How to make a chimney for a fireplace: the rules of the device of the smoke channel and a comparison of designs

The proper functioning of the fireplace depends not only on the installation of the furnace, but also on the competent design and installation of the chimney. Everything is important: from calculations of the pipe section to the nuances of thermal insulation. Only a quality chimney will maximally meet its purpose.

Do you want to build a chimney channel, but don’t know which pipe to choose and how to install it later? We will help you deal with this problem - in the article we examined in detail how to make a chimney for a fireplace, paying attention to the pros and cons of pipes from various materials.

And also brought important requirements for the arrangement of fireplaces and the preparation of the project. The article material was supplemented with detailed instructions for the installation of the chimney, providing it with step-by-step photos.

The content of the article:

Design features of the chimney

The purpose of the chimney chimney, as well as the main function of the chimneys of stoves or boilers, is the output to the atmosphere of the products of combustion of fuel. Gases along with soot come from the furnace into the pipe under the influence of traction.

The correct formation of the chimney consists in the selection and construction of such a structure, in which at least soot remains on the pipe walls, and the draft prevents the entry of gases into the room.

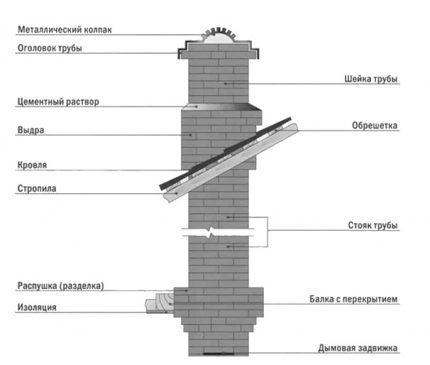

Chimneys of various materials have their own characteristics and may vary in design. For example, a traditional brick chimney consists of the following parts.

When choosing a material, it is necessary to take into account the temperature of the gases: in the furnace it is higher, the output is lower, however, even at the highest point it can reach +100 ° С. The creation of traction is built on the temperature difference - hot air is replaced by cold.

Also important are indicators such as the height and internal diameter of the chimney - they are calculated during the preparation of the project.

With all desire, it is impossible to build a chimney that does not need to be cleaned. Even in a ceramic chimney assembled in accordance with all the rules, soot accumulates over time, making it difficult for gases to escape. therefore chimney cleaning need to be carried out regularly. This is usually done during the period when the fireplace is idle.

In addition, it is necessary to monitor the integrity of the joints and the inner surface: cracks, bumps or protrusions that may appear over time interfere with the normal circulation of hot air.

Norms and rules for the installation of a fireplace

Consider excerpts from SNiP 2.01.01-82, which may come in handy when installing a chimney for a fireplace.

The chimney and ventilation duct have different purposes, so you cannot combine them or use one instead of the other. Only one heater with an open type of combustion can be connected to one chimney (the same applies to the stove).

If two fireplaces are located on the same floor, they can be connected to one smoke exhaust channel, but it must be equipped with a cut made in the form of a transverse wall at a height of 75 cm or more.

For concrete and brick chimneys, the minimum dimensions of the channel section are indicated. For example, if the power does not exceed 3.5 kW, the smallest cross-section is 14 cm x 14 cm (for a circular cross-section - a diameter of 16 cm), if the power is higher than 5.2 kW - from 14 cm x 27 cm (for a circular cross-section, a diameter from 22 cm).

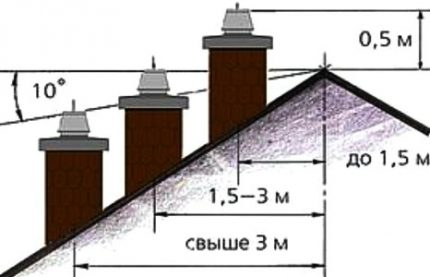

The draft characteristics depend on the height of the chimney. The minimum allowable size is 5 m from the grate to the extreme point of the outer pipe section. With insufficient height and the wrong choice of the channel section, you may encounter the problem of reverse thrust.

The thickness of the walls of brick structures is not less than 12 cm, smoke exhaust channels from concrete - from 6 cm. The base of the chimneys must be equipped with windows with doors for cleaning. To facilitate cleaning work during the construction of a brick pipe from the inside, there should be no concessions or excavations that provoke soot accumulation.

If it is necessary to remove the pipe (for example, bypassing the beam), inclined (up to 30 degrees) and horizontal (up to 1 m in length) sections of the same diameter as the main channel are possible.

The floor, walls and ceiling in the adjoining areas of the fireplace must be protected with fireproof materials - metal sheets, asbestos board, plaster.

