Indirect heating boiler for gas boiler: specifics of operation and connection

A powerful gas boiler installed in the cottage can easily solve the problem of heating and supplying the house with hot water. But the amount of heated liquid for hygiene and household needs is limited and does not always suit the owners. To compensate for its shortage, install BKN - indirect heating boiler for a gas boiler.

Consider the features and functional capabilities of the storage unit, and also find out how best to use it in tandem with a gas boiler, so that the result is as effective as possible.

The content of the article:

Distinctive features of indirect heating boiler

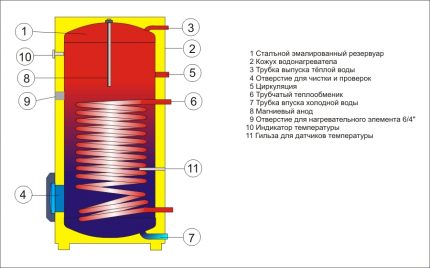

A boiler is a large barrel, the main function of which is the cumulative one. It happens of various volume and form, but its purpose does not change from this. Without a boiler, a problem may arise when using, for example, two showers or a shower and a kitchen faucet at once.

If a household 2-circuit boiler with a capacity of 24-28 kW gives out only 12-13 l / min to the duct, and 15-17 l / min is required for one shower, then when you turn on any additional tap, there will be a shortage of water supply. The boiler simply does not have enough working capacity to provide several points with hot water.

All storage boilers can be divided into 2 large categories:

- direct heating, creating a reserve of hot water using a heating element - for example, an electric heater;

- Indirect heating, preheating the water already with a hot coolant.

There are other types of boilers - for example, conventional storage water heaters. But indirectly only energy storage devices can receive energy and heat water.

BKN, in contrast to the volatile equipment running on electric, gas or solid fuel, uses the heat generated by the boiler. Simply put, its functioning does not require additional energy.

The drive easily fits into the DHW system, while not causing problems during operation.

Users see the use of BKN many advantages:

- the unit does not require electrical power and wins on the economic side;

- hot water is always “ready”, you don’t need to skip the cold water and wait for it to heat up;

- several points of water distribution can work freely;

- stable, non-falling water temperature during consumption.

Disadvantages are also available: the high cost of the unit and additional space in the boiler room.

By all characteristics, BKN is suitable for use in conjunction with gas boiler. Moreover, this is one of the best solutions for equipping a hot water preparation system for a private house with a large number of residents.

But boilers are different, so consider both acceptable options and those where problems may arise.

Gas heating equipment + BKN

In the country house for a summer vacation, it is not necessary to establish a complex communication system, while for a cottage of permanent residence it is simply necessary. It is not worth considering whether an additional boiler for a gas boiler is needed - of course, it will turn out to be a very useful acquisition, significantly increasing the comfort of living in the house.

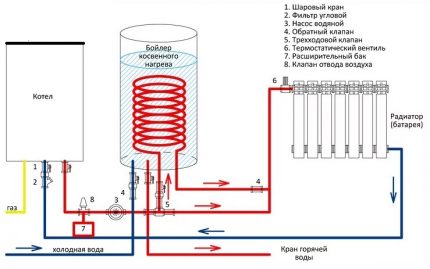

We will review the basic connection schemes of the BKN in order to prevent errors that are possible with self-installation of equipment.

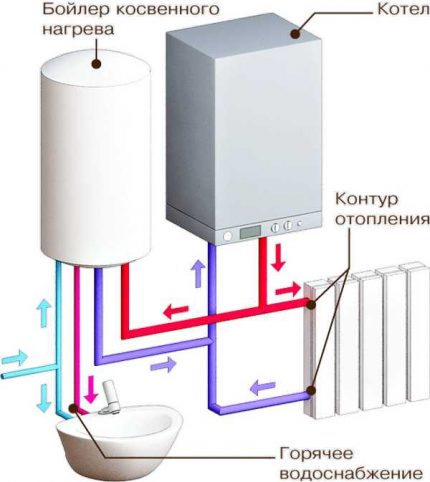

Connection diagram for a 1-circuit boiler

Single-circuit units perform one of the functions declared by the manufacturer: they either provide water heating for domestic hot water, or they heat a house - and the second option is used much more often in everyday life.

The combined solution - a 1-circuit gas boiler + BKN - is one of the best for a small cottage.

