Pipe cutting at an angle: advantages and disadvantages of different methods + example of work

Pipes are a widespread building material. They are used in the installation of various systems. During installation, situations happen when pipes need to be joined at an angle. The production technology of such works is not standard, but you need to know about it.

To create a complex joint configuration, pipe cutting at an angle is required. We will describe how such operations are performed and what cutting methods exist.

The content of the article:

Pipe cutting techniques at an angle

Considering the methods of work - cutting directly or at an angle - it is necessary to take into account the different material of the products subjected to processing. So, hoses made of polypropylene or thin copper are easier and easier to cut than thick-walled steel pipes.

Plastic products of small diameters are cut at the right angle with special scissors. In this case, you can control the angle with a conventional protractor. Cutting of polymer pipes is also performed by a conventional hacksaw with a fine-toothed blade.

The most frequent installation need is cutting water, sewer and ventilation pipes at an angle of 45º.

Find out what devices can be used for cutting at different angles.

Paper pattern for pipe

For the execution of a relatively accurate cut, you can apply a simple technique, where an ordinary sheet of paper acts as a kind of pattern. For example, it is suitable for creating patterns of A4 printer paper.

Previously, the sheet is marked out under a square using a ruler. The diagonal size of the square should be equal to the circumference of the pipe to be cut. Excess parts of the sheet are cut off.

Next, the following steps:

- Bend the sheet diagonally, aligning opposite corners.

- Rotate the resulting triangle so that the hypotenuse line is perpendicular to the axis of the pipe.

- In this position, wrap the pipe surface with paper, aligning the extreme points of the hypotenuse together.

- Mark with a marker the cut mark along the line of any of the legs of the triangle.

- Trim the pipe along the intended line.

In this way, it is quite convenient to mark and cut pipes at an angle of 45º in the range of diameters from 32 to 63 mm. For greater convenience, it is recommended that you take thick but soft paper. You can also use paronite and similar materials.

How to choose wisely pipe cutter for plastic pipes and how to apply it in practice is described in detail in our article.

Properly made patterns for figured pipe cutting allow you to cut sections with extremely high accuracy. At the same time, a gap between the prepared workpieces is still possible. In the connection of metal pipes, it is “closed” with a weld seam, when connecting plastic parts, a specialized soldering cord is used.

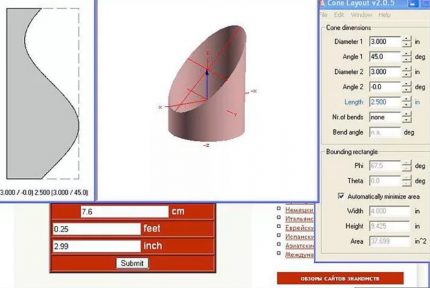

Programs for calculating cutting angles

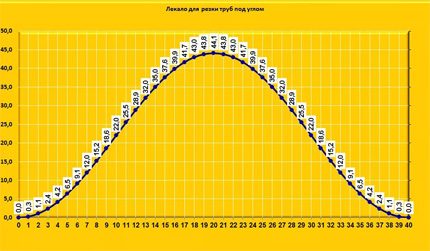

Cutting technology for patterns allows you to get different cutting angles. But for the formation of a pattern at angles other than 45º, it will already be necessary to perform mathematical calculations and, based on the calculated data, cut out a template from paper or similar materials.

True, there are computer programs designed to save the wizard from the production of calculations.Patterns for pipe cutting such programs are printed on a printer.

A simple calculation program, created on the basis of MS Excel, allows you to calculate and compose a pattern for almost any value of pipe diameters and the required cutting angles.

All that the user needs to do is enter the corresponding values in the “Outer Diameter” and “Cutting Angle” cells. According to these parameters, a pattern will be formed that can be sent for printing.

The disadvantage of the program is that it does not take into account the thickness of the pattern sheet, which leads to minor inaccuracies.

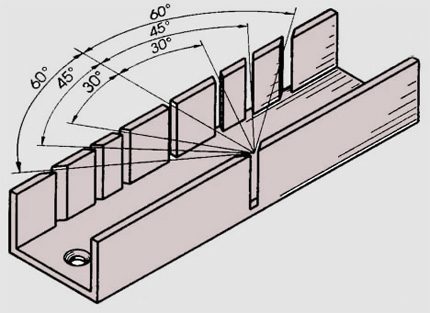

Pipe cutting miter box

There is a simple tool, often used in everyday life, mainly for working with wood. It is called - a miter box. So, this same device is suitable for cutting pipes, and at different angles.

