How to calculate gas consumption for heating a house in accordance with the norms

The determination of the amount of costs for centralized or autonomous heating of a private house is carried out at the construction design stage, or before choosing the type of energy carrier or the optimal model of a boiler unit.

What factors are taken into account when calculating the gas flow rate for heating a house, and how, without resorting to the services of specialists, to determine the average flow rate based on a simplified methodology, we will consider in our article.

The content of the article:

Determining factors of gas mixture consumption

Heating a house using natural gas today is considered the most popular and convenient. But in view of the rise in price of "blue fuel", the financial costs of homeowners have increased significantly. And therefore, most zealous owners today care about the average gas consumption for heating a house.

The main parameter in calculating the fuel consumption spent on country house heatingare the heat loss of the building.

Well, if the owners of the house took care of this even during the design. But in most cases, in practice, it turns out that only a small part of homeowners know the heat loss of their buildings.

The consumption of the gas mixture directly depends on the efficiency and power of the boiler generator.

No less influence is also exerted by:

- climatic conditions of the region;

- design features of the building;

- number and type of installed windows;

- area and height of ceilings in the premises;

- thermal conductivity of applied building materials;

- quality of insulation of the exterior walls of the house.

Keep in mind that the recommended rated power of the installed unit demonstrates its maximum capabilities. It will always be slightly higher than the operating indicators of the unit, functioning in normal mode when heating a particular building.

For example, if the passport boiler power 15 kW, the system will really function effectively with a thermal power of about 12 kW. The power reserve of about 20% is recommended by specialists in case of accidents and in excess of cold winters.

Therefore, when calculating fuel consumption, one should focus on real data, and not be based on maximum values calculated for short-term operation in emergency mode.

Average flow rate calculator

The nominal gas flow rate for the past heating period is not so difficult to calculate. It is only necessary to take the meter readings every month. After the season, summarize the monthly readings. Then calculate the arithmetic mean value.

If you need to know the nominal values at the design stage of the house, or when choosing an effective, but at the same time economical heating equipment, you have to use the formulas.

To obtain approximate calculations, the specific heat consumption is determined in two ways:

- Focusing on the total volume of heated rooms. Depending on the region, 30-40 watts are allocated for heating one cubic meter.

- According to the total square of the building. They take as the basis that 100 W of heat is spent on heating each square of the area of the rooms, the wall height of which reaches an average of 3 meters, on average. When determining the value, they also focus on the region of residence: for southern latitudes - 80 W / m2, for the north - 200 W / m2.

The main criterion, which is mandatory to be guided by in the calculations, is the necessary heat capacity to ensure conditions for high-quality heating of the premises and replenishment of its heat losses.

The basis of technological calculations is the average proportion at which 1 kW of thermal energy is spent on 10 squares of area. But it is worth considering that such an averaged approach, although convenient, is still not sufficiently able to reflect the real conditions of your construction, taking into account the climatic region of its location.

Having correctly calculated the estimated fuel consumption, you can clarify for yourself what measures should be taken to reduce its consumption. As a result, reduce the regular payments for the consumed “blue fuel”.

Network gas for heating

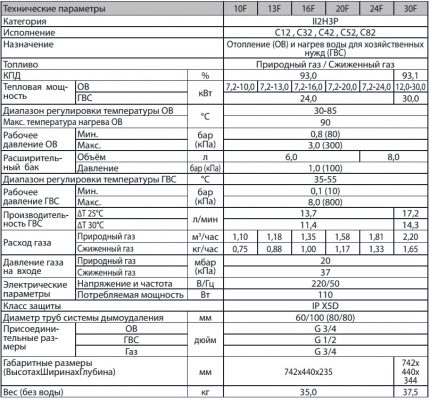

G20 gas mixture flows to private houses from a centralized highway. In accordance with the adopted standard DIN EN 437, the indications of the minimum value of specific heat during the combustion of fuel grade G 20 is 34.02 MJ / cubic meter.

