Plastic pipes: types, specifications, installation features

In many ways, plastic pipes surpass their closest competitors: polymer, copper, cast iron and steel material for laying highways. Their properties are especially significant when the heating system is installed.

In order for the metal-polymer composite to realize the qualities fully declared by the manufacturer, it is necessary to choose the type of pipe correctly. It must comply with upcoming operating conditions and facilitate installation. You will learn all about pipes made of metal and plastic, as well as guidelines for their selection, from our article.

The content of the article:

The structure of pipes made of metal-plastic composite

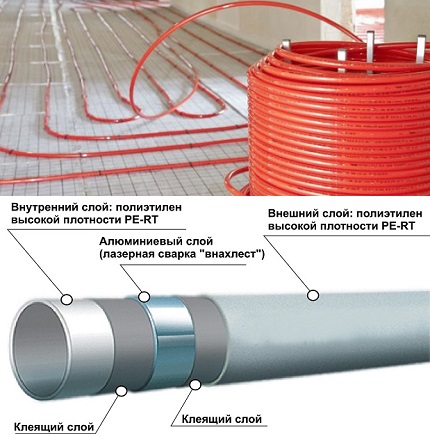

The metal-plastic pipeline has gained popularity due to the combination of the strength of the metal and the flexibility of the polymer. The design of composite pipes is a multi-layer “cake” of polymer layers reinforced with an aluminum layer.

The symbiosis of plastic with metal provides high mechanical strength, prevents the diffusion of oxygen from the atmosphere and minimizes the thermal expansion of the material.

The inner polyethylene “liner” is characterized by absolute smoothness, providing unhindered passage of the transported medium and preventing the appearance of scale deposits. The polymer is resistant to aggressive substances and is not susceptible to corrosion.

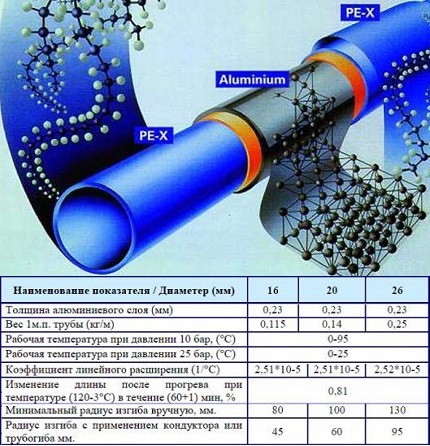

A metal core is responsible for the rigidity of the product and increases the temperature resistance of the pipeline. The ends of the aluminum are joined by laser welding. The thickness of the aluminum sleeve is 0.15-0.75 mm - this allows you to withstand frequent temperature jumps and high pressure.

The outer polymer layer is a particularly durable plastic, resistant to mechanical damage, high humidity and aggressive reagents. The outer shell reduces the rate of condensation on the pipes.

The initial characteristics of the product are largely determined by the type of polymer used:

- Pex - high pressure polyethylene;

- PE-RT - heat resistant polymer;

- PE-R - polyethylene;

- PP-R - polypropylene.

For the integrity of the entire assembly meets the adhesive composition. Manufacturers introduce their own patented formulations, and the ingredients and ratio of components are not advertised. A high-quality adhesive layer levels the tension inside the structure between the polymer and aluminum, prevents delamination and increases the wear resistance of the pipeline.

Physicotechnical Specifications

The properties of metal-plastic pipelines depend on the dimensions of the product (diameter, wall thickness), type of polymer and manufacturer. However, all indicators must comply with the standards according to GOST 18599 (2001), R-53630 (2009) and R-52134 (2003).

General requirements for a metal-plastic line according to GOST:

- yield strength of the hot plastic layer - up to 0.3 g / 10 minutes;

- the absence of delamination of the leading edge in tension up to 10%;

- minimum permissible resistance to delamination under loads - 15 N / cm, without loads - from 50 N / cm;

- crosslinking of polyethylene layers - from 60%;

- thermal stability of plastic components;

- the limit value of oxygen permeability at a temperature of + 40 ° С is 0.32 mg / sq.m * day; at + 80 ° С - 3.6 mg / sq.m * day;

- the degree of strength of the polymers used is from 8-12 MPa;

- the temperature of the initial fluidity of the adhesive composition is a minimum of + 120 ° C.

GOST also regulates environmental parameters. The fraction of volatiles in metal-plastic pipes should not exceed 0.035%.

