Connecting copper pipes: instructions and comparison of various installation technologies

Copper pipes are used in the installation of domestic hot water, cold water, air conditioning, heating, gas supply. They are expensive, but durable, ductile, and resistant to corrosion. But for engineering communications from them to last for decades, the connection of copper pipes must be carried out correctly.

We will describe how the device of copper pipelines is made, which ensure the tightness of the transported medium or the circulating coolant. The article presented for familiarization describes installation technologies in detail. Based on our advice, the construction of the systems will be “excellent”.

The content of the article:

Nuances of working with copper pipes

To perform the installation of internal pipelines in the house, you can choose a pipe made of plastic, metal-plastic or stainless steel. But only an analogue of copper can last without problems and overhaul for more than half a century.

Properly mounted copper piping systems in practice work properly throughout the entire life cycle that is reserved for a cottage or an apartment building.

Copper pipes are not afraid of prolonged heat loads, chlorine and ultraviolet. When freezing, they do not crack, and when the temperature of the internal environment (water, sewage, gas) does not change their geometry.

Unlike plastic counterparts, copper pipelines don't sag. This plastic is subject to expansion at high temperatures, with copper, this does not happen by definition.

Pipe copper products have two drawbacks - the high price and softness of the metal. However, the high cost of the material pays off for a long service life.

And so that the pipe walls are not damaged by erosion from the inside, filters must be installed in the system.If there is no pollution in the form of solid particles in the water, then there will be no problems with the destruction of pipelines.

Pipe processing and welding requirements

When working with copper pipes, the following rules must be observed:

- When mounting a cold water or hot water supply by soldering, the use of lead solder should be excluded - lead is too toxic.

- The speed of the water flow should not be higher than 2 m / s, otherwise the smallest particles of sand or other solid matter will gradually begin to destroy the walls of the pipe.

- When using fluxes, after the installation is completed, the pipeline system must be washed out - the flux is an aggressive substance and will contribute to the corrosion of copper pipe walls.

- When soldering, the connection point must not be overheated - this can lead not only to the formation of an leaky joint, but also to the loss of strength of the copper product.

- It is recommended that pipe transitions from copper to other metals (steel and aluminum) be made using brass or bronze adapter fittings - otherwise steel and aluminum pipes will quickly begin to corrode.

- Burr (bursts of metal) and burrs at the cutting points must be removed - their presence leads to the formation of turbulent turbulences in the water flow, which contributes to erosion and a decrease in the operating life of the copper pipe.

- When preparing copper pipes for connection, it is strictly forbidden to use abrasives - their particles remaining after installation inside the assembly will damage the metal and form a fistula.

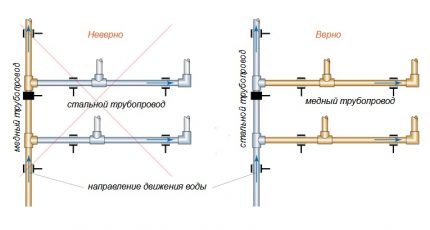

If in the water supply or heating system in the house, in addition to copper, there are also pipes or elements made of other metals, then the water flow should go from them to copper, and not vice versa. The flow of water from copper to steel, zinc or aluminum will lead to rapid electrochemical corrosion of the pipeline sections from the latter.

Due to the ductility and strength of the metal, copper pipes are subjected to cutting and bending without any problems. The rotation of the pipeline can be performed both by using a pipe bender, and using fittings. And for the device of branching and connections with various devices, there are many parts made of heat-resistant plastics, brass, stainless steel and bronze.

On the interaction of copper with other metals

In most private homes, domestic water pipes are assembled from steel and aluminum pipes. In heating systems, there are also radiators made of steel or aluminum. Incorrect insertion into such a wiring of copper pipes is fraught with considerable problems.

The most optimal installation option is the use of pipes and devices exclusively from copper and its alloys. Now, without problems, you can find bimetal aluminum-copper radiators, as well as the corresponding fittings and valves. Combining different metals is only in extreme cases.

If the combination is inevitable, then copper should be the closure in the chain of pipeline elements. It is impossible to rid her of the ability to conduct electric current.

And even with a weak current, this metal creates galvanic fumes with steel, aluminum and zinc, which inevitably leads to premature corrosion. When installing a water pipe between them, it is absolutely necessary to insert adapters of bronze.

It is also a potential problem - oxygen in water. The higher its content, the faster the pipes corrode. This applies to pipelines made of one metal or made of different ones.

Often, cottage owners make a serious mistake, often changing the coolant in the heating system.This only leads to the addition of completely unnecessary portions of oxygen. It is best not to change the water completely, but to top it up when the need arises.

Installation choice: detachable vs one-piece

To connect copper pipes into a single pipeline system, you can use several ways to connect them. Various plumbers use crimp and press fittings, welding or soldering. But before you start work yourself, you need to decide whether it is one-piece to be a pipeline or one-piece.

