DIY electric underfloor heating: device, installation technology and wiring diagrams

The type of heating in which heat is generated by using electric energy is notable for its simple design, and its installation takes a minimum of time. It is not necessary to be a professional in order to arrange an electric heated floor with your own hands, you just need to follow all the instructions exactly.

In the article we presented, all types of electric floor heating systems are described in detail, their characteristics and pluses with minuses are given. For independent home masters, we have provided step-by-step installation guides. Based on our tips, you can build and connect your own electric floor.

The content of the article:

Electric floors and their varieties

Depending on the heater used, electrically heated floors are divided into 2 categories: with a heating element in the form of a cable and with infrared.

According to the method of production, they are divided into 4 types:

- Heating cable. It can be one-2-core including self-regulating.

- Heating mats. It is a cable on a mounting grid.

- Film. Flexible polymer sheets with integrated infrared heating element.

- Rod. Consists of carbon fiber rods connected in series.

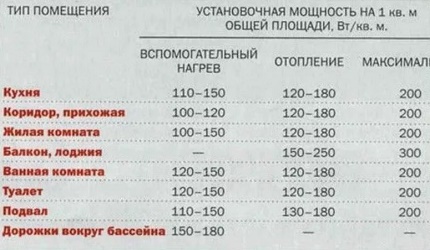

A warm electric floor is calculated based on the dimensions of the part of the room free from the situation. Under the furniture, laying heating elements is not recommended due to the excess load on the system in these areas. The floor power is selected from considerations of 0, 1 kW / m² on average. For different rooms, this indicator is different.

It is important before starting work to calculate the step with which the cable will then be laid out. To do this, find the quotient of the area planned for laying the heating system in m², multiplied by 100 and divided by the length of the section in m, taken from the passport.

With arguments and criteria for choosing the best option for you personally warm floor device will introduce next articlewhich we recommend that you read.

Cable heating system

The heat transfer of a cable underfloor heating is very high; in fact, all electrical energy is converted into heat. It includes a heater cable, coupler, adjustment and control devices. The cable is laid both in the screed and under the floor covering.

Features of work and device

There is no heating boiler in the system; the electric cable itself gives off heat. Most often it is used as an auxiliary type of heating, but if the house is well insulated, the floor, heated with a cable, can also serve as the main source of heat. Lay the cable in 3 ways: under the screed, inside and above it.

It is necessary to arrange it evenly, maintaining a distance from one to the other heating line of at least 80 mm and avoiding intersections, kinks and tension on bends. During installation, the cable is easy to damage, so experienced craftsmen recommend wearing soft shoes or covering already mounted areas with sheets of plywood.

Installation of an electric floor in a coupler

The installation process in the screed of electric floor heating is labor intensive. The advantage of this method is that the heating element, being in the center of the screed, heats the surface more quickly and evenly. The technological process consists of several stages.

First fill the first layer - this will be the basis. Pre-clean the plates. Expand cracks more than a millimeter wide with a puncher and fill them, as well as chips and holes, with a solution.

The plate is aligned horizontally, if necessary, apply the composition of "bulk floors". After drying, the foundation is applied liquid waterproofing, and leave for 2 hours to dry.

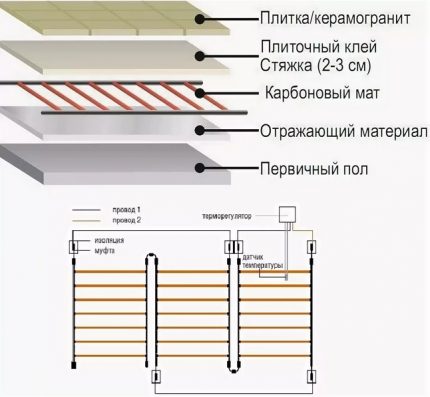

A heat-insulating substrate with a foil-coated heat-reflecting layer is spread on the surface. If there is an unheated room below, then choose a heat insulation from 5 to 10 cm high. Otherwise, a layer of 2-3 cm is enough. Seams and joints are sealed with foil tape.