When passing a brick or concrete chimney through the ceiling, the gap should leave at least 13 cm (the same applies to insulated pipes), for ceramic structures, the norm increases to 25 cm.

Professionals insist on installing the chimney not in the outer wall of the house, but in the inner carrier, explaining this by the harsh Russian winters. Mounting it in the outer wall (in extreme cases), you should carefully protect the structure from freezing by thickening the masonry or a thermal insulation device made of non-combustible materials.

Types of chimneys for a fireplace

An analysis of various types of chimney channels allows you to find out which chimney is better for a home fireplace. Structures may differ both in design and in material of manufacture, and the second factor is decisive.

Therefore, when choosing a scheme, you need to start from the material, but the choice of material for construction depends on the regulatory requirements and the wishes of the owners of the house.

Option # 1 - Ceramic

If funds allow, this is the first option that you need to pay attention to. Manufacturers, using popular schemes for the construction of fireplaces, thought out the manufacture of all kinds of parts, so you can purchase a ready-made kit for construction.

Of course, the number of parts can be different - depending on the shape and size of the structure.

What else positively differ ceramic chimneys:

- perfectly smooth surface of the inner walls;

- fast heating and slow cooling;

- resistance to temperature up to + 900-1000 ° С;

- compactness in comparison with other designs;

- service life up to 50 years.

The disadvantages include significant weight, because of which it is necessary to arrange an installation site or a special foundation.

Also, many are confused by the high cost of the units and the services for their installation. Indeed, when mounting parts, care must be taken, use special glue and, at the last stage, use a finish made of heat-resistant materials.

When choosing, it is better to focus on the established brands: Hart, Tona, Ecoosmose, Schiedel, Effe2.

Option # 2 - brick

Brick is a traditional, one might even say ancient material. Over the centuries, many technologies have been invented for the construction of various types of stoves and fireplaces, and today it is possible to use the best of them.

The masonry mortar is also important, the main purpose of which is to provide a tight, tight connection between the bricks. Normal cement mortar is not suitable. It is necessary to mix a solution of sand, cement and lime (5: 2: 1), which resists high temperatures, does not crack and does not crumble ahead of time.

When masonry is carried out, make sure that the mortar from the joints does not protrude into the inside. The smoothness of the pipe is one of the main conditions for a long and trouble-free operation. More information about brick chimneys below.

Option # 3 - Steel

If the temperature of the gases in the smoke exhaust channel does not exceed + 400 ° C, steel chimneys can be used. Modern pipes made of heat-resistant anticorrosive steel are lighter than ceramic counterparts and are suitable for almost all modifications of fireplaces and stoves. It is not necessary to erect additional sites or foundations for metal pipes.

Installing and connecting steel parts is easier than building brickwork or mounting fragile ceramics. They can be inserted inside old brick chimneys, making a sleeve.

Conventionally, steel chimneys are divided into 2 categories:

- simple "hot" typewithout thermal insulation;

- sandwich pipesconsisting of three layers - thermal insulation is inserted between two layers of metal.

The heat-insulating material has special requirements.It should not emit products dangerous to human life during heating, have minimal thermal conductivity and do not burn. In construction markets, you can buy ready-made sets of sandwich parts and assemble a sandwich chimney do it yourself. And you can make an order for a private project.

The cost of the chimney can not be called budgetary, but it justifies itself.

Option # 4 - Glass

A beautiful glass chimney is attractive not only externally. It is made of durable tempered glass, which is inert to chemical influences that are characteristic of combustion products.

In addition, perfectly smooth walls prevent the deposition of soot in large quantities, as a result of the chimney has to be cleaned much less often.

The disadvantages of glass are additional requirements for insulation and insulation, special assembly technology (difficulty in creating tight joints), the possibility of condensation.

If we compare expensive glass and ceramic chimneys, then the latter will benefit both in technical characteristics and operational performance in general.

Having looked at the overview of pipes made of various materials, you still could not decide which is best for you? Then we advise you to look at our other article in which we cited important selection criteria chimneys to be guided in specific conditions.

Ceramic Smoke Canal Construction

The most reliable and safe version of the chimney device in a wooden house is a construction of ceramic blocks. The outside of it practically does not heat up, which means that there will be no problems with passage through the floors.

Consider the assembly sequence of the smoke channel from the components of the German brand Schiedel Rondo Plus:

We will make a reservation right away that a radical, i.e. stand-alone pipe for which a separate foundation is arranged.

All technological holes are cut along the construction site. Cutting is done with a conventional grinder with a diamond disk.

To make geometrically accurate holes, a ceramic chimney is equipped with a template. Further:

The assembly of the ceramic chimney is carried out in the standard order: the modules are expanded one by one. However, it is worth paying attention to the specifics of the passages through the attic floor and through the roof.

