Gas infrared emitters for industrial premises: device, principle of operation, varieties

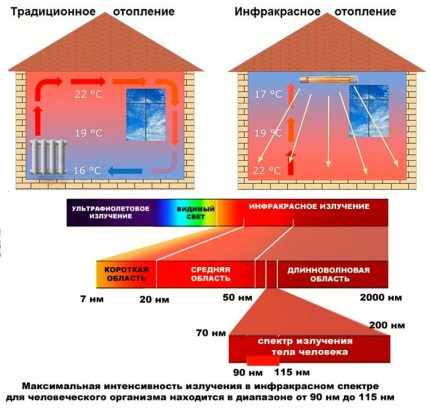

IR devices that generate heat and light fluxes are actively used in various fields of production and private economy. The most popular gas infrared emitters for industrial premises. Their action is based on the ability of a heated body to release the received heat into space.

You will learn all about the principles of operation of infrared equipment from our article. We will talk about the varieties of infrared equipment and their characteristic differences. Introducing market leading models.

The content of the article:

The essence of infrared radiation

Infrared radiation differs from ordinary and such familiar visible light. They are similar in speed with which they spread and cross space. Both varieties are capable of refracting, reflecting and gathering “in a bundle”.

Unlike ordinary light radiation, which is electromagnetic waves, the IR flux has both wave and quantum properties. That is, it transfers both light and heat.

The light supplied by infrared devices moves in waves. Electromagnetic light vibrations are in the spectrum segment from 760 nm (nanometers) to 540 microns (micrometers). The heat generated by IR emitters is a flux of quanta. Their energy ranges from 0.0125 to 1.25 eV (electron volts).

The heat and light flux emitted by infrared devices are interconnected. With increasing light intensity, the quantum heat flux decreases. Depending on the temperature, infrared radiation can be perceived and not perceived by our eyes. Thermal radiation is not visually detected.

This specificity of infrared radiation is used in industry to accelerate the polymerization and solidification processes. The thermal part of infrared radiation provides the ability to determine the presence and location of a person or animal in a poorly lit and unlit night period.

The non-standard operation of infrared devices emitting light in combination with heat has become the basis for the development of night vision devices. It is used in flaw detection, in the means of a hidden alarm and in technical devices for photographing in the dark.

Both components infrared radiation almost do not dissipate in the treated space, they seem to focus on objects in the zone of their influence. Heat enters the body of the heated object, the penetration depth depends on the properties, structure and material of the object. Depth varies from a tenth of a mm to several mm.

When used for industrial purposes, the wavelength from infrared emitters is selected based on the technical characteristics of the object or substance. IR rays freely pass through the air mass, so heating is carried out without noticeable losses. This circumstance is justifiably considered a weighty advantage in production.

In addition to heating and lighting the zone treated by the device, infrared emitters are used to solve the following problems:

Types of infrared sources

The simplest sources of infrared radiation are familiar to all of us. incandescent lampsoperating under low voltage. Under such conditions, they mainly emit infrared streams. The proportion of light electromagnetic waves is negligible, but nevertheless it is determined optically.

Now at the disposal of private consumers, construction and manufacturing organizations, many different types of infrared emitters.

The scope of their application is determined by:

- operating temperature;

- the maximum value of the wavelength;

- an area in which the infrared flux is evenly distributed.

Given the above characteristics, they select a radiating device designed to solve specific problems.

The most common types of infrared emitters include:

- Lamps with mirror reflective devices. At maximum radiation, their wavelength is 1.05 microns.

- Quartz tube lamps. Their wavelength at maximum radiation is in the range from 2 to 3 microns.

- Rod non-metallic heaters. Structurally, they are supplemented with reflectors, the maximum wavelength is from 6 to 8 microns.

- Tubular electric heaters. Widely used in everyday life, used in production devices with heating elements.

- Infrared burners. They are equipped with ceramic or metal perforated nozzles. They are used in construction for heating outdoor and indoor areas during the construction of a building, finishing work.

