DIY heat gun: manufacturing options for different types of fuel

With the help of heat guns, you can quickly increase the air temperature even in large rooms, so they are so successfully used for heating farms, greenhouses, warehouses and other industrial buildings.

But if you are looking for an inexpensive appliance for private use: heating a garage, appliances or drying finishing materials - a homemade product made from completely affordable components may be the solution. And how to properly assemble the heat gun with our own hands, we will consider in this article, offering you three simple options.

But first, we will deal with the main varieties of these devices and their features. We also pay attention to the rules of safe operation.

The content of the article:

Varieties of heat guns and their features

The principle of operation for all guns is almost the same - they draw in cold air, heat it and scatter it around the room in a warm stream. The main structural elements of the heat generators: housing, engine, fan (except for infrared devices) and a heating element.

The main difference between the devices, on which their power and productivity depends, is the energy source.

Consider the existing types of heat guns and the nuances of their operation.

Type No. 1 - liquid fuel units

The most powerful guns, widely used for industrial, construction and agricultural purposes, run on liquid fuel (diesel, diesel, gasoline, kerosene and even oil processing) The fuel ignites directly in the gun chamber and warms up the air pumped by the compressor to high temperatures.

Thanks to non-freezing fuel, such units are effective even in the open air at temperatures of -30 degrees and below.

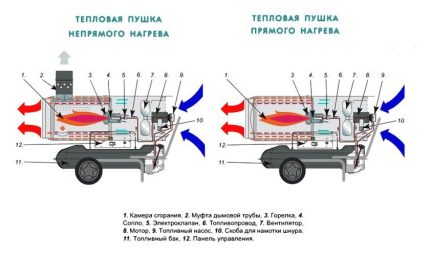

According to the type of heating, they are divided into:

- Direct-flow - the most powerful devices among all varieties of heat guns, which impress with their productivity. Their efficiency confidently reaches 100%, the maximum power is 220 kW, and the outlet air temperature is up to 400 degrees. But, despite such high efficiency, the use of such guns is limited to non-residential buildings, where there are no people or other living creatures, and open building sites. And all because because with direct heating in a hot stream of air remain unhealthy substances.

- Aggregates indirect heating - have a closed combustion chamber, equipped with a discharge chimney, so they can be used in crowded rooms. And although the efficiency of such devices will be significantly lower than that of direct-flow (about 60%), but due to the minimum power consumption and low cost of fuel, they are popular both on an industrial scale and for private use.

Depending on the availability and quality of filters, as well as other structural nuances, there are diesel or multi-fuel guns.

The former prefer “winter” DP, kerosene and diesel fuel, the latter are well aware of cheaper types of fuel, including used oil, which is why they are especially in demand when heating workshops, gas stations and other premises where there is an abundance of this fuel.

An overview of the best manufacturers of guns for direct and indirect heating, we gave in this article.

Type No. 2 - gas heat generators

Gas heat guns can play the role of stationary heaters and connect to the main pipeline with natural gas. But you can also use them as mobile structures, if you stock up on a cylinder with liquefied propane / butane, which is desirable to equip gearbox for safe operation.

Like liquid fuel, gas guns are divided into devices for direct and indirect heating.

The principle of operation of the gas unit:

- The flow of gas enters the burner in the chamber.

- Ignition ignites the fuel and heats the heat exchanger to a high temperature.

- The fan circulates the flow of cold and hot air.

- Gas combustion products either remain in the stream (with direct heating) or are discharged into the chimney.

The disadvantages of the device include loud operation (loud pops are connected to the fan noise when connected to the cylinder) and the need for regular ventilation of the room.

The power of gas heat generators reaches 140 kW, which is much higher than electrical appliances, but inferior to diesel units. The main advantages are fast room heating and low fuel costs.

View No. 3 - electric heat guns

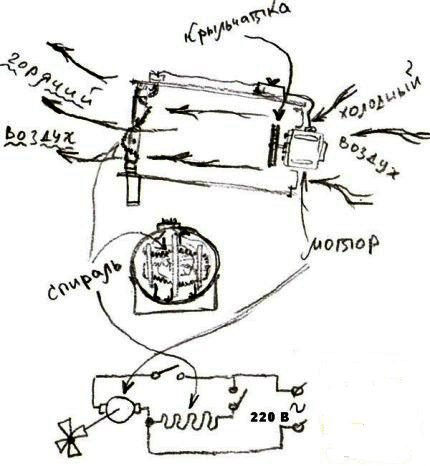

Inside the metal case of the device is an open spiral or TENthat converts electric current into thermal energy. Thanks to the fan, the air circulates along the heating element, increases its temperature and leaves the gun’s “barrel” already warm.

