Copper pipes and fittings: types, marking, features of the arrangement of a copper pipeline

Despite the popularity of metal-plastic and polypropylene, copper pipes and fittings are widely used for the installation of heating and water supply networks. They are considered the best option for equipping refrigeration equipment and air conditioners.

We will try to understand the variety of copper products and find out which pipe connection methods are the most effective.

The content of the article:

Copper pipes for internal wiring

Unlike metal-plastic analogues, copper pipelines have minimal thermal expansion, do not deform for a long period and do not respond to sunlight. They can be installed in winter and summer - the technical characteristics of copper from exposure to low temperatures do not change.

All types of home communications are built from copper pipes:

We offer information that may come in handy when selecting or installing copper pipe material.

Varieties: isolated and uninsulated

We are used to seeing bare copper pipes - reddish metal nets assembled using fittings made of copper, bronze or brass, sometimes soldered or joined by a welded sleeve method.

Domestic and foreign manufacturers offer products that differ not only in size, cross-sectional shape or manufacturing method, but also in their external design.

Thus, among the copper pipe rolling, you can find the following types of pipes:

- uninsulated for installation of house networks and assembly of gas and electrical equipment;

- with PVC insulation for protection against corrosion and mechanical damage;

- with flexible polyethylene insulation for water supply systems;

- with polyurethane foam insulation for networks with maximum heat-saving requirements;

- with protective insulation for underfloor heating and complex systems.

To connect copper pipes with insulation, fittings without insulation are used, and the installation methods do not differ from conventional ones.

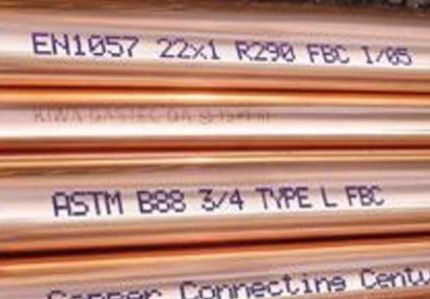

How to understand the labeling?

In order not to be mistaken when buying pipes for self-assembly, you must learn to read the markings and color marks.

The manufacture of pipes of domestic brands is made in accordance with GOST 617-90, the section of which is called “Pipes of copper”.

Marking is done according to the general scheme, it indicates the following information:

- manufacturing method (drawn, cold rolled - D, extruded - G);

- section (round - КР);

- manufacturing accuracy (normal - N, high - P);

- condition (from soft - M to solid industrial strength - H);

- length (non-dimensional - ND, multiple measured - KD, in bays - BT);

- special conditions.

Special conditions include designations of products of increased length or high accuracy in curvature and length.

The GKRPT 32 * 3 * 5000 M3 marking sample is deciphered as follows: pressed solid round cross-section with increased manufacturing accuracy, with an external cross-section of 32 mm, a wall thickness of 3 mm, a measured length of 5 m, made of MZ brand copper.

In addition to GOST marking, a designation system according to the international standard NF is used: the country, manufacturer, plant number, and size are necessarily indicated.

Range and selection conditions

Small copper pipes of small cross section are sold in bays of 25 m and 50 m, and large diameter products are cut in lengths, most often 3-5 m. The so-called “soft” types are rolled into bays, which are widely used for floor heating.

In the installation of copper pipelines, three varieties are used, differing in degree of hardness:

The thin cord is easily bent and does not require the installation of fittings or other elements that ensure the installation of turns of a rigid type pipeline.

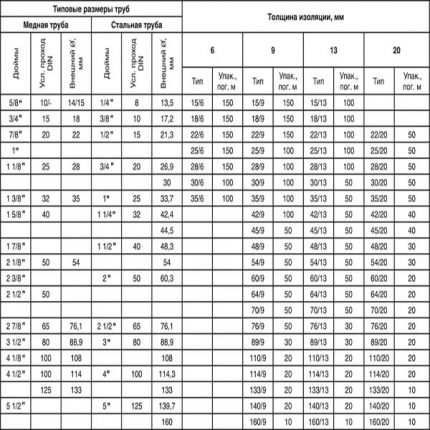

To determine the parameters or characteristics of the pipe material of various sections use tables.

Some types of pipes are in high demand. For example, products from 12 mm to 22 mm in diameter are used for water supply, and for drain systems - from 32 mm and above.

In addition to the external cross-section, it is customary to indicate the wall thickness or internal diameter (suppose 12/2 or 12/14 is a pipe with an external diameter of 14 mm, an internal –12 mm and a wall thickness of 2 mm).