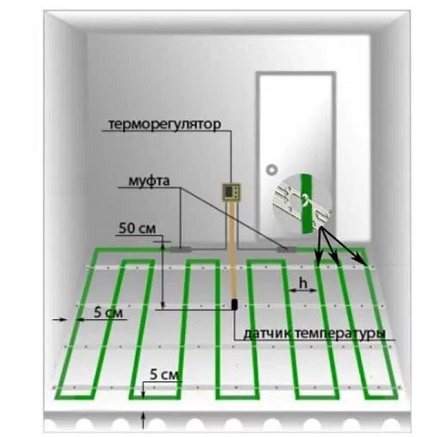

Assemble the heating circuit. In the perpendicular direction with respect to the wall selected for installation of the control unit, strips with latches are mounted to fix the cable. The edges of the polymer strips should end at a distance of 50-100 mm from the walls.

If mounting rails are taken instead of strips, then they are removed from the walls by 200 mm. Before laying a warm floor, check the cable resistance with a tester. Indications are verified with a passport, the allowable difference is 10% maximum.

The starting point in the cable connection scheme for the electric underfloor heating according to the classic version is the control unit. Make out the calculation in the form of a "snake" and placed parallel to the wall.

All transitions to the next turn should be outside the border rails. An insulated end should be at the end of the opposite wall. The option when installation starts from the end is also possible.

After the line is completely laid, a temperature sensor is mounted between the turns in a metal corrugated pipe. The wires are led towards the baseboard, and then to the control unit. It is not necessary to brick up the sensors in concrete - it becomes very difficult to remove them if necessary.

After checking the reliability of fixing the stacked elements, they are poured with a concrete screed, the power of which depends on the technical data of the object and the type of electric heating system. The solution must be well sealed. If voids remain, the thermal conductivity of the top layer will decrease.

Acts as a control unit for the warm floor temperature controller. He is responsible for processing the information received from the temperature sensor, and disabling or enabling the system in accordance with the settings. The temperature controller can be either programmable or without software. Connect it to a 220 V outlet. Choose a place for installation on a site with free access.

Experts do not recommend connecting the control unit to a conventional outlet. This may create additional strain on the wiring. You must create a separate branch to connect the system.

In some cases, the cable is laid in strobes made in a concrete screed. The cable in the strobes is filled with tile glue. The advantage of this method is that the level of topcoat remains the same. After the installation of the cable is completed, the floor is turned on only after 2 weeks.

Thermomat-based electric floor

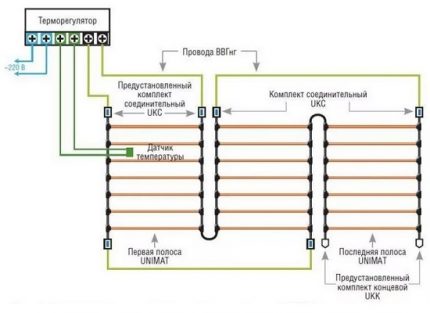

For the production of thermomats, a cable no thicker than 45 mm is used. It is fixed on a fiberglass mesh 0.5 m wide. The cable has a shielded core protected by an external sheath. For residential premises, heating mats with a double core are used because of their significantly lower level of electromagnetic radiation.

Principle of action and construction

The heating mat includes 2 elements: the actual thermomat with cable and corrugation. A sensor is inserted inside it, and it protects it from moisture and aggressive influences. If the glue layer is so thin that it cannot completely close the corrugation, you need to use a moisture-proof sensor.

The temperature controller complete with an external temperature sensor, mounting boxes, wires are purchased additionally. When choosing the first element, the maximum energy consumption is taken into account. The cross section of the wires is selected, focusing on the power of the system and the material of manufacture.

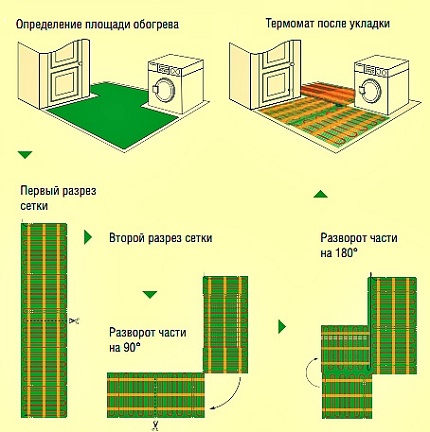

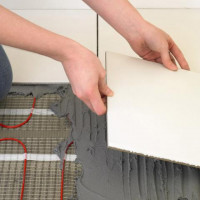

The installation process is extremely simple, because Thermomat - a product completely ready for installation. There is no need to fix the heating cable, and the evenness of laying is ensured by the design itself. Its cost is higher than that of the cable floor, but it has a lot of advantages, which include faster heating of the surface.