Basic averaged physical and technical characteristics:

- Assortment. Manufacturers offer metal-plastic moldings with an internal cross section of 14-60 mm, wall thickness - 2-3 mm. The length of the bay is 50-200 m.

- Strength. Under transverse loads, the minimum tensile strength is 2880 N. The strength of welding with metal and adhesive joints is 57 and 70 N / sq. Mm.

- Heat resistance. The composite retains its characteristics within a temperature range of + 95 ° C. Suppose a short jump to + 110 ° C, at -40 ° C the thermoplastic freezes.

- Linear parameters. The bending radius is directly proportional to the diameter of the pipe line. With manual installation, the value is 80-125 mm, with a machine (pipe bender or conductor) - 46-95 mm.

The boundary pressure indicator in the system depends on the temperature of the transported agent.

In accordance with the passport operating standards, the service life of the metal is 50 years. Use in "hot" engineering networks (coolant temperature over 25-30 ° С) the period of work is reduced to 25 years.

Performance and scope

The structure and technical characteristics of metalloplastics determined a number of strengths of the composite highway.

The positive aspects of operation include:

- anticorrosion - the inner surface is not covered with rust and does not silt;

- good throughput due to the low hydraulic resistance of the pipeline;

- chemical inertness to most toxic substances and aggressive environments;

- flexibility to minimize the amount of installation connectors and corner pieces;

- gas tightness - elements of the pipeline system (radiators, boilers, pumping equipment) are protected from the harmful effects of oxygen;

- noise absorption - quiet transportation of fluid along utilities;

- wear resistance, ease of use and lack of need for additional maintenance.

Pipes are lightweight, therefore, easy to transport and install. Additional advantages: aesthetics, affordable cost and virtually waste-free use.

Along with the positive sides, the metal layer also has disadvantages:

- The difference in thermal expansion. Plastic quickly "adapts" to changes in water temperature than aluminum. This difference negatively affects the material - over time, the jointing connections weaken, and the risk of leakage increases.

- Bending requirements. Repeated bending / unbending or a one-time bending over the norm can lead to deformation of the layers of metal-plastic moldings.

- UV susceptibility. The polymer outer layer during prolonged exposure to ultraviolet loses its protective properties.

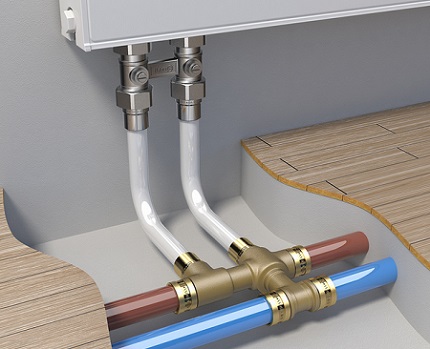

The installation of the metal-polymer pipeline occurs through crimp fittings.

These deformations may result from freezing of the coolant in the pipe. The solution to the problem: insulation of the main at the installation stage or replacement of transported water in the heating system with non-freezing.

The operational properties of metal-polymer pipes allow them to be used in private, industrial construction and other areas of management.

Main scopes:

- communications of water supply systems;

- supply of aggressive liquids, gas in agriculture and industrial facilities;

- arrangement of insulated "water floors", including for heating the soil in greenhouses;

- insulation of electric cables and wires.

Reinforcement made of a metal-plastic composite is widely used in the installation of ventilation, conditioning and watering systems from wells.

Operation Limitations:

- rooms belonging to category “G” according to fire safety standards - there are substances whose treatment is accompanied by heat generation or sparks;

- buildings with heat sources if their heating temperature exceeds 150 ° C;

- centralized heating with "insert" of the elevator unit;

- when supplying hot coolant with a working pressure of 10 bar or more.

Metal-plastic components are not recommended for implementation in open-type engineering pipelines. Temperature surges and exploitation in frost will lead to the destruction of the pipeline.

Selection of metal & plastic products

The quality and operating conditions of metal-plastic products depend on the type of polymer component, dimensions, the technology of joining an aluminum sleeve and the reliability of the manufacturer. According to the listed criteria, you can classify the entire range of pipe products.

Type of polymer used

Based on the composition, plastic for the production of pipes is conditionally divided into two groups: high and low pressure polymers.

The first group includes:

- Pex- crosslinked polyethylene;

- PE-RT - heat resistant polymer.

