Mats for underfloor heating: selection tips + styling guide

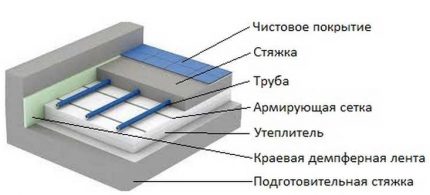

An important condition for the proper functioning of a warm water floor is the use of thermal insulation, which helps reduce energy costs and avoid heat loss.

The most modern and convenient type of insulation is mats for a warm water floor, represented by a wide range of products on the construction market.

The variety of thermal insulation materials is sometimes quite difficult to understand, is not it? Each manufacturer tries to demonstrate the best aspects of his product, sometimes ignoring the possible disadvantages.

We will help you find the best solution for warming the water floor. The article describes the different types of mats based on polystyrene foam, provides practical advice on their selection and installation. We also identified manufacturers whose products have won the trust of consumers and are in high demand.

The content of the article:

What is the function of thermal insulation?

When arranging a water heating system, the most important task is to minimize heat loss and direct all the heat directly to the room where the structure is installed.

If you simply lay pipes on the main floor, then there will be very little benefit from this system, since most of the thermal energy will go down to the basement or to the neighbors on the lower floor.

To solve this problem, thermal insulation is precisely intended, which, on the one hand, is an obstacle for the intake of cold air from the basement (if the system is installed in a private home), and on the other hand, it serves to preserve and evenly distribute heat throughout the room.

Correctly selected and installed thermal insulation eliminates the loss of thermal energy and redirects the heat flows coming from the heating pipes upward towards the room.In addition, the insulation prevents condensation from accumulating and prevents the formation of mold on the walls.

The classic types of insulation, which were universally used before - ecowool and polystyrene. Actually, even now, the inexpensive cost of these materials still attracts very frugal buyers.

However, progress does not stand in one place, and manufacturers offer more practical and convenient thermal insulation materials - special mats for the water floor.

Features of the material for the production of mats

Modern mats come from extruded polystyrene foam - a material that not only has excellent heat-insulating properties, but also has a whole list of other advantages.

Main advantages:

- Low vapor permeability (0.05 mg (m * h * Pa). For comparison, for mineral wool, this indicator is 0.30. This means that expanded polystyrene does not pass water vapor well and does not accumulate moisture, is constantly in a dry state, and as a result does not contribute to the formation of condensate.

- Low thermal conductivity, and therefore the maximum heat storage in the room.

- Soundproofing characteristics.

- Doesn't attract rodents and is not a breeding ground for the formation and development of microorganisms.

- Durability. According to the results of the tests (alternating high and low temperatures from plus 40 to minus 40 degrees and exposure to water), the service life of products from this material is up to 60 years.

Expanded polystyrene with a density of up to 40 kg / m is used in mats3therefore they withstand great loads.

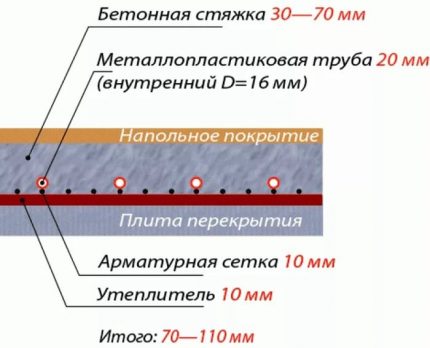

This property is especially valuable when water floor devicesince a rather heavy construction consisting of water pipes, a layer of concrete and a finishing floor covering is laid on top of the mats.

The main advantages of using mats

Mats for water heating structures - a modern heat-insulating material, manufactured in accordance with accepted European standards for quality and safety.

Plates are manufactured using the latest technology and combine all the advantages of traditional insulation, and at the same time are devoid of their inherent disadvantages.

Advantages of mats:

- have excellent performance;

- have good thermal and sound insulating properties;

- suitable for both semi-dry laying and wet screed;

- with prolonged use they do not deform and do not change size;

- equipped with a locking system, thanks to which the plates are quickly and easily stacked;

- most mats are marked, which greatly simplifies the process of installing pipes;

- not subject to decay, resistant to bacteria;

- Do not swell from exposure to water;

- safe for humans, in normal temperature conditions do not emit harmful odors;

- withstand both high (up to + 180 ° C) and low (up to -180 ° C) temperature;

- have a long service life, which is up to 50 years.

It should be noted that untreated polystyrene foam is a combustible and fire hazardous material and emits toxic smoke during combustion.

To reduce this property, flame retardants are added to the insulation during production, which makes it a self-extinguishing material. In domestic products, such material is marked with the letter “C” at the end.

