Solder for brazing copper: types of solder and their characteristics + selection tips

Copper pipes are parts for global or local communication systems that transport gas, water, oil products, coolants and other important resources. To combine individual fragments into a single network, solder is used to solder copper. They select it depending on the conditions in which the operation of the system takes place.

A properly designed joint ensures the tightness of the entire complex and prevents leakage of the feed composition into the environment. And their incorrect connection in the future can result in a lot of problems.

Let's try to understand the types of solder and which one is better to give preference in a particular situation.

The content of the article:

What is solder?

Solder is a pure metal or thermoplastic alloy of several components. Designed to connect copper parts into a single integrated network.

The technology of joining two fragments, carried out according to this principle, is called soldering.

Among the main advantages of the technique, it is worth highlighting:

- connection without deformation;

- preservation of the original shape of the workpiece;

- the absence of any internal tension;

- excellent strength and high level of tightness of the created seam;

- resistance of the bonded area to different temperature conditions, including intense heating;

- simple separation of suture areas in case of need to change the format of the system.

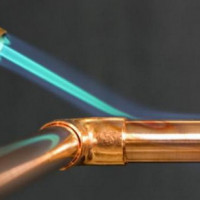

Solder with special equipment - a soldering iron, gas burner or blowtorch. Immediately before work, the area is thoroughly cleaned from surface defects and technical oils, and only then they begin work.

The process of joining pipe fragments is easy and quick, but requires the observance of the rules of elementary safety. To avoid problems and injuries, put on tight working gloves on your hands, cover your face and eyes with special glasses or a mask, and protect your clothes with a tight apron. This will save the master from potential accidents.

Classification of solders for copper pipes

Solders for high-quality and reliable soldering of copper pipes are made of various components. From each other, products differ in shape and chemical composition.

The type and parameters of the connecting elements are determined by the area of subsequent operation of the pipe system of copper parts.

Differences in melting point

According to the level of heat treatment, solders are divided into three types:

- low temperature;

- medium temperature;

- high temperature.

Low temperature options melt in the range from 150 to 450 ° C. Do not change the original physical parameters of the parts. A neat but not too durable seam is created in the joint area. Designed for use in heating and water supply networks that are not exposed to severe loads.

Provide tightness and integrity of pipes with a diameter of up to 10 cm installed in communication systems transporting a coolant with a temperature of up to 130 ° C.

Medium temperature and high temperature materials soften at rates ranging from 450 to 1100/1850 ° C. They guarantee the most durable, strong connection, not sensitive to external influences.

The area connected by medium-temperature or high-temperature solder shows resistance to mechanical damage and quietly transfers active thermal loads.

Separation by chemical composition

The chemical composition of modern, practical solders is distributed on soft low-melting and hard refractory.

The first category includes the following items:

- lead - contain only lead in its pure form and melt at a temperature of 180 to 230 ° C;

- pewter - consist of tin and melt at 220 ° C, create a strong and plastic seam;

- lead tin - may contain from 15 to 90% tin. The melting point of such elements is 183-280 ° C;

- tin-copper - 97% composed of high quality tin and 3% copper. Belong to the most popular and sold at a reasonable price. Form a strong joint with good corrosion resistance;

- copper with silver - 95% composed of copper and 5% silver. They are characterized by high strength characteristics and provide reliable adhesion between fragments.

Soft fusible components are used to combine pipes into a single complex with a diameter of 6 to 108 mm. In the butt area they form a neat seam with a width of 7 to 50 mm.

Lead is considered an element harmful to human health. The use of lead-containing solders is strictly prohibited in networks supplying water to apartment buildings or private houses, enterprises or public institutions. For other types of communications this prohibition does not apply.

For high-temperature processing, solid refractory materials are suitable:

- copper combined with silver and zinc - contains copper 30%, silver - 44% and zinc - 26%. The adhesion region is characterized by good strength, retains ductility, effectively resists corrosion and exhibits increased thermal conductivity;

- phosphorus copper - an alloy of 94% copper and 6% phosphorus. In the process of soldering does not need to use flux. Makes a strong and reliable connection, but partially loses elasticity at low ambient temperatures;

- silver - during soldering requires the mandatory use of flux. Creates a strong, reliable seam with good ductility and high corrosion resistance. It is much more expensive than analogues of simple metals and has no wide distribution. It is used where there is economic feasibility and increased demands are placed on the quality of the pipe connection.

Using refractory solders, pipe complexes with a diameter of 12 to 159 mm are mounted, including gas communication networks, heating routes and water mains with a diameter of 28 mm.

The use of classic copper-phosphorus or any other elements is allowed when creating lap joints. This clutch option provides maximum structural strength and increases the period of operation of the pipeline.

Soft solders for convenience are usually made in the form of coils. Solid elements are supplied in the form of wires of different lengths.

Flux - features and purpose

Flux - This is a specific technical material for soldering copper pipes. Protects the surface of parts from oxidation and slag. Prevents contact of the welded seam with oxygen. It improves the overall quality of the joint and gives it good strength and optimum ductility.

Fluxes for soldering copper pipes are available in different consistencies.

Among the most sought after and popular:

- paste;

- powder;

- liquid.

Substance in the form solder pastes copper pipes are more expensive than other materials, but fully lives up to their high price. It is suitable for use immediately after purchase and does not require the master to add something to the composition to improve working qualities.

The paste is purchased for responsible soldering, which requires the most accurate and high-quality sealing of the butt areas. The substance easily lays on a copper surface, perfectly adheres to it and is well distributed over the treatment area during heating.

The finished seam looks neat and ensures the adhesion of all fragments of the system. Residues are easily removed at the end of work.

