Pressure testing of metal-plastic pipes: the order and nuances of the work

A successful alternative to traditional steel pipes is technological products made of metal-plastic. It was especially popular in the plumbing industry. Plastic is used in the assembly and repair of pressure communications, pressureless circuits of hot and cold water supply, as well as heating systems.

In the formation of compounds, a simple and affordable method is used - crimping metal-plastic pipes. We will tell you how this work is done, what tool an independent plumber will need to build or restore systems. Our recommendations will help to achieve the highest quality result.

The content of the article:

Crimping: a concept in the broad sense

The very concept of “crimping”, as applied to metal-plastic sleeves, should be considered in the broad sense of the word. For example, crimping is often understood to mean standard tests carried out hydraulically or pneumatically.

But modern practice shows that the term “crimping” also quite logically approaches the procedure for connecting a fitting and a metal-plastic pipe. This type of connection is performed using force crimping technology using a special tool (press pliers).

Regardless of the installation conditions and applied technologies, the installation of plumbing or other communications based on plastic pipes is accompanied by tests for tightness and strength.

Usually, test process carried out hydraulically.But the possibility of producing tests by the pneumatic method is not excluded.

Methods of crimping metal plastic

The hydraulic method involves filling metal-plastic pipes with water, followed by an increase in pressure to set values. Tests can affect the entire mounted trunk or only its individual sections.

The pneumatic method involves the use of compressed air instead of water. This crimping method is considered less efficient and more dangerous than the hydraulic version. And it doesn’t matter, metal pipes or metal-plastic ones are tested.

Option # 1: hydraulic

The process is no different from the standard version, which is used on steel water mains. The only caveat is that the working pressures for plastic pipes have lower values than those adopted for metal products.

Accordingly, the test pressure is calculated taking into account standard operating pressure settings for plastic according to the formula:

Ri = Rrp * 1.5,

In it, Ri is the pressure of testing; RRP - working pressure of a plastic pipe.

The water temperature inside the pipeline is allowed within the plus values of 5 - 40ºС.

Procedure progress:

- Prepare the test site (put cranes, plugs).

- Install 2 gauges at different points on the line.

- Install an air vent on the upper level of the line.

- At the lower level of the line, connect a water pump.

- Fill the line with water supply from the lower to the upper level.

- Open the air vent to bleed air from the system.

Inside the highway from plastic pipes build up pressure should be slow, excluding sudden jumps. Such pressure conditions are provided by manual hydraulic press.

Until the pressure reaches the operating level, it is recommended to periodically check visually the areas of possible leaks.

These sites are usually:

- pipe-to-pipe connections;

- pipe and fitting contact;

- installation points for taps and plugs.

An increase in pressure inside the metal-plastic pipes to a value exceeding the operating parameter by 1.5 times is allowed only in the absence of people near the test line.

The established test pressure inside the pipeline must be maintained for a certain time. For water supply from metal-plastic pipes, designed for operation in domestic conditions, a five-minute minimum exposure period is adopted.

During the accepted minimum value of the test time, a pressure drop at the installation points of the control pressure gauges is not allowed. When changes in minus are observed on the control devices, this condition indicates an incomplete tightness of the system.

It is necessary to relieve pressure to the operating value and carefully check the places of possible leaks over the entire section of the plastic pipes. Detect any defects and repeat the test procedure.

Leak tests are passed when they satisfy the following conditions:

- no leaks were visually detected;

- no visual breaks in the walls of the pipes;

- five minutes there was no change in pressure on the control gauges;

- no visible pipe deformations.

Meanwhile, it is necessary to clarify: if the exposure time exceeds a five-minute interval, a slight drop in the test pressure is allowed due to a natural change in the temperature of the water inside the metal-plastic pipes.

Option # 2: pneumatic

In case of impossibility of hydraulic crimping for any reason, an alternative is allowed - pneumatic test.

The pneumatic test method differs in a slightly different way of checking for leaks, but in general it practically repeats the hydraulic method. This technology is used not so often on pipes, but for crimping individual devices, for example expansion tanks, boilers, heat exchangers, etc., is widely used.

To detect leaks under pneumatic pressure testing, as a rule, soap solution is used. The installed line is filled with air under pressure Ри = Ррп * 1.15 and the places of potential leaks are irrigated with soapy water. The air outlet is determined by the inflation of bubbles.

This verification technique allows you to visually detect even minor leaks. But it is quite difficult for an inspector to monitor for leaks in places that are difficult to access for visual observation.

The pneumatic test method is well suited for leak testing plastic pipe fittings or according to the “pipe in pipe” scheme. But when it is required to test the piping system for strength, this method is clearly not the best. Here you need to refer to testing hydraulically.

Crimping as a connection method

The practice of installing metal-plastic pipes is noted by using several methods suitable for making all kinds of connections:

- soldering;

- spanner;

- crimp.

The last method of the three is just crimping the metal-plastic pipe in the area of its articulation with the fitting.

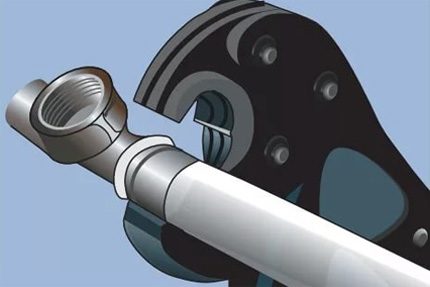

The technique of such crimping is distinguished by simple actions that are available for execution even to unprofessional plumbers. The only caveat - for work requires the so-called press pliers - a special tool, thanks to which a reliable crimp connection is created.

