Underfloor heating under the laminate on the wooden floor: which system is better + installation instructions

To even walk barefoot calmly in the winter, sit by the fireplace or play with the child on the laminate floor, it is worth making an additional heating system. But many owners of wooden houses are concerned about the compatibility of such a device with fire and environmental safety of housing.

We suggest figuring out whether it is possible to make a warm floor under a laminate on a wooden floor, what are the pros and cons of such a decision. We will show you how to choose the best installation method, and also describe in detail the technology for arranging a floor heating system.

The content of the article:

Is heating compatible with laminate flooring?

Although the laminate is advertised as a wooden coating, in fact it is a multi-layer “cake” made of protective film, paper impregnated with various resins, and the base is a plate made of pressed sawdust. Therefore, the security issue is really relevant.

When heated, the resin and glue release phenol, phthalate, toluene, the infamous formaldehyde and other toxic substances that negatively affect our health.

But it is important to consider the following nuances:

- Harmful vapors are released only with strong heating - from 40 ° C and above.

- To protect the coating from overheating and arbitrary self-ignition, it is necessary to install for a warm floor system temperature controller with temperature sensor, which will control the temperature and turn off the system when the specified parameters are exceeded.

- If the protective layer of the chipboard is not damaged, then even at high temperature volatiles get into the air in an insignificant concentration.

- For residential premises with heated floors, it is worthwhile to purchase a decorative coating with an emission indicator of E0 (in extreme cases - E1), where the concentration of volatile substances is several times lower than the permissible norm.

If you take these simple rules into account, under the laminate you can safely install a floor heating system and enjoy comfort in the cold season.

Options for arranging warm floors

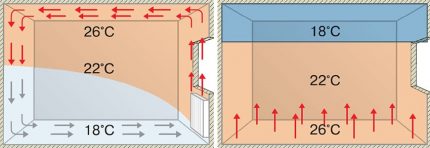

For underfloor heating can be installed water or electric system heating up. If desired, any of these structures can be hidden under a laminate and laid on a wooden floor, so we will consider all the options to choose the best.

Varieties of electrical systems

Electric underfloor heating is considered the best solution for heating floors with a dry screed. It does not require the creation of a complex multilayer structure and concrete pouring, and even a beginner in the repair business can cope with its installation.

True, there are several types of electrical systems, each of which has its own characteristics and nuances of installation.

The “progenitor” of warm electric floors is a cable system. For its arrangement, a well-insulated heating core is cut into sections and laid on the floor with fixation with special clamps. When connected to electricity, the cable transfers heat to the floor.

A more modern version of the design is thermomats, in which the wiring is already fixed to a fiberglass mesh, which greatly facilitates the installation process.

Infrared film floor - the most popular option for mounting on a wooden floor under a laminate today. In fact, this is a film with polymer strips sealed inside with a thin layer of carbon fiber, silver or graphite, which when connected to a network emits electromagnetic waves in the infrared range.

The main feature of this design is the absence of incandescent elements, so that heat is released without the risk of self-ignition.

Warm carbon floor - Another system based on the work of infrared rays. It is based on carbon rods connected by a high-strength copper cable.

Although this design is quite expensive, it has several advantages over other types of heating: it does not heat up, consumes a minimum of energy, automatically controls the heating temperature and is not afraid of the load of heavy furniture.

The advantages of infrared floors compared to cable:

- Heating is faster and more uniform., because the cable heats the coating only in places of contact with the floor, and the film - over its entire area.

- Easy installation - the film system can be mounted in just an hour of work and immediately begin laying the laminate.

- Reliability - in case of mechanical damage, only one segment fails, and the system continues to work.

- Health benefits - far infrared radiation supports the immune system and is even used to treat certain diseases.

In general, the disadvantages of electrical systems are relatively few.For example, it may be difficult to rearrange furniture, as heavy objects can pinch a cable or film and damage the structure.

Well, the most important drawbacks, as with any electric appliance, are high energy consumption and the danger of short-circuiting, followed by ignition of wooden materials. The infrared and carbon floors are most reliably protected from the latter.

Advantages and disadvantages of the water circuit

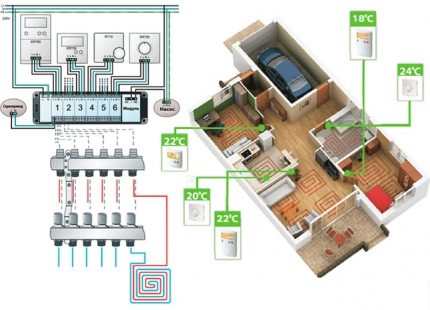

Water underfloor heating is a small diameter pipe laid under a decorative floor covering and connected to a heating boiler or central heating system.

