inspect the fan;

- diagnose the pressure switch;

- ring the control board.

E07 - all also no traction. But this time, the symptom is dominated by the problem with the fan.

What malfunctions can be with this element:

- the control board jams (if necessary, it will have to be replaced);

- the fan is broken - damage, lack of lubricant for the shaft, clogging in the impeller;

- broken electrical circuit.

Well, do not forget about unlocking K1.

Error with code F23 accompanied by a complete violation of traction, its absence. First of all, check the pressure switch and in case of its malfunction, be sure to replace it. Then they look through all the electrical circuits and contacts, and then the main elements - a fan, an electronic board.

Problem number 4 - a failure in the electronics

E09 and F25 - It is always a replacement for an electronic board due to an error in its internal memory.

By the way, please note that blocking does not occur, that is, you do not need to press K1 after troubleshooting. But the boiler still does not function in the period after the detection of this malfunction. F25 indicates a failure of the internal ROM and EEPROM.

E21 again, it is connected with the electronic board and indicates an error checking its components. Unfortunately, in the event of a malfunction, it will be necessary to change it, it remains only to hope that the problem is in the electrical circuit or contacts.

The good thing is that Baltgaz produces spare parts for its gas boilers and it is easy to purchase them in ordinary or online stores.

F13 also called remote reset lock. It is necessary to turn off the power to the device and restart it after turning it on.

F22 indicates a voltage surge of 170 - 250 V. In order to restore the boiler, it is necessary to adjust the voltage.

In general, such work is difficult to carry out without any experience with the use of gas-powered equipment. It is best to call a wizard from the service department or a specialist from the supplier's distribution unit.

Problem number 5 - violations in the temperature sensor

F31 and F32 - malfunction of the temperature sensor of the heating circuit.

F31 occurs due to interruptions in the element connection circuit, when the sensor no longer contacts the electronic board or the temperature readings differ from the recommended parameters.

But there is another reason - a short circuit on the sensor if the temperature rises above the recommended one. To check, you need to measure the resistance of the element, and all the specified parameters are in the manual. Usually in this case a new sensor is installed, if it doesn’t work out, they pay attention to a failure in the control board.

Code F32 is also associated with a temperature sensor, only external, remote, if installed in the system. In spite of everything, the boiler works actively for heating. The reasons are a malfunction in the electrical circuit, a breakdown on the board or the sensor itself. It should be noted that the error will be removed automatically and you will not need to unlock it after fixing the problem.

Other boiler faults

In addition to code settings, non-fixed display problems may occur.

The boiler does not turn on at all.

Possible reasons:

- There is no power supply. Check if the line is dead and current is being supplied. No - contact your electricity supplier to determine the causes and timing of the outage.

- Also, the fuse in the board could blow and in this case they simply install a new one.

- If the reason lies in the fact that water has got on the board, try putting it on natural drying for 48 hours until the moisture has completely evaporated.

- The boiler does not start even if there is a malfunction on the control board. Try restarting or replacing this item.

If the actions did not bring any positive result, there is only one way out - contact a service center.

The burner makes strange popping sounds:

- Insufficient air flow occurs when the duct is clogged, improperly installed, or for other reasons.

- A spark slips past the burner.

- The burner is clogged.

No hot water or insufficient pressure. Check for clogged filter, heat exchanger, and flow restrictor.

The device does not heat the room, but at the same time it works in the DHW mode. The problem may be due to jumpers, malfunction of the thermostat and temperature sensor, or simply to incorrectly set temperature parameters.

The coolant inlet is too low. Check the set temperature and temperature sensor.

The heating system is too low. Inspect the system for possible leaks, inspect the pressure gauge for proper operation, clean / replace safety valve.

Error Code Archive

You can look at the boiler archive of errors and locks.

Unfortunately, the error archive is not provided in all gas boiler models.

To access the archive, proceed as follows:

- Turn on the gas boiler.

- Press the reset button (K1). Hold it for 10 seconds to activate some functions of the boiler.

- Using the buttons K5 and K6 you need to get into the H1 archive.

- When In appears in the display, press K1.

- To select the item that you need in the archive, navigate the menu using K5.

- After selecting the desired parameter, press K3 (or K4).

To exit the archive, you must either press K2 or wait 2 minutes for the automatic exit in inaction.

An error archive is needed for diagnosing the boiler’s “illness” by the specialists of the service department or in case you are not at home when the code appears, when no one else recorded it.

Video and useful conclusions on the topic

Brief overview of the BaltGaz-Neva gas boiler, inspection, possible malfunctions and maintenance:

Thus, repairing or diagnosing a Baltgaz gas boiler will not bring much trouble to the owners. Most of the most frequently occurring faults will be almost instantly captured by the appearance of an alphanumeric code on the display. At the same time, many of them are easily eliminated with the help of automatic functions, which can be started using the manual for the device.

Do you have a Baltgaz boiler installed in your home? Have you got error codes and how did you deal with them? Share your experience in the comments and ask questions of interest to the topic of the article.

Kiturami gas boiler errors: trouble codes and troubleshooting

Kiturami gas boiler errors: trouble codes and troubleshooting  Junkers gas boiler malfunctions: breakdown codes and troubleshooting

Junkers gas boiler malfunctions: breakdown codes and troubleshooting  Rinnai gas boiler errors: trouble codes and ways to fix them yourself

Rinnai gas boiler errors: trouble codes and ways to fix them yourself  Immergas gas boiler errors: error codes and solutions

Immergas gas boiler errors: error codes and solutions  Bosch gas boiler errors: decipher common errors and resolve them

Bosch gas boiler errors: decipher common errors and resolve them  Maintenance and repair of gas boilers "Buderus": methods for dealing with typical breakdowns

Maintenance and repair of gas boilers "Buderus": methods for dealing with typical breakdowns  How much does it cost to connect gas to a private house: the price of organizing gas supply

How much does it cost to connect gas to a private house: the price of organizing gas supply  The best washing machines with dryer: model rating and customer tips

The best washing machines with dryer: model rating and customer tips  What is the color temperature of light and the nuances of choosing the temperature of the lamps to suit your needs

What is the color temperature of light and the nuances of choosing the temperature of the lamps to suit your needs  Replacement of a geyser in an apartment: replacement paperwork + basic norms and requirements

Replacement of a geyser in an apartment: replacement paperwork + basic norms and requirements