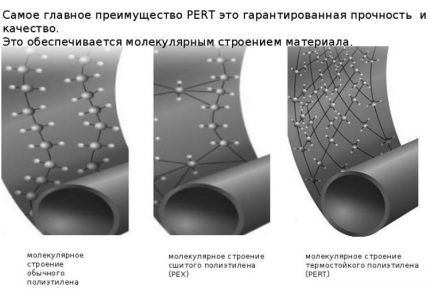

PEX - polyethylene with "crosslinked" molecular chains. Cross links transform a linear structure into a stable three-dimensional connection.

This property increases the resistance of pipelines to water hammer.

The type of intermolecular bonds is determined by the crosslinking catalyst used:

- Pex-a. The new chains inside the structure are the result of processing polyethylene with peroxide. The maximum level of “firmware” is reached - up to 85%. Pluses: preservation of elasticity, high strength and pronounced molecular "memory". The downside is the high cost of technology, and as a result, the high price of pipes.

- Pex-b. The optimal alternative to "A-bonds." Silane crosslinking technique. The main advantage is the reduction in production costs. Technological nuances: degree of crosslinking - 65%, reduced elasticity, more stringent restrictions on pipe bending. In PEX-B polymers, a sluggish crosslinking process is maintained - the material changes its initial characteristics over time.

- Pex-c. The formation of new bonds under the influence of electron radiation. The quality parameters of the finished product are significantly inferior to pipes of category PEX-A. Plus - low cost.

- Pex-d. Intermolecular bonds are the result of nitrogen treatment. PEX-D pipes do not withstand competition with their counterparts, their production is reduced.

RE-RT pipes are characterized by long-term heat resistance. Thermostable polyethylene has persistent numerous intermolecular bonds. The production involves the technique of controlled processes of spatial formation of macromolecules.

Due to the high technical characteristics of metal-plastic pipes with RE-RT polymer, the scope of their application has been expanded. The highway withstands temperatures up to + 124 ° C and is not afraid of freezing.

For the device of the "cold" pipeline suitable models of low-pressure polyethylene. Possible designations: PE-RS, PE, PEHD, HDPE. Features of materials:

- a temperature of 70 ° C is critical - the pipes are deformed;

- system pressure limit - 8-10 bar;

- deterioration under the influence of the sun.

Composite material of metal and low-pressure polymers is selected with the aim of "cutting" the budget for the pipeline.

Pipe dimensions: diameter and thickness of reinforcement

The size of the pipeline is determined by the scope of its use. The assortment of leading manufacturers includes modifications with an outer diameter of 16-50 mm.

Below are the characteristics and features of the use of pipes with a diameter of XX * YY, where XX is the outer section, YY is the inner diameter.

16*12. Pipes are used mainly for equipping the water circuit (water supply to meters, mixers) and the heating system of the house. Larger diameter products may be used for the main pipeline.

20*16. The device is "warm floor", water supply systems. Fittings have better throughput compared to previous counterparts, so they are recommended to be installed with unstable water pressure.

26*20. The wall thickness is 3 mm. This option is preferably used in a private house for autonomous systems, where it is important to provide some reserve bandwidth in case of possible "outages" of pressure.

32*26. The dimensions of the pipe allow it to be used as a riser or the main pipeline for low-pressure systems. The volume of the transported unit is increased due to the large cross section.

40*32. Thickness - 3.9 mm. Pipes have found application in the laying of long lines of engineering networks in civil and industrial construction. Suitable for water treatment, air conditioning, individual and centralized water supply.

The thickness of the armolayer determines the strength, flexibility and thermal conductivity of the pipes.

When choosing the following nuances are taken into account:

- the thicker the aluminum layer, the stiffer the pipeline;

- independent installation is easier to perform from products with a metal layer of 0.15-0.2 mm;

- with an increase in the proportion of reinforcement, the loss of thermal energy during transportation of the coolant increases.

For domestic work, the optimal size of the reinforcing layer is 0.3-0.5 mm.