Types of expanded polystyrene plates

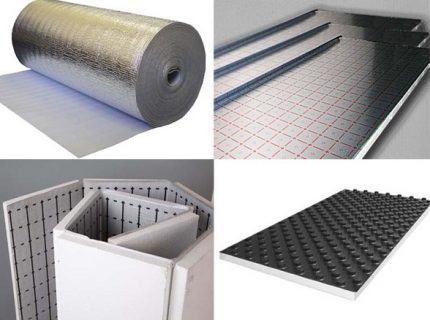

There are four types of mats that are suitable for use in the arrangement of water floors.Each of them has its own characteristics and is intended for installation in certain conditions.

Types of mats:

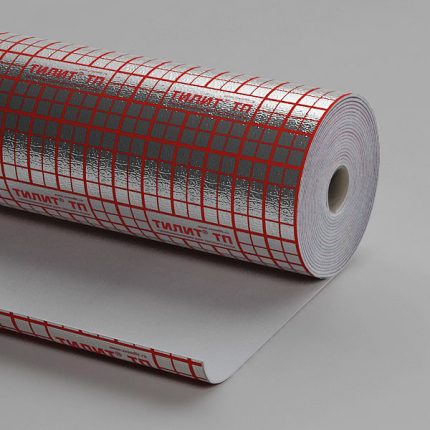

- Roll materials provided with a foil layer.

- Expanded polystyrene plates.

- Expanded polystyrene panels with foil and film coating.

- Profile mats with "bosses".

The choice of a heat-insulating coating depends on the parameters of the room, the base on which it is laid, the dynamic and mechanical load that the insulation has to withstand. The plates have different heights, so the thickness of the future screed must also be taken into account.

Roll foil insulation

Heater in rolls is made from penofol with a thickness of 2 to 10 mm. On the one hand, the material is coated with aluminum foil or polymer film, the function of which is to direct the heat flux and distribute heat throughout the floor area.

This type of heat-insulating material can be attributed to mats very conditionally, since it has low heat-insulating properties. This leads to a rather limited scope of its application.

Foil insulation is used only when the water floor is used as an additional heating system and the main floor already has some degree of insulation.

It is not advisable to lay the rolled material on the ground floors of buildings and in rooms, below which there are unheated areas, since the efficiency of insulation in this case will approach zero values.

Laying is a challenge floor heating pipes on this heat-insulating material. It is required to use additional fasteners: staples, clamps, reinforcing mesh, etc.

When laying the coverings, the webs are placed end-to-end with each other, to ensure better sealing, the seams are glued with special foil tape.

However, despite the very modest characteristics, the insulation in rolls under certain circumstances is the only possible option of insulation, for example, at a low room height, when every centimeter of area is counted.

Expanded polystyrene insulation boards

As thermal insulation for a water floor, flat polystyrene mats can be used. The simplest and cheapest option is ordinary polystyrene foam, a more durable and high-quality insulation is an extruded polystyrene foam plate.

If you decide to stay on a more affordable polystyrene, then when you buy it, you need to focus on the density of the material. This indicator should be not less than 35 kg / m3. At lower strength values, the insulation may not be enough to hold the load of the heating system.

It is more preferable to use the second option with higher quality indicators. The best representative of this series is Penoplex. It has a closed cellular structure, is durable, and can withstand loads.

To improve the thermal insulation characteristics on top of the mats, it is possible to lay foil insulation in rolls.

The edges of the plate are equipped with special locks, which simplifies its installation. There is also material with markings already on sale. The pipes are fastened with plastic brackets, which simply stick into the plates in the right place.

Expanded polystyrene panels with foil and film

This type of insulation is expanded polystyrene mats with a foil and film layer applied.

They are available either in two forms:

- individual tilesequipped with a locking connection;

- in the form of panelsbonded together by a common film coating.

In the first case, when laying the tiles are fastened together with waterproof tape. In the second - mats are simply laid out on the surface.

A grid is placed on top of the panels, the pitch of which is 50 or 100 mm. The marking helps to find out how best to make the laying of the pipeline, and allows you to quickly lay the pipes in accordance with the selected scheme.

Staples are also used here for fastening pipes, a laying option with a reinforcing mesh, which is laid on top, is possible.

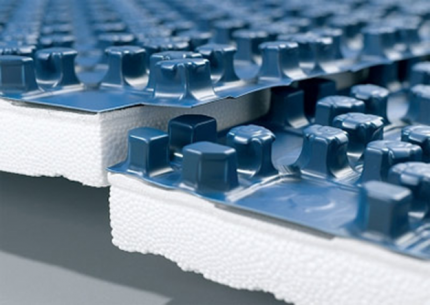

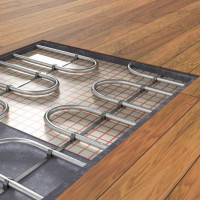

Profile mats with "bosses"

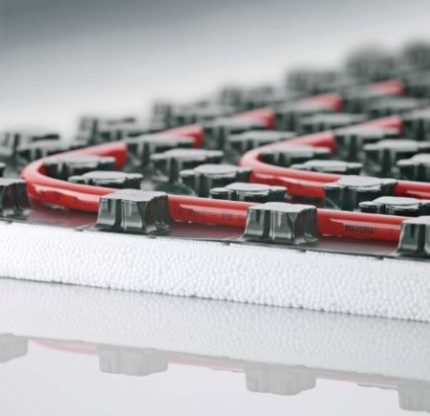

The most perfect and most convenient insulation. Mats are specially designed for installing a warm water floor.