In general, for the execution of work using the crimping technique, the following tool kit is required:

- pipe cutter for plastic pipes;

- calibrator, expander, chamfer;

- press pliers.

The pipe cutter makes an even cut-off for a given size, without deformation of the pipe and at a right angle.With the calibrator and the chamfer, the end of the metal-plastic sleeve is prepared for subsequent articulation with the fitting.

Sometimes an expander is also required for operation. Press tongs in the process occupy a special place. It is with the help of this tool that the prepared compound is crimped.

Crimp and compression (they are also threaded) fittings are used in the assembly of metal-plastic pipelines, the steps of their installation are largely similar:

How to crimp a plastic pipe

The crimping procedure regarding the connection of a metal-plastic pipe with a fitting provides the following sequence of actions:

- Cutting plastic pipes to size.

- Perform calibration of its end sections.

- Chamfering the inner radius.

Then, the crimp sleeve is installed on the end of the pipe.

After these actions, the fitting part of the fitting is inserted into the metal-plastic pipe from the end where the crimp sleeve is located. Move the crimp sleeve over the pipe body, set it parallel to the fitting. Guidelines for working with press fittings in the assembly of a metal-plastic pipeline given here We recommend reading useful information.

Impose on the junction area press tongs, supplemented with accessories corresponding to the size of the diameter of the processed pipeline. Squeeze the tool handles all the way.

Such actions are typical for crimping using a hand tool. Meanwhile, in addition to manual crimping, there are electrical, hydraulic, pneumatic devices.

These design options are usually rarely used in everyday life. Their purpose is industrial production. They are also very different in configuration from manual models.

It should be noted some features when working with press pliers.Only one-time crimping is always permitted. If for some reason it was not possible to make a high-quality crimp the first time, do not try to repeat the action. Defective crimping must be removed, and the crimping procedure must be performed first.

Advantages and disadvantages of crimping

Evaluating connection of plastic pipesmade with the help of press tongs, it is impossible not to note the advantages and disadvantages.

Both one and the other determine the conditions where this method is suitable.

The list of noted benefits is as follows:

- an unattended connection is created;

- calculation for high working pressures;

- high mechanical strength;

- long service life;

- Easy easy and quick installation.

From the point of view of existing shortcomings, experts also identify some factors and usually associate them with the criteria for maintenance or installation:

- a non-separable connection is created;

- special tool required (press pliers).

The downside is that every crimping error reduces all work to zero.

In addition to these shortcomings, you can add the high cost of the main tool - a tick press.

True, manual adaptation to domestic conditions has a price not as high as automatic designs. But even in this case, buying is not profitable, since the need of the tool is actually one-time.

Conclusions and useful video on the topic

From the video you can learn about how to work with mechanical-type press tongs, namely how to crimp fittings of metal-plastic pipes.

Installation of metal-plastic pipes by crimping is recommended to be performed in ambient conditions with a temperature of at least + 10ºС. It is advisable to withstand the purchased material (pipes) in the new conditions for at least 24 hours and only then begin installation.

The installed plumbing system must be tested for leaks and strength by means of hydraulic and pneumatic tests.

Do you have experience in working with plastic pipes and in the device of their connections? Own the technological subtleties of the production of this work, not covered in the article? Please write comments in the block form below, ask questions, post photos.

Press fittings for plastic pipes: types, marking, purpose + installation example

Press fittings for plastic pipes: types, marking, purpose + installation example  Pipe cutting at an angle: advantages and disadvantages of different methods + example of work

Pipe cutting at an angle: advantages and disadvantages of different methods + example of work  How metal pipes are bent: technological subtleties of work performance

How metal pipes are bent: technological subtleties of work performance  Do-it-yourself installation of plastic pipes: connection technology and wiring examples

Do-it-yourself installation of plastic pipes: connection technology and wiring examples  Soldering polypropylene pipes: work rules and analysis of possible errors

Soldering polypropylene pipes: work rules and analysis of possible errors  Replacing Bathroom Tubes: A Step-by-Step Guide to Work

Replacing Bathroom Tubes: A Step-by-Step Guide to Work  How much does it cost to connect gas to a private house: the price of organizing gas supply

How much does it cost to connect gas to a private house: the price of organizing gas supply  The best washing machines with dryer: model rating and customer tips

The best washing machines with dryer: model rating and customer tips  What is the color temperature of light and the nuances of choosing the temperature of the lamps to suit your needs

What is the color temperature of light and the nuances of choosing the temperature of the lamps to suit your needs  Replacement of a geyser in an apartment: replacement paperwork + basic norms and requirements

Replacement of a geyser in an apartment: replacement paperwork + basic norms and requirements

In the presence of the necessary tool (a special pipe cutter and press tongs), crimping metal-plastic pipes is not a big problem and is quite easy to do on your own. If something is not clear, then just watch a couple of videos that are full on the network. Another thing is that not everyone has a tool, but it costs a lot.

Yes, and there is no reason to buy them if you are not professionally doing this. I just rented these press tongs, now there are a lot of companies where this can be done.

Hello. Is it necessary to chamfer when manufacturing pipes in the place of cut?