The miter box is on sale, but if you want, you can always do it yourself and adjust the design to the desired pipe diameter:

- Take a wooden board with a width equal to the diameter of the pipe, 400-500 mm long.

- Take two more boards of the same size, but in width increased by the thickness of the first board.

- From three boards to assemble the design in the form of an inverted letter "P", where the first board is installed as the base.

- In the central part of the structure, mark a rectangle, the two sides of which pass along the inner borders of the side boards.

- Divide the rectangle with diagonals and along the lines obtained on the upper faces of the side boards, make cuts down to the base.

In this way a template is made for cutting at an angle of 45º. But with the help of a protractor, you can mark almost any angle and make cuts under the pipe cut for a specific angle.

The advantage of the miter box - the tool is suitable for repeated use. Work with the tool is permissible to such a degree of wear of the walls of the slots, while they can provide high precision cutting. It is recommended that the tool walls be made of a material of higher strength than wood.

The advantages of the method are obvious - simplicity, ease of manufacture of the tool (miter box), efficiency, versatility. The disadvantages of working with such a snap option are the need to adjust the size of the miter box to the pipe diameter, provided that an accurate cut is made. That is, for each pipe you have to make your own tool.

Also, with the help of a miter box, you can cut a pipe only with a hacksaw for metal or a secateurs (for plastic products). For working with thick-walled metal pipes under a cut grinder, this tool will not work.

Simple cutting equipment

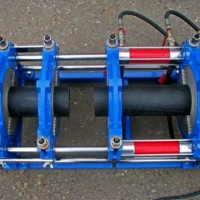

Metal products of round and rectangular shapes, having sufficiently thick walls, are conveniently cut at an angle using straightforward electromechanical equipment.

The cutting element of such a tool is a cutting disc or circular saw mounted on an electric motor shaft. In turn, the electric motor with a torch is part of the entire equipment, which includes the desktop, pendulum support, clamp.

To install the pipe at the desired angle and then fasten it, an ordinary clamp and two metal corners are used.One corner (short) is attached to the base of the swing mechanism - the pendulum. The second corner (long) is in a free state.

Pipe laying and cutting procedure:

- The rotary mechanism sets the desired cutting angle (for example, using a ruler and protractor).

- The found position is fixed by clamping screws.

- Between the short and long corners, a pipe is laid and pressed against the clamp screw.

- A voltage is applied to the electric motor.

- Applying a slight pressure force to the torch disc, the pipe is cut in the right place.

The advantages of this technique are fast work, accurate cut, the ability to process a large number of pipes in a short period of time.

Disadvantages: restrictions on use in domestic conditions, increased noise, work with pipes of only small and medium diameters. In addition, the snap cutting process is carried out stationary at a distance from the installation site, which is not always acceptable.

If you are going to make a copper pipe at home, then you will need special pipe cutters, the selection rules of which we advise you to read.

The nuances of working with a rectangular section

To perform cutting of rectangular products, it is recommended to prepare template cuts of corners in advance. They are easy to make from a metal corner, previously marking with the same protractor.

Marking can be done for different angles. To use the template in the case, it is enough to attach it to a rectangular pipe in the right place and mark the cut line. Then, with any suitable tool, cut along the intended line.

Precision Cutting Machines

Among the branded devices that could be used in everyday life for cutting at an angle, you can pay attention to Italian-made technology.

The MASS Mini Cut Band Saw is a small-sized device with a manual clamp, for working not only with pipes, but also with corners, rods, and profile elements.

The machine supports setting the cutting angle from 0 to 45º. The procedure is carried out using a tape web at a speed of 45 reciprocating movements per minute. The device is equipped with an electric motor with a power of 370 W, which is powered by a household network. The maximum allowable diameter of the cut round pipe is 65 mm.

Numerous installations with electromechanical and electric drives have been developed on an industrial scale for pipe cutting. Technically sophisticated machines allow for high precision thermal, oxygen and plasma cutting:

Industrial models (for example, BSM)

There are special industrial machines for precise angle cutting operations. A good example: devices manufactured under the brand name "BSM". The machine manufacturer is the German company Rexinger.

