How to make a chimney in a private house with your own hands: design options and their implementation

The chimney is a necessary part of the heating system of a private house. It ensures the proper functioning of the furnace or boiler, organizes the removal of harmful combustion products outside the home.

We will try to figure out how to equip the chimney with your own hands, so that the heating communications are safe for both people and the house.

The content of the article:

Chimney design requirements

The installation of heating appliances is subject to the requirements set forth in the regulatory documentation.

Installation of devices is regulated by provisions SNiP 2.04.05–91 and DBN V.2.5-20-2001. It is also advisable to study materials about heating systems (SNiP 41-01-2003), about heat generation devices (Airbag 252–98), on the technical conditions for the operation of thermal devices (GOST 9817–95), on the rules and regulations for the operation of smoke channels (VDPO).

Part of the requirements is addressed specifically to the installation of chimneys. The design of the structure can be anything, but the material of manufacture must be non-combustible.

The materials used for the construction of chimneys can be:

- steel;

- ceramics;

- brick.

Without exception, all designs are prefabricated, and the installation itself is fragmentary, since the chimney passes through several rooms (for example, a room and an attic).

In order for the structure to meet fire safety requirements, it is necessary to correctly calculate its parameters, as well as select all component parts in size.When installing factory equipment, it is necessary to comply with all the recommendations set out in the instructions, including the assembly procedure and methods of installation of parts.

The documentation contains certain provisions that also need to be taken into account, for example:

- the length of the chimney can be any, but not less than 5 m (the height of the ventilation ducts is not less);

- the pipe section must correspond to the inlet in the generator or exceed it;

- each heat generator needs a separate chimney;

- flowing air speed inside the pipe - from 15 m / s to 20 m / s;

- pipe thickness determined by the material of manufacture (the norm for steel is not less than 0.5 mm);

- for regular inspection and cleaning activities, chimneys are equipped with pockets (niches) with a depth of 0.25 m;

- the maximum number of turns of the chimney - 3;

- the radius of curvature must exceed the diameter of the channel;

- the height of the pipe above the roof is regulated by the roof structure: on a flat roof - 0.5 m; above the roof by 0.5, if it is located at a distance of 1.5 m (or less) from the ridge; equal to or greater than the axis of the ridge, if located at a distance of 1.5-3 m.

The procedure for erecting the structure is established - always from the bottom up, that is, from the heat generator (boiler, furnace) through the ceiling to the roof. In prefabricated structures, each subsequent pipe part is introduced into the previous one.

The operating temperature of the sealants used to fix the parts should be at least 1000º. Outside the connections are equipped with clamps, the mounting material should not fall into the chimney.

The normative documentation defines the places where it is allowed to install chimneys. The material of the walls must be non-combustible, but if this condition is not met (for example, in a building with wooden walls), then for installation, for protection purposes, pipe or crown pipes should be used.

Instruction for laying a brick chimney

The most ancient chimneys known to mankind were made of stone, and then of brick, together with the first stoves. To this day, natural material is used for the construction of heating systems in private homes. Consider the main stages of the construction of a brick chimney.

Brick Pipe Design Features

There are two options for connecting a brick pipe. The first, lighter, is installed directly on the stove, the second is built nearby and connected with an adapter. The fact is that the weight of a brick chimney with a height of 5 m or more is quite large, and not every heat generator can withstand it.

For the construction of one pipe, from 500 to 800 bricks are required (depending on the height of the ceilings and the roof), the weight of each of them is 3.8 kg.

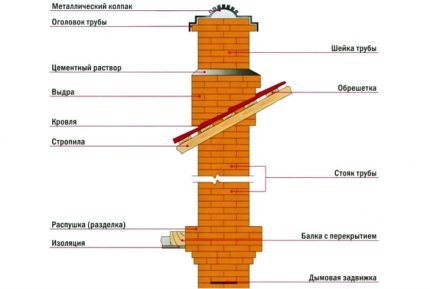

In any case, the chimney is not just a hollow inside the structure, but a complex structure consisting of several functional parts.

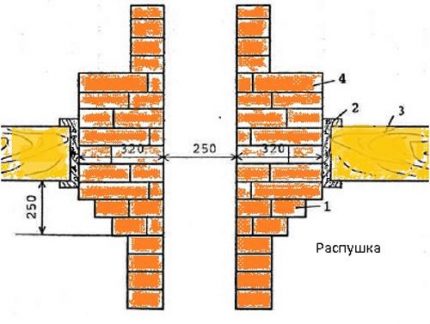

When the chimney passes through the ceiling, a fluff is arranged, which is a thickening. The following thickening of a similar configuration is constructed during the transition pipes through the roof. It's called "otter».