Installation of thermal mats

Before unfolding the heat mat, the floor is covered with a primer layer. This will increase the adhesion of the adhesive to the concrete surface. Usually the glue is applied immediately to the mat, but if it is a damp room, then after applying and drying a thin layer of glue it is covered with waterproofing, and then again with glue.

In order not to violate the integrity of the cable and evenly apply a binder, it is necessary to distribute the adhesive with a plastic comb. Tile is laid on the glue and level it.

Tile plus glue should total 20 mm, although some manufacturers recommend a minimum of 50 mm. This is explained by the fact that with such a thickness of the layer heat is distributed more evenly.

In accordance with the EMP, a protective shutdown must be installed, which guarantees safety and a circuit breaker. If the system is mounted in the bathroom, the thermostat should be moved to an adjacent dry room.

Film floor specifics

In the device system warm film electric floor no special difficulties. Many lay it on their own. It is suitable for any floor coverings. The system, whose operation is based on infrared radiation, is safe even for laminate and other wooden coatings.

There are 2 types of such floor film:

- Solid. Available in the form of a thin two-layer polyurethane film with continuous carbon spraying inside.

- Striped Including the same 2 layers of film from lavsan, polyester or polyurethane with carbon or ultrathin aluminum strips located between them.

Thermal elements in these systems have parallel and serial connections. Along the edges they have bimetallic current-carrying tires made of silver and copper strips stacked on top of each other. IR film floor is not made either with screed filling or with a layer of glue. Only “dry” styling is suitable.

Warm infrared floor has several advantages.

These include:

- simple and quick installation;

- small film thickness (0.3 cm) which does not significantly reduce the height of the room;

- the possibility of eliminating such a working moment as pouring screed;

- lack of influence on humidity in the room;

- anti-allergic effect;

- relatively low energy consumption - 20% less than other types of electric thermal systems;

- air ionization;

- easy dismantling if necessary;

- high reliability.

The standard set of materials includes thermofilm twisted into a roll, contact clamps, insulation and electrical wiring. To this kit you need to add a thermostat equipped with a temperature sensor, as well as a plastic film, adhesive tape, foil material. Before you get all this, you need to calculate the required footage of the film.

The easiest way is to sketch the room on graph paper. Further, it should be noted the places where the sensors and connection points will be placed. Select the part of the room where you plan to lay the warm infrared floor, then calculate how many heating elements are required.

Compare device specifics film and cable floors The information outlined in our recommended article will help.

The installation process of the infrared system

If the previous coating is in normal condition, then the technology of laying the electric infrared warm floor is allowed not to dismantle it. Simply clean and eliminate the differences. A roll of film floor is cut using conventional scissors.

It should be borne in mind that when forming the surface of the strip, they should not intersect or come into contact with current-carrying tires. Typically, manufacturers indicate the cutting location. This does not mean that the film cannot be cut in other convenient places.

The main thing is that the cut should go through the gap between the heating elements. If the cut fell on the indicated line, only collector bimetallic plates are isolated. In other cases, tape ends are taped.

First, a waterproofing layer is laid to protect the floor from moisture from the concrete floor. Next comes thermal insulation, preventing heat loss from radiation leaving the base. Any material can be used, the main thing is that the metallized side is directed outward.

Mark out the places where the wiring will take place. After they take the place for the installation of the temperature sensor. The channel under the temperature sensor is about 20 mm wide. The wiring for the sensor is placed in a corrugated tube, then placed in a prepared channel.

Then lay prepared strips according to the sketch. In order to reduce the length of the wire when laying the strip, turn the end faces to the wall, where the thermostat will subsequently be located and stop, not reaching centimeters 15.

If the room has a fireplace, at least 1 m away from it. The film is laid with that side up, which is indicated by the system manufacturer in the product briefing. Connect the clamps to the edge of the bimetallic strip, then connect the wires - to the left clamps fasten the left ones, and to the right ones - the right ones.

The wiring for the temperature sensor should be hidden under the thermal film. For this purpose, narrow grooves of 1 cm wide are cut out in thermal insulation, and adhesive tape is glued along the power cable laid in them and covered with thermal film. The wires must not be allowed to rise above the thermal insulation.

