Which warm floors are better: water or electric? Comparative review

Everyone who is sure that the warm floor is a modern invention is greatly mistaken. This idea came to the minds of the ancient Romans, who in this way successfully heated their baths - ancient baths. Since then, centuries have passed, the design has undergone significant changes and new technologies have appeared.

Today, the user can choose from different options, the main difference between the systems is the type of coolant. To understand which warm floors are better - water or electric, you need to learn about the features of the device, installation and operation of heating systems.

The final decision on the organization of floor heating is made based on the budget of the upcoming repair, as well as the type of room and operating conditions. You will find answers to all these questions in our article.

The content of the article:

All about water systems

Before choosing one of the two popular systems, you should get acquainted with the features of each.

The principle of operation and design features

Water-type floor heating is very easy to install. Under the floor finish in the form of a closed loop, pipes are laid along which the coolant is launched. Depending on the type of heating system, this may be a solution of antifreeze or water, etc.

Given that the length of such a circuit is usually quite large, a circulation pump must be present.

It will provide the fluid with the necessary circulation speed. Two methods can be used to heat the coolant.

Option number 1. Getting hot water from a centralized system. You need to understand that this can only be done by obtaining permission from the heat supplying company, with the installation of additional equipment. For illegal connections, large fines are imposed and dismantled.

In practice, this option is used extremely rarely. Moreover, it is permissible only in the first floors of multi-storey buildings because of the impressive weight of the floor with a screed for which no overlap was calculated, and because of the likelihood of leaks and too costly, complicated emergency response arrangements.

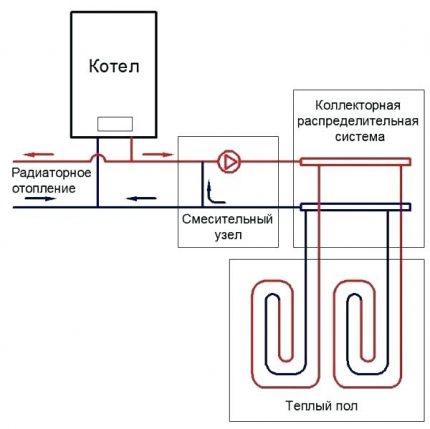

Option number 2. Connecting the system to the boiler. There are subtleties here too. SNiPs prohibit floor heating above 30 ° C, so the temperature of the coolant cannot be higher than 35 ° C.

Standard boilers heat the liquid to higher temperatures, on average up to 65-95ºС. Therefore, additional equipment will be required to reduce the temperature of the coolant.

For these purposes, the so-called mixing unit in which the hot liquid is mixed with the cold coming from the return pipe.

An exception can be considered condensation type boilers. These devices are able to heat the coolant to small values, which is ideal for a warm floor. Installation of the mixing unit in this case is not required.

For comfortable operation of the water floor is provided temperature regulatorworking in conjunction with temperature sensors. The latter are placed in a heated room at a certain height. The information coming from them is analyzed by a thermostat, which in turn controls the degree of heating of the coolant.

A more convenient option is to equip thermostatic regulators of each of the collector inputs.

Nuances of system installation

A water-type floor can be arranged in several ways. Each of them is quite complicated and costly.

Option number 1. The most common method is screed use. In this case, it is assumed that first thermal insulation is mounted on the aligned base. This is a must, when ignored, part of the heat will go down, heating the basement.

Thus, the heating fee will be higher than necessary. The insulation thickness is calculated individually for each room.

Be sure to use additional insulation around the perimeter of the room. A damper tape or tape insulation is placed here. This is necessary to prevent heat loss through the walls and to prevent the appearance of cracks due to thermal expansion.

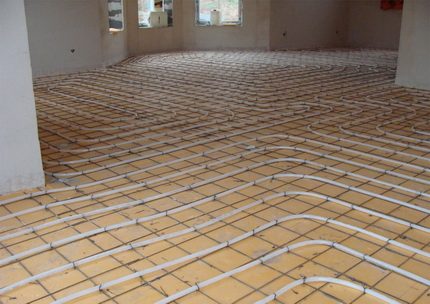

Pipes are laid directly on the thermal insulation. There are several mounting options: on a reinforcing screed mesh, on fixing tapes, on special substrate. Next, pouring the solution. This is concrete, in which additives that increase thermal conductivity are added.

The thickness of the screed should be such that at least 3 cm of the composition is above the pipes. Further, it takes time for the concrete to dry out and gain strength. On average, it is not less than 28 days. During this time, underfloor heating is prohibited.

Of the disadvantages of this method of arranging the system, the most significant ones can be distinguished:

- large mass, which gives a significant load on the carriers;

- low maintainability - in the event of a leak, you will have to dismantle the flooring, break the screed;

- significant height - on average, taking into account the insulation, the water floor has a height of about 9-10 cm, which significantly takes away the height of the room.