The material from which they are made is still the same - expanded polystyrene, but thanks to the use of advanced technology of hydropellent stamping in production, there are special protrusions (bosses) on the mats.

Boss can have a variety of shapes: round, cylindrical, cubic, polyhedrons, etc. Protrusions located at a certain distance from each other, provide reliable fastening and fixing of the pipeline in the desired position.

When using these mats, the possibility of displacement of pipes during their installation and subsequent pouring with concrete is practically eliminated.

Mat coverage varies by model and manufacturer. Some types of heat insulators are produced without any coating whatsoever; you can buy models with a top film layer or a drawn waterproofing film. This indicator does not affect the quality characteristics of the product.

For convenience and ease of installation, the insulation is equipped with special locking joints, which, among other things, provide good tightness of joints.Mats form a continuous surface without cracks and gaps, on which any kind of screed can be laid.

Another undoubted advantage of the profile polystyrene mats is that they create an excellent anti-noise barrier, the insulation can significantly reduce the noise level to 25 dB.

Recommendations for choosing mats

When choosing a heater, you should pay attention to such various technical and operational indicators.

The main selection criteria:

- waterproofing;

- the ability of the material to withstand static and dynamic loads;

- pipe diameter;

- features of the room in which the water floor is laid.

So, rolled material, due to its low waterproofing characteristics, is not suitable for installation on basement floors. It should also be used with caution in apartments where people live from below, because if pipes leak, it will not be able to retain moisture, and water will pour directly into the neighboring apartment.

In contrast, sheet mats and foamed polystyrene blocks have good waterproofing properties, which eliminates the possibility of leakage. In addition, they relate to materials whose thermal conductivity is very low, due to which, when used, the maximum level of heat transfer to the floor is ensured.

When organizing a water heated floor, such a characteristic of the material as load retention is no less important. Profile mats made of polystyrene foam with a density of 40 kg / m3 are excellent at this. Flat boards and foil mats also have high density.

These heaters can be safely used to organize an underfloor heating system in an apartment or in a private house, which will be used as the main heating.

But the rolled material remains in the outsiders and in this position. Its density is not enough to withstand loads, so it can only be used to organize additional heating.

Another parameter to consider is the thickness of the mat. If any insulation has already been laid on the floor, thinner boards can be used. Also taken into account is the height of the room itself, the diameter of the pipes, thickness of future screed and floor facing.

Thermal Insulation Tips

Despite what kind of mats will be used for a warm water floor, it is necessary to lay a layer of waterproofing under it. This is necessary to protect the lower layer from the penetration of moisture droplets, as well as to create a durable barrier that can prevent flooding of the lower floors of the building in case of leakage of pipes.

A waterproof polyethylene film, bitumen coating or penetrating waterproofing can serve as a waterproofing agent.

If a film is used, it must be glued to the walls with a damper tape. The same tape is mounted around the entire perimeter of the room after laying the mats.

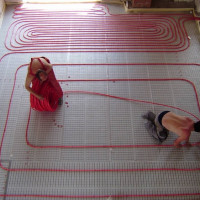

The easiest laying option is when using profile mats. They need to be laid on a waterproofing layer and fastened together using a lock connection. Then, in the intervals between the bosses, a pipeline is laid by the selected laying method, and with a light foot pressure the pipes are fixed in the desired position.

Installation of flat polystyrene plates also does not cause much difficulty. The panels are either fastened with locks, or simply glued to the waterproofing, and their joints are fixed with waterproof tape.

Most of all installation questions are caused by rolled insulation. It is laid so that the foil layer is on top. The heat insulator also needs to be glued to the base, and the joints between the tiles are connected by a mounting tape.

Then marking is applied to it, and stacked pipes. Fixation of the pipeline is carried out using clamps or clips.

The complexity of laying is that a thin and light insulation is very mobile. Therefore, you must very carefully produce his screed so as not to shift the structure attached to it.

It should be noted that when laying mats of any kind, only plastic fasteners can be used, metal parts can damage the integral design of the mats and violate their tightness. Installation of the piping system can only be carried out after all work on the installation of thermal insulation is completed.

Overview of manufacturers and models

Mats for warm water floors are produced by many foreign and domestic companies. However, only four brands occupy leading positions, whose products are most in demand among buyers.

