DIY boiler repair: possible malfunctions and instructions for their elimination

An electric water heater, like everything on earth, is not eternal. Poor quality of the device itself, improper operation, installation errors and unfortunate accidents can ruin the device. In the event of minor breakdowns, repairing the boiler with your own hands is not difficult, but a number of malfunctions can be fixed only in the service center.

We will talk about what violations in the operation of water heating equipment can be eliminated with one's own hand. In the article we presented, the nuances of diagnosis are given, methods for restoring the operation of the unit are described in detail. Useful recommendations for maintenance are given.

The content of the article:

How does a boiler work?

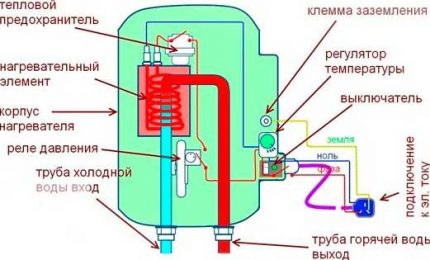

There are accumulative and flow type water heaters. The first consists of a large tank in which a heating element is installed. Inside the device, water enters, which is stored there at a certain temperature.

Via temperature sensorconnected to the thermostat, the temperature is maintained at the set level. To prevent the loss of thermal energy, the housing of the storage tank is closed with a layer of insulation.

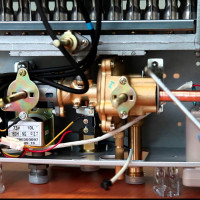

Flow models work differently. They also have a housing and a heating element, but no water is stored inside. The device turns on at the moment when a stream of water begins to pass through its body.

The fluid quickly heats up to the desired temperature. These devices are more powerful than storage models, they consume more electricity. But their dimensions are compact, and installation is a bit easier.

And yet, in everyday life, an accumulative version of a water heater is more often used. Failures in different types of devices are similar, and they are eliminated by approximately the same means.

To automate the operation of a water heater, use a thermostat. This item retrieves the current status using temperature sensor. It turns on and off the heating element based on the incoming information.

This helps not only to maintain the optimum temperature inside the drive, but also makes it possible to save energy. The device also prevents dangerous overheating of water, which can cause a serious accident.

Hot water is gradually taken from the tank and replaced by cold streams from the water supply. At this moment, the heating element is usually turned on. If hot water has not been used in the boiler for a long time, then it can cool. Too low temperature also gives a signal to turn on TENA.

With features of choice electric heaters for water will introduce an article devoted to design differences and technical characteristics of equipment models popular among consumers.

Types of heaters according to the used heating elements

Distinguish between dry and wet boilers TENOM. In the first embodiment, the heating element is placed in a special flask, and in the second it is in direct contact with water. Both models have certain advantages.

In terms of boiler repair, it is considered that “dry” TEN replacing is much easier than “wet”, because for this you just need to remove it from the bulb and put a new element in it.

In the case of “wet” TENOM You will first have to completely drain the water from the tank, and only then make a replacement. Usually, “dry” heating elements are less efficient than the “wet” option, therefore, in the boiler, more often than not one, but two such heating elements are installed.

Due to the nature of operation, “dry” TENY burn out more often and need replacing, therefore models with “wet” TENami more popular. It is worth noting that you can find modern boilers with very reliable “dry” TENami the latest generation, but the cost of such devices may be too high.

But on the amount of scale generated during operation, type TENA does not affect. But if the “wet” element deposits scale directly on the surface, then with a “dry” heating element, deposits accumulate on the protective flask.

Vulnerable elements of a water heater

Even before installing the device, you should carefully study its technical passport and operating instructions. These documents usually accurately reflect the device’s device, describe the position of the main elements, give recommendations for proper use, etc.

Many failures of water heaters are somehow connected with the tank, and they appear in the form of a leak. In order to properly respond and choose the right strategy for troubleshooting, you should determine the location of the leak and identify its cause.

Not always the cause of the leak is the damage to the tank, more often its presence indicates that:

- the protective gasket has lost weight;

- there were problems in the operation of the heater;

- the temperature regulator is damaged and / or temperature sensor.