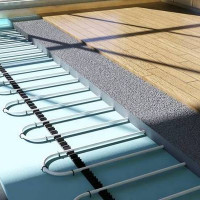

Option number 2. The so-called flooring system.In this case, the pipes are laid without using a screed. To form the structure, special plates are used. They can be made of polystyrene or wood.

Grooves are formed on the sheets into which it is convenient to lay pipes. Given that the material has a low thermal conductivity, the plates are necessarily supplemented with metal elements.

The topcoat can be laid directly on wooden sheets. In the case of polystyrene, an additional solid base for the finish will be required.

This installation method is less time consuming and costly. An additional plus - the flooring system can stacked on wooden floorsbecause its weight is light. In general, the installation of water heating is quite complicated in execution.

Why choose a water floor

In general, underfloor heating is a very effective way of heating a home. The temperature distribution with such heating is very favorable for humans. The air warms up evenly, and in the lower part of the room, the warmest zone is formed, at the level of the head it is slightly cooler.

Convective streams characteristic of the use of spot heaters that carry dust and microorganisms are absent.

Water floors can be used as additional or as the main source of heat. For relatively warm regions, the second option is preferable. For harsh areas, the first choice is the best. The main thing is preliminary calculate system, correctly determine the diameter of the pipes and the pitch.

In addition to high efficiency, it allows significant savings on heating. If two heating circuits are laid from the boiler, then the heated liquid will first go to the radiators.

After it cools down a bit, it is served on the warm floor, where it cools down even more. After this, the coolant is sent to the boiler. As a result, for one heating the user receives the maximum heat output. The room will be heated as quickly and efficiently as possible.

In addition to the undeniable advantages, the water floor also has disadvantages. The most significant is the high cost of arranging the system.

The cost of components is high, the cost of installation, given all its complexity, too. However, these costs are fully recouped in the process of its use. Water floors are effective, their efficiency is quite high. All this makes the cost of their operation minimal.

In fairness, it is worth noting that the cost of heating the coolant depends on the type of boiler used. Minimum costs will be for a gas-powered appliance.

If there is a need for repair, it will be easier to work with flooring systems. It will be enough to dismantle the flooring, after which access to the pipes will appear. In this case, we can talk about relatively inexpensive and simple jobs.

In the case of screed repair, most likely, will be impossible. For its implementation, it is necessary to dismantle the screed itself, which is very expensive and time-consuming. It will be easier to put a new system.

What you need to know about electrical systems

Under the general name "electric floor" hides several systems at once. They significantly differ in principle of operation, operational characteristics, cost, etc.

The principle of operation of warm electric floors

There are two main varieties of the system, both of them use electricity for their work.

Option number 1. Infrared heating.In this case, the heating of the rooms occurs due to infrared waves, which emit a radiator laid under the floor covering. It could be flexible IR film carbon-coated or carbon-fiber rods mounted as mats. In both cases, the principle of action is the same.

When current passes through a carbon emitter, it generates long-range infrared waves. They are absolutely safe for living things and they feel like warmth.

The waves reach a dense barrier, in this case it will be a floor covering, and accumulate in it. The floor warms up itself, after which it begins to give its heat to the surrounding air. This process goes very quickly - literally, in a few minutes.

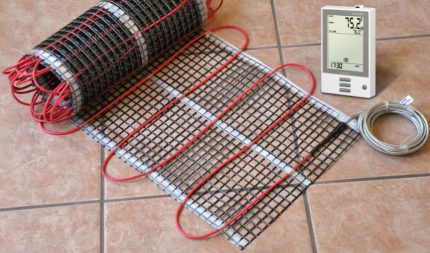

To regulate the degree of heating, thermostats with mechanical or automatic control are mounted.

Types of warm infrared systems:

- Film heaters - The most convenient to use and easy to install. They are carbon fiber strips laminated in a polymer film. The thickness of such a heater is about 3-5 mm. A winning feature - it can be mounted in a dry way, directly under the floor covering.

- Carbon rods look like a thick wire attached to a plastic mat. They can only be laid in the “wet” way, that is, in the screed. But the cost of such heaters is 15-20% lower than film.

It should be remembered that there is a possibility of damage to the film, therefore, a hard coating is required.

Option number 2. Cable systems. They also differ in variety. First of all, the difference lies in the type of heating cable. In all cases, this is a resistive wire. Its main feature is the generation of the maximum amount of heat when electricity passes through it.