The heating process occurs as follows:

- cold water enters the boiler, where it is heated to the desired temperature (for example, + 80 ° C) by a gas burner;

- heated coolant enters the heating circuit - to the radiators - and to the heat exchanger storage water heater, i.e. a boiler;

- by increasing the temperature of the heat exchanger, the water in the boiler is heated and when the taps are turned on, it enters the consumer.

When implementing this scheme of a gas 1-circuit boiler with an indirect boiler, the technical data are of primary importance - the power and flow rate of the coolant.

According to average indicators, the water in the boiler, if it has not previously functioned, is heated from zero to an acceptable temperature in 5-15 minutes, that is, the wait will not last long. Typically, the unit is in working condition, so there is always access to heated water.

Let's analyze the features of the binding of the devices in question.

First you need to choose the most convenient place for installation - most often it is a boiler room, a separate non-residential premises. It is better to arrange the units at a close distance from each other - so the heating process is faster, and less materials are consumed.

The strapping takes place on two sides: loading and water supply.

At the exit of the boiler, it is recommended to install diaphragm expansion tankcompensating for thermal expansion and stabilizing the system. All circuits must be equipped with ball valves and check valves that control the direction of flow of the coolant.

The installation of filters will not be superfluous - the water is supplied to the system differently, and during the accident sand or other debris can get into it, which can contaminate the coolant and disable the equipment.

On both sides of the pump, shut-off valves are installed. The same tap - at the entrance of cold water to the boiler.

A tee with a drain cock is installed on the boiler nozzle, and shut-off valves are installed on both pipes so that the unit can always be cut off from the boiler for cleaning or other maintenance. At the inlet, in front of the stopcock, an air vent must be placed.

The best option is to connect using a three-way thermostatic valve, which organizes the exit of the coolant from the boiler and its division into two streams - into the boiler and the heating sector. With it, you can adjust the temperature: if heating is suitable for radiators up to + 80-90 ° С, then for warm floors it is better to limit it to + 45 ° С.

If there is no three-way valve, then install two circulation pump, one of which serves BKN, the other is for the heating branch.

Sometimes circuits with coolant recirculation are used - for example, to constantly maintain a heated towel rail in a “working” state. Heated water circulates in a closed circuit, preventing the pipe from cooling. An obligatory element is a circulation pump, and a check valve is not needed. The disadvantage of such a system in the summer is the energy overrun.

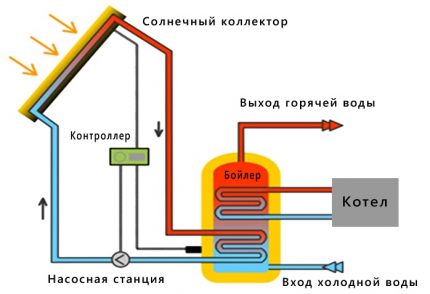

With the transition of the gas boiler to “summer mode”, the heating circuit is simply cut off - the gas burner heats the coolant for the boiler. But there is another way out - just turn off the gas boiler and use only a boiler. This is possible if the drive is additionally equipped with an autonomous heating source - heating elements.

Two applications with a 2-circuit boiler

Owners of gas heating equipment are also interested in how it works. indirect heating boiler with a 2-circuit gas boiler. Experts believe that the interaction of the units is possible, but the result depends on the connection scheme: with one of them they simply are not designed to work with each other.

Integration of the boiler into the DHW circuit

First, consider the option when the boiler is embedded in the DHW circuit. From a hydraulic point of view, everything looks right. A three-contact mechanical thermostat, placed in the boiler body, closes the pump power circuit when the temperature drops.

He, in turn, begins to pump water, which circulates along the circuit between two heat exchangers: heats up from a gas burner, and then moves to the BKN coil.

The problem arises precisely because of the mismatch of temperature parameters. Suppose that initially the boiler filling temperature is + 15 ° C, and the recommended temperature for heating the water in the boiler + 60 ° C is no longer allowed by the automatic limiter.

The difference between the two given parameters at 45˚ is significant, therefore, heat transfer in the boiler is quite intense.But the temperature begins to rise, and when it reaches + 40˚С, the difference is already much smaller - only 20˚. Accordingly, heat transfer slows down.

Do not forget that water continues to circulate between the two devices. It is not the 15-degree coolant from the cold water system that is recommended by the manufacturer that begins to flow to the gas burner of the boiler, but the 40- and then 50-degree heated fluid from the boiler.

In the boiler, the water begins to cool - the sensor turns on again, and the circulation process resumes. And so constantly. This leads to the fact that the water in the boiler does not reach the desired temperature, but remains not hot enough, which is not suitable for domestic use of hot water.