Powder products sold at a lower price and are well stored in special containers. Maximum efficiency is demonstrated in conjunction with reinforced, refractory solders. They are considered less convenient due to the difficulty of uniform application to the treatment area.

Liquid substancessold in closed bottles.Normally in contact with soft solders and easily lie on a copper surface, providing high strength adhesion seam. To ensure a good connection, liquid flux and solder are always used simultaneously, and not separately.

Regardless of the consistency, flux must be applied immediately after stripping the copper fragment. If this moment is ignored, the metal surface is again covered with oxides and it cannot be treated evenly.

After flux treatment, solder the parts immediately. This will eliminate the chance of foreign particles entering the work surface.

In the process of connecting parts, you need to be careful and careful. The contact of flux on the skin provokes not only a thermal, but also a chemical burn.

If this still happened, you should immediately stop soldering and rinse the substance off the skin with plenty of soapy water.

Flux Quality Requirements

There are some requirements for fluxes for individual and industrial use.

The substance must meet the following criteria:

- structure density and viscosity lower than that of solder (for correct replacement);

- the ability to evenly distribute across the work surface;

- dissolution of the oxide film;

- prevention of re-oxidation of copper elements;

- resistance to aggressive high temperatures;

- the ability to solder both horizontal and vertical sections of the communication system;

- creating a neat, aesthetic seam.

When using fluxes of good quality, dust and dirt formed as a result of soldering are removed quickly and easily, leaving no traces on the pipe element that spoil the appearance. The compound is reliable and retains structural integrity for many years.

Popular varieties of material

In the market, fluxes for brazing copper pipes are presented in the widest assortment.

The following substances are most popular:

- with high anticorrosive ability;

- with noble materials in the composition;

- rosin based.

Corrosion-resistant flux consists of several complex elements, solvents and phosphorus. In the process of heating, they dissolve in a liquid, enter into a reaction and form organic components.

Protect the suture area from oxidation and premature corrosion. Contribute to the outflow of excess moisture from the soldering zone.

In the second type of fluxes, salicylic acid acts as the main active ingredient. In the process of use, it is dissolved in a composition of ethanol, gold-containing substances and industrial petroleum jelly.

Creates a perfectly smooth, neat and aesthetic connecting seam that does not require additional complex processing. Does not spoil the material of the pipe adjacent to the processing zone

The classic active flux contains rosin and some sodium salt. The substance has pronounced protective characteristics and effectively protects the pipeline from corrosion. Rosin covers the seam with a thin and strong protective film, and sodium salt inhibits oxidative processes.

Such a flux is sold for a reasonable price and provides a strong, reliable connection. However, the finished seam remains highly visible and immediately catches the eye on the outer parts of the copper pipe.

Regardless of the type and basic composition, the flux must be applied as evenly as possible, avoiding even a millimeter gap. If this part is not present on any part of the metal, the pipe will begin to rust over time and will need to be replaced.

How to choose the right solder?

Correctly selected solder will help to organize a communication system of any complexity without much effort. When it comes to working at home, it is worth using material that melts at low temperatures.

The use of high-temperature hard-melting elements in everyday life is problematic, since it requires heating the working alloy to 600-900 degrees. To achieve this without special equipment is quite difficult.

The use of metals and their derivatives, melting at high temperatures, is associated with some risk. During processing, they can damage or even burn a thin-walled copper pipe.

To prevent this from happening, it makes sense to take a durable, but low-melting soft solder, and leave the solid version for thick-walled copper communications.

To connect copper pipes in gas networks, it is worth choosing silver-containing solders. They provide maximum joint strength, neutral to vibration and high resistance to external and internal influences.

To pay for silver will have a little more expensive, but the safety, reliability and durability of the system over time will pay off all the financial costs.

Conclusions and useful video on the topic

In the video, we will talk about how to solder copper pipes:

About which fluxes to choose for soldering copper pipes at home will be discussed in the following video:

The technique of soldering copper pipes using soft solder:

Proper use of solder allows you to easily and quickly connect copper pipes into a single system. The finished seam is neat and ensures the tightness of the network of any configuration.

No longer have to worry about the possibility of a leak or release of a valuable resource. The highway, with the help of high-quality solder combined into an integrated complex, works reliably and serves for a long time, without requiring constant attention or painstaking care from the owners.

Soldering copper tubes with a gas burner: useful tips and steps for self-soldering

Soldering copper tubes with a gas burner: useful tips and steps for self-soldering  Welding machine for polypropylene pipes: classification, rating of the best + selection tips

Welding machine for polypropylene pipes: classification, rating of the best + selection tips  Copper pipes for heating: types, specifics of marking + application features

Copper pipes for heating: types, specifics of marking + application features  Plastic pipes: types, specifications, installation features

Plastic pipes: types, specifications, installation features  Tools for cleaning sewer pipes: the top ten tools + tips for choosing the right drug

Tools for cleaning sewer pipes: the top ten tools + tips for choosing the right drug  Soldering of copper pipes: step-by-step analysis of work and practical examples

Soldering of copper pipes: step-by-step analysis of work and practical examples  How much does it cost to connect gas to a private house: the price of organizing gas supply

How much does it cost to connect gas to a private house: the price of organizing gas supply  The best washing machines with dryer: model rating and customer tips

The best washing machines with dryer: model rating and customer tips  What is the color temperature of light and the nuances of choosing the temperature of the lamps to suit your needs

What is the color temperature of light and the nuances of choosing the temperature of the lamps to suit your needs  Replacement of a geyser in an apartment: replacement paperwork + basic norms and requirements

Replacement of a geyser in an apartment: replacement paperwork + basic norms and requirements