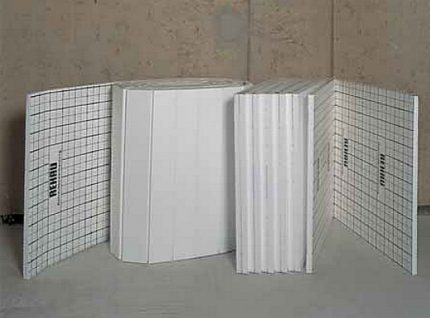

High quality and performance indicators are heaters of the German brand Oventrop. In the lineup there are profile mats with bosses, plates for dry laying, mounting roll and folding heaters in a polypropylene film.

Another German manufacturer of thermal insulation is a company Rehauwhose mats also arouse increased consumer interest. The main products are expanded polystyrene mats with bosses, equipped with layers of thermal and sound insulation.

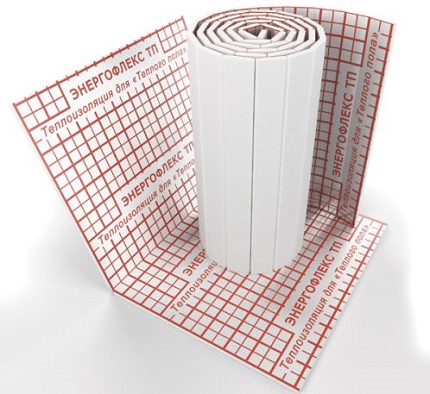

Among Russian manufacturers, the most famous products of the company Energoflex.

The model line includes several items:

- foamed polystyrene plates;

- thin rolled insulation with foil;

- polystyrene boards with bosses.

All heat insulators are marked with a grid with a pitch of 50 mm.

Excellent consumer and operational characteristics have heaters for the water floor, produced by the Russian brand Ecopol.

The manufacturer offers smooth polystyrene foam boards and boss mats. The panels are equipped with a locking connection and are covered with film waterproofing.

Conclusions and useful video on the topic

Video talks about the advantages of Ecopol mats

How to install a floor heating system can be found in the following video plot:

Expanded polystyrene mats are a modern universal heater, they are great for arranging a water floor.

An improved design ensures efficient and long-term operation of the heating system and greatly facilitates the process of installing the pipeline, which even a layman can easily cope with.

Have experience with insulating mats when organizing a water floor? Please tell readers about the specifics of their application and share feedback on the operation of such systems. You can leave comments and attach a photo in the form below.

Insulation for warm water floors: rules for selection and installation

Insulation for warm water floors: rules for selection and installation  Laying schemes for a warm water floor: analysis of the most effective installation options

Laying schemes for a warm water floor: analysis of the most effective installation options  Water underfloor wiring diagram: versions and device manual

Water underfloor wiring diagram: versions and device manual  Pipes for underfloor heating: a comparative overview of all options + design tips

Pipes for underfloor heating: a comparative overview of all options + design tips  Thermostat for underfloor heating: principle of operation + analysis of types + installation tips

Thermostat for underfloor heating: principle of operation + analysis of types + installation tips  Calculation of pipes for underfloor heating: selection of pipes according to parameters, choice of laying step + calculation example

Calculation of pipes for underfloor heating: selection of pipes according to parameters, choice of laying step + calculation example  How much does it cost to connect gas to a private house: the price of organizing gas supply

How much does it cost to connect gas to a private house: the price of organizing gas supply  The best washing machines with dryer: model rating and customer tips

The best washing machines with dryer: model rating and customer tips  What is the color temperature of light and the nuances of choosing the temperature of the lamps to suit your needs

What is the color temperature of light and the nuances of choosing the temperature of the lamps to suit your needs  Replacement of a geyser in an apartment: replacement paperwork + basic norms and requirements

Replacement of a geyser in an apartment: replacement paperwork + basic norms and requirements

The underfloor heating system was mounted in a country house at the repair stage independently with a friend. We are not experts, experience is only with my “partner”, who already installed this system for himself before. For thermal insulation, plates of extruded polystyrene foam were chosen. We decided not to save money and not just put polystyrene sheets, but to choose a better and more technological material.

We changed ecowool to polystyrene foam. I can’t say by the results (the frost hasn’t hit yet), but the fact that I got rid of ecowool is 100% good. A decent number of negative nuances, and how it was deformed in operation, is a separate song.

We took rolled foil substrates, they are convenient for installation, acceptable at a cost, let's see what will happen to them in a year.

Wonderful article!

In a frame house on a wooden floor according to OSP-3 22mm, we will arrange a warm floor on profile mats with bosses, on top of 2 sheets of GVL.

There are 2 questions:

1. How to attach GVL to mats and OSB?

2. What is the thickness of the GVL?