To protect the storage water heater, it is included or built into the housing in the strapping circuit safety valve, the presence of which significantly reduces the number of breakdowns and the occurrence of emergency situations.

Sometimes a leak occurs at the entrance to the boiler body of hot and cold water pipes. Most often, this is a consequence of improper installation, which appears immediately after commissioning the device or shortly after.Care must be taken in advance to properly seal all joints.

High-quality boilers usually install not one, but two or three thermostats. The first regulates the water temperature in the device, the second is needed to monitor the state of the first, and the third device allows you to check the working condition of the heating element.

The design of these elements may vary. Rod and capillary devices are popular, the electronic version of the thermostat is considered very convenient in operation. But the principle of operation of such devices is almost the same, in case of breakdown, the device simply needs to be replaced with a similar model.

However, such a malfunction will not be critical for the operation of the boiler. If TEN OK, the device will still warm the water. But the lack of control over the heating temperature can lead to incorrect operation of the device. The result may be a breakdown of the heating element or other problems.

Cleaning and maintenance

Following manufacturer's recommendations can save a lot of problems for the boiler owner. For example, the instructions usually recommend regular maintenance of the boiler, which boils down to an external inspection and cleaning procedure.

Usually the recommended maintenance periods vary depending on the type of heating element and the nature of its operation. For wet TENA cleaning is recommended annually, and for “dry” - at least once every two years.

If the device is used at high loads, for example, at the factory or in a public place, then maintenance should be carried out every six months, regardless of type TENA.

The maintenance procedure may affect warranty service. Sometimes the manufacturer indicates in the documents that the procedure should not be carried out by the owner of the device, but by repairmen certified by the manufacturer. In this case, it is better to follow the manufacturer's instructions.

Independently carry out maintenance is not too difficult. To do this, disconnect the boiler from the power supply and water supply, and then drain the water inside. After that, the housing is opened by unscrewing the mounting bolts and removed TEN. The heater and the inner surface of the tank are cleaned of scale and dirt.

Replace the protective pad and the magnesium anode. Then carry out the reassembly of the device and its connection to the electric and water supply network. One of the common causes of damage to the boiler tank is the so-called electrical corrosion. It gradually destroys the surface of the drive, which leads to leakage.

To prevent this problem, many manufacturers install next to TENOM magnesium anode. This element is not eternal, the task of the device owner is to timely replace it with a new element. Unfortunately, some people forget about this, as a result of which their boiler may be completely damaged.

Do not forget about such an important protective element as grounding. Its absence not only poses a risk of injury during operation of the device, but also can amplify or provoke electrocorrosion.

Repair common breakdowns

The surface of the tank consists of several layers: the tank itself, insulation, the outer casing, etc. This allows you to save heat and save electricity, but makes it difficult to repair the device.

The fact is that if the integrity of the inner tank or the outer shell is damaged, then this also destructively affects the state of the insulating material.

The cause of a tank breakdown may be careless handling of the device during installation and / or operation. If you drop a heavy object on the case or accidentally hit it, a chip, crack, or other similar damage may form on the surface.

It is almost impossible to fix such a breakdown on your own, you will either have to contact a service center, or just buy and install a new boiler. Of course, you can solder a hole inside or outside, but this method will only solve the problem for a while.

It is unlikely to be able to provide sufficient protection for the thermal insulation material at home. Gradually, it will collapse, as a result, the boiler will retain heat much worse, and corrosion processes will develop. If the boiler starts to leak, this does not necessarily mean that the tank has deteriorated.

First you need to establish the exact location of the leak. If water leaks in the place where the gasket is installed, you may just need to replace this element. The procedure for the maintenance of the device during which such an operation is performed has already been described.

One of the most obvious and common boiler failures is a malfunction. TENA. If the water inside stopped to heat up, most likely this problem arose.

Of course, before you start dismantling and disassembling the device to replace the heater, you should make sure that there is power supply in the house, and the electricity flows unhindered to the boiler. For such a check, you should use the tester, attaching it to the contact points.

For verification, it is recommended to perform the following operations:

- The tester measurement scale should be set between 220 and 250 V.

- Fix the voltage value at the terminals of the device connected to the mains.

- If there is no voltage, a heater malfunction can be confidently detected.

