How to assemble and install a do-it-yourself sandwich chimney: installation instructions

The chimney sandwich has many advantages: ease of construction, safety, aesthetic appearance. Why not try to assemble a chimney sandwich with your own hands? As practice shows, it is really quite simple. And everyone will be able to lay down such a chimney as a designer.

For this work, knowledge of the design of the chimney and its installation will be required - it is this material that we examined in detail in our article. We picked up photos and diagrams describing the main elements of the chimney system, gave step-by-step instructions for assembly and installation.

And also supplemented the material with useful tips for improving traction and a video showing the process of installing a chimney in a country house.

The content of the article:

- Pros and Cons of Using a Chimney Sandwich

- The material from which the pipes are made

- The effect of fuel on the operation of the chimney

- Structural elements and their features

- How to choose the required diameter of the chimney?

- Installation of a sandwich system for smoke exhaust

- What to do to improve traction?

- Operation of chimney sandwich systems

- Conclusions and useful video on the topic

Pros and Cons of Using a Chimney Sandwich

Disadvantages of chimneys assembled from sandwich pipes:

- violation of sealing after a certain number of heating and cooling cycles;

- Compared to a brick structure, a chimney sandwich has a higher cost;

- the service life is about 15 years, while traditional chimneys made of refractory bricks serve 10 years more.

This short service is mainly due to the use of low-quality materials in production.

Choosing products from a trusted brand is the first thing that can be done for the long and successful operation of the chimney.

The advantages of a chimney sandwich are as follows:

- Insulated walls. Thanks to thermal insulation, even a chimney placed outside does not lose traction. Laminated walls prevent the cooling of the combustion products, which are faster discharged through the chimney, to prevent the condensation and soot from actively forming.

- Simple installation. Having studied the principles of building chimneys, even a beginner can assemble them.

- Variety of options. To assemble the structure, straight and angular modules are produced. The chimney can be led up or into the wall, it can go around the rafter system, various architectural elements.

- Minimum soot settling. Due to the smooth surface of the pipes, ash and soot are more quickly released into the atmosphere and accumulate more slowly.

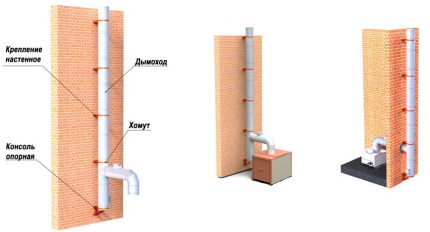

In addition, the sandwich system has a relatively low weight, which means that it is easier to create a support for it and does not require the construction of a special foundation, like for a brick chimney. It can be attached to ceilings and walls, installed directly on heating equipment.

Compared to single-wall, sandwich chimneys almost do not form condensate and are fireproof.

The material from which the pipes are made

For different heating devices and fuels, their type of steel is selected. It should be highly alloyed and stainless, suitable for the manufacture of chemically resistant and refractory flues.

When various substances are burned in a chimney, chemically active substances can accumulate: sulfuric acid, sulfur, hydrochloric acid. In addition, the temperature during combustion of various fuels can vary greatly.

When heated with wood or gas, it does not rise above 450 ° C; when coal is burned, it can reach 700 ° C. Metals react differently to these indicators. therefore choosing a smoke exhaust system, pay attention to the main characteristic - the quality and property of steel.

Option # 1 - Stainless Steel with Alloy Additives

The main brands of steel alloys that are used for the production of chimney sandwich:

- Titanium Stabilized Stainless Steel (AISI 321). Used for wood burning equipment. It is unstable to corrosion in sulfur-containing environments. Permissible operating temperature is 600-800 ° C.

- Molybdenum Stabilized Stainless Steel (AISI 316). Installation of a chimney sandwich from this steel grade is carried out for heating systems that run on wood, gas, diesel fuel. The metal is acid resistant, characterized by increased corrosion resistance, aggressive environments of various nature.

- Heat Resistant Steel (AISI 304). The inclusion of chromium and nickel makes the steel insensitive to elevated temperatures and acidic environments. It is used for the production of chimneys with a high temperature of exhaust gases - about 1000 ° C. At a temperature of 600-800 ° C, it is prone to loss of viscosity and ductility, which leads to embrittlement.