In our example, the chimney and the ventilation riser are located nearby, because of which we had to slightly hang the rafters:

Also on our website there is another article containing step-by-step instruction on the construction of a ceramic chimney, its fastening and decoration of the outer part.

Brick Chimney Construction

Regardless of the material used, the rules and regulations must be observed during the construction of the chimney. If it is incorrect to calculate the diameter or height of the pipe, choose a brick that does not meet the standards, forget about thermal insulation in the cold zone, the result may be disappointing.

Design Guidelines

There are two options for building a brick chimney:

- with rectangular section - using only brick;

- with round section - with an external calculation of chimney bricks and an internal ceramic (asbestos-cement, steel) pipe.

The first option is common, but not desirable. The design with internal corners is inferior to the cylindrical shape in the quality of smoke extraction. In a chimney of rectangular cross-section, soot accumulates faster, and it is more difficult to clean it, therefore, if possible, it is better to choose a combined design

Modern asbestos cement is not more harmful than slate or asphalt, so you should not be afraid to use pipes. However, there is one nuance that manifests itself with insufficient insulation - this is the rapid absorption of condensate. It is clear that a pipe with a broken structure will not last long, which is why ceramics are becoming more and more popular.

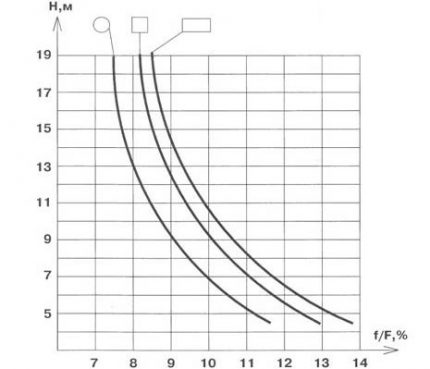

In order to accurately calculate the internal diameter of a brick or ceramic chimney for a fireplace, it is better to consult with specialists: the height of the pipe, its orientation, number of turns, material of manufacture, volume and temperature of the exhaust gases, type of fuel, fuel combustion rate, etc. are taken into account.

However, there are several general rules that should not be overlooked. Suppose, for chimneys of cylindrical section, the standard proportion with respect to the furnace is 1:10.

It is also believed that the cross section of the chimney must exceed the diameter of the blower. When calculating the height, it is necessary to focus on the height of the building (including the roof), the type of roof, the location of neighboring buildings.

If a horizontal section is planned in the structure, then its length should not exceed 1 m.This requirement is explained by the natural movement of heated gases vertically, which means that most of the soot will be deposited on the walls of the horizontal section - the most difficult to clean.

Constructional nuances of construction

One of the hallmarks of masonry is drawing up layered schemes.At the same time, the composition of the adhesive for the joints of the ceramic pipe and mortar is selected to create a sealed brick structure.

It is important that during heating, the seams do not deform and do not change the shape of the pipe. The inner surface should be as smooth as possible, without protrusions and nicks.

In addition to reducing adapters, other shaped parts are also used - revision openings with doors, tees, corner elements.

To prepare for work old, long-unused chimneys, one cleaning is not enough. For effective work, a sleeve is needed - the insertion of a metal pipe of circular cross section. The brick walls of the chimney and steel should not be in contact, a gap should be left between them.

Mandatory stage - thermal insulation. It allows, on the one hand, to increase the heating rate of the pipe, and on the other, to reduce or eliminate the formation of condensate. Also, the insulating material for chimneys is a barrier against heating of combustible materials in the vicinity of the pipe (although this should not be the case under the rules).

Of particular note is the arrangement of the passage through the ceiling and roof, in the construction of which wood is involved.

It is also necessary to finish the outer part of the pipe over the roof. To protect against debris and precipitation, “houses” are installed, stylized weathercocks, deflectors.

Step by step instructions for laying the chimney

The prepared project is a guide to action: it has a masonry scheme, an estimate, a listing of construction activities. The laying of a brick chimney is the final part of the construction of the fireplace.

Step 1 - preparation of materials and tools. To prepare the solution, sand, cement, lime (or special clay), a container are useful; for the construction of masonry - embroidery, trowel, hammer, level.

Step 2 - preparation of the solution. Masters usually know special secrets on how to make the solution more elastic and not cracking. For example, some lime is added to it. The consistency of the mass should resemble sour cream, be thick, but easy to separate.

Step 3 - masonry. Ready-made ordering facilitates the work - each row must be stacked according to the schemes. If a ceramic or steel pipe will pass inside the brick case, this also needs to be taken into account when choosing a scheme and section size.