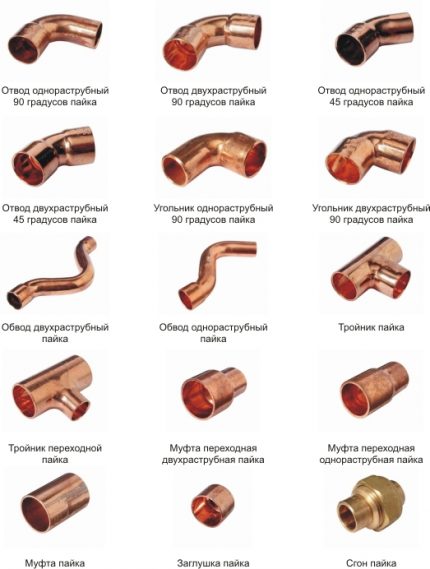

Types of fittings for copper piping

Fittings are necessary when assembling pipelines to create reliable detachable and one-piece connections. The result of a properly made connection is the operation of the network without repair for 15 years or more. Consider what types of fittings are used for copper pipes.

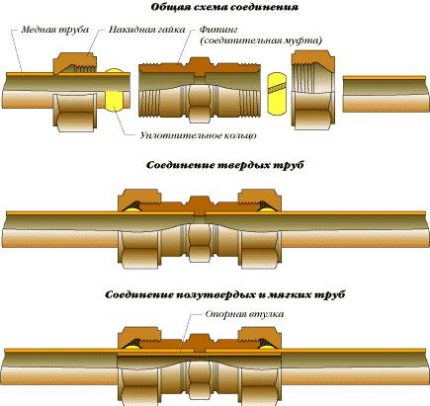

Option # 1 - compression

For installation of compression fittings, no soldering is used. Collet constructions are called conditionally detachable, as they create a tight connection, which from time to time needs to be tightened. In this regard, pipelines must not be sewn into the floor or walls.

To install a compression fitting, a special tool - pliers or clamps - is not needed. First, crimping is done manually, and then the union nut is reached with an adjustable or open-end wrench.

It is recommended to use a pair of keys: one to hold the body, the second to make semi-rotational movements. For a strong connection, usually 2-3 extra turns are enough.

Collet fittings have standard sizes - along the cross section of the pipes, and their inner wall is pre-calibrated (to make a socket connection). In addition, they differ in purpose.Suppose the parts for the plumbing and heating system may differ structurally.

Option # 2 - Press Fittings

Compression fittings have a completely different design. They have a tubular structure, and each end is equipped with a recess with a seal. The principle of fastening on a pipe is based on one of the qualities of copper as soft and pliable in metal processing.

In the process of crimping, the design of the part is deformed so that the material with the o-ring creates an inseparable tight connection.

To assemble the pipeline using press fittings, a special tool is needed - press pliers. A manual apparatus is suitable for temporary and one-time work, but with constant professional use it will quickly cause fatigue.

For qualified plumbers, hydraulic and electromechanical models are provided - expensive, but saving power and time.

The complexity of pressing lies in the fact that after crimping it is sometimes difficult to distinguish a machined fitting from just worn on a pipe. To avoid gaps, manufacturers supplied parts with special signal elements that change their appearance after crimping: bright plastic rings or deformable bulges called SC-Contur.

It is not difficult to distinguish the parts by purpose, as they are marked with a marker with a different color:

- blue or red - water supply (drinking or non-drinking);

- green - heating;

- yellow - gas supply.

There are universal options: for example, yellow-blue marking indicates that the fittings can be used in gas and water movement systems. Color is also used to mark the seal (yellow for gas, black for water, etc.)

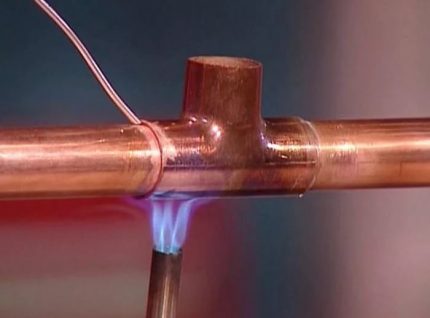

Option # 3 - soldered

Soldering provides a durable and integral connection of two pipe fragments. It is carried out using a special tool. Just before soldering, the ends of the pipes overlap, that is, they use a socket connection.

However, a small gap should remain between the walls, necessary to fill with molten solder. The gap is from 0.02 mm to 0.4 mm.

The main tool for soldering is burnerbut for the primary processing of pipes they also use a calibrator (expander), chamfer, pipe cutter and all kinds of cleaning tools (brushes, skins).

For home use, a hand burner with a 200 ml gas can is suitable.A light and convenient hand-held device forms a flame with a temperature of + 1100 ° C, which is quite enough to melt a soft solder.