The insulation on the edge of the wire is removed, rolled up, the wire itself is pushed through the clamp, fixed with pliers, then the connection point is isolated with bitumen tape. By connecting the entire circuit, measure the resistance of the resulting structure.

The final stage is the installation of the finish coating. The principle of connecting the thermostat is the same for all types of warm electric floors.

Some useful tips

Before completing the job by laying the topcoat, the system is tested. If the thermal film meets all the requirements, sparking and overheating of the areas will not be observed anywhere. If any defects are discovered, the floor is covered with another layer of a film of polyethylene with a minimum thickness of 80 microns. It is lapped with an approach of about 20 cm.

There are a number of additional recommendations from professionals regarding installation:

- The warm film system must be installed at moderate humidity (maximum 60%) and plus temperature.

- You can’t connect the film when rolled up to the network.

- Before connecting the film floor, it is necessary to check the insulation of the contacts in the places where the canvas was cut.

- In case of damage to the thermal film in the place where the graphite spraying is located, double-sided insulation is applied.

- If flooding of the floor has occurred, it is immediately disconnected from the mains and left to dry in natural conditions.

- You can’t walk on the finished floor in shoes.

Do not block the temperature sensor. It is necessary to leave the opportunity for its control and replacement. Also, carpets and other dense natural coatings should not be placed on the warm floor. To ensure ventilation and eliminate the possibility of deformation of the finish coating due to temperature changes, it is recommended to leave a slight gap between the wall and the coating.

Rod type underfloor heating

A carbon core rod is a rod structure that heats a room with far-infrared rays. There is no electromagnetic radiation in this range. Its peculiarity is that it is not the atmosphere that is heated, but the objects present in the room.

Subtleties of work and organization

It contains carbon rods connected in parallel into elastic mats with a width of 0.8 m and a length of 25 m using a power wire. Inside the "carpet" placed heating elements. The inside of the rods consists of carbon, silver, copper, and the first one emits heat.

In addition to the rods, such a floor has a temperature sensor and a temperature controller. This gender has the property of self-regulation. This means that the amount of heat is directly proportional to the temperature. The disadvantage is that its installation is possible only with the use of a screed, therefore, there can be no question of its dismantling.

If you put any object on the floor plane, the heat transfer in the place occupied by it is reduced, and the rods begin to produce less heat, thereby lowering the temperature. Consequently, the temperature controller here is needed only for power control, the core floor itself performs the function of preventing overheating.

Nuances of installation and connection

Although the core floor is considered an intelligent system, you can lay it yourself. The technology is simple, but it will work provided that all the requirements are met.

The process consists of 8 consecutive steps:

- foundation preparation;

- laying heat reflector;

- mounting rods;

- interconnecting bands;

- power cable connections;

- connecting the structure to the thermostat;

- temperature sensor connections;

- screed pouring or installation of a tiled-type finish.

Before performing these works, they plan in which direction the heating mat will be laid and calculate the amount of material. The carbon floor comes on sale as a kit, but sometimes you have to buy some of the supplies.

Two factors influence the choice of power: area and type of heating. According to their power rod warm floors are divided into 2 types: up to 160 W / m² and up to 220 W / m².

The most rational option for the location of the heating mat is along a long wall with an orientation to the heat regulator, because in this case, when connected to a temperature controller, you can take shorter wires and reduce the number of cuts.

Mostly manufacturers produce a complete set for installation. At a minimum, it includes a core mat, a connecting kit and an end, wires, installation instructions. Everything else: thermal insulation, adhesive tape, corrugated pipe with a plug, thermostat, sensor, bitumen insulation - are purchased additionally.

About what option of a warm floor: electric or water is better to arrange for the subsequent laying of the laminate, it is written in detail in articlededicated to this issue.

Conclusions and useful video on the topic

Video # 1. You will learn all about laying a core floor from this video instruction:

Video # 2. Choosing the type of electric floor will become easier if you familiarize yourself with this video:

Video # 3. How not to spend too much when buying a warm floor system will teach the author of this video:

Heating a house with the use of electric underfloor heating will maintain a comfortable temperature. The temperature difference between the top of the room and the floor will be minimal. If you choose the right system, calculate everything accurately and do the installation work yourself, then you can win in terms of finances.

And what type of floor heating did you prefer for arranging your own summer house / apartment? Possible, do you have a desire to share the intricacies of installation, known only to you? Please write comments in the block below, ask questions, post a photo on the topic of the article.

