The connection of plastic pipes with metal: an analysis of the best methods and mounting nuances

Sometimes when installing communication systems you have to combine elements made of different materials. Especially often in construction practice there is a connection of plastic pipes with metal, for the implementation of which you can use different methods.

We will tell you how to connect the plastic section of the pipeline to an existing steel or cast-iron system with maximum reliability. We have described in detail the technology to ensure tightness when docking. The article describes the fixtures and tools necessary for work.

The content of the article:

Reasons for using dissimilar materials

Typically, when laying water, sewer or other systems, builders try to use the same material. However, in some cases, combined designs are indispensable. The most common causes are as follows.

Scheduled replacement and urgent repairs. The cast-iron communications with which the houses built several decades ago are equipped gradually break down. Over time, metal elements corrode or become clogged, which is why they need their planned or emergency replacement.

It is quite natural that in this case the old cast-iron or steel pipes are replaced with polymer ones, which are distinguished by lower cost and ease of installation.

Building. The process of individual or public construction of houses is associated with the laying of heating mains, sewers, water supply.Often the installation of various systems is carried out by different organizations, because of the inconsistent work of which several types of pipes are delivered to the construction site - both metal and plastic.

Special cases. In some situations, combining dissimilar materials is an urgent need, for example:

- connection of the pipeline to technological equipment, the high temperature of which fusible plastic products cannot withstand;

- laying a line in areas subject to high loads, for example, under busy roads or when leaving the garage. In this case, more durable metal elements are laid in complex areas, and polymer elements in the rest.

As we see, the need to combine different types of pipes arises quite often.

Types and characteristics of pipes

For the correct connection of pipes made of various types of materials, one should know the main types and properties of such products.

Option # 1: metal

Such elements, characterized by hardness and mechanical density, can withstand considerable loads. A common disadvantage of metal products is the high cost.

Among the most common options are the following types of pipes.

Cast iron pipes. The most popular material, which is characterized by good durability, durability, as well as a relatively budget price.

Negative factor cast iron pipes is fragility due to which these products require careful handling during storage and transportation. Before starting work, it is important to inspect the cast-iron elements for chips, cracks and other defects.

Steel pipes. Under this name, various product variants are connected:

- Pipes made of ordinary steel are quite easily rusted, and also have a tendency to overgrow the internal space, which leads to blockages.

- Galvanized steel is not prone to corrosion, but it is quite difficult to install.

- The highest consumer properties (resistance to aggressive substances, strength) have a “stainless steel”, however, products from this type of metal are expensive and require laborious processing.

It should be noted that steel elements are more expensive than cast iron.

Copper pipes. A rather rare option, since copper pipes have a high cost. However, such high-quality elements are sometimes used for communications (elevator unit) in the construction of private houses.

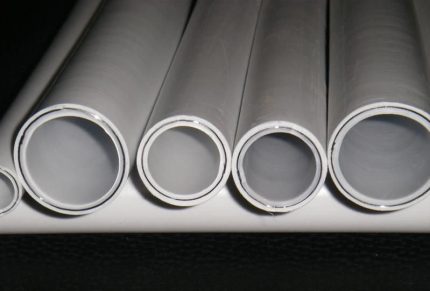

Option # 2: plastic

For laying communication systems, pipes are used in the manufacture of which various types of polymers are used. All plastic products are characterized by such important advantages as inertness to chemical media (even aggressive ones), resistance to corrosion, tendency to blockages, and also affordable cost.

At the same time, a number of characteristics of plastic pipes directly depends on the characteristics of the material from which they are made.

Most commonly used:

- Polyethylene: Products from this polymer have good elasticity and sufficient density. However, they are not able to withstand high temperatures (PET softens even at 80 degrees Celsius), which is why it is undesirable to use them for transporting hot liquids and gases.

- Polypropylene: pipes made of this plastic are most widely used, since this material ideally combines light weight with strength and resistance. Polypropylene elements withstand high temperatures, which allows them to be used in hot water systems even without reinforcement.