Although it is traditionally recommended to lay the water circuit on concrete, for underfloor heating in a wooden house, a dry screed can be arranged under the laminate so as not to overload the floors.

The advantages of a water circuit on a wooden substrate:

- Cost-effectiveness. The minimum cost of electricity compared to other types of underfloor heating.

- Safety. No risk of short circuit and spontaneous combustion of materials.

- Maintainability. If repair is necessary, you can simply remove the laminate and replace the problematic section of the pipeline without encountering the dismantling of the concrete screed.

The main disadvantage of the water system is that for its operation it is required to start the boiler and wait for the coolant to warm up, so there will be no fast heat transfer. And if the system is connected to central heating, then it will work only in the heating season.

By the way, in apartment buildings, such structures are not allowed to be mounted on their own, so joining a heat-insulated floor to radiators is possible only in a private house.

The pipes also have lower heat transfer - after all, they do not adhere so tightly to the laminate as an infrared film or an electric cable, although this issue can be partially solved by installing heat distribution plates.

Well, the last drawback is the complexity of installation, where accurate calculations and experience are required, so it is better to entrust it to specialists.

The nuances of floor heating with a wooden base

First of all, we distinguish between the concept of wooden floors. If we are talking about old boards with which the floor in the houses of the Soviet era was laid, then it is better to remove such a base and lay the heating system using a standard concrete screed.

The reasons are obvious: the new floor will be perfectly smooth, without waves, squeaks and other consequences of "savings".

But if it is impossible to overload the floor slabs (as, for example, in old buildings, houses made of glued timber or logs) or if you do not want to reduce the already critical height of the ceilings, the best solution would be the so-called dry warm floor with a wooden base.

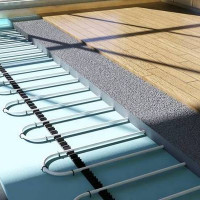

But there are a number of nuances. If for the infrared floor there will be enough flooring made of durable plywood or chipboard, then this will not work with the water circuit - the probability of damage to the pipes with subsequent flooding is too high.

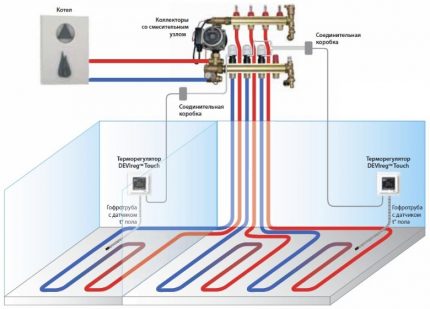

Therefore, if it is not possible to arrange a concrete screed, for the installation of water floors, you can use the modular system - special lattice sections from OSB or chipboard with provided channels for placing pipes that are laid directly on the logs.

Their width varies from 13 to 28 cm and is selected depending on the pattern and the step of laying the contour. Between themselves, the plates are fastened with lock latches and form a trellised flooring.

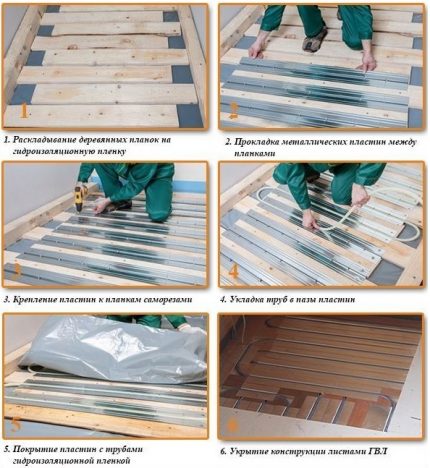

The second option for mounting water pipes on a wooden floor is a rack system. To do this, install rails from a board, plywood or chipboard on the draft floor, and contour pipes are laid between them. This method will take more time and effort, but it will save a lot on buying ready-made modules.

Installation instructions for the water circuit

To arrange water heating, you can use ready-made modules, slabs from OSB or chipboard with channels cut by the milling cutter for pipes. Also necessary choose pipes, thermostat, insulation, waterproofing.

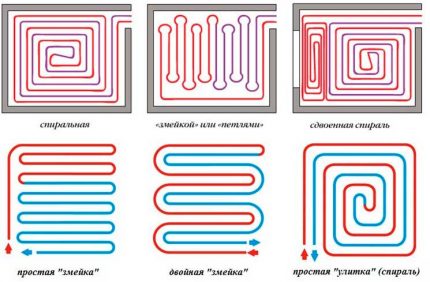

The length of the pipes is calculated based on the layout method and the size of the heating zone - a warm floor can be both an additional and the main source of heat.

For wooden houses, racking is most often used. To do this, you need to prepare the surface of the subfloor - make the flooring on the beams of plywood or OSB with a thickness of 15-20 mm, if necessary, level and insulate (the maximum allowable unevenness is 2 mm per 1 running meter).