Sources of infrared rays have found application in the farm. With their help, the heating of poultry young animals and recently born domestic animals is carried out. The emitters are installed in greenhouses to stimulate the growth of cultivated varieties, in ovines and granaries for drying.

Sources of infrared streams are divided into:

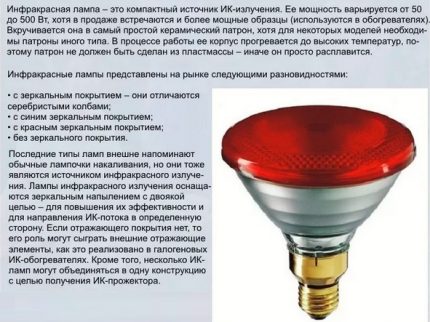

- Infrared lamps. These are “light” emitters and devices supplying thermal radiation.

- Heaters. Devices used for heating enclosed spaces and open spaces. Among them are models powered by power, liquid or gaseous fuels. The heating element can be either a heating element or a spiral made of an alloy with high resistance.

According to the classification by wavelength, infrared sources are divided into two main groups: dark and light. The former work by emitting long waves into space, the latter - short.

Dark and light IR emitters

By definition, “bright” sources are capable of emitting light. The streams emitted by them are perceived by sight, although it is still difficult to name them and use them for precisely this purpose at all.

“Dark” devices deliver an invisible heat flux for humans, sensed by the user's skin, but not visually detectable. The boundary value between “light” and “dark” is considered to be a wavelength of 3 μm. The boundary temperature of the heated surface is 700º.

The most famous representative of the "dark" heating unit is brick Russian stove, many centuries successfully heating low-rise buildings. Among the “bright” ones, as we already understand, an incandescent light bulb appears if it supplies no more than 12%. Its main energy is directed to the generation of heat.

Features of the device light devices

Structurally, light sources are similar to a typical incandescent lamp. However, there are differences in the bodies of heat. For light infrared devices, the temperature cannot exceed the limit of 2270-2770 K. This is necessary to increase the heat flux by reducing the light emission.

Just like with standard bulbs, a tungsten filament body is placed in a glass flask. Only the bulb is equipped with reflectors, thanks to which all radiant energy is focused on the heated object. At the same time, a small part of the energy is spent on heating the base of the bulb.

The flask of light infrared sources is heated to high temperatures, because it also participates in the process of heat transfer to space. Thermal energy from a heated bulb is not focused by the reflector and goes into an unworkable space, and it is a component that reduces the efficiency of the device.

The performance of a bright infrared source does not exceed 65% on average. It is increased by placing the tungsten heating body in a tube made of quartz glass or a similar flask. This solution allows you to increase the wavelength to 3.3 microns, and reduce the temperature to 600º.

This option is used in quartz infrared heaters, in which a nickel-chromium wire is wound around the quartz rod and all this together is located in a quartz tube.

The essence of the work is the double use of wire filament. The heat released is partly used for direct heating, and partly for raising the temperature of the quartz rod. A heated red rod also generates heat fluxes.

The advantages of tubular devices include quite reasonably the resistance of all components made of quartz and ceramics to atmospheric negative. The disadvantage is the fragility of ceramic parts.

The specifics of the work and design of dark heaters

The so-called "dark" sources of IR streams are much more practical than the "light" counterparts. Their radiating element in structure differs for the better. The heated conductor itself does not radiate thermal energy, it is supplied by the surrounding metal shell.

As a result, the operating temperature of the device does not exceed 400 - 600º. In order for thermal energy not to be wasted, dark emitters are equipped with reflectors that redirect the flows in the right direction.

Long-wave emitters of the dark group are not afraid of shocks and similar mechanical effects, because a fragile polymer or ceramic element in them is protected by a metal like shell and a protective heat-insulating layer. The efficiency of the emitters of this group reaches 90%.

But they are not without flaws. Heaters of the dark group depend on the design features of the device. If the distance between the main radiating element and the surface of the device is large, then it will be washed and cooled by the air flowing past. Efficiency is reduced as a result.