- Polyvinyl Chloride (PVC). The least common option, since products made from this plastic are quite fragile. Such pipes should be laid only in places where loads will not drop on them, most often they are used to create sewer systems.

In everyday life, all the listed types of pipes are used.

Option # 3: metal-plastic

The combined material, which has recently received great recognition, consists of five layers, including two plastic shells (internal and external), two layers of glue and aluminum foil.

Such products are distinguished not only by high consumer qualities (durability, reliability, lightness), but also by their beautiful appearance, which allows them to be used without additional decoration. Plastic pipes can be used for laying various communications: water pipes, sewers, heating and drainage systems.

How to connect sewer pipes?

Depending on the purpose of the system, metal and polymer elements can be mounted in different ways. The simplest way is to connect sewer pipes made of different materials.

In order to combine them, special products are used (corrugated cuffs, plastic corner bends, gaskets), which can have different sizes and configurations.

Using such a device, you can easily dock the polymer pipe with a cast-iron neck.In order for these products to fit snugly together, it is important to choose a cuff or corrugation that is suitable for the parameters. If this fails for some reason, you can use finely porous rubber (even an old car floor mat).

A long narrow tape is cut from the material, which fastens the fasteners between the pipes. It is convenient to carry out such an operation with a wide, unsharpened screwdriver, and you need to work carefully, but carefully, remembering the possible deformation of the plastic.

It is strongly recommended not to seal a plastic element in a metal bell with the help of embossing or to seal the joint with cement.

In the first case, you will not be able to achieve a tight connection, since due to the plasticity of the polymer the pipe will deform. In the second, the thermal expansion of the plastic will prevent a good result: under the influence of a hot pipe, the fasteners will be broken and the joint will lose tightness.

Connections of heating and water pipes

This option is considered more complex because the communication system is under pressure. In this case, you can apply several methods of connecting pipes:

Threaded

For pipes whose diameter does not exceed 4 centimeters, the best option is to connect fittings. Such convenient devices can have various configurations and parameters, however, they have a common design feature.

One end of the fitting ends with a smooth sleeve designed for the polymer element, the other has an internal or external thread at the end, designed to secure the metal pipe.

For more complex connection options, a fitting tee is designed, using which you can dock two plastic and one metal (usually steel) element into a single system.

Flange

For pipes of large diameters (60 cm and more), it is better to use special detachable fasteners-flanges, which consist of two identical parts, bolted together.

This avoids manual tightening of the thread, which is difficult to do on large parts, but at the same time create a solid reliable fastener.

Special Views

Other types of fittings can be used for joining parts, for example, a special coupling or Gebo fittings. The latter option is especially recommended for combining small pipes or systems located in difficult places (for example, close to the floor).

Metal hose

To combine plastic elements with metal pipes, you can also use a special device - a metal hose, which is designed to work in extremely difficult conditions (high pressure, exposure to aggressive substances).

Typically, such a device is used when laying gas pipelines or installing systems in chemical plants, but it can also be used in construction.

A metal hose, one example of which is flexible eyeliner for mixer, attached to a metal pipe using an ordinary thread (in the case of connecting elements of large diameter, you can use a flange of the appropriate size). An additional fitting with a polymer sleeve is put on the second end of the metal hose, which fits into the plastic product.

A particular advantage of this method is the ability to create a flexible connection, so that the design is able to "get around" various obstacles.

Below we will consider in detail the installation of connections of various types.

Features of mounting threaded fittings

Thanks to various varieties of threaded fittings, the installation of the pipeline achieves the ability to perform the most complex bends and turns.

The most popular device for joining polymer and metal elements is the American fitting, which is available in various sizes. A convenient fixture with a plastic sleeve and metal thread is extremely convenient to install, allowing you to create a reliable tight connection in a short time.

Step-by-step installation instructions

To connect a metal pipe with a polypropylene or other plastic pipe, you must:

- Using a special soldering iron, weld the fitting sleeve to the end of the polymer pipe, and then wait for the joint to cool.