Part of the pipe from the cannon to the otter is the external chimney. Rises above the roof neckending with a head (alternative to the deflector).

The main condition for safety is the distance from the internal channel through which hot smoke and gases pass to the surface of walls and floor elements. It equals 0.25 m - this is exactly the length of one building element, red solid brick.

The second condition concerns the location of the chimney. It must be erected strictly vertically, the maximum possible error is 3 degrees. And the third condition is the perfect tightness of the masonry, in which there should be no through holes and cracks.

The dimensions of the chimney depend on the power of the heater. Usually choose one of the traditional masonry: with the smallest cross section - “four” (12.5 cm x 12.5 cm), rectangular - “five” (25.0 cm x 12.5 cm) or large - “six” (25 cm x 25 cm).

The latter option is preferable for Russian stoves, rectangular - for fireplaces. For small stoves, the first solution is suitable.

Material selection and solution preparation

The stove chimney is equipped with brick oven. If another unit is installed, then the pipe is built up after its installation. For construction, you will need a brick and mortar, as well as tools: a trowel, a plumb line and a special hammer for knocking out.

Bricks are pre-soaked. For the device of flaking and otter, pieces of bricks of ½, 1 / 4.1 / 8, размером in size will be required.

The usual cement mortar is not suitable for masonry, a mixture of clay and sand is needed. This is justified by the characteristics of clay, which has a linear expansion coefficient close to brick parameters. Depending on the type of clay (lean or oily), its ratio to sand may vary: 1: 3 or 1: 4.

Clay is pre-prepared - soaked in water and kept for about 3 days. Before use, the material should have a consistency resembling liquid sour cream, and not have foreign impurities. Special requirements apply to the sand. The best option is rough, with grains of 0.9-1.0 mm.

Clay and sand are mixed in small portions during masonry. Sometimes you need to add water. The quality of the solution can be easily determined by the way it contacts the trowel: the mass should leave marks on the surface, but not drain from it and not stick in large pieces. If you have problems with self-preparation of the mixture, you can buy a ready-made one.

The laying order of the main parts

If the boiler is installed or the furnace is finished, you can start to build a brick chimney. The working procedure is traditional: applying the mortar, then installing the brick, adjusting it relative to neighboring parts with your hands and a small hammer.

The vertical position is checked after laying each row with a plumb line. The width of the wall is 12.5 cm. The straight pipe element is completed 4 rows before the flare - expansion in the ceiling.

It is necessary to exclude the pressure of the ceiling structure on the masonry, therefore, a gap of 2-3 cm wide is left between the overlap and the fluff. It is used for the installation of insulating material, for example, mineral wool plates.

A straight section of the pipe again passes through the attic, then an otter is made. Its bottom row must be laid out when the outer edge of the chimney has passed through the roof. At this stage, cement is often used to prepare the solution, more durable and wear-resistant than clay.

The otter consists of 6 rows, the indent of each subsequent is 1/8 of the whole brick. The holes around the pipe are insulated and covered with steel roofing sheets.

The next stage is again direct - the neck, which is crowned by the head.

For the chimney is necessary deflectorso that puffs of smoke do not return back to the chimney. Along the perimeter of the head mount mounts for the cap - protection against precipitation. Caps are often used as an element of decor, so they are given an interesting and beautiful shape.

The construction of a ceramic chimney

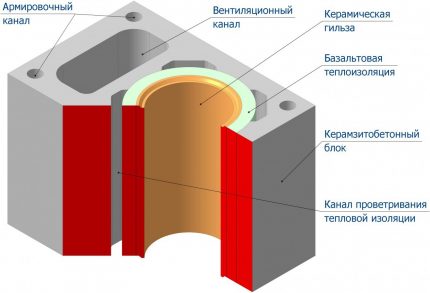

Prefabricated ceramic chimneys have become popular due to their strength, safe composition, environmental friendliness, ease of installation. They borrowed the best technical specifications from steel and brick models. The only negative is the high cost of the kits. Consider how a chimney made of ceramic in a private house occurs.

Prefabricated Type

Unlike brick chimneys, ceramic is mounted already from the finished elements, gluing from each other with a special solution. It is not possible to make ceramic parts yourself; ready-made kits are purchased for construction.

