Indirect heating boiler: device, principle of operation and wiring diagrams

In private homes, cottages, sports complexes and hotels, they often use an indirect heating boiler - the water heater operates without being connected to a centralized water supply. This equipment copes with heating large volumes of water, easily maintains the desired temperature and ensures uninterrupted supply of a hot stream.

In a word, if you are looking for a budget water heater in a kit for a single-circuit boiler - consider installing in a BKN house. And in order to simplify the task of choice, we suggest that you familiarize yourself with the criteria for buying a boiler, the principle of its operation and connection schemes.

The content of the article:

Design features and principle of operation of the BKN

Indirect heating boiler can only work on the resources of an external source, but for the maintenance of the system in the warm season, you can connect the heater.

In order to ensure uninterrupted supply, a recirculation loop is provided in the system - water will constantly move through the pipes, and when the tap is opened, a hot stream will flow at the points of draw-off connected to the loop.

Thus, the device can significantly save on energy resources, but at the same time get no less comfort than when using a centralized hot water supply system.

How is the indirect heating boiler arranged

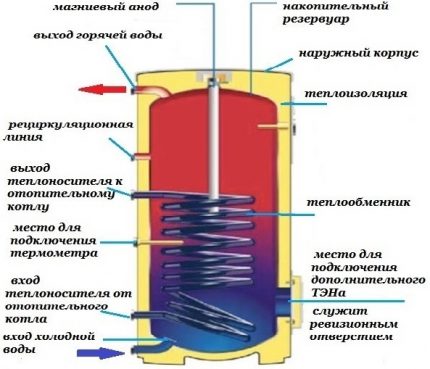

A device that heats water according to an indirect principle. - This is an insulated storage tank, inside of which a heating element is installed, operating from an external coolant.

The tank itself can be made in the form of a rectangle or a cylinder, and nozzles are provided in its walls for circulating hot water from the heating system and the input / output of water pipes.

The basis of the design is a metal or plastic container with a capacity of from ten to several thousand liters. From the inside, the tank can be coated with enamel, ceramic or glass porcelain, which helps to maintain proper water quality and avoid corrosion.

The housing is protected from heat loss by an insulating layer of polyurethane, foam rubber or mineral wool.

To prevent scale in the upper part of the tank, a magnesium or titanium anode is installed, which softens the water, protects the metal from galvanic corrosion and increases the life of the device.

The device is also equipped with a temperature controller that controls heating to a certain temperature, and safety valvesincluded in the protection group.

Pros and cons of BKN

The main advantage of an indirect heating boiler is energy savings. For its operation, you do not need to connect a gas burner or use electricity, as the direct heating device requires.

The heating system provides all the necessary resources, so hot water is an almost free “bonus”, which will help to significantly save the family budget in the cold season.

Other benefits of BKN:

- High performance - a tank with a volume of 100 liters is capable of “dispensing” about 400 liters of hot water per hour (provided a sufficiently powerful boiler is available).

- Long service life - the coolant does not come into contact with running water, as in similar direct heating devices.

- Does not overload the power grid - works from an external source of energy.

- Instant hot water - no need to wait until the cold stream flows, as when using gas columns, or the used tank heats up, like electric boiler.

- Affordable cost - If desired, the system can be assembled with your own hands.

- Ability to connect to multiple energy sourcesfor example to a vacuum solar collector, boiler, geothermal heat pump.

Of course, there were some minuses here as well.With all its merits, the speed of heating the water in the device leaves much to be desired - for the processing of 100 liters, even modern equipment will spend at least 15-20 minutes, and home-made systems can not cope in an hour.

Also, indirect heating boilers are quite bulky, so they occupy an impressive amount of free space. Large tanks may require a separate room.

Indirect heating boiler can also be made from improvised materials using a bent copper pipe for the coil, a capacious barrel with a lid or a gas cylinder for the tank:

Another version of a home-made indirect heating boiler is made using a casing from a conventional storage water heater:

In addition, this device will be truly economical only in the heating period, and in the warmer months you will have to either turn on the boiler or provide alternative heat sources - solar panels, TEN. And the price of a high-quality “indirect man” exceeds analogues with direct heating.

Types and model varieties of equipment

The most common type of device is a storage tank, inside of which are placed steel or brass pipes (coil) with circulating heat carrier.

The speed of heating the water depends on the number of turns on its spiral. The principle of operation of this design of an indirect heating boiler is extremely simple: cold water enters the tank, and the coolant, moving along the coil, heats it to the desired temperature.