If a highly efficient condenser boiler is installed, the minimum specific heat for “blue fuel” of category G 20 is 37.78 MJ / cu. meter.

The formula for calculating fuel consumption

To determine the gas flow, taking into account the energy potential embedded in it, a simple formula is used:

V = Q / (Hi x Efficiency)

Where:

- V - the desired value that determines the gas flow to generate thermal energy is measured in cubic meters / hour;

- Q - the value of the estimated thermal power spent to heat the building and ensure comfortable conditions is measured in W / h;

- Hi - the value of the minimum value of specific heat during combustion;

- Efficiency - boiler efficiency.

The efficiency of the boiler generator shows the efficiency of the use of the thermal energy generated during the combustion of the gas mixture, which is directly used for heating the heat carrier. It is a passport value.

In the passports of modern boiler units, the coefficient is indicated by two parameters: the highest and lowest heat of combustion. Both values are prescribed through the fractional line “Hs / Hi”, for example: 95/87%. To obtain the most reliable calculation, they take the basis indicated in the "Hi" mode as the basis.

The value “Hs” indicated in the table defines the highest indicator of the calorific value of gas. It is indicated in the table for the reason that the water vapor released during gas combustion is also capable of converting latent thermal energy. If you correctly use this thermal energy, you can increase the total return on the spent fuel.

The work of a new generation of boilers — condenser units — is built on this principle. In them, due to the conversion of steam into an aggregate liquid state, about 10% of heat is additionally generated.

In addition to gas of the G20 brand, an analog of the second group of the G25 brand can also be used for domestic purposes. G20 gas is produced from Siberian fields, and G25 is supplied from Turkmenistan and the Volga region. The difference between the two is that G25 emits 15% less heat when burned.

You can specify what type of gas “flows” in the mains at the gas supply company in your region.

Example of calculating network gas consumption

We propose to consider an example of calculating the gas consumption for heating a country cottage, the initial data of which have the following parameters:

- the area of the premises reaches 100 square meters. meters;

- recommended power of the heat generator - 10 kW;

- The boiler efficiency reaches 95%.

To simplify the calculation, the joules are converted to another unit of measure - kilowatts. So, provided that 1 kW = 3.6 MJ, the heat of combustion of gas grade G 20 will be 34.02 / 3.6 = 9.45 kW.

It is also worth considering that the recommended heat generator capacity, indicated as 10 kW, is required only for space heating under the most adverse conditions. In fact, throughout the heating period, the number of such adverse days will be calculated in units.

On the remaining days of the cold season, much less power is required to heat the building. Therefore, to obtain the correct calculations, as well as to determine the average and not the peak consumption of “blue fuel”, the boiler power readings are taken not “10 kW”, but “half” 5 kW.

Substituting the obtained data in the formula, perform the calculations: V = 5 / (9.45 x 0.95). It turns out that for heating a cottage with an area of 100 squares, the gas consumption leaves 0.557 cubic meters / h.

Based on the data obtained by simple calculations, it will not be difficult to calculate the gas consumption for the whole heating season, which lasts about 7 months in regions of medium latitude:

- For a day it is 0.557 x 24 = 13.37 m3.

- For a month 13.37 x 30 = 401, 1 m3.

- For the heating season lasting 7 months 401.1 x 7 = 2807, 4 m3.

Knowing the price of one cubic meter of “blue fuel”, it will not be difficult to plan both monthly expenses and “accounting” for the entire functioning of the heating system.

The consumption of liquefied propane-butane mixture

Not all owners of country houses have the opportunity to connect to centralized gas pipeline. Then get out of the situation using liquefied gas. It is stored in the foundation pits. gas tanksand replenish, using the services of certified companies that supply fuel.

If liquefied gas is used to heat a country house, the calculation formula is taken as the basis. The only thing - it is necessary to consider that bottled gas is a mixture of brand G30. In addition, the fuel is in an aggregate state. And therefore, its consumption is considered in liters or kilograms.