- Widespread brands AISI 409 and 430 weakly resist high temperatures and effects of acids. Most of the Chinese products and part of the domestic are made from steel of these grades.

Checking the grade of steel is visually impossible. When buying, you can verify the markings on the product itself or try to approximately determine the quality using a magnet.

A low-quality material will attract a magnet, metal with the addition of alloying additives - no.

Option # 2 - ferrous metal for chimneys

By itself, the black metal wears out quickly - it oxidizes and burns out. Therefore, to protect it, special enamel is used. This increases the resistance to acidic conditions.

Enamel can serve for a long time at a temperature of no more than 400 ° C and can withstand a short-term increase to 750 ° C.

Enameled pipes are used to divert combustion products from heating columns, stoves, heating boilers, fireplaces. Unlike steel, they can be painted in various colors. This allows you to select the right shades for the interior or facade of the house.

Option # 3 - Combined Chimney Sandwich

To reduce the cost of production, enterprises are trying to use cheaper materials. If the inner pipe is made of expensive stainless steel, and the outer one is made of galvanized or enameled metal, this has little effect on the service life of the product.

Worse, if vice versa: stainless steel is used outside, and cheap low-quality material is hidden inside. Such a pipe with intensive use can last a year and fail, which will entail new costs for materials and installation.

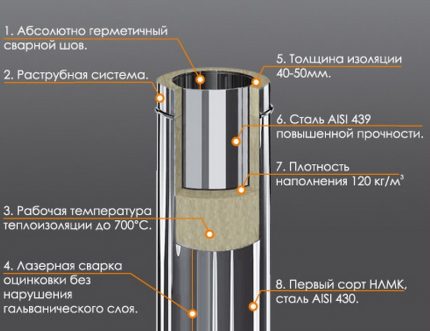

Between the two chimney sandwich pipes there is a layer of insulating material that retains heat inside and thereby maintains a good draft. As insulation, basalt or ceramic wool is used - fibrous materials with the highest fire resistance class.

Basalt wool can withstand temperatures up to 600 ° C, ceramic - up to 1000 ° C. Both materials have good thermal insulation properties. Apply a layer of insulation 25-50 mm. For a chimney that is mounted externally, the larger it will be, the better.

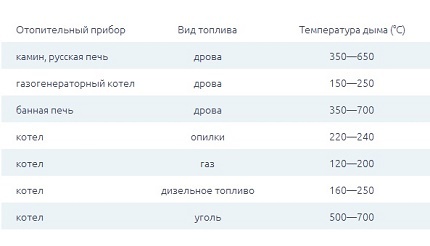

The effect of fuel on the operation of the chimney

Below is a table that will help determine how to choose the right chimney for different types of heating equipment so that it works longer.

By installing a sandwich chimney for gas equipment, you can do with a cheaper design option. But for a Russian or sauna stove, it is better not to save and choose a system whose quality is beyond doubt.

Structural elements and their features

A variety of products allows you to perform complex tasks for the construction of a chimney sandwich.

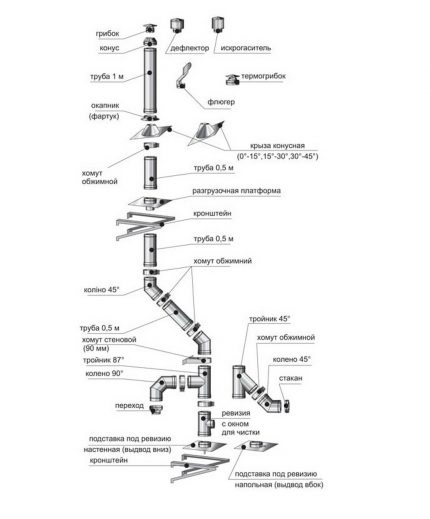

The main structural elements of the chimney channel are:

- Straight pipe sections. Segments with a diameter of 80-600 mm, length up to 1 m. The ideal design of the chimney is straight, but in practice this is difficult to achieve.

- Knees and tees. They are used if it is necessary to remove the chimney through the wall, outside the building, or bypass the structural elements of the house - beams, rafters. Sometimes for turns (especially straight, 90 °) tees with revision are used - they allow you to clean the chimney in hard-to-reach places. They are installed and strengthened with brackets so that they do not bear the weight of the superior structure.