Stages of upcoming work:

- Think over the layout and execute calculation of pipes for the floor. It is important that the rack base is installed perpendicular to the support lags.

- Then cut out strips of moisture-resistant plywood that are 2.5-3 cm wide less than the pitch for laying out the pipes. For example, for a step of 20 cm, strips 17 cm wide are needed, for 30 cm - 27, etc. The thickness of the rails should exceed the diameter of the pipes by 10-15 mm.

- Lay a layer of hydro and steam insulation (most often foil polyethylene is used).

- A damper tape is fastened around the perimeter of the walls, which will provide the necessary clearance when expanding materials from heating.

- On the floor, in accordance with the layout plan, transfer the marking of the location of the pipes.

- Then, cut rails are mounted on the logs or the surface lined with wooden materials so as to form a groove for the pipeline. In places where it is planned to turn the contour according to the marking, it is advisable to round the trims themselves, and then fix them with self-tapping screws.

- Now heat-conducting plates are laid between the rails, which should occupy at least 80% of the floor area to ensure uniform heating of the laminate.

- In the grooves of the profile, pipes of the water circuit are installed.

Then the design is checked for operability by connecting to the heating circuit. To make sure there are no leaks and deformation of the pipes, it is worth observing the operation of the system for a couple of days, creating maximum pressure.

At the finishing stage, it remains to close the “pie” with waterproofing (for example, a layer of polyethylene with a thickness of at least 100 microns) to reduce the noise effects during heating and cooling of the pipes. For the arrangement of the finishing flooring, plywood that has passed the chamber drying, or gypsum-fiber sheets that conduct heat well are best suited.

But before the sheathing begins, the warm floor must work at least 2 days, then cool down to a temperature of 15-17 ° C.

Additional information on arranging warm water floors on a wooden base is provided in this article.

How to make an electric floor heating yourself

Cable and film floors vary significantly in thickness, so their installation has a number of nuances. But to imagine the scope of the upcoming work, we will consider the main stages of installation of both systems.

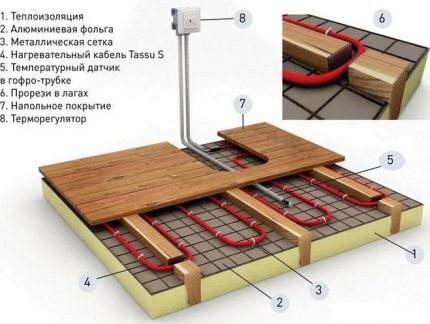

Cable Installation Instructions

Installation of the structure of conductive cables is carried out by analogy with the installation of a water floor, with the difference that such spacious niches are not required for wiring, so instead of racks you can do with small recesses.

The sequence of work looks like this:

- The gaps between the beams are insulated with a layer of thermal insulation (for example, mineral wool, ecowool or perlite).

- Then a heat-reflecting layer of foil material is laid, on top of which a grid with a cell of 50 * 50 or 40 * 40 mm is attached.

- In the logs of the subfloor, small grooves are made in the places where the cable turns, and metal insulation is applied to each cut.

- Then the electric cable is laid, fixed to the grid with special clamps.

- A temperature sensor is installed between the wires, enclosed in a corrugated tube and connected to a temperature regulator.

The power cable is connected to a power outlet in a metal sleeve and connected via a thermostat, after which the design is checked for operability.

After that, you can lay the rough floor for laying the laminate.

Installing a film infrared floor

As already mentioned, the easiest and most accessible option for beginners in the repair business is the option of arranging heated floors - an infrared system.

Work algorithm:

- A heat-reflecting substrate (4 mm thick) with a lavsan coating that does not conduct electric current is laid across the entire area of the room. The joints between the layers of material are glued together with mounting tape.

- Marking of the heated area is done.

- The heating film is cut at the cut points according to the layout plan.

- Then the film is spread on the floor, the cuts are connected to each other in parallel with the help of eyelets. After supplying and crimping the wiring, the junction is sealed with bitumen insulation, and the strip of film is fastened with butt / butt tape.

- To prevent the wires from being deformed, small grooves are cut through the insulating layer with an office knife, the cable is placed there and fixed with tape.

- Now it installs a heating sensor (its wire is also hidden in foil material).

- A hole is made on the wall (usually at a height of 50-100 cm from the floor) under the thermostat, a groove is made to it for wiring the sensor and power supply.

During installation, try not to bend or wrinkle the film so as not to damage its integrity, because the operability of the entire warm floor system depends on this

A few tips for safe operation

When planning the installation of a warm floor, do not forget that under heavy pieces of furniture, neither electric cables nor water pipes should be laid. Also, do not install a warm floor in the immediate vicinity with a wood, gas fireplace, stove and other heating devices.