Due to the design features, dark models are installed for heating rooms with low ceilings and areas requiring linear heat supply. Light - set where processing of rooms with a high ceiling and vertically elongated areas is required.

Gas burners as a source of infrared rays

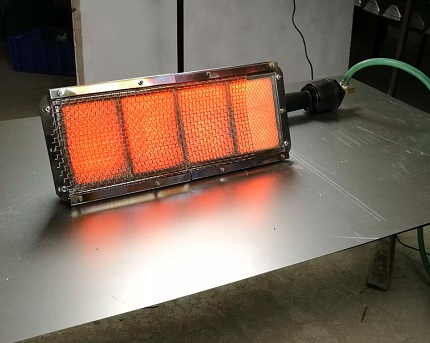

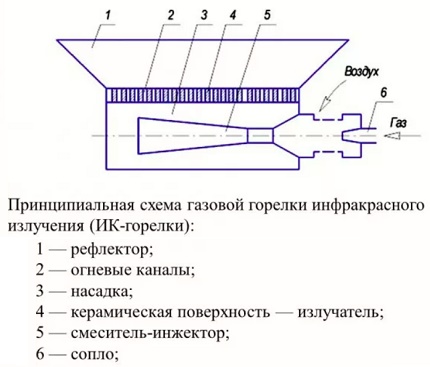

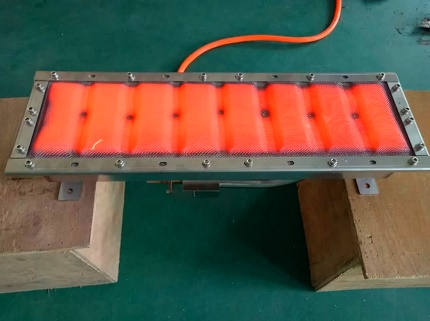

Devices in which flameless gas processing occurs are called gas burners or gas infrared emitters. The thermal energy released with great tension is transferred to space through the radiating surface of the unit.

It is gas-fired infrared heaters of the burner type that are used on an industrial scale during construction and installation works. The predominant amount of thermal energy is transmitted by the ceramic burner nozzles.

As nozzles are used:

- perforated ceramic plates that are flat or embossed;

- ceramic plates with evenly distributed pores;

- ceramic elements with a mesh nichrome screen, metal mesh and all kinds of catalytic nozzles.

All of the above types of holes in a ceramic or metal element are fire channels.

The main gas for operation of this type of infrared emitters is gas, as well as its liquefied version or artificially created gases. In Russia, burners are designed for the processing of liquefied and main gas. Foreign equipment is mainly designed for processing liquefied and artificial options.

If the operating rules are not violated, the combustion products from the operation of the gas burner are emitted in a minimum amount with a slight content of nitrogen oxides and carbon monoxide.

To supply gas, gas infrared burners (GIG) are equipped with nozzles through which gas is pumped at high speed. This gas supply provides the injection of air required for combustion. It is “pushed” by a high-speed flow through the injector into the distribution chamber.

Gas not only injects air, but also mixes with it in the injector, resulting in a gas-air mixture suitable for complete combustion. This mixture moves to the surface of the ceramic nozzle through its pores, perforated holes or slots, where it burns completely in a thin layer of a thickness of not more than 1.5 mm

Burners with flat ceramic nozzles

The predominant amount of thermal energy is transferred to ceramic tiles heated to ultra-high temperatures in less than a minute.The outer surface of the ceramic element turns into an additional source of heat flux.

Ceramic nozzles account for 40 to 60% of the radiation transmitted by an industrial gas infrared heater. In order to increase the efficiency of the device, a mesh screen is installed over the nozzle. To increase the heat transfer surface, perforated tiles are glued using refractory putty.

An important indicator is the diameter of the fire channels. It depends on which gas the appliance can process. The total number of holes in the ceramic tile depends on the diameter. The more of them, the more fragile the radiating element will be and will be sensitive to mechanical damage of the GIG.