True, the BSM series machines are designed exclusively for working with polypropylene pipes of sufficiently large diameters. Processing of products like PP, PVC, PE, PVDF is supported.

The cutting tool of the machine is a band saw, due to which the cut is performed at angles from 0 to 67.5º. The precision of the process is provided by a laser cutting recognition.

Despite the configuration of the device for large diameters, you can use a special table with which pipes of small diameters (50 - 200 mm) are also successfully cut, which are easier to cut with using a pipe cutter. A wide range of BSM devices is available.

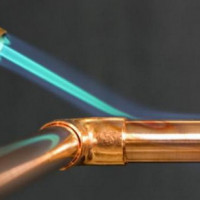

The use of thermal methods

In addition to mechanical methods, thermal methods are often used, where welding or cutting machines work as tools. For example, an autogenous gas cutter or a conventional welding machine (direct / alternating current).

Using such cutting machines, thick-walled metal pipes are available. However, it is extremely difficult to obtain a perfectly even high-quality cut using the electric welding or gas autogen method.

Electric and autogenous cutting technology is ubiquitous. The technique does not provide high precision cutting, but when installing pipes this factor is often not determining

Usually, after thermal cutting, the products are subjected to additional processing. The cut line is aligned, the values of the required angle are adjusted. This approach is economically disadvantageous, as it is accompanied by additional costs for machining.

As a rule, the thermal cutting technique is applied in the conditions of the industrial-production sphere. True utility services also often resort to such a technique.

Thermal cutting is also used for working with plastic material. There are devices - thermal guillotines. The sharp thin blade of such devices is heated to a high temperature, and then perform a cut.

Thermal guillotines support cutting at an angle, and this is their advantage. However, to work with tougher materials than polyvinyl chloride, wood, chipboards, these devices cannot be used.

For cutting plastic pipes need pipe cutters, able to evenly divide into parts of the product with a multilayer structure. The article recommended by us is devoted to their varieties and methods of application.

Conclusions and useful video on the topic

The video shows the calculations and shows a workshop on how to cut pipes at angles of 45º and 90º:

For each individual installation case, you can choose the most convenient and less expensive method of cutting. The specific choice depends on the material of the pipe, its diameter, wall thickness.

Using simple marking methods, you can get a fairly accurate angle at which you want to cut the workpiece. At the same time, turning to a complex calculation procedure, it is possible to cut at non-standard angles with high accuracy.

Do you have useful information on the topic of the article? Do you have questions in the process of familiarization with the material or found controversial issues? Please write comments in the block below.

Pressure testing of metal-plastic pipes: the order and nuances of the work

Pressure testing of metal-plastic pipes: the order and nuances of the work  How metal pipes are bent: technological subtleties of work performance

How metal pipes are bent: technological subtleties of work performance  Press fittings for plastic pipes: types, marking, purpose + installation example

Press fittings for plastic pipes: types, marking, purpose + installation example  Soldering of copper pipes: step-by-step analysis of work and practical examples

Soldering of copper pipes: step-by-step analysis of work and practical examples  Welding polyethylene pipes: a comparison of methods + installation instructions

Welding polyethylene pipes: a comparison of methods + installation instructions  Replacing Bathroom Tubes: A Step-by-Step Guide to Work

Replacing Bathroom Tubes: A Step-by-Step Guide to Work  How much does it cost to connect gas to a private house: the price of organizing gas supply

How much does it cost to connect gas to a private house: the price of organizing gas supply  The best washing machines with dryer: model rating and customer tips

The best washing machines with dryer: model rating and customer tips  What is the color temperature of light and the nuances of choosing the temperature of the lamps to suit your needs

What is the color temperature of light and the nuances of choosing the temperature of the lamps to suit your needs  Replacement of a geyser in an apartment: replacement paperwork + basic norms and requirements

Replacement of a geyser in an apartment: replacement paperwork + basic norms and requirements

There is no good way anywhere, all sorts of rubbish everywhere! Well, what is a folded sheet in a scarf attached to a pipe ... a madhouse! I tried, from cardboard, and a 45 degree square, to get the IDEAL line of the oval ... Everyone thinks what they think ... the result is manure!

Watch at least the numerous videos on YouTube, everything works out for people. Perhaps the problem is not in the method, but in the execution? In addition, you must understand that it will be difficult to achieve the ideal result manually. Even in industry there is a tolerance of up to 0.5 degrees