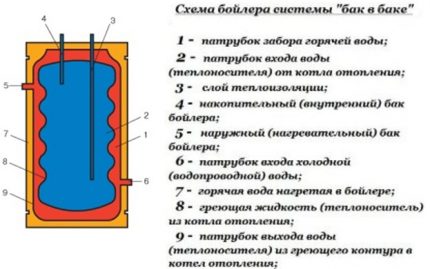

But there are also devices designed according to the “tank in tank” scheme, where instead of a spiral pipeline two containers of various diameters are used.

The system works like this: cold water enters the smaller tank, which is heated by the hot coolant circulating between the walls of the tanks.

In such devices, water becomes warm in a matter of minutes - a large heating area allows the equipment to operate efficiently in flow mode, guaranteeing an uninterrupted supply of a hot stream.

The combined BKN for heating water can use energy from several sources at once or be equipped with a built-in heating element.

Varieties of boiler KN

By placement:

- Wall - Usually, this is a small device with a displacement of up to 200 liters. It is fastened with special brackets to any vertical surface strong enough to support the weight of a completely filled tank (plasterboard partitions definitely will not work). It can be located high enough and not occupy the useful area of the room.

- Floor - a capacious boiler designed for a large number of consumers. However, for a device with a capacity exceeding 1000 l, it is recommended to allocate a separate room - equip a boiler room. But such a system is usually installed to service large cottages, enterprises, hotels and other institutions, for family use you can do with a 250-300 liter appliance.

According to the shape of the tank:

- Horizontal - It takes up a lot of space, but it is easier to independently maintain the desired water level in it without resorting to connecting pumps.

- Vertical - saves free space, but is very limited in capacity.

Depending on the nuances of use, the features of the layout and the availability of free space, you can choose the optimal model of BKN, which organically fits into the design of the room and provides your home with an uninterrupted supply of hot water.

What to look for when choosing a BKN

One of the main parameters that should be the decisive argument when buying a boiler is its capacity. To find out the required tank capacity, we recommend that you focus on the number of people in your family.

Displacement recommendations:

- 80-100 l - 2 consumers;

- 100-120 l - 3 persons;

- 120-150 l - 4 users;

- 150-200 l - 5 consumers.

It is important to separate the concepts of “total tank capacity” and “working capacity”, because a spiral pipe located inside the boiler occupies a significant area. Therefore, be sure to check when buying how much real water is placed in the device. In the technical specifications, this nuance should be indicated.

Also, in addition to the “universal” recount of potential consumers, it is necessary to take into account both the frequency and volume of water use. For example, if your family likes to soak in a warm bath rather than taking a quick shower, the working capacity of the tank should be appropriate - at least 120 liters.

Other important parameters:

- Power - the greater the water consumption, the higher should be the resource of the device. But it is important that the power of the "indirect" does not exceed the capacity of the heating system (or other external energy source). For example, if the volume of the storage tank varies between 120-150 liters, the boiler power must be at least 23 kW, and for 160-200 liters it will already need 31-39 kW.

- Heating time - a parameter depending on the volume of the tank and the number of turns on the coil (large or combined containers can be equipped with several spirals).

- Tank material - for long-term use, stainless steel or medical steel boilers are best suited.

- Thermal insulation - in cheap models, foam rubber is used, which quickly wears out and transmits heat, so it is better to purchase a more expensive device that used polyurethane.

- Control - the device will be able to work in automatic mode, if necessary, turning off and starting the current of water, control the heating using a temperature sensor.

When choosing the shape and size of the tank, it is also necessary to take into account that although theoretically the boiler can be installed in any room where there is access to the heating main, its optimal location is next to the boiler. So heat transfer is most efficient.

Indirect heating boiler can be made by hand.Instructions for the manufacture of the unit are described in this article.

Nuances and boiler connection schemes

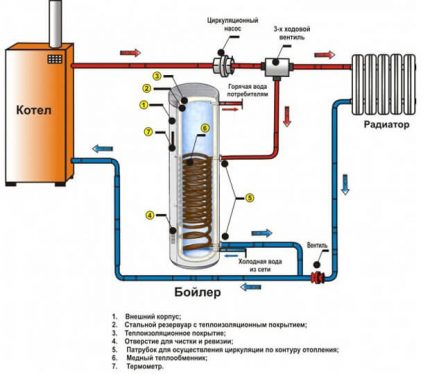

As already mentioned, BKN uses the energy of an external source to heat water. Therefore, before connecting to a coolant, it is important to choose a suitable circuit for mounting the device. Consider the most common options.