The formula for calculating the consumption of a combustible mixture

A simple calculation will help to estimate the costs of a liquefied propane-butane mixture. The initial data for the construction are the same: a cottage with an area of 100 squares, and the efficiency of the installed boiler is 95%.

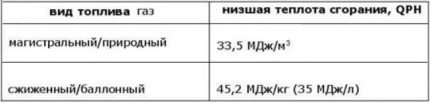

When performing the calculation, they are guided by two significant physical characteristics of the liquefied mixture:

- the density of the balloon gas is 0.524 kg / l .;

- the heat released during the combustion of one kilogram of such a mixture is equal to 45.2 MJ / kg.

To facilitate calculations, the values of the released heat, measured in kilograms, are converted to another unit of measurement - liters: 45.2 x 0.524 = 23.68 MJ / l.

After that, the joules are converted into kilowatts: 23.68 / 3.6 = 6.58 kW / l. To get the correct calculations, the same 50% of the recommended unit power is taken as the basis, which is 5 kW.

The obtained values are substituted into the formula: V = 5 / (6.58 x 0.95). It turns out that the consumption of the fuel mixture brand G 30 is 0.8 l / h.

Example of calculating the flow of liquefied gas

Knowing that in one hour of operation of a boiler generator, an average of 0.8 liters of fuel is consumed, it will not be difficult to calculate that one standard cylinder with a filling volume of 42 liters is enough for approximately 52 hours. This is a little more than two days.

For the entire heating period, the flow rate of the combustible mixture will be:

- For a day 0.8 x 24 = 19.2 liters;

- For a month 19.2 x 30 = 576 liters;

- For the heating season lasting 7 months 576 x 7 = 4032 liters.

For heating a cottage with an area of 100 squares, you will need: 576 / 42.5 = 13 or 14 cylinders. For the entire seven-month heating season, 4032 / 42.5 = 95 to 100 cylinders will be needed.

A large amount of fuel, taking into account transport costs and creating conditions for its storage, will cost not cheap. But still in comparison with the same electric heating such a solution to the question will still be more economical, and therefore preferable.

Ways to reduce consumption

The main reason for significant heat loss, which leads to inefficient use of the heat generated by the boiler, is the insufficient insulation of the structural elements of the house. Through “cold bridges” up to 40% of heat is wasted in vain.

In order not to waste money every time, heating the street, it is better to spend money on quality building insulation. Believe that the cost of it will fully pay off in 3-4 years.

Thermal insulation of a house includes:

- Wall insulation. The easiest to implement and affordable option is the installation of polystyrene foam panels. The thickness of the panels is chosen, focusing on the climatic conditions of the region of construction, the thickness of the walls of the building and the type of material used in their construction.

- Insulation of the roof or attic floor. For these purposes, wood sawdust, mineral wool or tiled polystyrene foam is used. Insulating material produced in the form of plates is mounted on the inner walls of the attic space or placed between the floor beams.

- Floor insulation. Good thermal insulation is needed not only concrete, but also wooden structures. Bulk and plate materials such as expanded clay and expanded polystyrene are used to form a thermally insulating layer.

- Window replacement. The most reliable shield that does not allow the penetration of cold inside heated rooms will be PVC windows with high-quality double-glazed windows. They are made for a specific window. Due to this, they hermetically close the window opening, reliably protecting households not only from the "leak" of heat, but also the penetration of street noise.

Proper thermal insulation device allows you to reduce heat loss to minimum values.

Among the additional measures to improve the efficiency of thermal return, experts include:

- Radiator Equipment thermostatic appliances. Thermal heads will maintain the necessary comfortable temperature in the rooms.

- In addition to radiators, install convectors with a directional circulation function. They in the area of the openings will create thermal curtains from the heated air.

- Connecting equipment that allows you to program optimal heating modes. The installation of chronometric thermostats is effective if there are rooms in the house that are empty for several days, which does not make sense to heat intensively.

