Insulation for heating pipes: overview of types + application examples

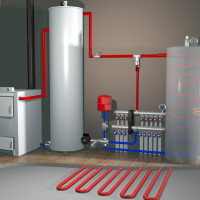

Owners of private houses often consider the thermal insulation of heating system pipelines an unnecessary waste of money. But such events are a direct path to significant savings in thermal energy.

The reduced amounts in bills from power engineers and for fuel for the boiler will necessarily cover the cost of thermal insulation. It is only necessary to choose the right insulation for heating pipes so that it lasts longer without losing its characteristics, and we will tell you how to do it.

The content of the article:

Why is it necessary to insulate heating pipes?

Typically, the owners of cottages produce insulation only those heating pipelines that are located outside the home. Heat losses there are most probable and large-scale. No wonder all urban heating mains are so thoroughly insulated. You also need to carefully choose yourself pipes for heating.

Power engineers have already learned how to count their money. However, the heating system pipes in the basement or boiler room are also worth insulating. To heat such non-residential premises in the house is a waste of money.

There are five good reasons to cover heating pipes with a heat insulator:

- Coolant protection against freezing.

- Prevention of condensation.

- Decrease in heat losses.

- Extension of the “life” of boiler equipment and pipelines.

- The possibility of laying the outer sections of the heating system in the ground above the freezing point.

The pipes are insulated in the basement, in the attic, in the boiler room and in outdoor areas. Install insulation on risers inside the house in living rooms is not worth it. If this is done, then the heat will still get into the room, but already through the radiator. There is no sense in such actions. Money will be spent on the heat insulator, and it will make zero sense from it.

When the coolant moves through insulated pipelines, it does not waste thermal energy in vain. All the heat goes to the heating of the necessary premises.At the same time, the boiler and pumping equipment in the boiler room do not have to work at maximum conditions in order to maintain a comfortable temperature in the rooms.

A couple more minuses of heating pipes without insulation are condensation and freezing. In operating mode, when the system is circulating coolant, most often - heated water, there are no problems with its freezing inside and condensation outside. But in case of accidents on the heating system, pipelines begin to “get wet”, and then freeze.

The heat-insulating material in this situation gives several additional hours, during which the coolant even cools, but not so fast.

In general, heat pipes are insulated:

- when laying communications of the heating system outdoors;

- in pipeline sections located in unheated subfloors and attics;

- during installation of heating mains and branches from them into risers in the basements of apartment buildings.

Insulated pipes are warm batteries while lowering energy costs. It is better to invest in heat-insulating materials than to pay huge bills for heating. It is always more efficient to make insulation than to spend money on fuel for a stove or boiler.

Overview of insulation in the modern market

All heat-insulating materials for heating pipes are divided into:

- rolled;

- cylindrical with and without a slit;

- semi-cylindrical (“shells”).

The first are sold in rolls, they wrap pipes. The second is a cylinder of insulation with an empty core, where the tubular product is inserted. The third are two halves in the form of half-cylinders, which are applied to the pipeline from below and from above, forming as a result of thermal insulation protection from all sides.

The rolled version is good in that it can be mounted on pipes of any diameter. Cylindrical materials are laid on pipelines of a specific size only. If you install them on a product with a larger cross-section than they are designed, then a gap forms in the heat-insulating layer. The effectiveness of insulation in this case will decrease sharply.

Depending on the type of insulation, “cylinders” and “shells” are either soft or hard. In the first case, the insulator can be bent for installation at the turn of the pipeline, and in the second, such sections of the heating system remain without an insulation coating.

View # 1 - fiber wool

Glass wool and basalt mineral wool in rolls are a classic of insulation. These materials are cheap, easy to install and have decent thermal insulation characteristics. Their main disadvantage is high hygroscopicity. They absorb moisture well, immediately losing all their warming properties.

Stone (basalt) mineral wool is least prone to absorb moisture. Glass wool is a little inferior to her in this. There is still a slag option, but it is better to immediately abandon it. This type of mineral wool has the highest hygroscopicity. For insulation of heating pipelines, water supply and sewage can not be used.