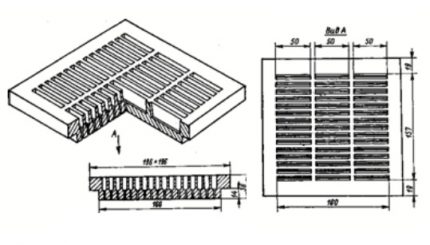

Finned Type Heaters

In addition to flat ceramic nozzles with perforation, relief elements are used. The use of a ribbed surface in this case stimulates the heat exchange flow between the radiating surface and the burning gas. Ribbed ceramic tiles heat up better, while the thermal load on the radiating element does not increase.

Flat and ribbed ceramic nozzles are heated up to 1473 K. But porous ceramic elements only up to 1237 K. The porous version is easier to manufacture, therefore, cheaper. In addition, waste from the ceramic industry is used in its production.

The thickness of porous tiles reaches 30 mm, which significantly increases the resistance of the nozzle to mechanical stress. During the operation of a burner with such a nozzle, the gas-air mixture leaving the distribution chamber burns up to 2 mm on the outer surface of the ceramic tile.

The combustion area in the porous nozzle moves from the outer surface to a depth of 3-5 mm. In this case, the heating temperature reaches only 1123 K.

The disadvantage of porous nozzles for GIG is an excessively high hydraulic resistance, because of which it is impossible to use low-pressure main gas in operation.

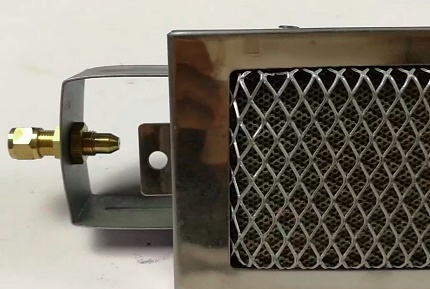

Equipment with metal mesh

However, all of these types of nozzles are made of ceramic, which means that despite the thickness and all kinds of tricks of the manufacturer who wants to increase strength, they are still fragile. Fragility is especially annoying if the device needs to be constantly moved.

Therefore, to heat the sites during construction or installation works, a more durable type of burner equipped with a double metal mesh was developed. In such a device, the gas-air mixture is processed in the gap between the nozzle and the nets. The surface of the external mesh heats up to only 1023 K.

In GIG with mesh nozzles, these elements are made of heat-resistant alloys with chromium and nickel.Nozzles are made so that the mesh size of the upper mesh allows the flame to pass freely, and the lower one is minimal, critical for the passage of fire. Here, infrared heat emitters can be both grids or one.

If an infrared burner processes main gas or a propane-butane liquefied mixture from gas bottle, only the upper grid is involved in the distribution of thermal energy. If gas with a low load is processed, both grids emit heat. In this way, heat transfer is increased.

However, the maximum value of the efficiency of GIG with grids does not exceed 60%, because the hydraulic resistance of the nozzles is two times greater than that of perforated ceramic tiles of all varieties. True, it is smaller than that of porous nozzles.

Devices with increased thermal power

The rather low efficiency of infrared gas emitters with ceramic plates and grids led to a search for ways to increase thermal power. The result was achieved by introducing a new type of nozzle, which is a ceramic panel with a number of slots.

In the slit, the slots have a sudden expansion, their inlet openings are smaller than the outlet ones. This solution improves the burner efficiency by recirculating the combustion products, i.e. their return to the base of the flame within the fire channel. In addition, the flame in such models is more stable and much less likely to die out in the open wind.

The live section of the slit panels averages 55-60% of their real total section. The burners equipped with them operate on medium pressure gas. The outer plane of the nozzle is heated to 1723 K.

Resistant to wind load

Stability of work under wind load is an important indicator for choosing a gas infrared burner used in the construction or assembly of production plants. This quality is far from all industrial infrared emitters that process gas.

For outdoor areas, special devices are needed that:

- characterized by stable injection, depending on gusts of wind;

- equipped with a device to prevent deviation of the jet exiting the nozzle;

- protected from active cooling of the radiation surface due to the effects of winds.

