Corner toilet with a tank: pros and cons, scheme and features of installing a toilet in the corner

The parameters of the bathrooms in the apartments do not always have sufficient area for the standard placement of all key plumbing fixtures. The solution to this problem lies in clearly thinking out the location and choosing compact models of functionally key objects. One of which is a corner toilet with a tank - a profitable design for the original design of the adjacent bathroom.

In this article we will analyze in detail the advantages and disadvantages of such toilet models, possible installation patterns and focus on the features of their connection to communication networks. Supplemented material will be supplemented with visual photos and useful tips on choosing a suitable toilet for installation in the corner of the bathroom.

The content of the article:

Advantages and disadvantages of angle instruments

The toilet, located in the corner, has almost the same design as in the standard version. The only difference that expresses this type of installation is the triangular shape of the drain tank. This does not affect the volume in any way.

Using the corner monoblock You can not only expand the free space in the bathroom, but also complement the interior of the room with an extraordinary model. By filling the corners with plumbing fixtures, the room acquires rounded shapes with a vast interior space.

In the Compact model, the bowl is divided with a drain tank, which, through installation, is sewn into a corner niche. The design, equipped with a hanging toilet, is quite weighty - its carrying capacity is almost half a ton.

If the apartment has separate bathroom rooms, then the use of a corner installation in the toilet will make it possible to place additional appliances, for example, a bidet. In addition to everything, the models in question can be adjusted in height up to 4 cm.

Separate praise deserves the strength of a drain tank made from solid material. Leaks are excluded in it.

If for some reason the drain tank breaks or cracks appear, you don’t have to worry about the neighbors below, the risk of flooding is minimal. Thanks to equipping with an emergency system, at the time of overflow, excess network water will be redirected to a special overflow channel.

There is a minor minus in such devices. It is associated exclusively with the installation method of attachments. The wall on which it is intended to be installed must be strong enough to support the expected weight. Also important choose the right height during installation, given the growth of all inhabitants of the house / apartment.

When it comes to gypsum plasterboard, it will be necessary to place a solid wood mortgage in advance under the skin and fasten with long bolts for through passage and the wooden part, and a sufficient recess in the main wall.

What are the types of corner toilets?

Consumer demand for non-standard sanitary fixtures tends to increase. In addition to the originality of the device itself, its main characteristics are also appreciated: comfort and functionality.

An important role is played by the design of the structure. In addition to the shape of the tank, the visually angular toilet is no different from the standard model, but this is not so - there is also a difference in installation.

Instrument manufacturing material

Despite the fact that the range of corner toilets is less extensive in comparison with the classics, you can still choose an interesting option.

The materials used for the production of corner sanitary models are standard.

The toilet may be made of:

- plastic;

- porcelain.

- faience.

Thanks to modern technology, plastic devices are made from acrylic, additionally reinforced with fiberglass and special resin. Lightness and simplicity of the product, a high degree of strength and a non-porous structure are the main advantages of such plants.

The disadvantages include poor resistance to mechanical damage and temperature changes.

The increased degree of durability of porcelain toilets is complemented by a high operational life. The basis of the production process is white clay, with the addition of natural minerals - quartz and feldspar. Glaze is traditionally used as a topcoat.

It is this composition that makes the structure of the device less porous, and accordingly, simplifies the maintenance of it. Its main disadvantage is its high cost.

The most popular models from an affordable price category are earthenware. Plumbing, made of earthenware, passes the firing procedure before the final stage of glazing.

These production processes help make the toilet durable, with high levels of protective functions, as well as reduce the porosity of the material, making housewives easier to care for. Product service life reaches 15 years.

In rare cases, you can find exclusive models from expensive materials: bronze, natural or artificial stone, steel. Due to low consumer demand for this kind of product, manufacturers are in no hurry to replenish the lineup.