Installation of mineral wool on the pipes is overlapped, followed by fastening the insulation from above with a steel tape or stainless steel wire. In terms of thermal conductivity, both minvats recommended for heating systems are similar. This indicator for them ranges from 0.035–0.044 W / (m *0WITH).

When using mineral wool, it must be remembered that over time it shrinks and condenses. As a result, the effectiveness of its thermal insulation is reduced.It is worth immediately laying a thicker layer so that after a couple of years it does not return to its original position and begin to re-lay the insulation on the pipes.

Glass and basalt mineral wool will last about 10 years. But this is only on condition that it will not get wet and subjected to mechanical stress.

View # 2 - foamed polymers

This category of pipe insulation includes materials based on:

- polyethylene;

- polystyrene foam (polystyrene);

- polyurethane foam;

- rubber.

The first of these heat insulators is offered in stores in the form of rolled material from several polyethylene layers with air bubbles between them, as well as in the form of shells made of foamed porous polyethylene.

The thermal conductivity of this insulation is in the region of 0.035 W / (m *0WITH). It is not afraid of moisture and remains elastic even with severe frosts.

Polystyrene foam heat insulator for heating pipelines is available in the form of two half-cylinders-shells. To guarantee the absence of gaps and cold bridges, many manufacturers make them with thorn-groove locks in length. For large diameter pipes, there can be not two, but three or four segments. Thermal conductivity of polystyrene foam - 0.037–0.042 W / (m *0WITH).

In terms of density and other characteristics, polyurethane foam is similar to a polystyrene foam analogue. Only it is slightly superior to the latter in terms of thermal insulation quality. The thermal conductivity of this insulation is 0.035 W / (m *0WITH).

It is it that is most often used for warming large pipes in factories. Such finished products are used when laying heating mains inside neighborhoods and for installing bends from common networks to cottages.

Polyurethane foam insulation for house pipelines is available in the form of hard shells with an outer layer of sheet steel. This polymer is afraid of ultraviolet radiation; it needs protection from light.

Foamed rubber follows most of the characteristics of a polyethylene analogue. However, it has a larger range of operating temperatures (from -190 to +175 ° C) and it costs much more. It is most often used for thermal insulation of ventilation systems and pipes with refrigerant, where its properties are more in demand.

View # 3 - Combined Materials

Mineral wool is prone to moisture accumulation and loss of thermal insulation properties. Polymer heaters are fragile and afraid of fire, ideally they need additional external protection. To get heat insulators with the necessary characteristics, many manufacturers combine them with each other and with other materials.

Combined heaters for pipes include:

- polyethylene with an external foil layer;

- polymer shells with a steel shell on top;

- mineral wool with waterproofing protection made of polyethylene or foil.

Also in stores there are thermal insulation materials with a self-adhesive layer. They are easier to mount and mount on pipes. The joints of such a heater are airtight without cold bridges. However, its price is slightly higher than that of the usual analogue.

It is not recommended to use aluminum foil without an insulating layer of polymers or mineral wool for thermal insulation of heating pipes. She has too high thermal conductivity. It can be used only as an additional layer.

View # 4 - paint and spray foam

In addition to ready-made factory-made heaters, which only need to be put on the heating pipe and fixed on it, there are various coloring and sprayed compounds. The latter are superior to “shells” and rolled counterparts in the quality of the connection with the surface of the pipeline and the tightness of the thermal insulation layer.

The sprayed polyurethane foam is an excellent insulation that covers the highway with a monolithic layer on all sides. However, you can not even think about its temporary dismantling for the repair of the heating pipeline. It is difficult to call this matter easy.

Plus, polyurethane foam breaks up over time under the influence of ultraviolet rays. It is better to use it only in cellars closed without windows, and when installing on the street, it is necessary to cover it with other building materials to protect from the sun.

The insulating paint consists of:

- ceramic microspheres;

- perlite;

- acrylic resins.

Using this paint, you can cover all the bends of the heat supply pipe. She has excellent heat-shielding characteristics. But experts recommend it to be used only as an additional insulation in the appendage to the main classic.

