Do-it-yourself vector gas column repair “Vector Lux”: common breakdowns + tips for fixing them

Among consumers, Vector gas water heaters have gained wide popularity due to their affordable cost, attractive design, and reliability. But any technique is not eternal, and individual elements and nodes of the columns are subject to wear. The simple design of the equipment allows, in most cases, to repair Vector Lux gas columns on their own, without waiting for the arrival of a specialist. This option not only saves time, but also money, agree?

But where to start and how to act? We’ll talk about all this in our article - to begin with, we’ll look at the features of the brand’s gas column and the causes of its malfunction. We also discuss repair methods and equipment maintenance procedures.

The content of the article:

Features of the columns Vector

Gas water heaters are available in two trim levels: JSD 20-W and Lux Eco. The difference in the design of the models is small, there are no fundamental differences in the design of the equipment.

Regardless of the modification, price, all Vector water heaters are equipped with electric ignition. This eliminates the presence of a constantly burning wick, which increases fire safety, equipment efficiency.

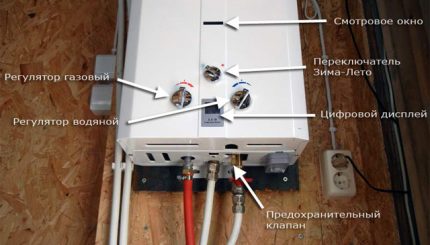

Brand column device

The device of a household gas column of the Vector brand is no different from most similar devices. We recommend that you familiarize yourself with typical column device.

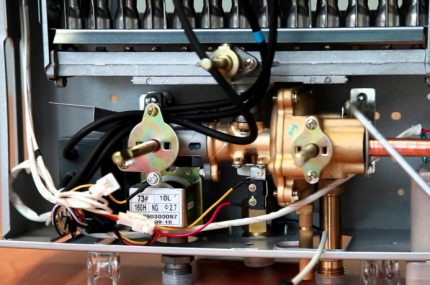

The “heart” of the device was a copper heat exchanger, which quickly heats up and has a high service life. It consists of hollow tubes into which cold water enters, and then is heated under the influence of a burner.

As you can see, the scheme of the household gas column of the Vector brand is quite simple, without a large number of additions, which ensures high reliability of the device.

The principle of the brand water heater

Columns consist of three main components, including water, gas nodes, the transition between them. After the tap opens, water enters the water unit. The valve responsible for supplying gas only works if there is sufficient network water pressure. For further supply, the gas pressure is controlled by a special regulator.

The burner ignites a mixture of air and gas, which during the combustion process in the chamber generates heat, which ensures the heating of water in the tubes of the heat exchanger.

Combustion products are discharged through a metal chimney. The toxic process is monitored by a sensor. In the absence of traction in the system, it contributes to the shutdown of the gas column.

To protect the gas water heater from overheating, the design uses a thermal relay. The device responds to changes in water temperature. When the indicator reaches 80 ° C, the burner shuts off. The design also provides a fuse that controls the pressure in the system.

The optimum temperature is considered an indicator not exceeding 55 ° C. Otherwise, scum forms on the inner surfaces of the tubes of the heat exchanger of the gas column, which will lead to malfunctions, the need to disassemble, clean the equipment.

In most cases, the water supply supplies hard water, so manufacturers do not recommend heating it to such an extent that it then needs to be diluted.

Causes of breakdowns and their elimination

Despite the simplicity of design, unpretentiousness in operation, the flow heater is not insured against breakdowns. If the gas column of the Vector brand does not turn on, do not panic. There can be several causes for the problem, and most of them can be fixed on your own.

Problem # 1 - lack of traction in the column

The absence of draft indicates that the products of combustion cannot be quickly removed from the room. This is a danger to users, so the sensor shuts off the gas column.

Sometimes the burner ignites, but immediately goes out. This can be when not enough combustion gas - the flame goes out due to a lack of oxygen to maintain combustion.

In any case, first you need to check the cravings by bringing the burning match to a special hole on the column body. If the flame is directed inward, then the chimney is working normally, the combustion products will be quickly removed, and the cause of the malfunction is different. If the flame remains stationary, directed upwards or towards the user, then it is worthwhile to carefully inspect the chimney, clean it.

Problem # 2 - difficulties with water pressure

Another reason, because of which the Vector gas brand household gas column is not ignited, may be a low pressure of cold water or its complete absence. Before you start looking for a solution to the problem, you need to make sure that cold water is supplied without interruption, to evaluate its pressure. With insufficient water pressure in the system, the solution may be to install a pump or replacing old, clogged pipes.

If there is no problem with water supply, it is worth going to the column inspection. The solution to the problem may be the adjustment of the water supply to the column.To do this, fully open the corresponding tap.

Another reason for insufficient water pressure in the column is a clogged filter. For its inspection, it is necessary to shut off the water and gas supply with valves, unscrew the nuts, and flush the net. If cleaning fails, the filter will have to be replaced.