The nuances of manufacturing technology

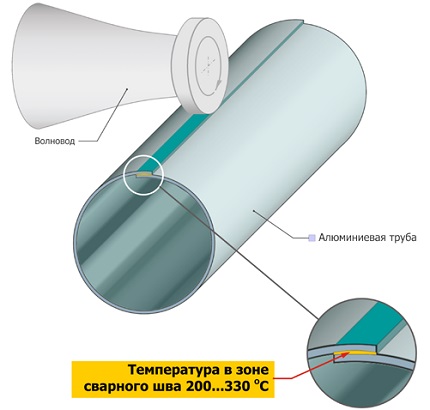

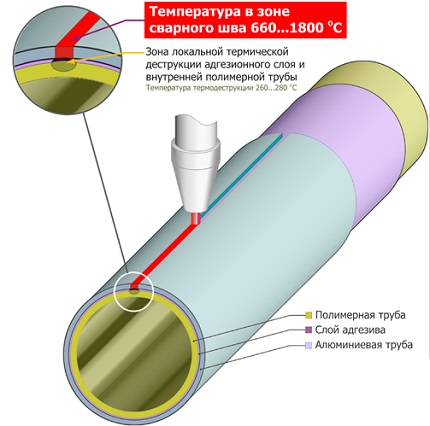

There are two basic techniques for the production of metal-polymer pipes: English and Swiss. The main difference between the technologies is the option of joining an aluminum sleeve.

From marketers you can often hear about the classification of pipes into “suture” and “seamless” depending on the manufacturing technology. However, delving into the basics of production, it can be understood that the docking seam is present in both versions, the difference in its performance.

English technology - lap welding. A pipe is formed from a metal tape, the edges of the "sleeve" are overlapped by ultrasound. On the outside and inside of the aluminum pipe, adhesive and polymer layers are applied simultaneously.

Swiss technology - butt welding. Production Stages:

- The manufacture of polymer pipes by extrusion.

- Application of adhesive to the outer surface of the plastic.

- The formation and "rolling" of the metal layer of aluminum tape.

- Bonding the edges of the reinforcing material end-to-end by argon-arc or laser welding.

- Sequential application of glue and polymer on the aluminum surface.

The final stage is the cooling of the finished product.

The assurances of sellers of "seamless" pipes about higher strength compared to "suture" should not be taken as an axiom. Welding specialists know that the strength of the lap weld is always higher than when butt welding.

Overview of manufacturers: quality-price ratio

An informal rating of manufacturers of metal-polymer pipes is represented by domestic and foreign companies.

Valtec (Italy, Russia). Metal-polymer pipe systems are manufactured using the organosilanide method (PEX-b). The degree of crosslinking of the working layer is 65%, and the protective outer layer is 55%. The combination of characteristics made it possible to obtain flexible material.

The estimated price of the product is 16 * 2 mm - 1 cu / m, 32 * 3 mm - 4.5 cu / m.

Henko (Belgium). Five-layer pipes made by "seamless" technology. In production, cross-linked PEX-C polyethylene is used, the degree of crosslinking is 60%. Pipes are produced with a diameter of 14-40 mm, thickness - 2-3.5 mm, length of the bay - 5-200 m.

The average cost of pipe fittings with a cross section of 20 mm is 0.8 cu / m.

Oventrop (Germany). The company specializes in the production of heat-resistant pipes based on PE-RT polymers. Due to the excellent technical and operational characteristics of the product are considered universal and are used in various fields of construction. The price is about 1.2 cu / m.

Comap (France). Metal-plastic pipeline using PEX-C and PEX-B polymer compounds. The products are characterized by absolute electrochemical stability and low wear rate. The pipes of the Multi-Skin series absorb noise well and maintain their desired bend shape.

Nanoplast (Russia). The domestic manufacturer has launched the production of metal pipes according to Swiss technology. The product feature is a reinforced reinforcing layer (metal thickness is 0.3-0.55 mm).

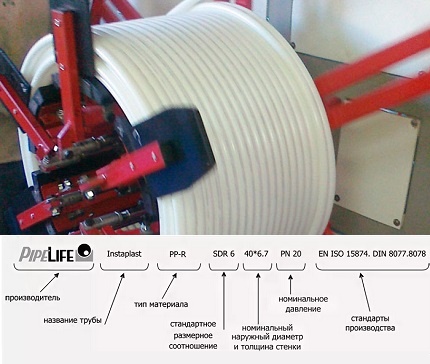

Decoding of the production label

The labeling contains basic information about the characteristics and purpose of the pipeline. The sequence of values for different manufacturers may vary.

Standard notation:

- name of the manufacturer;

- production standard, certificate number;

- type of materials used;

- nominal dimensions;

- maximum permissible pressure;

- suitable for transportation;

- additional operating conditions (temperature).