In addition to all of the above materials for pipe insulation, you can use simple expanded clay. He is not afraid of fire and moisture. Plus it is very cheap. To perform thermal insulation around the heating main, it is necessary to make a box of boards or metal.

And after falling asleep in the last expanded clay so that the pipeline is closed by sprinkling on all sides.

Which warming option is better?

When choosing a heater for pipes of a heating system, it is necessary to take into account:

- The location of the highway (in the ground, in the basement, in the attic).

- The presence of problems with rodents.

- Financial opportunities.

- Pipe diameter and pipeline configuration.

- The temperature of heating the coolant.

In practice, rats and mice bypass only glass wool. Plus, the paint is just too tough for them. They can bite the rest of the heaters to fill their nest.

Polyethylene in all its variations is resistant to the aggressive effects of cement. If the pipe with insulation is laid in the wall with the subsequent filling of the hole with concrete, then it is worth choosing polyethylene material.

Polyurethane foam allows you to get to all sections of the highway, reliably covering it with a monolithic heat-insulating layer. However, its application requires special equipment. Plus, spraying such insulation on thin pipes is difficult, most of the foam will be on the surrounding walls.

When installing the heating system in areas with unstable soils and connecting several buildings to one boiler, the most optimal insulation is light polyethylene or thin foam. It’s not worth using heavy stone wool here. Highways during soil movements may not withstand additional loads and burst.

Conclusions and useful video on the topic

When choosing a heater for heating system pipelines, several factors must be taken into account at once. To make it easier for you to understand this issue, we have made a selection of video materials. The given reviews and comparisons will surely help you to navigate in the selection of a heat insulator for pipes.

Insulation of the street pipeline from the boiler room to the house:

Overview and installation rules for the heater pipe Energoflex:

Technology of pipe insulation with foamed foam insulation:

It is not difficult to warm the heating pipelines, you just need to correctly select the heat-insulating material. For heating mains in the ground, it is better to prefer moisture-proof and rigid insulation with an outer shell of steel, and for sections in the attic it is worth taking a light mineral wool.

All of them can reduce the cost of heating a house and increase the efficiency of the entire heating system.It is only necessary to choose their thickness correctly, being guided by SP 41-103-2000.

If you have questions or want to supplement the material with valuable information on the topic - please leave comments under our article.

Installation of heating from polypropylene pipes: how to make a heating system from polypropylene

Installation of heating from polypropylene pipes: how to make a heating system from polypropylene  Installation of copper heating pipes: features of the technology of work

Installation of copper heating pipes: features of the technology of work  Which pipes are better to choose for heating: a comparative review

Which pipes are better to choose for heating: a comparative review  Features of flushing the heating system: an overview of the best ways

Features of flushing the heating system: an overview of the best ways  Types of heating systems for a private house: a comparative overview + the pros and cons of each type

Types of heating systems for a private house: a comparative overview + the pros and cons of each type  Voltage stabilizer for a gas heating boiler: types, selection criteria + overview of popular models

Voltage stabilizer for a gas heating boiler: types, selection criteria + overview of popular models  How much does it cost to connect gas to a private house: the price of organizing gas supply

How much does it cost to connect gas to a private house: the price of organizing gas supply  The best washing machines with dryer: model rating and customer tips

The best washing machines with dryer: model rating and customer tips  What is the color temperature of light and the nuances of choosing the temperature of the lamps to suit your needs

What is the color temperature of light and the nuances of choosing the temperature of the lamps to suit your needs  Replacement of a geyser in an apartment: replacement paperwork + basic norms and requirements

Replacement of a geyser in an apartment: replacement paperwork + basic norms and requirements

Pipes go into the house at our place three meters underground, therefore even the most severe frosts are not terrible, but they already go to the bathhouse above, therefore they were insulated immediately at the initial stage of construction. Glass wool was immediately chosen for insulation, the price is adequate and different rodents will not be able to damage it. For two winters without any problems, the main thing is to additionally protect from moisture outside.

You write too categorically that rodents are not interested in glass wool. Yes, they gnaw at it less willingly, but when there is no choice they can equip a nest in it.