There are three mounting technologies for connecting copper pipes:

- electric welding;

- soldering with a torch or electric soldering iron;

- pressing.

All these technologies can be applied in the formation of both a split and one-piece system. Here the question is more about the use of a variety of fittings and adapters or the rejection of them.

If the pipeline system needs a detachable, as well as simpler in terms of repair and adding new elements, then the connections must be made detachable.

To do this, use fittings:

- compression;

- threaded;

- self-locking.

Detachable connections are easier to do on their own, you can do without soldering. They do not require the master to be overly qualified.

However, such nodes require constant inspection and tightening of the nuts to prevent leaks. Differences in pressure and temperature in the system lead to weakening of the fasteners. And from time to time it is recommended to tighten them.

If access to copper pipes is planned to be closed tightly with finish or concrete screed, then it is best to connect them into an integral structure by soldering or welding. Such a system is more reliable, durable and resistant to gusts.

It is forbidden to apply thread on copper products. This metal is too soft in structure. When installing a split pipe, all threaded connections must be made using fittings. The latter can be connected to a copper pipe by pressing or soldering.

Before making the connections, copper pipes are prepared in a special way:

Three basic connection methods

Before connecting the pieces of copper pipes, it is necessary to cut them in accordance with the wiring diagram and prepare. You will need a pipe cutter or a hacksaw for metal, a pipe bender and a file. And for stripping the ends, fine-grained emery paper does not hurt.

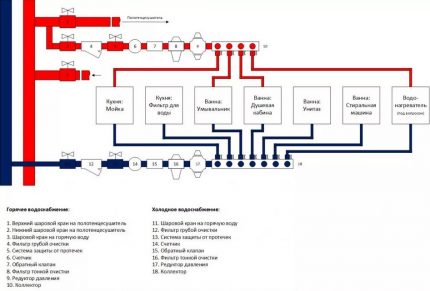

Only having the scheme of the future pipeline system in hand can you calculate the required amount of consumables. It is necessary to determine in advance where and what diameter the pipes will be mounted. It is also necessary to clearly understand how many connecting elements will be required for this.

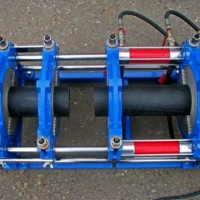

Option # 1: Welding Copper Pipes

To perform automated or manual welding of copper pipes, electrodes and gas are required to create a protective environment (nitrogen, argon or helium). You will also need a DC welding machine and, in some cases, a torch.The electrode may be graphite, tungsten, copper or carbon.

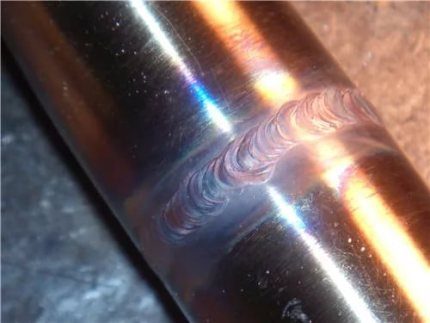

The main disadvantage of this installation technology is the significant differences in the characteristics of the resulting weld and pipe metal. They differ in chemical composition, internal structure, electrical and thermal conductivity. If welding is improperly performed, the joint can even diverge subsequently.

Welding copper pipes can be correctly connected only by a qualified craftsman. It requires certain knowledge and skills.

This mounting option has a lot of technological nuances. If you plan to do everything yourself, but there is no experience with the welding machine, then it is better to use a different connection method.

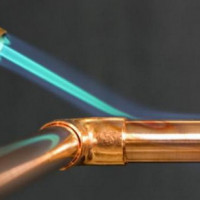

Option # 2: Capillary Soldering

In domestic conditions, copper pipes are rarely connected by welding plumbing. This is too complicated, requiring specialized skills and laborious business. It is easier to use the capillary soldering method using a gas burner or blowtorch.

Soldering copper pipes happens:

- low temperature - soft solders and a blowtorch are used;

- high-temperature - refractory alloys and a propane or acetylene burner are used.

Particular difference in the final result of these copper pipe soldering methods Dont Have. The connection in both cases is reliable and tear resistant. The seam with the high-temperature method is somewhat stronger. However, due to the high temperature of the gas stream from the burner, the risk of burning through the metal of the pipe wall increases.

Solders are used on the basis of tin or lead with the addition of bismuth, selenium, copper and silver. However, if the pipes are brazed for the drinking water supply system, then it is better to refuse the lead option because of its toxicity.

There are two ways to weld copper pipelines:

- bell-shaped;

- using fittings.

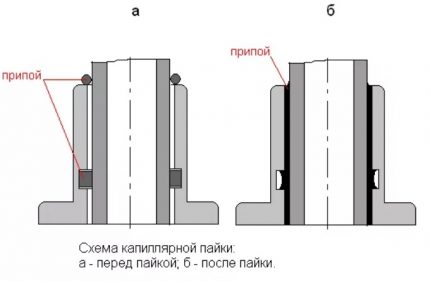

The first option involves expanding the end of one of the connected pipes with a special expander. Then this socket is put on the second pipe, and the joint is soldered with solder.