General principles for installing the device

It is necessary to mount the boiler on a prepared, level surface in the immediate vicinity of the boiler. Suspended models are mounted on a concrete or brick wall, at the same level or slightly higher than the boiler.

For an outdoor appliance - level the area reserved for placing the tank (if the floor is critically uneven, you can make a stand in the form of a podium).

Herself strapping BKN Designed to connect the device to two systems - water supply and heating. For this, there are special nozzles on the body.

Accession Principles:

- Cold water from the drainage system should enter the lower part of the tank, and hot water should exit the upper part.

- Inlet of cold water should be installed check valve, which will prevent the leakage of hot flow from the boiler in the event of a decrease in pressure in the system.

- In the middle of the device, a point for recirculation can be located.

- When the heating circuit is switched on, the coolant should move from top to bottom. That is, a pipe with hot water enters the upper pipe, and a pipe with a cooled one comes out from below.

- All nozzles must be equipped with taps with union nuts to ensure that the boiler can be switched off, for example, in case of replacement of the device or repair work.

Thanks to this scheme, the maximum efficiency of the device is achieved, since the coolant circulating in the coil heats the water in the upper part of the tank, transfers the remaining heat to the low-temperature layers and enters the boiler for new heating.

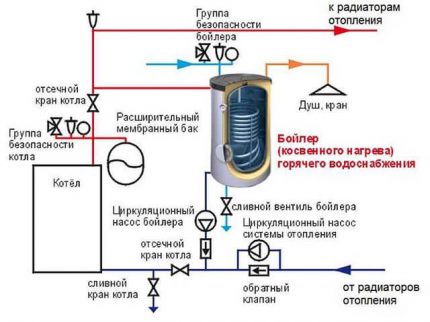

Schemes for connecting the BKN to the source

In order to choose the right scheme for connecting the boiler to the heating system, it is necessary to take into account the possibilities of the existing wiring and the installation location of the heating device. There are several solutions.

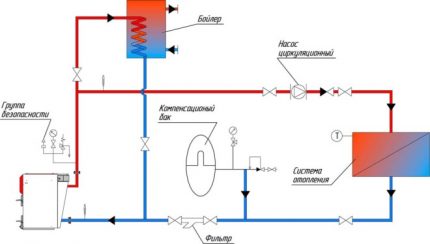

Option 1. The most common scheme for constant use of hot water is a connection through a three-way valve. It assumes the presence of two heating circuits - the main and separate for BKN.

To do this, crashes into a hot water supply circulation pump, and after it a three-way valve is installed, which is controlled by a boiler thermostat.

The scheme works as follows: when the water temperature in the boiler drops below a predetermined mark, the valve switches the system to heat the storage tank at the signal of the thermostat, and after reaching the desired value, it sends the flow to circulate along the common house circuit.

Option 2. Installing a dual-pump system - it is advisable to use the scheme if there is no need for constant and large volumes of hot water. For example, a boiler is installed in a country house and is used only on weekends.

In this case, the BKN and the heating boiler are connected in parallel, and the coolant flows will move along two highways. For the forced movement of water, two pumps are installed: on the heating circuit and the supply pipe for the boiler.

Heating is carried out using a thermostat, which temporarily turns off the radiator heating, directing the entire resource of the system to the boiler.

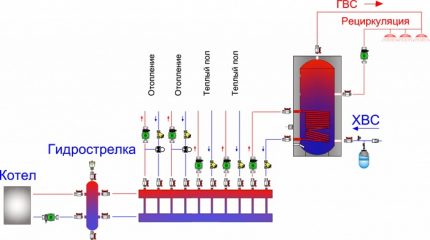

Option 3. For rooms where a multi-circuit heating system is used, for example, in addition to radiators installed warm flooruse a hydraulic distributor.

Hydroarrows redistribute pressure in individual sections of the circuit and ensure uninterrupted movement of the coolant even without the help of circulation pumps.

Without a hydrocollector in a multi-circuit system, pumping equipment can fail and even heat stroke can occur with damage to radiators.

Return Circulation System

If a third input is provided in the boiler, a recirculation system can be connected to it. To do this, a loopback loop is started at the recirculation point on the device body.

To implement the scheme, you need to mount an additional circuit and install the following elements:

- Check valve at the inlet to the heater.