You will also need a flux solution that lubricates the connecting parts of the fitting and pipe.

Fluxing of the surface of copper parts is carried out with a brush. It provides uniform spreading of solder along the joint zone.

For soldering, low-temperature technology is usually used. Fittings for this type of welding are equipped with a strip of soft solder, which is placed in a special girdle groove.

A high-temperature welding method is used in production, when creating industrial networks. Distinctive features - the use of solder, in the future the ability to move gases and liquids under high pressure. Read more about how to braze copper pipes in this stuff.

How is capillary soldering with a fitting made?

Before starting work, prepare the tools and materials:

- gas burner;

- flux;

- solder;

- pipe cutter;

- chamfer;

- brush and fine sandpaper.

Procedure:

After cooling of the tin solder, a strong joint is formed, which ensures one hundred percent tightness. The soldering process without fitting is carried out according to the same scheme, but with the only difference: instead of the connecting element, the end of the second pipe is worn, which is put on top with an overlap. The gap between the pipes in the same way is filled with molten solder.

Instructions for pressing copper pipes

The only tool that will be required for the behavior of the pressing procedure is press pliers. Before starting work, we prepare pipe segments according to the instructions described above.

Step-by-step instruction:

We remind you that crimping creates an unattended connection that lasts up to 30 years or more. The finished pipeline can be laid in strobes, sewn up with drywall or filled in with a screed.

There are a number of nuances, the knowledge of which helps to cope with the independent pressing of copper fittings, even if this is your first time doing it.

When crimping manually, try not to exert excessive force so as not to deform the pipes.

The choice of fittings depends on many reasons, including your skills. If the skills are not enough, then you should not take the burner, and make a crimped or extruded connection for forces and beginners.

We also recommend reading our other articles, where we examined in detail the types of copper pipes:

2. Water pipes made of copper.

Conclusions and useful video on the topic

While watching videos, you can see the technical nuances that are difficult to imagine when reading the article.

Video instruction for pressing a gas pipeline:

Video review of copper fittings for various purposes:

How to make copper pipes and fittings:

The whole soldering process in one clip:

The connection of copper pipes into one system is carried out by analogy with steel and metal-plastic products, but with the use of special fittings - brass, copper and bronze.

If you master the pressing technology or the more complex method of soldering, you can independently mount the heating network or water supply. But keep in mind that copper communications are a very expensive pleasure!

Please write your comments on the topic of the article in the block below. Perhaps you know the nuances that we did not mention in this article? Share them with other site visitors.

Fittings for steel pipes: types, classification, marking and installation examples

Fittings for steel pipes: types, classification, marking and installation examples  Fittings for plastic pipes: types, applications, an overview of the best manufacturers

Fittings for plastic pipes: types, applications, an overview of the best manufacturers  How to choose a hydraulic pipe bender: types of equipment and its features

How to choose a hydraulic pipe bender: types of equipment and its features  Pipe cutter for copper pipes: types, selection tips, rules and nuances of use

Pipe cutter for copper pipes: types, selection tips, rules and nuances of use  Revision plumbing hatches for the bathroom and toilet: types, placement rules, mounting features

Revision plumbing hatches for the bathroom and toilet: types, placement rules, mounting features  Polypropylene or plastic pipes: a comparative overview and the choice of the best option

Polypropylene or plastic pipes: a comparative overview and the choice of the best option  How much does it cost to connect gas to a private house: the price of organizing gas supply

How much does it cost to connect gas to a private house: the price of organizing gas supply  The best washing machines with dryer: model rating and customer tips

The best washing machines with dryer: model rating and customer tips  What is the color temperature of light and the nuances of choosing the temperature of the lamps to suit your needs

What is the color temperature of light and the nuances of choosing the temperature of the lamps to suit your needs  Replacement of a geyser in an apartment: replacement paperwork + basic norms and requirements

Replacement of a geyser in an apartment: replacement paperwork + basic norms and requirements

12/14 - wall thickness 1 mm, not 2.

I don’t even know who can afford copper pipelines, non-ferrous metal in itself is a very expensive pleasure. And the fittings and fittings are many times higher than the cost of other materials. During my practice, I only soldered copper twice, there is nothing particularly complicated. But this is such painstaking work, slow and boring.

During the time while one connection is soldered, it is possible to solder 4 points from polypropylene to solder. Copper is relevant only for radiators, and there are completely different volumes.

Yes, copper is relatively expensive, but copper piping is far from rare. I know many examples when people in freshly built cottages prefer copper to other materials. Durable, flexible, easy to install - copper pipes have enough advantages.