The extension of the end is made so that between the external and internal walls of the products to be joined, a gap of 0.1-0.2 mm remains. No more. Solder on it due to the capillary effect will still fill the entire existing gap.

In this technology, it is important not to damage the pipe when expanding. If it is made of solid copper (R 290), then it will have to be burned first. In this case, the metal at the junction acquires the properties of a soft analog. It is important not to forget about these changes when calculating the parameters of the working pressure in the pipeline.

To simplify the soldering of the elements of the copper pipeline with your own hands, it is enough to purchase ready-made couplings, turns, tees and plugs. They already have the necessary bell. The use of these parts leads to an increase in the cost of installation, but greatly simplifies them.

To clean the metal at the place of soldering and lubricating the solder, the ends of the pipes to be joined are coated with a flux. It should be applied exclusively to the pipe walls from the outside. Sockets and fittings from the inside are not processed. This is simply not necessary.

To solder, the pipes are inserted into the socket and heated by the burner. When the desired temperature is reached, solder is brought to the gap. It begins to melt and flow inside.

If too much gets into the joint, then it will leak from the inside of the pipeline, which will lead to a narrowing of the inner diameter of the pipe. And at a low flow rate, the connection will be insufficiently soldered.

If there are problems with the use of solder, then you can use fittings in which it is already in the right volumes. To simplify the work, now at the factory, a capillary belt of the corresponding alloy is introduced into these connecting elements from the inside. This part only needs to be put on the pipe and heated with a burner.

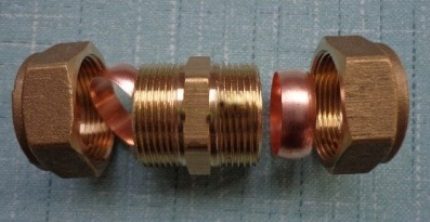

Option # 3: Collet fittings and press couplings

One-piece copper pipe joint can be performed using press couplings or crimp (collet) fittings. They use a sealing ring instead of solder. The first option is clamped to the pipe with special pliers, and the second - with union nuts and a key to them.

When tightening the nut, the end of one copper pipe is pressed against the other. As a result, the copper is rubbed, creating a strong connection without gaps. Leaks when using such couplings are virtually eliminated.

To assemble and install a copper pipeline specialized pipe cutter, designed to be divided into segments of this particular type of material. Our guide article will familiarize you with the guidelines for choosing this tool.

Conclusions and useful video on the topic

How work with pipes looks in practice can be seen in the following videos.

Video # 1. All about brazing copper pipes with a gas burner:

Video # 2. Analysis of typical errors in connecting copper pipes with soft solder:

Video # 3. About the features of mounting press fittings:

There are several ways to connect copper pipes to each other with fittings. Some of them are easier to perform on their own, while others will be cheaper, but require a special tool. There is nothing particularly complicated in such installation.

However, before proceeding directly to the soldering of the pipeline, it is worth practicing in the use of the burner. During work, do not allow burnout of copper.

Do you know the technological nuances of connecting copper pipes that are not noted in the article? Want to tell how you assembled a copper pipe with your own hands? Please write comments in the block below, ask questions, share impressions and photos on the topic.

The connection of plastic pipes with metal: an analysis of the best methods and mounting nuances

The connection of plastic pipes with metal: an analysis of the best methods and mounting nuances  Press fittings for plastic pipes: types, marking, purpose + installation example

Press fittings for plastic pipes: types, marking, purpose + installation example  DIY copper pipe installation: copper pipe installation technology

DIY copper pipe installation: copper pipe installation technology  Soldering of copper pipes: step-by-step analysis of work and practical examples

Soldering of copper pipes: step-by-step analysis of work and practical examples  Pipes for irrigation in the country: a comparative overview of various types of pipes

Pipes for irrigation in the country: a comparative overview of various types of pipes  Welding polyethylene pipes: a comparison of methods + installation instructions

Welding polyethylene pipes: a comparison of methods + installation instructions  How much does it cost to connect gas to a private house: the price of organizing gas supply

How much does it cost to connect gas to a private house: the price of organizing gas supply  The best washing machines with dryer: model rating and customer tips

The best washing machines with dryer: model rating and customer tips  What is the color temperature of light and the nuances of choosing the temperature of the lamps to suit your needs

What is the color temperature of light and the nuances of choosing the temperature of the lamps to suit your needs  Replacement of a geyser in an apartment: replacement paperwork + basic norms and requirements

Replacement of a geyser in an apartment: replacement paperwork + basic norms and requirements

I noticed that wherever I met copper pipes, they preferred to connect by soldering. Although, in principle, it is possible with fittings, you only have to tinker a bit longer. But the adapters have never yet been caught. I don’t even know why. Maybe because without them, the joints are almost invisible and easily painted over with a suitable color paint. Myself, too, would probably be connected by soldering.