If you take the standard option, the best products are made of porcelain. The use of high-quality materials in production, with a low degree of moisture absorption, allows you to create a model that over time does not lose its original qualities, both functional and visual.

Suggested Bowl Types

Depending on what type of bowl is used in a particular corner installation, the degree of comfort during operation, volume, amount of spray during rinsing and economy in water flow are determined.

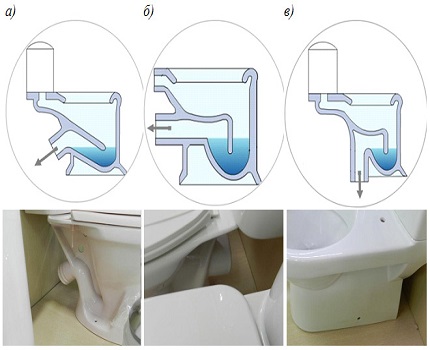

The market offers a choice of three options: with a shelf, funnel-shaped, with a slope of the back or front wall.

An angular toilet with a shelf has a lot of minuses. Due to the fact that all emptying products initially remain on the stage of the device, there will be a characteristic unpleasant odor in the bathroom. Also, after washing off, it is almost always necessary to use a brush to remove residues.

In addition, the bowl forms a water lock in which water is constantly present. But when using water of poor quality, as well as due to deposits of urine salts, plaque forms and rust can appear. And such problems have to be regularly fought, using for cleaning the toilet effective means ..

This type of product is not different and economical water consumption. Its only plus is flushing with almost no spray.

The next type of bowl has a slope of the front or back wall, which is why the corresponding name for the plumbing device is with a slope. Such features make it possible to minimize the penetration of unpleasant odors.

This is due to the fact that, through the wall with a slope, the waste enters immediately into the water. Despite this, you have to use the brush almost all the time.

For a funnel-shaped device, a brush is used in rare cases. Such a monoblock is the most hygienic and economical, since draining does not require large expenditures of water. Unpleasant odors are practically absent. However, when washing off, the device releases a lot of splashes.

With the help of an invention called “Anti-splash”, based on adjusting the water level (the lower it is, the lower the splash level), the problem of spraying has been eliminated.

Bowl drain

The direction of release does not affect the comfort of using a corner plumbing fixture. It is also impossible to visualize external differences, however, the parameters and location of the sewer entrance in the bathroom can affect the choice.

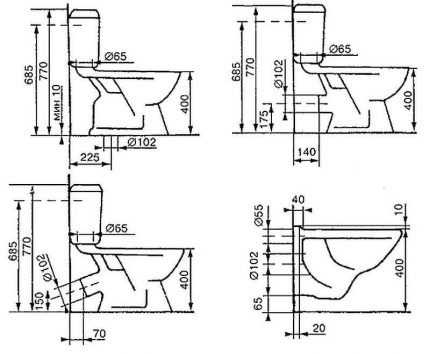

Allocate such types of taps of the bowl in the toilet:

- Horizontal outlet. It is used if the bell of the sewer riser is 5-10 cm above the floor.

- With a vertical branch. Ideal for the bathroom, where the sewage line is directed to the floor. With this arrangement, maximum space savings are achieved, however, you can rarely find such an arrangement of the sewage line in multi-storey buildings.

- With oblique drain hole. The most common option that was first introduced to the markets.This model assumes a bell located at an angle or close to the floor.

It is not possible to replace the toilet with a horizontal outlet to a vertical one. This problem can only be resolved if the location of the sewer bell is changed.

Features of connecting corner models

Next, we analyze the installation features of the toilet models, which have a different supply of sewage.

Corrugation Installation Diagram

Non-standard models of corner products have their own characteristics not only constructive, but also expressed in the installation process. Initially, this is a suitable sewage supply.

However, in low-rise buildings, old buildings, the riser is located along the wall, which complicates the installation of the corner monoblock. You can solve this problem using an extension cord, which is used as corrugated pipe.