In the data sheet of gas equipment capable of heating with a gusty wind and not go out, wind resistance is indicated. This characteristic of commercially produced infrared burners is approximately equal to that for direct, i.e. frontal exposure to wind, and with side airflow.

A reduction in the injection coefficient causes a flame to appear on the outer surface of the radiating panel. In this case, the temperature drops sharply. Reduces its cold air penetrating the combustion area.

Wind resistance is physically interconnected with the specific heat load and the volume of air entering the nozzle during the combustion period. With an excess and high speed of the air flow, the efficiency of the infrared emitter is reduced. It is accompanied by a reduction in the appearance of flames, darkening of the radiating surface and the termination of the unit in flameless mode.

Overview of manufacturers of IR heaters

Both domestic companies and foreign companies produce gas appliances for creating a favorable microclimate on the construction site, in the workshop, production workshop and similar facilities.

According to consumers, the rating of Russian-made products is led by gas burners of the Solyarogaz brand. The assortment presented by this company includes models designed for heating areas of various sizes. Units can be used in greenhouses, garages and on the open areas.

The only drawback that buyers and real owners of gas burner and stove models from the capital's manufacturer should take into account is the lack of security system sensors. In view of what, they can be used in everyday life, but with the observance of precautionary measures.

Products from the Pathfinder company are not inferior in popularity. However, consumer products and travel options predominate in the range of products offered to the buyer.

The tiles used both in heating and in the preparation of simple dishes are quite justified; mini burners from spray can.

Excellent characteristics from consumers received gas heaters with the Aeroheat logo. This equipment attracts with reliability, justified by the use of high-quality components, and affordable cost. Tiles and gas-fired burners from Dikson and Sibiryachka have proven themselves well.

The list of decent gas heaters from foreign suppliers is headed by gas burners and stoves from the South Korean company Kovea. The brand’s products are actively used in small workshops, at painting and construction sites, on camping trips and fishing.

To equip the workshops, gas heaters from the Italian company Sistema are more often used. Models from South Koreans Hyundai, Italian gas stoves Bartolini, which can be used both at home and in the office, are actively in demand. Reliability and stable operation are distinguished by the Swedish Timberk stoves, Chinese Ballu equipment.

Conclusions and useful video on the topic

The author of the following video will tell you in detail about the principle of operation and advantages of IR gas burners:

Details of the organization of infrared heating are presented in the following video:

The steps for installing a ceiling-mounted gas heating appliance are shown here:

In the Russian Federation, various types of infrared burners are produced, including wind-resistant models. The range offered by the company allows you to choose a device for heating outdoor and indoor areas.

It is important before buying to decide for what purpose and in what conditions the equipment will be used, and then choose either a more productive or durable model that is not afraid of repeated movements.

Heating elements for heating: types, principle of operation, rules for the selection of equipment

Heating elements for heating: types, principle of operation, rules for the selection of equipment  Expansion tank for closed heating: operating principle and device + how to choose and install in the system

Expansion tank for closed heating: operating principle and device + how to choose and install in the system  Gas heat generators for air heating: types and specifics of gas equipment

Gas heat generators for air heating: types and specifics of gas equipment  Infrared heating of a private house: an overview of modern infrared heating systems

Infrared heating of a private house: an overview of modern infrared heating systems  Collector for heating: principle of operation, installation and connection rules

Collector for heating: principle of operation, installation and connection rules  Selection of a circulation pump: device, types and rules for choosing a pump for heating

Selection of a circulation pump: device, types and rules for choosing a pump for heating  How much does it cost to connect gas to a private house: the price of organizing gas supply

How much does it cost to connect gas to a private house: the price of organizing gas supply  The best washing machines with dryer: model rating and customer tips

The best washing machines with dryer: model rating and customer tips  What is the color temperature of light and the nuances of choosing the temperature of the lamps to suit your needs

What is the color temperature of light and the nuances of choosing the temperature of the lamps to suit your needs  Replacement of a geyser in an apartment: replacement paperwork + basic norms and requirements

Replacement of a geyser in an apartment: replacement paperwork + basic norms and requirements