Manufacturers present standard kits from which to assemble chimney for fireplacestove or boiler.

In addition to ceramic pipes, the kit includes the following parts:

- base element with drain for condensate;

- a part for connection with a nozzle (angle 90º or 45º);

- revision chamber with a door;

- lightweight blocks for external framing;

- set for external design (on the roof);

- non-combustible insulation material for installation;

- paste glue.

Additionally required fasteners (brackets) and non-combustible material for cladding: plaster, natural stone, ceramic or clinker tiles.

Assembly and installation rules

According to the norms of installation and operation of the ceramic chimney, it should not be further than 2 m from the heat generator (the closer, the better), as far as possible from walls and ceilings of combustible materials, and should not cross the supporting elements.

During installation, you must adhere to these rules:

- a prerequisite is the construction of a foundation covered with a fire retardant;

- installation begins from the bottom - the base, then sequentially continue towards the roof;

- the parts are glued together with a special glue, which is included in the kit;

- the diameter of the pipe should be larger than the outlet pipe of the heat generator;

- for thermal insulation use mineral wool and plaster;

- the junction of the pipe and the roof is protected with a metal apron;

- if the roof is covered with combustible material, it is necessary to equip a spark arrester.

If the chimney channel is installed without fasteners for more than 3.9 m, it must be reinforced with steel rods. Especially for this purpose, holes are provided in the pipe parts at the corners.

The upper part of the head is equipped with an umbrella to protect from rain, debris and strong winds.

The nuances of installing and connecting pipes

The elements from which the chimney is assembled are made of ceramics with the addition of chamotte - this composition tolerates high temperatures, and parts from it have a long service life. They cannot be used as independent units, external protection is absolutely necessary.

The lower part of the chimney - the base - is equipped with an opening for the removal of condensate, which is formed during the removal of combustion products. The accumulated liquid moves to a sewer that has been supplied in advance.

It should be remembered that moisture from the chimney is detrimental to the bacteria of the septic tank, therefore it is better to prepare a separate container to collect the liquid.

Elements are installed one on top of another according to the instructions without changing the order established by the manufacturer. Correspondence of the dimensions of the chimney and the parameters of the house must be checked in advance.

How to cook and apply glue?

In order for the chimney parts to be hermetically connected, a special acid-resistant glue is used. This is a thick mixture, which is prepared manually from dry powder and water in a ratio of 7: 1, preferably at room temperature.

At first, the solution looks unusually dry, but after about 7-8 minutes it acquires the necessary pasty appearance.

One of the nuances of applying glue is the preliminary wetting of the ceramic surface. It is impossible to save the adhesive mass - only hermetically filled seams guarantee the full functioning of the chimney.

The remaining glue must be removed: from the inside - so as not to accumulate soot, from the outside - for aesthetic purposes.

If subsequently there is a desire to mask the pipe with a decorative partition, a technical inspection hole should be available.

The device of a metal sandwich chimney

Steel chimneys are popular both in industrial construction and for the improvement of the private sector. Their installation resembles the assembly of a ceramic structure, respectively, is easier than building a brick pipe. Let's consider in more detail how to properly make a metal chimney, avoiding errors.

Materials for the installation of metal construction

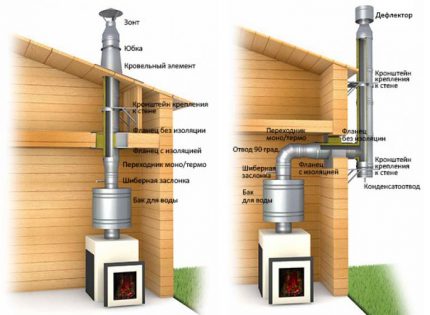

Sandwich chimney is a sealed system of pipes and adapters leading from the heat generator to the roof space. It can pass inside the building (internal) and outside, along the wall (external).

Non-combustible heat-insulating material has a different thickness - on average from 2.5 cm to 10 cm. Manufacturers most often use one of the best materials - dense basalt cotton wool (from 200 kg / m³).

To assemble the chimney, you need to connect several parts of various shapes, using the method of connecting the narrowed ends and sockets. Simply put, one element is inserted into another. On the outside, the joints are reinforced with overhead clamps, which tightly tighten after installation.

When installing a steel chimney inside the building, the openings in the ceilings and the roof are much smaller in diameter than for brick or ceramic counterparts.