- Bring the metal part to the other end of the "American" and then tighten the thread. To seal the joint, it is desirable to additionally wrap along the thread with one or two layers of FUM tape, tow or flax fiber (additionally can be coated with silicone).

- The fitting must always be twisted by hand: the use of tools is undesirable and even dangerous. Special equipment does not allow full control of the applied forces, which can lead to damage to the part.

- After completion of work, it is important to check the strength of the obtained fastening. To do this, just turn on the water and make sure there is no leakage. If moisture is still filtered through the joint, you can try to tighten the bolt a little more. With the further flow of water, it is necessary to unwind the thread again and carry out all the manipulations again.

The shape of the finished joint can be changed if the plastic part is softened with a building hair dryer, and then the bend required by the design is made.

Threadless metal pipe connection

There are situations when a plastic pipe must be connected to a metal analogue that does not have a thread.

This problem can be solved by a special tool called a “thread carrier” or “thread cutter”, with which you can apply grooves on a part made of steel or cast iron.

There are two options for adaptation:

- Electric, the set of which includes several cutters designed for pipes of different diameters. Such models are comfortable and easy to operate, but have a high cost.

- Manual thread carrier is much cheaper, but working with it requires more physical strength and certain skills.

In detail about how to thread pipes, you can read in the article we proposed.

When using thread cutters, you should follow a few simple rules:

- The tool cannot be operated if the pipe is at a small distance from the wall.

- The electric thread carrier heats up quickly, so when processing several elements, you will have to rest periodically.

- When working with a manual fixture, it is important to observe the alternation of movements, performing half a turn forward and a quarter turn back, until you cut the thread to the desired length.

To thread a pipe, it is necessary to thoroughly clean the pipe, if necessary, remove the existing paint and grind metal streams. Then thread with an electric or carved tool.

It is good to clean the cut grooves and grease with solid oil, oil or other grease, and then apply for connection with the fitting.

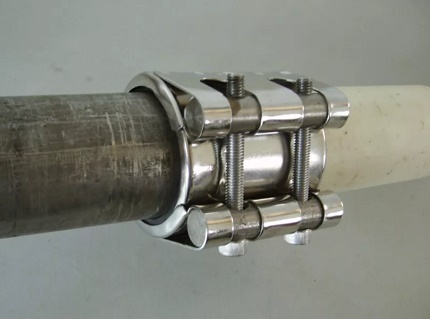

Features of flange mounting

With this option of fastening polymer and metal pipes, special detachable devices are used - flanges and clamps. They not only allow you to create a strong joint, but also provide access to the pipe junction (just unscrew the bolts for this).

There are several options for such devices, among which are especially common:

- Loose clamps resting on a straight shoulder. Such parts are intended for mounting light elements with a diameter of up to 30 cm, as well as for medium and heavy pipes, in which this figure does not exceed 15 centimeters.

- Loose clamps supported by a conical shoulder will help to create structures from pipes with a diameter of not more than 20 cm.

- Blade fasteners with a figured flange and a steel ledge are considered universal, they can be used for joints of different elements, it is important to pay attention to size.

- A straight shoulder with a conical transition can significantly increase the strength of the connection.

Regardless of the clamp model used, to create a connection, you must adhere to the following work procedures:

- Before starting the manipulation, it is important to choose an element of the required type, the size of which would correspond to the diameter of the metal part of the pipeline.

- You should carefully inspect the selected part: there should not be sharp burrs on the part that could scratch and damage sufficiently fragile plastic grooves.

- The place of the proposed tie-in is determined on a steel (metal) pipe, then it is carefully cut (the edges should be even).

- After that, a clamp is put on a metal part. To ensure a tight connection, a rubber gasket is added to it, which should not go beyond the cut line by more than one centimeter.

- Next, you need to connect all the elements of the mounting unit, fastening the bolt clamp on a metal pipe with a similar element mounted on a polymer part.

Tightening the bolts must be done calmly and evenly, making a complete turn of the thread and avoiding the excessive use of forces so as not to damage a sufficiently fragile part.

The use of clamps in connecting, repairing pipes and fixing openly laid pipelines is written in detail in this article.