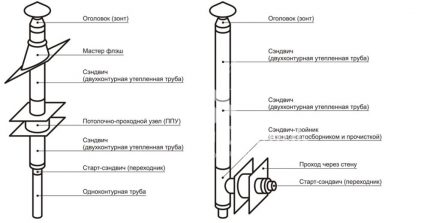

- Passage pipe. It isolates the pipe from the partition walls, serves as a fixture for the chimney.

- Roofing. It is a metal cone that is mounted on the roof at a certain angle. Helps to pass a pipe through the roof without violating its tightness and increasing fire safety. Instead, a special silicone sealant can be used, which serves as the best protection against leakage.

In addition to the above elements, there are many more devices for mounting a chimney from a sandwich pipe, as well as its further operation.

How to choose the required diameter of the chimney?

The choice of the diameter of the chimney is carried out based on data on the power of the boiler.

For low-power heating systems with less than 3.5 kW, pipes with a diameter of 8 cm are used, for boilers with indicators of no more than 5.2 kW, pipes with a diameter of 9.5 cm and over 5.2 kW are used. Chimney narrowing is not allowed, and broadening, on the contrary, can be carried out.

Another indicator that affects the diameter of the chimney is the thickness of the insulating layer. It can be 25-100 mm. The larger it is, the better it shows its properties, but its value also increases. The thickness of the metal itself used for the production of pipes can be up to one millimeter.

If it is necessary to add, replace or modernize any section of the chimney, the consumer may be in a difficult situation. Elements from different brands are not able to provide a tight joint.

When acquiring the missing parts, it is better to find (order) components of the same brand as the rest of the design.

Installation of a sandwich system for smoke exhaust

Before installing the structure, you must carefully familiarize yourself with the technical documentation, safety rules.

Be sure to carry out all measures to prevent fire during the operation of the chimney.

Step # 1 - assembly of chimney elements

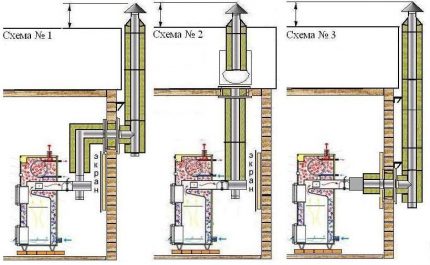

Installation of the structure always starts from the bottom up. Sandwich chimneys must not be connected directly to a heating device.

First, install a special adapter or single-wall steel pipe with a length of half a meter.

If it is planned to bring the pipe directly into the wall, then install a horizontal branch with a slight slope of 2 °.

A section of an uninsulated pipe can be short, or long, if one expects a large heat transfer. Walls and structures located near it must be protected by a screen or casing.

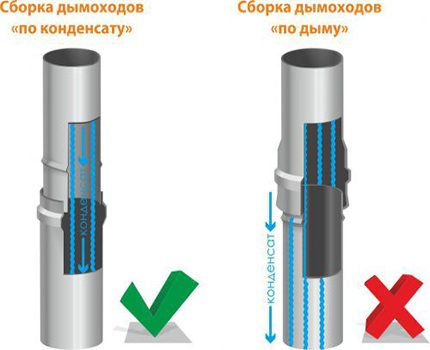

Install it “by smoke”, that is, put it on top of the pipe of the heating device and additionally protect the joint with a heat-resistant sealant.

The chimney sandwich element can be connected to the heating device through an adapter - a double-circuit pipe, the lower part of which is installed “by smoke” and the upper “by condensate”.

All subsequent pipes will be mounted “by condensate”, which will prevent its leakage and will protect it from damage to the insulation layer.

Places of absolutely all joints are fastened with couplings. Near each junction install a clampdesigned to mount the system to the wall.

To prevent lateral displacements of the structure, wall brackets are used at every two meters, and support tees are used. The system is attached to the wall using consoles or support platforms every five meters.