- If voltage is present, the test must be continued.

- Disconnect the water heater from the mains.

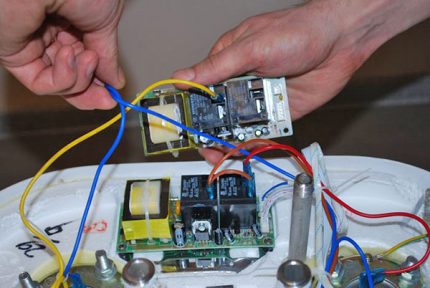

- Then detach the thermostat from TENA and remove the insulation from the contacts of the heating element.

- Now you need to use a tester to measure the voltage on uninsulated contacts.

- The lack of reaction allows us to conclude a malfunction TENA, its presence indicates that the device is in good condition.

TEN working properly, but the water does not heat up? The thermostat is probably defective. To check this version, you should set the tester to maximum, and then check the voltage sizes at the input and output of the device.

Lack of response will indicate that a replacement is necessary. The presence of voltage does not give a clear signal that the thermostat is in good condition, the test should continue.

Now you need to set the tester to the minimum value, and take measurements on the thermostat contacts for some time. If the sensors cannot be fixed, you need to ask someone for help.

Should heat the edge temperature sensor (e.g. using a lighter), and follow up thermal relay. If the heating caused it to open, you can consider the device in good condition. A lack of response indicates that a replacement is necessary.

If TEN, and the thermostat is working properly, there may be no heating due to improper device settings. Easy adjustment will help fix the problem. Another possible scenario in this situation is a breakdown of the control board. In this case, you will have to seek help from a specialized center.

Replacing TENA, gaskets or any other element of the boiler must be carried out on a new part, which in all respects corresponds to a faulty one. Therefore, it is better to dismantle the old element and take it with you to the store.

It does not hurt to study the product labeling or its characteristics set forth in the technical passport of the boiler so that the serviceable element corresponds to the broken one not only externally.

Boiler disassembly for repair perform in the following order:

- Turn off the power and water supply.

- Drain the water inside.

- Unscrew the fasteners from the protective cover.

- Remove the cover.

- Dismantle TEN.

- Take out the thermostat and temperature sensor.

It is usually more convenient to work with mounted models if you first remove them from the wall. The cover can be located at the bottom, side and even on the front panel - it all depends on the model. Particular care must be taken with temperature sensor.

If the flasks of the device accidentally break, they cannot be repaired. Most likely, you will have to completely replace the entire thermostat.

Caution will not hurt when removing the heating element. If on the surface TENA or the bulb that protects it, too much scum has accumulated, it may not be easy to remove it from the tank. Sudden movements and excessive force can cause permanent damage.

Faced with a problem that you cannot solve on your own, be sure to contact a service center. Only a specialist can make an accurate diagnosis, correctly perform repairs or install a new part.

Conclusions and useful video on the topic

The experience of professionals and amateurs is the best adviser when doing DIY repairs. Helpful videos may help you identify the problem and fix it.

An option for eliminating boiler leakage using cold welding is presented in this video:

The procedure for cleaning the boiler is graphically presented here:

This video demonstrates the procedure for checking the electrical elements of a boiler using a tester:

Self-repair of the boiler is reduced mainly to the replacement of damaged elements. Timely maintenance, proper installation and compliance with operating rules will prevent a lot of breakdowns and extend the life of the device.

Please write comments, post photographs, ask questions in the block below. Tell us about how to restore the efficiency of the water heater with your own hands. It is possible that your recommendations will be very useful to site visitors.