Problem # 3 - Inadequate Gas Pressure

Sometimes the gas pressure is not enough to ignite the flow column, its normal operation. However, a similar problem cannot be solved independently. It is necessary to contact the gas service.

Problem # 4 - lack of ignition when turned on

The presence of an electric ignition system ensures the comfort of operation of the gas column, eliminates the use of a wick that is constantly on. However, it is this element that can cause the malfunction of the device.

When the tap is opened, automatic ignition should fire. This action is accompanied by a characteristic crack. If the ignition does not work or the spark is too weak to ignite the gas, the speaker will not be able to connect. Help solve this problem. battery replacement.

Problem # 5 - clogged tubes

Through the gas column Vector in the process of running water, gas. Using filters allows you to clean them from unnecessary impurities. However, the presence of blockages can cause the device to simply not turn on.

However, the filter is not always able to bring water to perfect condition. Soluble salts enter the heater together with the liquid and settle on the walls of the heat exchanger. As a result, patency of thin tubes is impaired.

Specialists remove scale using specialized reagents. A home craftsman can handle it using a solution of citric acid or vinegar. To clean the heat exchanger, it is necessary to remove it, place it in a warm solution with the addition of vinegar. You can also use special purchased products - "chemistry", designed for cleaning heat exchangers.

We talked in detail about cleaning and repairing the heat exchanger. in the next article.

Gas water heater maintenance

To prevent the gas column from repairing for a long time, it is important to periodically inspect the water heating equipment and carry out its maintenance.

To exclude the occurrence of fire hazard situations, it is necessary to pay attention to the state of the ignition group, the main burner. The equipment must be promptly cleaned of accumulated carbon deposits, not to allow the lumens of the heat exchanger to become clogged with soot.

The body of the gas column is cleaned using soapy water, detergents without abrasive substances.

Maintenance of the water heater must be carried out gas company specialists and at least once a year.

A number of activities for cleaning the column You can do it yourself, among which:

- burner cleaning;

- lubrication of moving elements;

- cleaning, replacing the water filter;

- column inspection for cracks, deformations;

- gasket replacement;

- heat exchanger cleaning;

- checking the performance of traction sensors, water temperature.

Before each start-up of the equipment, the serviceability of the chimney system, the presence of draft and the absence of gas leakage are checked. The latter is determined by the presence of a specific smell or reaction special sensor.

If any malfunctions are found, it is important to turn off the speaker immediately, consult a specialist, or fix the problem yourself.

Conclusions and useful video on the topic

In order to fix the gas column yourself, you must have at least minimal repair skills, understand the device and the principle of operation of the device.

A detailed overview of the failures of a gas water heater. Vector can be seen in the video:

Looking at the above information, it is worthwhile to conclude that malfunctions of the gas column can be caused by insufficient pressure when providing water and gas, improper maintenance of the water heater, and the presence of breakdowns in individual components of the equipment. Individual problems are easy to fix on your own.

However, for more complex column repair issues, you should contact qualified craftsmen. This approach is relevant for incorrect operation of the gas column for no apparent reason. In this case, a thorough diagnosis is necessary, a professional approach to repair.

You have a gas heater “Vector Lux” and you want to talk about your experience in repairing it? Or would you like to add another list of breakdowns considered in the framework of this article? Write comments, add unique photos of the Vector column for your own repair, ask questions, participate in the discussion - the feedback form is located below.

DIY gas heater setup and repair: a guide for water heater owners

DIY gas heater setup and repair: a guide for water heater owners  Rating of gas water heaters: 12 leading models + recommendations for future owners

Rating of gas water heaters: 12 leading models + recommendations for future owners  DIY boiler repair: possible malfunctions and instructions for their elimination

DIY boiler repair: possible malfunctions and instructions for their elimination  Rating of instantaneous gas water heaters without chimney: the best offers and tips for choosing

Rating of instantaneous gas water heaters without chimney: the best offers and tips for choosing  Do-it-yourself repair of a gas column heat exchanger: the main stages of soldering a copper radiator

Do-it-yourself repair of a gas column heat exchanger: the main stages of soldering a copper radiator  How to clean your Bosch geyser with your own hands: care guide + valuable tips

How to clean your Bosch geyser with your own hands: care guide + valuable tips  How much does it cost to connect gas to a private house: the price of organizing gas supply

How much does it cost to connect gas to a private house: the price of organizing gas supply  The best washing machines with dryer: model rating and customer tips

The best washing machines with dryer: model rating and customer tips  What is the color temperature of light and the nuances of choosing the temperature of the lamps to suit your needs

What is the color temperature of light and the nuances of choosing the temperature of the lamps to suit your needs  Replacement of a geyser in an apartment: replacement paperwork + basic norms and requirements

Replacement of a geyser in an apartment: replacement paperwork + basic norms and requirements