- Automatic air ventprotecting the pump from air ingress before starting.

- Safety valvewhich will protect from pressure drops.

- Diaphragm expansion tank, in which excess water will flow away with increasing pressure in the system. Please note that the capacity of the reserve capacity must be at least 1/10 of the volume of the BKN itself.

If the branch pipe for the recirculation circuit is not provided in the device of the indirect heating boiler, it is possible to insert the return line into the cold water pipe and install the pump. Then the connection is carried out according to the scheme below.

Connection according to the return circuit ensures an uninterrupted supply of hot water - that is, it will not be necessary to wait until the coolant warms up the water in the tank.

Conclusions and useful video on the topic

Before deciding to purchase and install a new water heater in the house, we suggest studying video materials that clearly demonstrate the advantages of the “indirect man” and the nuances of connecting it.

In this video you can find out how indirect heating boilers work with a coolant located inside the coil:

All the nuances of the internal structure and the operating principles of various types of indirect heating boilers in a detailed video educational program from a practicing master:

Overview and connection of a 300 liter device that runs on two coolants - a boiler and solar panels:

A detailed analysis of the BKN device and its connection schemes. Practical tips and tricks from the wizard:

As for maintenance, the indirect heating boiler is a fairly unpretentious equipment. With proper installation and smooth operation of the system, it may only be necessary to replace the magnesium anode every 6-12 months and preventive flushing of the tank.

The frequency of service depends on the quality of tap water and the intensity of use. But if you have installed a device that works on the "tank in tank" technology, which has a self-cleaning function, you will not need to change the consumable.

However, you can always agree on regular maintenance of equipment with the craftsmen specializing in the installation and repair of water supply systems.

Have a question? Or is there a desire to share personal experience in choosing, connecting and using an indirect heating boiler? Please leave comments on this article.

Indirect heating boiler for gas boiler: specifics of operation and connection

Indirect heating boiler for gas boiler: specifics of operation and connection  How to make a do-it-yourself indirect heating boiler: instructions and manufacturing tips

How to make a do-it-yourself indirect heating boiler: instructions and manufacturing tips  The layout of the binding of the indirect heating boiler + the rules for its installation and connection

The layout of the binding of the indirect heating boiler + the rules for its installation and connection  Electric storage boiler for heating water: criteria for choosing a water heater + rating of the best manufacturers

Electric storage boiler for heating water: criteria for choosing a water heater + rating of the best manufacturers  Safety valve for the boiler: design structure, operating principle and installation rules

Safety valve for the boiler: design structure, operating principle and installation rules  Schemes for connecting a water heater to a water supply system: how not to make mistakes when installing a boiler

Schemes for connecting a water heater to a water supply system: how not to make mistakes when installing a boiler  How much does it cost to connect gas to a private house: the price of organizing gas supply

How much does it cost to connect gas to a private house: the price of organizing gas supply  The best washing machines with dryer: model rating and customer tips

The best washing machines with dryer: model rating and customer tips  What is the color temperature of light and the nuances of choosing the temperature of the lamps to suit your needs

What is the color temperature of light and the nuances of choosing the temperature of the lamps to suit your needs  Replacement of a geyser in an apartment: replacement paperwork + basic norms and requirements

Replacement of a geyser in an apartment: replacement paperwork + basic norms and requirements

It was interesting to read. Since I live in my house, I use an electric water heater. In summer, we rarely use hot water, mainly wash our hands and dishes. We wash mainly in the bath. But in winter, consumption of hot water increases significantly. So I was thinking of putting an indirect heating boiler. Only the space near the boiler is very small. Now, if the boiler was two times less, then the very thing.

Well, put a boiler at 100 liters, it is not too big in size. In addition, they are usually put in the basement, where they do not interfere too much. The truth is not the fact that a volume of 100 liters will be enough. It depends on how many people live in the house.

A great purchase, especially if you live in a village and pump water from a well. There will always be hot water at home, as in an ordinary city apartment, and it’s not very expensive for money. The information is presented correctly, he himself at one time re-read a lot of different material on this topic. Everything is set out correctly, you can take note, and as a guide to choosing a boiler to your home is quite suitable.

If I understood correctly, then this boiler will work from a boiler, or from a heating element and in general, all the disadvantages that ordinary boilers have are inherent in it. In fact, this is a storage tank with hot water. In this case, I would recommend installing good filters at its inlet, since not a single anode will save the internal walls of the tank from corrosion.