Advantages of electric heaters:

- No harmful fumes - the device is environmentally friendly and does not pollute the air with fuel exhausts.

- Accessibility of the energy source - for low-power devices, a conventional 220 W power supply is sufficient, but devices with characteristics of 5 kW or more will require a three-phase network.

- Low price - electrical appliances belong to the most budget segment of heat guns.

- Ability to work at low temperatures.

- Do not need refueling.

In addition to being “tied” to electricity, one of the drawbacks is the low power of the device (from 1 to 45 kW) - for outdoor areas or poorly insulated buildings they are ineffective. Also, the heating elements greatly dry the air, so the room will have to be regularly ventilated. Well, the main minus of any electrical engineering is the impressive electricity bills.

View No. 4 - water and infrared devices

And we will finish the review of the assortment with two varieties of heat generators, which have significant structural differences from other guns.

In infrared devices, thermal energy is converted into a stream of infrared radiation, which heats the air a second time, because the bulk of the heat goes to the objects where the “barrel” is directed. Therefore, such heaters are widely used in severe frosts to start equipment, as well as at a construction site - for drying materials, screeds, plasters, paints and varnishes. The device itself works on DP or diesel fuel.

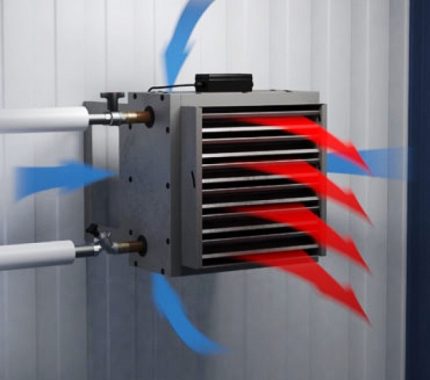

The design of the water gun is supplemented by a heat exchanger with hot water. In fact, it’s all familiar air heaters or an additional battery with a fan that connects to the central heating system.

The essence of the device is simple - the circulating hot water gives its heat to the pipes of the heat exchanger, they heat the air, and the fan distributes it throughout the room.

Options for self-manufacturing heat guns

If it is better to purchase a water and infrared unit in a ready-made form, then an electric, diesel and even gas heater is quite affordable to do it yourself.

Let us consider in more detail the sequence of work on the manufacture of simple low-powered guns.

DIY # 1 - do-it-yourself gas cannon

To heat a garage, a country house or a small greenhouse, you can make a thermal unit that will be connected to a gas cylinder. But this will require a grinder, a drill with drill bits for metal and a welding machine.

Have you ever been involved in welding? In this case, we recommend educational program for electric welding for beginners.

To assemble the structure, you will need such elements:

- thick-walled refractory pipe, which will play the role of a body, 1-1.5 m long and up to 18 cm in diameter;

- a second metal pipe with a smaller diameter for the combustion chamber;

- metal plate strips 2 mm thick - 4-8 pcs;

- burner (it is possible from a gas boiler or column);

- a hose with a reducer for adjusting the gas supply;

- a fan, the size of which coincides with the inner diameter of the future case;

- fittings for legs or a pallet on which the gun will be placed.

Step-by-step instructions for manufacturing:

- In the pipe, you need to drill holes on both sides at a distance of 2-3 cm from the edge. The first is designed to supply gas, so its diameter must match the size of the hose. The second is for the outlet pipe with hot air, with a diameter of about 5 cm.

- A narrower pipe starts up inside the casing - the future combustion chamber.It is necessary to weld metal plates to it, which will securely fix the structure, and this “core" is installed so that its edge protrudes beyond the boundaries of a large pipe.

- Metal sheet grinder is cut, and then a circle of such a size is welded to hermetically close the end gap formed between the inner and outer pipe.

- Now a burner is installed in the combustion chamber (some craftsmen replace this with a metal nozzle from the shower, but it is better to use a factory part). Then an ignition hole is drilled and attached gas hose.