The costs of acquiring and installing automation will more than pay off already during the first heating season.

And finally, it's worth reviewing if the system is too busy. It is possible that it produces excess heat. And it is likely that without compromising the comfort of households, you can reduce the temperature in the rooms by a couple of degrees.

At first glance - a trifle. But, considering the situation on a scale of at least one month, and even more so the heating season, such a decision can have a beneficial effect on the wallet.

Conclusions and useful video on the topic

One of the options for calculating the consumption of network gas:

Example flow rate for heating with liquefied gas:

Simple ways to reduce gas costs will be discussed in the following video:

The average value of the calculation will be useful for calculating material costs exclusively for heating the building. When planning to use gas appliances or a stove during the heating season, the data should be adjusted.

If after studying the material you have questions about gas flow calculations, you can ask them in the box below. In addition, if inaccuracies were noticed or you would like to supplement the material, please leave your comments.

Gas consumption for heating a house 100 m²: calculation features for liquefied and natural gas + examples with formulas

Gas consumption for heating a house 100 m²: calculation features for liquefied and natural gas + examples with formulas  The average gas consumption for heating a house is 150 m²: an example of calculations and an overview of heat engineering formulas

The average gas consumption for heating a house is 150 m²: an example of calculations and an overview of heat engineering formulas  Gas consumption for heating a house 200 m²: determination of costs when using main and bottled fuel

Gas consumption for heating a house 200 m²: determination of costs when using main and bottled fuel  Thermal calculation of a heating system: how to correctly calculate the load on a system

Thermal calculation of a heating system: how to correctly calculate the load on a system  Calculation of the heating system of a private house: rules and examples of calculation

Calculation of the heating system of a private house: rules and examples of calculation  Gas heating in an apartment: how to make an individual circuit in an apartment building

Gas heating in an apartment: how to make an individual circuit in an apartment building  How much does it cost to connect gas to a private house: the price of organizing gas supply

How much does it cost to connect gas to a private house: the price of organizing gas supply  The best washing machines with dryer: model rating and customer tips

The best washing machines with dryer: model rating and customer tips  What is the color temperature of light and the nuances of choosing the temperature of the lamps to suit your needs

What is the color temperature of light and the nuances of choosing the temperature of the lamps to suit your needs  Replacement of a geyser in an apartment: replacement paperwork + basic norms and requirements

Replacement of a geyser in an apartment: replacement paperwork + basic norms and requirements

I have long wanted to know how gas consumption is calculated, since I never understood where such large numbers come from for paying utility bills at the end of the month. I highlighted a couple of key points from the article, now I am well versed in this issue and understand what needs to be paid. The calculation system, it turns out, is not so complicated as I expected.

It seems to me that all these calculations are really averaged. And in such a case, the error is very large. Why am I saying that?

Because no one will tell you the exact figure, what kind of gas is there in the highway. Here, for example, I have the same kettle on the same burner that boiled the same in 7 minutes, but now you can go and get some bread and return while it boils. Dilute the gas with air, the counter shakes like crazy, but there is no heat.

Nikolai Yuryevich, hello. You yourself understand, even from the course of chemistry, that air is not pumped into gas in such volumes, it would be an explosive mixture and we would hardly have talked with you now (although, perhaps, we would have talked thanks to bread 🙂

Rather, the quality of gas, especially in winter, is greatly reduced due to poor-quality drainage. In any case, if you are unsatisfied with the quality of the fuel supplied, you can contact the State Supervisory Authority, who will be required to carry out an audit in accordance with GOST 5542-87 “Combustible natural gases for industrial and domestic purposes. Technical conditions. "

However, if the verification of violations is not found, the examination will be paid from your pocket. Again, the gas supplying organization will be notified of the timing of the inspection in advance, that is, they will have time to put the gas in order for a certain period so as not to pay for the examination and losses.