Do-it-yourself vector gas column repair “Vector Lux”: common breakdowns + tips for fixing them

Do-it-yourself vector gas column repair “Vector Lux”: common breakdowns + tips for fixing them  How to make a repair of a water heater with your own hands: methods available for a home master

How to make a repair of a water heater with your own hands: methods available for a home master  Do-it-yourself repair of a gas column heat exchanger: the main stages of soldering a copper radiator

Do-it-yourself repair of a gas column heat exchanger: the main stages of soldering a copper radiator  DIY gas heater setup and repair: a guide for water heater owners

DIY gas heater setup and repair: a guide for water heater owners  Oasis gas column repair: an overview of typical breakdowns and recommendations for their elimination

Oasis gas column repair: an overview of typical breakdowns and recommendations for their elimination  How to make a do-it-yourself indirect heating boiler: instructions and manufacturing tips

How to make a do-it-yourself indirect heating boiler: instructions and manufacturing tips  How much does it cost to connect gas to a private house: the price of organizing gas supply

How much does it cost to connect gas to a private house: the price of organizing gas supply  The best washing machines with dryer: model rating and customer tips

The best washing machines with dryer: model rating and customer tips  What is the color temperature of light and the nuances of choosing the temperature of the lamps to suit your needs

What is the color temperature of light and the nuances of choosing the temperature of the lamps to suit your needs  Replacement of a geyser in an apartment: replacement paperwork + basic norms and requirements

Replacement of a geyser in an apartment: replacement paperwork + basic norms and requirements

I want to ask if the safety valve began to leak, what they do in such cases, where to start the repair? I also wanted to clarify the following situation, when we turn on the water in the tap, sometimes it feels like it is slightly shocking, can this mean that there is some kind of breakdown in the boiler? Or is it not related to the boiler? We also have suspicions that the heating element in the washing machine could have covered itself.

Hello. Unfortunately, this can mean anything and it is not worth experimenting here if you do not know the source exactly. Do not open the water taps when the boiler or washer is plugged in until the electrician rings the system carefully. Slightly may become a serious electric shock. You can dig as much as you like in the washer, sin on the boiler, and the reason may be generally in the wiring or in something else. Before the ringing - only guessing on the coffee grounds, but we do not recognize such methods.

Now about the valve. Because of what it can leak:

1. Poor safety valve (solution - replace).

2. Clogging that prevents the check valve from tightly closing (clean, but easier to replace).

3. Increased pressure in the water supply system (here it is best to install a pressure reducer, because if the valve breaks, even a rupture of a water bulb can occur with this focus).

On average, per day, a 100 liter boiler can release from 3 liters of water into the drainage system. The maximum figure is 5 liters, but it is better to look in the passport of the device.

Again, here it is impossible to diagnose the state of the boiler by letters. You would take a picture of your system, tell it in what state it is leaking - with or without water supply, when working on the network or on vacation, and so on. And in which place, in what quantities. What is your water supply system and so on. Then we would be able to answer you what happened there and how to “cure” it.

Is the valve leaking accurately? You may be confused with a device for dumping excess fluid, a safety valve. In this case, the broiler is functioning normally. Regarding the current, it's hard to say right away. If you take into account the washing machine, then I would advise checking the grounding. The main thing is not to turn a blind eye to this. Water and current are not toys, you understand.

If the boiler is shocking and does it on an ongoing basis, then it is likely that there is a break through the heater. I would smoke in the direction of this - I would check the heater for breaking, but I would not be stingy and take the cord with the amp amperes at 16 - 20. So at least you will not be killed by electric current if something happens.

Hello. Your comment is curious. The safety valve is equipped with a starting spring mechanism in the inner part of the groove, which functions as a check valve and a spring mechanism on the outlet part, which is a water discharge device when the pressure rises. These are not different devices. That is, formally, to say that the valve is leaking is true, even if it comes from a water discharge tap.

A boiler was recently installed in our house - at first the ten burned out and the valve in cold water broke. Valve replaced. And in the morning there was noise in the pipes and everywhere there was hot water (in the pipes). They blocked the water, turned off the electricity - the hose burst onto the washing machine and hot steam went from there. What is the cause of the breakdown?

Hello. There are problems with the connection. Please take a picture of the connection diagram of your boiler.

After a year, the magnesium anode looks like nothing to me. In the sense, it is practically nonexistent.Apparently the quality of the water is so poor that it simply dissolves in it. Therefore, I change it more often - once every half a year. In a good way, you need to put a filter at the input, but I still can’t get it. There is no money, then time.

Hello! I have a flat Ariston VLS 50L, after service on replacing the anodes in the on state, it began to give an error “There is no hot water when the heating element is on - the inlet tank of the water heater”. Tell me, what could break these grief masters?