Installation diagrams of a sandwich chimney

Consider two schemes for installing a sandwich chimney: with an internal arrangement that requires the organization of holes in the roof and ceilings, and with external installation, which is carried out from the outside and installed parallel to the wall of the house.

The internal installation scheme is often used in baths, since a steel pipe can simultaneously heat both stones and a tank of water. If the bath is not installed separately, but is an extension to the house - this is the most appropriate and effective option.

The disadvantages of the internal system are the need to make holes in the ceilings and the roof, as well as a decrease in usable space.

To install an external system, it is enough to make one hole in the wall and provide a vertical arrangement of pipes using brackets. Piping out reduces the risk of poisoning from combustion waste. Minus - arrangement of additional protection against the effects of the external environment.

Installation procedure:

- connection to the boiler (or other heat source) adapter;

- punching holes in the wall (average size - 40 cm x 40 cm), upholstery with fire-resistant material;

- installation in the wall of the passage block with thermal insulation;

- installation of a horizontal pipe segment from the boiler (furnace) to the hole in the wall;

- arrangement of the support node from the outside (platform on the brackets);

- installation of a vertical pipe;

- mount at the top of the cone and head.

When assembling, it is necessary to focus on the technical documentation prepared in the process of compiling the project.

Inside Tube Tips

When choosing an internal model, it is necessary to remember some technological nuances. For example, it is important to install a valve in the transition section from the boiler so that it is possible to retain heat.

Docking of two adjacent elements in the transition area is prohibited. The location of the attic rafters and beams should be taken into account: the further they are from the chimney, the better. Read more about self-assembly of a sandwich chimney in this material.

Conclusions and useful video on the topic

To imagine how the installation process of chimneys of various types takes place, we offer useful and informative videos shot by skilled craftsmen.

Do-it-yourself brick chimney:

Stages of installing a ceramic chimney brand TONA:

Tips for installing a sandwich chimney:

The construction of a chimney for a gas boiler, stove or fireplace is a responsible task requiring special permission, designing and professional skills. If you are not confident in your abilities, entrust the installation of the pipe to specialists who will perform the work taking into account all norms and requirements.

If you have already had to build a chimney yourself or are an expert in this matter, please share your experience and knowledge with our readers. Tell us about the nuances of building a chimney in the block below.

How to make the right chimney for a do-it-yourself stove: a step-by-step instruction

How to make the right chimney for a do-it-yourself stove: a step-by-step instruction  How to make a spark arrestor on a chimney with your own hands: a step-by-step guide

How to make a spark arrestor on a chimney with your own hands: a step-by-step guide  How to make a chimney for a fireplace: the rules of the device of the smoke channel and a comparison of designs

How to make a chimney for a fireplace: the rules of the device of the smoke channel and a comparison of designs  How to make a gate for a chimney with your own hands: instructions for making a valve

How to make a gate for a chimney with your own hands: instructions for making a valve  How to put a deflector on a chimney with your own hands: step-by-step instruction

How to put a deflector on a chimney with your own hands: step-by-step instruction  Do-it-yourself garage oven: a step-by-step guide to design

Do-it-yourself garage oven: a step-by-step guide to design  How much does it cost to connect gas to a private house: the price of organizing gas supply

How much does it cost to connect gas to a private house: the price of organizing gas supply  The best washing machines with dryer: model rating and customer tips

The best washing machines with dryer: model rating and customer tips  What is the color temperature of light and the nuances of choosing the temperature of the lamps to suit your needs

What is the color temperature of light and the nuances of choosing the temperature of the lamps to suit your needs  Replacement of a geyser in an apartment: replacement paperwork + basic norms and requirements

Replacement of a geyser in an apartment: replacement paperwork + basic norms and requirements

Last year, we decided that we would come to the country in the winter. There is no heating there. So I had to learn the profession of stove-maker - he laid out the stove and built a chimney.The stove turned out not bad, but when arranging the chimney, I did not take into account that a deflector was needed - there was a lot of smoke. It’s good that I tested the stove in the fall and managed to finish it before the winter. Now I can do the neighbors.

Making a chimney on your own is not such a simple task as it seemed before. At a minimum, there should be a couple of people who undertook to help. When I was making a chimney, I invited all my friends. I decided to make a sandwich, the most important thing is that in winter it will practically not freeze. And it will be necessary to impose bricks. I will not take up such work myself anymore, I will invite specialists.