How to connect a warm floor with your own hands: the steps of connecting a water floor

How to connect a warm floor with your own hands: the steps of connecting a water floor  How to make a heated floor in the bathroom with your own hands: a step-by-step guide

How to make a heated floor in the bathroom with your own hands: a step-by-step guide  How to make a water-heated floor with your own hands: a step-by-step guide from design to assembly

How to make a water-heated floor with your own hands: a step-by-step guide from design to assembly  How to make a warm floor under the tile: laying rules + installation guide

How to make a warm floor under the tile: laying rules + installation guide  How to make an infrared warm floor with your own hands: installation and connection of a film floor

How to make an infrared warm floor with your own hands: installation and connection of a film floor  How to make an electric heated floor for tiles: film and cable option

How to make an electric heated floor for tiles: film and cable option  How much does it cost to connect gas to a private house: the price of organizing gas supply

How much does it cost to connect gas to a private house: the price of organizing gas supply  The best washing machines with dryer: model rating and customer tips

The best washing machines with dryer: model rating and customer tips  What is the color temperature of light and the nuances of choosing the temperature of the lamps to suit your needs

What is the color temperature of light and the nuances of choosing the temperature of the lamps to suit your needs  Replacement of a geyser in an apartment: replacement paperwork + basic norms and requirements

Replacement of a geyser in an apartment: replacement paperwork + basic norms and requirements

I bought a warm floor, based on the quadrature of the kitchen, but taking into account the places where the furniture will stand. Stacked directly under the tile.The most difficult thing was to connect to the regulator (laying wires and a temperature sensor, the corrugation of which is not so small (I had to stomp the floor, making a niche for it). Otherwise, it’s a very simple system, quite accessible for installation by an unskilled specialist.

I live in Ukraine. Every month I pay big money for gas to heat my house. Can you imagine how much I pay for gas, if there is none at all in Ukraine! Now I decided to abandon the gas boiler and make the floors warm in the house, but I just can’t choose the right heating element. While I settled on infrared film, but maybe there is something better and more efficient? For me, the main thing is that underfloor heating should be reliable, strong, economical and durable. Help with advice, if not difficult. The area of the house is 142 sq.m., a one-story brick building of new construction. Is it possible to heat the whole house with an infrared film?

It is possible to heat the house with an infrared film as the main source of heating, but it will turn out to be expensive. I don’t know how it is with gas prices, but I’m not sure that it will turn out cheaper. In my opinion, the infrared film should be set only as additional heating.

If you still decide to abandon heating on gas in favor of electric, then first of all I recommend switching to a dual-zone meter. And also draw up a project for electric heating, which will reduce tariffing by up to 40% in the heating season!

Regarding the infrared film that you are going to use as the main source of heat: from my own experience I will say that it will be a little expensive. Yes, and it will be more practical to make a warm floor from a heating cable, and in each room put on an electric convector. Tie this whole system to a thermostat, which will maintain the necessary temperature in the house. As for me, this is the most optimal solution.

Great article! Thank you 🙂 I would also like to know what are the problems with underfloor heating. We had a situation after installing (electric, cable two-wire) floor. They turned it on a month later (according to the instructions), worked for several hours, checked, turned it off.

Summer is over, we turn on the floor, but it shows no signs of life at all. They complained to the store, and they went to the manufacturer. As a result, we were refused for the reason that there is no stamp of the installation organization. However, the specialist who installed has a license to perform electrical work ...

Hello. The problem may be in:

1. Faulty temperature controller.

2. Damage to the temperature sensor.

3. Damage to the cable and the thermostat.

As for the denial of claims, you need to look at the warranty obligations of the seller and the manufacturer. According to the installation organization - an excuse. If the defect is in the material itself, they were obliged to check it with an unexpired warranty and then already issue a verdict, the reason for factory defects that ensured the duration of work or improper installation.

But, with one caveat - if you do not have a postscript in the documents - installation is possible only by specialists of the service organization of the store or manufacturer. Although even in this case, it was necessary to draw up an act of acceptance of work and a contract. That is, to put that very seal. Then the organization that works for the store / manufacturer would be responsible for the installation.

If the installer is a representative of another company, it would be possible to file a claim with this organization. But again, as I understand it, you do not have any evidence of who did it to you or when.