- The opening of the casing is closed on the second side by a fan, which is fixed with screws on a metal flange and welded to the pipe.

- For proper installation of the device, it is important to consider a stable base, for example, to make a frame structure of iron reinforcement.

After assembling the heat gun, you need to check the quality of the seams and the tightness of all joints (especially the gas hose). Only after that it is possible to do a trial run: light the burner through the ignition hole, open the fuel supply valve, make sure that the gas starts to burn and turn on the fan.

In addition, it is possible to equip the gun with a thermostat so that it stops when the room temperature reaches the programmed indicator (and, accordingly, turns on when the degree decreases).

And to control the power of the air flow will help the gate or a rotating flap installed between the homemade metal and factory fan flanges.

Homemade # 2 - an electric heater with a heating element

An electric mains heat gun is the easiest device to manufacture. True, due to the large consumption of electricity it is rarely used as the main heating, but this is a good option in order to reduce humidity and quickly warm up the room for spending the night in a country house or while working in a garage, workshop.

For manufacturing you will need:

- Billet for the case - it can be a sheet of galvanized metal with a thickness of 1 mm, an asbestos pipe, an old pan or other container with a diameter of up to 25 cm (it is better to focus on the size of the fan and the heater).

- A heating element.

- An electric motor with an impeller - depending on the size and power of the gun, it can be either a fan from a household hood, or an element from an old Soviet vacuum cleaner.

- A circuit breaker that opens and connects a network circuit.

- Pads for fixing the heater.

- Safety automatic devices - for a spiral on 25 A and for the engine on 6A.

First we make a case with a diameter of 20-25 cm - if it is a sheet of iron, it must be bent, giving the shape of a cylinder, welded or fixed with rivets. Inside the "barrel" is placed the heater and fixed at right angles to the walls of the housing.

Instead of pre-fabricated heaters, you can also use a nichrome thread wound on a frame made from a strip of asbestos sheet or other suitable material. Such a design will occupy a large area (almost the entire length of the pipe) and, accordingly, will heat the room faster.

The second edge of the gun is closed by the impeller and fixed to the standard mounts.After that, it remains to separately connect the heating element and the fan to the power cord through the fuses and connect the switch that opens the mains.

Mandatory moment - all wires and the ends of the spiral outside the gun must be carefully insulated.

If a sheet of metal was used for the case, it is worth thinking about its additional thermal insulation and a stand from the same reinforcement. And for convenient transportation you need to equip the gun with 1-2 handles.

Do not want to bother with making homemade products? In this case, it’s easier to buy a ready-made gun in the store - we recommend that you familiarize yourself with top manufacturers such equipment.

Homemade # 3 - diesel gun

To assemble a unit that runs on liquid fuel, you need to make three basic structural elements - a body, a combustion chamber and a fuel tank equipped with a pump. And for this you need a welding machine and good experience with it.

The algorithm for assembling a liquid fuel gun:

- For the body, you need to choose a cylindrical container or a galvanized pipe of large diameter. A combustion chamber is placed inside - a thick-walled pipe with a diameter half as small as the body, at the end of which a nozzle is mounted. Also, the combustion chamber must be equipped with a spark-generating device, for example, piezo ignition or a candle.

- After installing and centering the camera, the outer casing is sealed on one side, and on the second it is closed by a fan. Only technological holes for the flue pipe and nozzle remain open so far.

- For fuel, you need to choose a tank with a volume of 5-10 liters. You can buy a finished tank or do it yourself, the main requirement is that it be made of a material with low thermal conductivity, eliminating overheating of the structure. If this was not found, take a metal container and simply wrap it with thermal insulation.

- Then you need to place a high pressure pump and a cleaning filter between the upper housing and the lower fuel tank.

- Now we connect the nozzle to the pump and filter using the red-copper annealed tube for supplying fuel, and we equip the fan with a dimmer and connect it to the mains.

- At the final stage, it remains to weld a pipe to the body with a pipe or corrugation for the output of combustion products.

Before making a trial run of the device, be sure to show it to a professional - for example, a specialist from a car service.

Rules for the safe use of guns

It is no secret that all home-made devices are objects of increased danger, because improper design and assembly can cause a fire, human shock, and other troubles.