Step # 2 - passing ceiling and wall ceilings

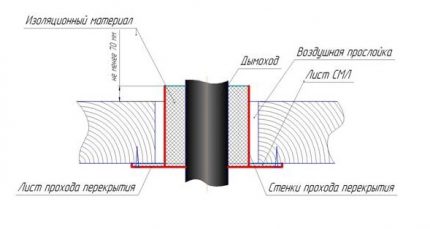

Even the fact that the sandwich chimneys have an insulating layer does not mean that their surface cannot heat up sufficiently. Therefore, it is forbidden to place them without additional insulation near combustible materials (wood, plastic, etc.).

The joints of the sandwich pipes for chimneys during their installation and operation should not coincide with the passage in the ceiling or wall.

The diameter of the hole in the wall or ceiling is cut 250 mm more than the diameter of the outer pipe.

Make it rounded or rectangular. Heat-resistant material is laid in the free space, which is hidden with decorative plates.

To pass through the ceiling and, especially, through easily flammable materials, a special passage unit is also used. An air gap is left between the outer contour and the inner surface of the assembly.

When passing through a ceiling or wall of low-flammable material, an unloading platform can be used instead of the passage unit. She will play the role of additional support.

Step # 3 - passing the system through the roof

Upon withdrawal chimney through the roof, its tightness is broken. To strengthen the pipe, fence it off from flammable roof elements and eliminate the possibility of leaks in the roofing, use special devices: conical rats, silicone seals.

These parts have standardized tilt angles, choose them, taking into account the parameters of the roof.

When placing the pipe, it is calculated so that the distance to flammable materials is not less than 37 cm. To protect against water entering the roof, an apron is installed on top of the rat. Its edges are brought under the roofing.

Step # 4 - placing the structure over the roof

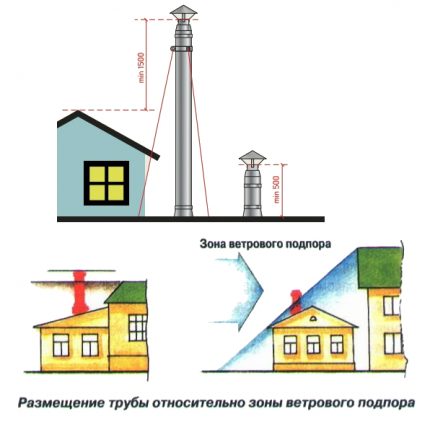

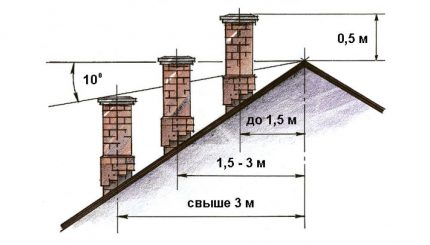

The height of the chimney pipe depends on the distance between the base of the pipe and the ridge, but not less than half a meter above the ridge, 1.2 m above the surface of a flat roof or 2 m with a combined roof. If the tip of the ridge is one and a half to three meters away, then it should be placed higher or opposite the ridge.

If the distance is 3 m or more, then it is allowed to place the tip no lower than the line that forms if you conditionally draw a horizontal line from the ridge and measure down an angle of 10 °.

In the presence of a closely located building, the top of the chimney should rise one and a half meters above its roof.

A pipe of this size must be further strengthened with stretch marks.

If combustible material was used to cover the roof, then in the chimney place spark arrester. The chimney design is completed by a cone-shaped head. Sometimes they protect him fungus or deflectorother devices.

What to do to improve traction?

The principle of operation of the chimney is based on the creation of draft - the effect of ventilation, which occurs due to the temperature difference in the middle and outside of the channel.

The density of warm air in the chimney system is less than cold outside, and this leads to a pressure difference. Due to this difference, cold air enters the inside of the furnace, and hot air rises through the chimney and goes outside.

Causes of Poor Combustion Products

A simple way to determine the presence or absence of draft is to visually assess the presence of smoke in the room or to identify the problem by the color of the fire.

Orange shades indicate insufficient traction, white flames and hum in the pipe mean excessive. Sometimes traction can change direction for a short time.