Practical nuances:

- After the repair is completed, the heating system should be turned on, and maintain the same temperature for 3-5 days. This precaution will allow you to evenly and thoroughly warm the entire floor "cake" and ensure reliable operation of the system.

- At the beginning of the heating season, you need to properly prepare the floor heating system for work. To do this, increase the degree of heating by 5-7 units every day until the temperature reaches the required value. This approach will avoid a sharp jump in temperature, which can damage the laminate and other materials. Similarly, the heating is turned off for a warm period.

- Do not forget that the film infrared floor does not tolerate moisture. Therefore, it is not recommended to install it in rooms with a humidity level above 70%, and after wet cleaning, wipe the laminate dry.

- The optimal temperature for warm floors is considered to be in the range of 20-30 degrees.

Lastly, do not cover the laminate with running carpets or other items that impede efficient heat distribution.

Conclusions and useful video on the topic

If you decide to install the heating system yourself, we suggest that you study the work of the masters and listen to some practical tips from our selection of video materials.

How to arrange a water circuit for heating a wooden floor:

Installation of an infrared film under the laminate and connection to a temperature sensor:

How to connect a water floor heating to the heating system:

As you can see, there is nothing super complicated in installing a warm floor under the laminate. But if you do not have experience in such work, it is worth making a plan for the future design and indicating the location of all elements of the system, and seek the advice of qualified craftsmen.

Share with your readers your experience in arranging a warm floor on a wooden base. Please leave comments, ask questions about the topic of the article and participate in discussions - the feedback form is located below.

Warm floor under the laminate on the concrete floor: design nuances + detailed installation instruction

Warm floor under the laminate on the concrete floor: design nuances + detailed installation instruction  How to choose a warm floor under the laminate: a comparative analysis of the best options

How to choose a warm floor under the laminate: a comparative analysis of the best options  Laminate underfloor heating: installation and installation of a film infrared system

Laminate underfloor heating: installation and installation of a film infrared system  Heated floor under linoleum on a wooden floor: step-by-step installation instruction

Heated floor under linoleum on a wooden floor: step-by-step installation instruction  Linoleum electric underfloor heating: system advantages and installation instructions

Linoleum electric underfloor heating: system advantages and installation instructions  Which underfloor heating is better for tiles: the pros and cons of various solutions + an overview of the best manufacturers

Which underfloor heating is better for tiles: the pros and cons of various solutions + an overview of the best manufacturers  How much does it cost to connect gas to a private house: the price of organizing gas supply

How much does it cost to connect gas to a private house: the price of organizing gas supply  The best washing machines with dryer: model rating and customer tips

The best washing machines with dryer: model rating and customer tips  What is the color temperature of light and the nuances of choosing the temperature of the lamps to suit your needs

What is the color temperature of light and the nuances of choosing the temperature of the lamps to suit your needs  Replacement of a geyser in an apartment: replacement paperwork + basic norms and requirements

Replacement of a geyser in an apartment: replacement paperwork + basic norms and requirements

I’m building a house from scratch, it’s possible to do everything with the latest technology. And I’m just wondering what would make a warm floor a heating system. There is a question about its compatibility with laminate or linoleum, which is very important for me now. For now, I will focus on the infrared type and high-quality flooring. With such a detailed analysis, I understood how and what to do, I will try to assemble and install everything myself without hiring specialists. I always have time to pay, and if I can do it myself - it will be doubly pleasant.

Laminate flooring and underfloor heating, of course, are a good thing.

I made a mistake in my time when I was making floor heating in rooms. I chose a 10 mm thick laminate, European quality, paid a ton of money. There was a special badge on it - suitable for a warm floor.

I thought it was some kind of special heat-conducting laminate, but it turned out that it is just suitable, in the sense it will not crumble with little heat and will not emit harmful substances.

So, this laminate, although beautiful, solid, safe, but it passes heat very poorly. Putting the thermostat on high temperature is very expensive for the money out.

So we now very rarely use it when it's very cold.

Oh how. And I always thought that for a water heated floor, you must definitely do a screed. And then it turns out you can do with slats.Well, as I understand it, under the pipes the system is the same as with the screed? In the sense of need to install insulation? And what about the space on top of the pipes? Is there just an air gap or something else you can (need) arrange?

Hello. This TP system looks something like this (see photo). Regarding the last question, it is voiced in the article:

“At the finishing stage, it remains to close the “pie” with waterproofing (for example, a layer of polyethylene with a thickness of at least 100 microns) to reduce the noise effects during heating and cooling of the pipes. For the arrangement of the finishing flooring, plywood that has passed the chamber drying, or gypsum-fiber sheets that conduct heat well are best suited.

But before the sheathing begins, the warm floor must work at least 2 days, then cool down to a temperature of 15-17 ° C.

“