But most accidents occur not so much due to design errors, but because of an elementary neglect of safety measures.

Recall the basic rules of operation:

- All direct heating heat guns can be used only with good (best forced) ventilation. But even in such conditions, staying longer than a couple of hours in a room with a direct-flow diesel or gas gun is fraught with headaches and other symptoms of poisoning.

- The gun body (especially if it is made of metal) is very hot during operation, because unlike factory models, home-made devices are not equipped with heat-insulating layers inside the casing. Therefore, it is important to take care of a stable base, which eliminates spontaneous rolling of the cylinder, and a handle that does not heat up.

- The "barrel" of units with open burners should be covered with a protective mesh screen, and it is advisable to equip the electric gun with grounding.

- Never direct a stream of hot air towards fuel cans or gas cylinders. In general, the distance from the outlet of hot air to the nearest facility should be at least 2 meters.

- To ignite the burner in a gas and diesel gun, use a special lighter on a long handle.

- Before shutting down, let the fan run for several minutes without supplying fuel so that it can cool the unit.

And the last - no matter how confident you are about the quality of the assembly and the safety of the connections, never leave a makeshift gun unattended.

Conclusions and useful video on the topic

To get a visual representation of the guns working from various sources of energy, we prepared several videos with tips from the masters, who have already assembled devices from all kinds of improvised materials. Perhaps one example will inspire you to experiment.

Gas gun made for heating a garage:

How to make an electric gun from an old fire extinguisher:

Home-made heat generator working on the development of oil:

Electric gun from a conventional pan:

Although it seems that a homemade gun is the most budgetary solution to the issue of heating non-residential premises, its manufacture requires certain knowledge and experience.

The price of a mistake can be an explosion of equipment, fire, poisoning by combustion products, and even human life. Therefore, really appreciate your skills and think: maybe you should enlist the support of specialists or just buy finished appliance.

Have you decided to assemble a heat gun from improvised materials and want to clarify a couple of nuances? Ask your questions to our experts and other site visitors in the block under this article.

Or maybe we already use a homemade gun and want to advise something to beginners in this matter? Share a unique photo of your creation, write recommendations, leave valuable comments.

Do-it-yourself electric heat gun: the pros and cons of homemade + assembly instructions

Do-it-yourself electric heat gun: the pros and cons of homemade + assembly instructions  Do-it-yourself diesel heat gun: homemade manufacturing instructions

Do-it-yourself diesel heat gun: homemade manufacturing instructions  DIY heat gun for used oil: step-by-step manufacturing instructions

DIY heat gun for used oil: step-by-step manufacturing instructions  Do-it-yourself heat gas gun: step-by-step assembly instructions

Do-it-yourself heat gas gun: step-by-step assembly instructions  Diesel heat gun direct and indirect heating: device, principle of operation + manufacturers review

Diesel heat gun direct and indirect heating: device, principle of operation + manufacturers review  Electric heat gun: types, how to choose, an overview of the best manufacturers

Electric heat gun: types, how to choose, an overview of the best manufacturers  How much does it cost to connect gas to a private house: the price of organizing gas supply

How much does it cost to connect gas to a private house: the price of organizing gas supply  The best washing machines with dryer: model rating and customer tips

The best washing machines with dryer: model rating and customer tips  What is the color temperature of light and the nuances of choosing the temperature of the lamps to suit your needs

What is the color temperature of light and the nuances of choosing the temperature of the lamps to suit your needs  Replacement of a geyser in an apartment: replacement paperwork + basic norms and requirements

Replacement of a geyser in an apartment: replacement paperwork + basic norms and requirements

I want to try to make a small heat gun for heating the loggia in the cold season. Loggia with cold glazing and ventilation holes in its lower part (do not close). I sometimes want to sit on the loggia in the winter without putting on winter clothes. Area of approximately 6 squares. Experts, tell me, what type of heat gun is best for this? I tend to electric, but on the loggia there is no electricity output yet, I have to do it.

Vladimir, you bow down correctly, especially if you only need to warm up the loggia from time to time. The electric heat gun is the most convenient option to use and safe for home. I've been making a gun for the garage.Often I spend a lot of time there in the winter (I work), so I chose a cannon from a gas cylinder, because in my case it’s easier to go broke with the electric one.