Not taking into account the uncleaned and clogged chimney in time, the reasons why it arises in it reverse thrustfollowing:

- incorrect calculation of the ratio of boiler power and pipe parameters;

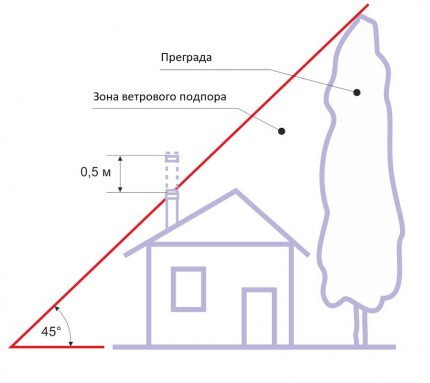

- adverse weather conditions - fog, rain, heat, strong wind;

- a large number of narrow sections and turns in the design of the chimney;

- the high location of the ridge in relation to the tip of the chimney or nearby tall buildings;

Even for the formation of normal traction, a lack of supply air and insufficient ventilation in the house.

How to prevent traction problems?

Here are some recommendations on how to assemble a chimney sandwich so that the heating device does not become a source of soot and soot in the house:

- the height of the structure should be equal to or greater than five meters;

- it is preferable to build a direct chimney - without bends and turns;

- turns (no more than three) are made at an angle of 45 °;

- an almost horizontal section of the chimney (with a slope of 2 °), but not more than one meter, can leave the boiler.

If during operation of the chimney there are problems with the exhaust of smoke, resort to the installation of special devices that enhance traction.

It could be:

- Deflector. It works on the principle of reducing pressure during the passage of air obstacles. It works effectively in windy weather, but in quiet weather it can, on the contrary, interfere with smoke removal.

- Stabilizer. It is an additional element that has the shape of an umbrella and is worn on top of the pipe. From below, through an open area, air enters, increasing traction.

- Rotary turbine. It works using wind power: rotating in one direction, it creates a vacuum in the air above the channel. In calm weather, it is not effective.

All of these devices are not a panacea, especially if the chimney is not originally properly constructed.

Operation of chimney sandwich systems

After installing the chimney, a test firebox should be carried out to check the tightness of the joints, make sure that adjacent structures and materials do not heat up.

The first use of the system may cause slight smoke and a specific smell from heating residual oil, sealant, dust on the surface of the pipes.

Proper operation requires timely soot removal. When cleaning, do not use any detergents. An overview of the best cleaning products and methods is discussed in our other article.

It is better if it will be carried out by an organization that has a special license that gives the right to carry out this kind of work.

Conclusions and useful video on the topic

More information on how to correctly assemble a reliable chimney from modular sandwich pipes can be viewed in the video:

Self-installation of the chimney from a sandwich pipe will require the user to study some of the nuances and subtleties. But then, having done the job correctly, you can be sure of the safety of your family and yourself.

Do you have experience building a chimney from a sandwich labor? Did you do the installation of such a chimney with your own hands? Share your experience with beginner home masters - write in the comment block what difficulties you had to face during installation, how long you have been using it and how to care for your chimney.

Do-it-yourself gas bath stove: manual for the installation and installation of a gas stove

Do-it-yourself gas bath stove: manual for the installation and installation of a gas stove  DIY miracle oven for a garage in a diesel fuel: step-by-step instructions for the construction

DIY miracle oven for a garage in a diesel fuel: step-by-step instructions for the construction  How to make a Buleryan oven with your own hands: step-by-step instructions on how to make

How to make a Buleryan oven with your own hands: step-by-step instructions on how to make  Do-it-yourself gas stove from a gas cylinder: diagrams, drawings + step-by-step guide

Do-it-yourself gas stove from a gas cylinder: diagrams, drawings + step-by-step guide  How to make a potbelly stove on waste oil with your own hands: a review of the best homemade products

How to make a potbelly stove on waste oil with your own hands: a review of the best homemade products  How to make heating on waste oil with your own hands: schemes and principles of arrangement

How to make heating on waste oil with your own hands: schemes and principles of arrangement  How much does it cost to connect gas to a private house: the price of organizing gas supply

How much does it cost to connect gas to a private house: the price of organizing gas supply  The best washing machines with dryer: model rating and customer tips

The best washing machines with dryer: model rating and customer tips  What is the color temperature of light and the nuances of choosing the temperature of the lamps to suit your needs

What is the color temperature of light and the nuances of choosing the temperature of the lamps to suit your needs  Replacement of a geyser in an apartment: replacement paperwork + basic norms and requirements

Replacement of a geyser in an apartment: replacement paperwork + basic norms and requirements