The process of interaction between the two units could take place if the boiler burner heated the coolant to + 80 ° C, but this is prohibited by the instructions for protecting users from burns.

Another reason not to use BKN and the DHW circuit of a gas boiler in steam is the inability to heat water in the boiler to a temperature exceeding + 60 ° C. This is due to sanitary standards.

It can be concluded that for just two, but significant reasons, the scheme for combining a gas boiler and BKN through a hot water circuit is recognized as ineffective and unsafe. If you already have a dual-circuit boiler, just use it for its intended purpose: use one circuit for the heating system, the second for domestic hot water.

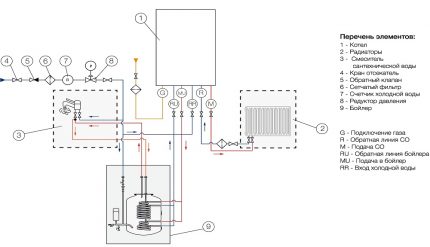

BKN interaction with a heating circuit

The second option is the interaction of the BKN with the heating circuit. The technical solution works great if there is not enough gas boiler performance, and this is the only effective way to connect the BKN to a 2-circuit boiler.

With electronic control, you need to configure the boiler to heat water + 70 ° C - just such coolant will go to the boiler, where further temperature control will take place. The thermostat located in the boiler will turn on the pump when the temperature drops, when it reaches the required value, turn it off.

With mechanical control of a gas boiler, everything happens differently. A second thermostat is connected to the boiler thermostat - a boiler, and then the first device can be controlled using the second. For example, if you set the temperature to + 80 ° С on the second, then the first, working one, will require heating the water to + 80 ° С, regardless of what temperature is set on it.

When the water in the boiler heats up to the desired temperature, the second thermostat breaks the circuit, and the first, located on the boiler, again becomes the “main one”. If at this moment the temperature is set at + 40 ° C, then it will drop to 40.

How to make binding without errors?

In order for both units - both the gas boiler and the BKN - to work smoothly and throughout the entire service life, it is important to correctly complete strapping, that is, establish a security group and other elements.

When installing coarse filters, be sure to check its location - an arrow is placed on the body, indicating the direction of water movement.

This filter cannot be installed vertically, since as a result coarse particles accumulate in the pipe, and not in the filter itself. Cleaning can only be carried out by washing under pressure - so you can stain the entire boiler room.

The expansion tank must not be installed separately, but between the boiler and the non-return valve, otherwise it will be useless and will not perform its functions.

Conclusions and useful video on the topic

How to make a strapping of a 1-circuit boiler with BKN:

About the nuances of connecting an indirect heating boiler:

Connecting a gas boiler to a BKN in practice:

We recommend involving specialists in the installation and connection of the boiler, so that in the future you will not encounter heating or hot water problems only due to incorrect piping or the absence of important elements in the system. Do not forget about the manufacturer's instructions, which often indicate the nuances of the unit working with a particular device.

Indirect heating boiler: device, principle of operation and wiring diagrams

Indirect heating boiler: device, principle of operation and wiring diagrams  How to make a do-it-yourself indirect heating boiler: instructions and manufacturing tips

How to make a do-it-yourself indirect heating boiler: instructions and manufacturing tips  The layout of the binding of the indirect heating boiler + the rules for its installation and connection

The layout of the binding of the indirect heating boiler + the rules for its installation and connection  Electric storage boiler for heating water: criteria for choosing a water heater + rating of the best manufacturers

Electric storage boiler for heating water: criteria for choosing a water heater + rating of the best manufacturers  How to use a water heater correctly: instruction manual for flow and storage units

How to use a water heater correctly: instruction manual for flow and storage units  Schemes for connecting a water heater to a water supply system: how not to make mistakes when installing a boiler

Schemes for connecting a water heater to a water supply system: how not to make mistakes when installing a boiler  How much does it cost to connect gas to a private house: the price of organizing gas supply

How much does it cost to connect gas to a private house: the price of organizing gas supply  The best washing machines with dryer: model rating and customer tips

The best washing machines with dryer: model rating and customer tips  What is the color temperature of light and the nuances of choosing the temperature of the lamps to suit your needs

What is the color temperature of light and the nuances of choosing the temperature of the lamps to suit your needs  Replacement of a geyser in an apartment: replacement paperwork + basic norms and requirements

Replacement of a geyser in an apartment: replacement paperwork + basic norms and requirements