To arrange the floor, one of two types of cable is used:

- Single core. This is the cheapest option, but its use is somewhat uncomfortable. He has only one heating core, which requires the installation of the connection beginning and end of the wire. In addition, the device during operation "gives out" a sufficiently large dose of electromagnetic radiation, which can adversely affect the well-being of people nearby.

- Two-core. The cable is distinguished by the presence of a second supply core. This allows you to mount it with great comfort. The connection of the two ends of the heating section is not required, which can significantly reduce cable consumption. In addition, it emits much less, this is a significant advantage.

Both types of heaters are available either in the form of a cable or in the form of mats. In the latter case, it is a mesh web on which a resistive wire is fixed.

Mats are much easier to stack, so it is worth choosing this option. At cost, a single-core cable is cheaper by about 15-20%.

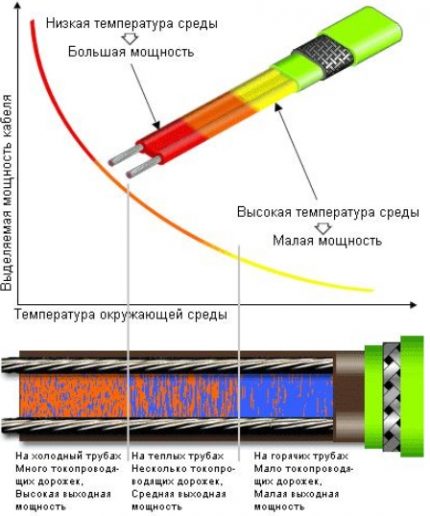

A common "trouble" of resistive heaters is the dependence of the length on the amount of heat generated. It is important to correctly calculate the length of the heating thread, otherwise it will burn out. A more advanced type of resistive heater is a self-regulating cable.

In its design there is a special sensitive film matrix. It is laid between two cores.With decreasing temperature, the electrical permeability of the film begins to increase, with increasing - decrease.

As a result, the cable heats up only when it cools down and disconnects when it is overheated. Such heaters can be operated without connecting a thermostat, since they themselves determine the need and duration of heating.

Favorable difference of self-regulating systems is profitability. In addition, their use allows you to move furniture after installing a warm floor. Resistive systems do not allow this, since the cable does not fit under large objects.

Otherwise, overheating and equipment failure should follow. Significant disadvantages of the self-regulating cable are the gradual loss by the matrix of its properties and high cost.

For more information on choosing an electric underfloor heating, see this article.

Features of the arrangement of electrical systems

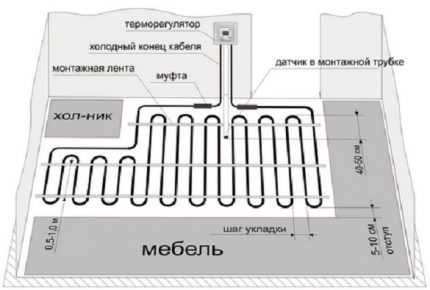

As already mentioned, only the film floor is mounted in a "dry" way, the rest of the varieties are placed in a screed. Consider the basic elements of a heating "pie".

First of all, this is a leveled base - elevation differences should be minimal. On top of the base insulation is necessarily laid. It is advisable to use metallized material to reflect thermal radiation.

It’s not worth taking foil, it will collapse very quickly. Be sure to fit and tape insulator along the walls. Next, heaters are mounted.

The most difficult option for laying is the cable in the bays. It will be necessary to put it at a fairly small distance from each other and securely fasten each wire, which is very time-consuming. Easier to spread the film or mats.

You need to know that resistive cables and film are afraid of overheating, so they are laid only where bulky furniture or plumbing is not installed. Stacking of heaters is carried out in strict accordance with the instructions given by the manufacturer.

The ends of the wires are connected to the thermostat, leading into the mounting box. You can use a warm floor without installing a thermostat, but then it will work inefficiently, it will give you excessive energy and an uncomfortable room temperature.

After a test start, making sure that the system is working, proceed to laying the screed. Usually it is placed on a reinforcing mesh. After drying, the screeds begin finishing work.

Film heaters do otherwise. Here you can lay the tile, glue is applied directly on top of the film, or collect the base from plywood or similar materials under the finish coating.

Pros and cons of electric floors

Like their water counterparts, electric floors provide a quick and very uniform heating of the room with the best temperature distribution from the point of view of doctors. Dust convection flows are also absent here. Air does not lose its humidity due to the lack of radiators.

Electrical systems are very adaptable, so you can achieve maximum efficiency in their use and get a comfortable indoor temperature.

Electric floors can be used as additional or primary heating. The power of the heaters in both cases will be different, but they will do their job well.

Operation of the electrical system does not imply any maintenance.With correctly performed calculations, installation and use, the service life of such equipment is at least 30 years.