Step 4 - a fluff. This element - the expansion of the pipe - is arranged when passing through the ceiling. The brick is shifted by ¼ towards the outer edge.

Step 5 - laying masonry in the attic. For non-heated premises, thermal insulation is required. The transition through the roof is equipped with another extension - the otter. It protects the attic from rain.

Step 6 - design of the outer pipe and head. If necessary, install spark arrester, a deflector (for adjusting traction), a ridge canopy or a cap (umbrella) above it. In the construction market, you can buy ready-made heads.

A few tips from the masters of stove and fireplace business:

Throughout the masonry, 2 points are important: for the tube to stand strictly upright and for its inner surface to be perfectly smooth. The sleeve guarantees smoothness.

Conclusions and useful video on the topic

The videos are useful for those who want to build a fireplace on their own and not make mistakes when designing and installing a chimney.

More information about sandwich chimneys:

Arrangement of a brick pipe on the roof:

Assembly of modular ceramic pipe:

The construction of a chimney for a fireplace is a fascinating task, but it will bring practical benefit only if the installation standards and rules are observed.

If you are at a loss with the choice of material or design of the pipe, we recommend that you turn to experienced stoves who know many secrets of the quality construction of fireplaces.

We decided to build a chimney for our fireplace with our own hands, but in the process of studying the information you still have unclear moments? Ask for advice from our experts and other site visitors - we will try to clarify difficult questions.

Or maybe you have practical experience in arranging chimneys and want to point out some inaccuracies or shortcomings in the material presented? Or do you want to supplement the material with useful tips from a professional? Please write about this in the comments section.

How is a ceramic chimney constructed: the specifics of installing a ceramic chimney

How is a ceramic chimney constructed: the specifics of installing a ceramic chimney  How to make a chimney in a private house with your own hands: design options and their implementation

How to make a chimney in a private house with your own hands: design options and their implementation  How to make the right chimney for a do-it-yourself stove: a step-by-step instruction

How to make the right chimney for a do-it-yourself stove: a step-by-step instruction  How to make a spark arrestor on a chimney with your own hands: a step-by-step guide

How to make a spark arrestor on a chimney with your own hands: a step-by-step guide  Gas boiler chimney deflector: installation requirements and installation rules

Gas boiler chimney deflector: installation requirements and installation rules  How to make a gate for a chimney with your own hands: instructions for making a valve

How to make a gate for a chimney with your own hands: instructions for making a valve  How much does it cost to connect gas to a private house: the price of organizing gas supply

How much does it cost to connect gas to a private house: the price of organizing gas supply  The best washing machines with dryer: model rating and customer tips

The best washing machines with dryer: model rating and customer tips  What is the color temperature of light and the nuances of choosing the temperature of the lamps to suit your needs

What is the color temperature of light and the nuances of choosing the temperature of the lamps to suit your needs  Replacement of a geyser in an apartment: replacement paperwork + basic norms and requirements

Replacement of a geyser in an apartment: replacement paperwork + basic norms and requirements

Wonderful video of installing a ceramic chimney, only WRONG. Could, at least, just download a training video, where at least the correct installation is shown. These are our builders - yesterday’s school losers with a sharpened scent for easy money. And so LITERALLY in everything!

Somehow I watched a video where one construction pepper rubbed the beauty and benefits of copper water pipes, not mentioning such a problem as condensate, and then began to do nothing more than directly through and through these pipes to push the VVG electric cable and not in the pipe, not in cable channel, but in an open way (the open wiring is not criminal in itself and can even look beautiful, but you need to do it CORRECTLY!) and this is in a wooden house.To celebrate, not forgetting to remind me of my steepness and the number of customers in the queue, I posted this nonsense on the Internet without a shadow of doubt. TRANSFER TO future owners.

I would not advise anyone to make a chimney on their own if there is no building experience and understanding of how the fireplace works. Your life depends on the chimney, and you need to approach its device responsibly. Ideally, you need to find experienced stove-makers who will do everything for you so that then there are no problems. It’s better not to skimp on such things and invite a really good master.

Well, about life - it's an exaggeration, but the normal functioning of the fireplace without a properly made chimney is impossible. And not everyone can do it on their own.

The complexity of installing the chimney of the fireplace is greatly exaggerated. Especially if it is a standard vertical output from a brick, without any complex conclusions or coaxial. It remains only to correctly calculate the cross section and then simply follow the standard instructions.

The conclusion of the chimney is much more complicated, especially if there is a configuration change. And then, yes - careful calculations are simply necessary, and here you can’t do without an experienced stove-maker.

Recently I watched a vidosik about the consequences of assembling a chimney with “experienced stoves”. Horror. In our couple, a reinforced concrete rule applies - if you want to do well, DO IT YOURSELF.