Special types of pipe connections

In some cases, it is advisable to use fasteners with other types of fittings. Consider two options for such work.

Fasteners using a special coupling

A fairly simple part can not only be purchased at building materials stores, but also made independently.

The device consists of the following parts:

- case made of cast iron or strong steel;

- two nuts that are located on two sides of the part;

- rubber gaskets to seal the connection;

- four metal washers that must be in the inner cavity of the coupling.

The parameters of all elements must correspond to the diameter of the pipes on which they will be used.

Instructions for use: insert the ends of the pipes up to the middle of the coupling, threading them through gaskets, washers and nuts, and then tighten the latter tightly so that they compress the gaskets.

Mounting by clamping and connecting sleeve (Gebo fitting)

Docking of metal and polymer pipes by means of a thread gives a guaranteed tight joint, however, this method is not always possible.

If the length of the metal pipe is small or adjacent to a horizontal surface, it is advisable to use a clamping and connecting sleeve, which is also called a Gebo fitting (for example, HEBO-QUIK).

A similar device consists of the following parts:

- housing;

- fixing nuts;

- clamping, clamping and sealing rings.

Work does not require special skills, special equipment or a long time.

Procedure:

- To clear edge of a metal pipe of pollution and old paint.

- Unscrew the coupling completely.

- In sequence, put on the cast-iron or steel element all the fasteners, while the o-ring should be at a distance of 1 or more centimeters from the end of the product.

- Insert the end of the metal pipe into the body of the coupling, slide all the available rings to it, and then tighten the bolt.

- An American fitting must be attached to the thread on the other side of the coupling, previously soldered to it with a polymer pipe.

To check the strength of the fasteners, you must carefully pull the element, holding the pipe to which it is attached.

The fitting must not move in the design. If it responds to your touch, tighten the thread more tightly. Movement in this case will mean that you have chosen the wrong size, as a result of which the coupling sits on the pipe loosely.

All types of fasteners described above can be used to connect metal pipes with metal-plastic elements.

Conclusions and useful video on the topic

The videos posted in this section demonstrate the procedure for fastening pipes made of metal and polymers using the American fitting and flange connection.

Practical use of the flange:

The process of joining metal (cast iron, steel) and polymer pipes requires certain strengths and skills. Regardless of the type of fastener, for perfect joints it is important to choose the right part of the right size, as well as carefully follow the instructions.

Want to talk about how you connected a plastic pipe during the repair to a steel or cast-iron pipe? Would you like to share useful information with us and site visitors? Please write comments in the block below, ask questions and post a photo on the topic of the article.

DIY welding technology for polypropylene pipes: an overview of methods and nuances

DIY welding technology for polypropylene pipes: an overview of methods and nuances Compound

copper pipes: instructions and comparison of various installation technologies

Compound

copper pipes: instructions and comparison of various installation technologies How to arrange a pipe box in the toilet: an overview of the best ways to mask the pipeline

How to arrange a pipe box in the toilet: an overview of the best ways to mask the pipeline How to crash into a plastic pipe: features of work and analysis of all important nuances

How to crash into a plastic pipe: features of work and analysis of all important nuances Press fittings for plastic pipes: types, marking, purpose + installation example

Press fittings for plastic pipes: types, marking, purpose + installation example Why the pipes in the apartment are buzzing: determining the causes and analyzing how to fix the problem

Why the pipes in the apartment are buzzing: determining the causes and analyzing how to fix the problem How much does it cost to connect gas to a private house: the price of organizing gas supply

How much does it cost to connect gas to a private house: the price of organizing gas supply The best washing machines with dryer: model rating and customer tips

The best washing machines with dryer: model rating and customer tips What is the color temperature of light and the nuances of choosing the temperature of the lamps to suit your needs

What is the color temperature of light and the nuances of choosing the temperature of the lamps to suit your needs Replacement of a geyser in an apartment: replacement paperwork + basic norms and requirements

Replacement of a geyser in an apartment: replacement paperwork + basic norms and requirements