Additional equipment for the operation of electric floors is not required. While water, for example, need to install a heating boiler.

The only requirement is the availability of sufficient power wiring, otherwise the system will not be able to function normally. Of the significant disadvantages, it is necessary to note the high operational cost.

For all its efficiency, heaters run on electricity, which every year only increases its value. Another minus is the need to ensure electrical safety. This is especially true for rooms where humidity is high.

It is highly desirable to create an effective grounding and the use of RCDs. For the same reason, it is optimal to trust the installation specialists.

Comparative evaluation of both systems

It is impossible to answer unequivocally what type of warm floor is better.

We can only draw a few general conclusions:

- Cost of arrangement - The components and installation of the systems are approximately the same. It all depends on the type and features of the system. In some cases, the electric floor can benefit from lower component costs.

- Operation cost for water systems is much lower than for electrical. Especially in the case when the coolant is heated by a gas boiler.

- Design constraints. Water systems are not used in the arrangement of multi-storey buildings.

- Power Dependence - electrical systems are dependent on the presence / absence of electricity, water systems will work regardless of this.

- Maintainability. Cheaper and easier to repair electrical systems. Watercrafts, with the exception of the flat options, are difficult and expensive to repair.

In general, both types of heating floors have worked well. They warm up the premises evenly and quickly enough, they are reliable, and with proper operation they serve for decades.

When calculating the costs of installing a particular system, you need to remember that before installing the water floor in the first floor of an apartment building, you will need to obtain a permit. And this means additional costs for collecting documents.

The choice of heating system type is also influenced by the flooring option, more details in the articles:

- How to choose a warm floor under the laminate: a comparative analysis of the best options

- Which underfloor heating is better for tiles: the pros and cons of various solutions + an overview of the best manufacturers

Conclusions and useful video on the topic

Which of the electric varieties of floors to prefer:

Water floor system - how it works:

Compare water and electric floors:

Warm floors of both electric and water types warm rooms equally well. The question of choice is most often purely economic, which one is cheaper.

For apartment buildings, it is easier and cheaper to install one of the electric varieties. True, the operation will cost more. For private, the best option is a water floor. Installation will result in a large amount, but subsequent operation will quickly pay back these investments.

Have experience arranging a warm floor? Please tell readers which system option you have chosen and why. Comment on the publication, participate in discussions and ask questions. The feedback block is located below.

Underfloor underfloor heating: step-by-step installation instructions

Underfloor underfloor heating: step-by-step installation instructions  Warm water floors on a wooden floor: features of laying the system on a wooden base

Warm water floors on a wooden floor: features of laying the system on a wooden base  Which underfloor heating is better for tiles: the pros and cons of various solutions + an overview of the best manufacturers

Which underfloor heating is better for tiles: the pros and cons of various solutions + an overview of the best manufacturers  Which floor to choose: which option is better + manufacturers review

Which floor to choose: which option is better + manufacturers review  Pipes for underfloor heating: a comparative overview of all options + design tips

Pipes for underfloor heating: a comparative overview of all options + design tips  How to choose a warm floor under the laminate: a comparative analysis of the best options

How to choose a warm floor under the laminate: a comparative analysis of the best options  How much does it cost to connect gas to a private house: the price of organizing gas supply

How much does it cost to connect gas to a private house: the price of organizing gas supply  The best washing machines with dryer: model rating and customer tips

The best washing machines with dryer: model rating and customer tips  What is the color temperature of light and the nuances of choosing the temperature of the lamps to suit your needs

What is the color temperature of light and the nuances of choosing the temperature of the lamps to suit your needs  Replacement of a geyser in an apartment: replacement paperwork + basic norms and requirements

Replacement of a geyser in an apartment: replacement paperwork + basic norms and requirements

In our house, we installed an electric system “warm floor”. It was estimated that even considering the cost of electricity, such a system would cost us more than water. We were satisfied with the choice, the house is always comfortable, even during the period when the heating has not yet been switched on. This system does not require any special maintenance, just set the required temperature and enjoy the heat!

When they did the repair, our choice fell on electric heated floors. They in our house are the main source of heating. Understood that water has more advantages, but trusted trusted professionals who convinced that with proper installation, electric floors will be much more efficient. Of course it turned out to be not cheap, but we were satisfied with the result.

The apartment has underfloor heating. At first they thought, they calculated which ones were more profitable, but they decided all the same electric ones. Moreover, for the construction of a water circuit, a bunch of agreements are needed, even though we have the first floor. Now we have electricity tariffs lower than the cost of water. Of course, the installation cost us a tidy amount, but now it is always warm and comfortable at home. Especially floors save in the fall, when the apartment is cold, and the heating season is still far away.