At the end, the batch number, shift, and production date are displayed.

Features of the installation of a metal-plastic pipeline

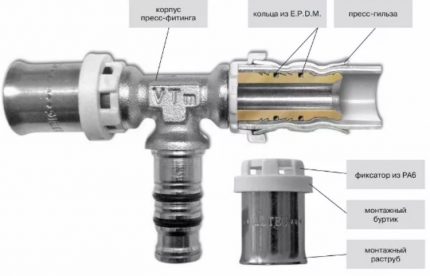

The assembly of the line from metal-polymer pipes is carried out using shaped fittings of three types: split, compressor, press fittings. For crimping connections, press pliersallowing the formation of a completely sealed unit.

Pipe connection using press fittings is as follows:

In addition to traditional crimp joints, another technology and type of fittings, called sliding ones, are used in working with metal-plastic pipes. In order to form a sealed unit in this case, in addition to the press tongs, an expander is also used, which is used to expand the socket. This technique is used to assemble systems laid in screed or with gates.

Pressing the sliding sleeve onto the expanded pipe mounted on the nozzle allows for a tight connection, but for a one-time assembly it is not always advisable to purchase the entire tool.

Detachable (collet) fittings consist of a body, an open crimp ring and a rubber gasket. A thread is provided for docking with household appliances.

Installation Order:

- Mark the installation location of the fitting and cut the pipe.

- Put the nut, crimp ring on the pipe.

- Install fitting, tighten nut.

- Check the dock for leaks.

Compressor fitting is considered conditionally split. To assemble the pipeline using this type of fittings, a minimum of tools is needed, a pair of wrenches is enough:

The fittings are easy to install:

- Align the pipe at the attachment point in the range of 10 cm.

- Cut the pipe evenly.

- Work the ends, put on the nut, ring.

- Cover the shank with sealant and insert into the pipe.

- Tighten union nut.

Most reliable connection in assembly of metal-plastic pipelines achieved by using press fittings. The method is optimal when installing hidden communications wiring. A pipe press, calibrator and pipe cutter.

With valuable tips on how to crimp metal-plastic pipes next article, in which all the mounting nuances are detailed.

Conclusions and useful video on the topic

Comparison of the resistance of metal-plastic and polypropylene pipes to high pressure:

Training video on step-by-step installation of a metal-polymer pipeline using press fittings:

Plastic pipes - a symbiosis of the advantages of both materials. The combined structure expands the scope of metal-polymer products in engineering communications systems of various construction projects. Significant arguments for: longevity and affordable price.

Want to tell how you chose pipes made of metal-plastic and installed them with your own hands? Do you have useful information on designing or upgrading communication systems? Please write comments in the block below, ask questions, share useful information and photos on the topic of the article.

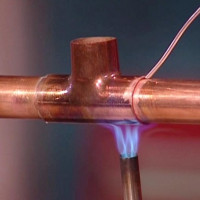

Copper pipes for heating: types, specifics of marking + application features

Copper pipes for heating: types, specifics of marking + application features  Press fittings for plastic pipes: types, marking, purpose + installation example

Press fittings for plastic pipes: types, marking, purpose + installation example  Polypropylene pipes and fittings: types of PP products for the assembly of pipelines and methods of connection

Polypropylene pipes and fittings: types of PP products for the assembly of pipelines and methods of connection  Solder for brazing copper: types of solder and their characteristics + selection tips

Solder for brazing copper: types of solder and their characteristics + selection tips  How to crash into a plastic pipe: features of work and analysis of all important nuances

How to crash into a plastic pipe: features of work and analysis of all important nuances  Pipe cutting equipment: types of tools and features of their application

Pipe cutting equipment: types of tools and features of their application  How much does it cost to connect gas to a private house: the price of organizing gas supply

How much does it cost to connect gas to a private house: the price of organizing gas supply  The best washing machines with dryer: model rating and customer tips

The best washing machines with dryer: model rating and customer tips  What is the color temperature of light and the nuances of choosing the temperature of the lamps to suit your needs

What is the color temperature of light and the nuances of choosing the temperature of the lamps to suit your needs  Replacement of a geyser in an apartment: replacement paperwork + basic norms and requirements

Replacement of a geyser in an apartment: replacement paperwork + basic norms and requirements