Installation begins with the installation of the toilet in the selected place and the outline of its borders. Marking of areas where it will be necessary to drill holes for dowels is also performed. To do this, at the base of the device, on the leg, there are special holes. Now the drain device must be rearranged and drilled backlash under the fasteners.

Next, the toilet is placed in its original position and fixed with dowels. One side of the corrugated pipe is led into the sewer, while the docking area must be treated with silicone, the other is put on the outlet.

To install the drain tank, it is necessary to combine the drain holes, while being careful not to shift the existing silicone gasket. This seal protects the structure from leakage. After tightening the screws.

Using a flexible hose, cold water is supplied. Using sealant, the gaps between the base of the appliance and the flooring are smeared. This prevents debris from entering the toilet, which simplifies cleaning in the bathroom.

We have a website step by step instructions with various ways to fix the toilet to the floor. We recommend that you familiarize yourself with them.

Now a control check of all connections by collecting water in the drain tank and draining it.

Using an adapter to connect

Another method of connecting the toilet to the central sewer system is through pipes. It is worth paying special attention to the type of monoblock release.

Oblique release involves the installation of a monoblock in the floor or in the wall, however, in the second version, the fan pipe starts at an angle of 30-40 °. For a vertical drain hole, the wall mounting method is used, while the location of the pipe should be at an angle of 90 °.

How to install a toilet with a different type of release?

Depending on the type of installation, two types of corner toilets are distinguished: floor and wall. In the first version, the drain mechanism is placed and mounted on the floor, in the second - on the wall.

The device of the floor candy bar is more familiar and understandable. Installation of such a design is simple and does not take much time.

With a pendant device, the situation is more complicated - it will require a special corner installation, which is a metal frame.A sewer pipe, water supply system is connected to the frame and a drain tank is mounted.

The design allows you to hide the water bowl and all communications by closing them with decorative elements. Installation can be drowned in a wall or simply installed in a corner.

There is another type of toilet - attached. The product, like the previous one, is mounted in a corner, but its vertical axis is not placed diagonally, but parallel to the wall. Due to asymmetric displacement, the drain can be installed close to the side wall.

Models with a lower type of water supply to the tank are widely represented on the market. Less common are side feed devices. The option with a lower eyeliner is more convenient - it is almost silent at the time of water intake into the drain tank.

The attached type of construction, like the previous one, masks all communications either in the wall or in a special nightstand. In most cases, they are already included with the cabinet, which greatly simplifies the choice.

Instruction # 1 - installation with vertical drain

Corner toilet models with a vertical drain hole are most often used in houses with an old layout or in private cottages.

The main positive aspects are that the working parts of the device after installation are not visualized, and the product can be placed as close to the wall as possible, since there is no need to leave a place for pipe fittings.

After completing the marking phase, a screw flange is installed in the hole defined for the connection of the drainage system to the sewage system. All flanges are identical and have the same dimensions. Even in production, toilets with a vertically arranged drain are equipped with parts that ensure their tight connection.

Next, the candy bar returns to its place. Make sure that all holes match. Having installed the structure, it is slightly rotated. At this moment, the fasteners are tightly joined. Tightness is ensured by a sealing ring located between two parts.

You decided to install and connect a toilet with a vertical outlet with your own hands, but have never done such work? Recommended reading step-by-step installation instructions this type of toilet.

Instruction # 2 - installation with horizontal release

If the sewer socket is located vertically, it is enough to simply connect a toilet bowl with a horizontal type outlet to it.

The device will be slightly indented from the wall and the riser, and the connecting elements are practically invisible due to the angular location.

A cuff or corrugated pipe is used as a contact element for connecting a corner monoblock with a horizontal type outlet to a sewer outlet.

After connecting, the adjacent sections of the nozzles and seal are treated with silicone. Thus, the leakage of the working fluid and the penetration of stock odors are prevented.

If the center of the horizontal outlet with respect to the sewer bell is displaced, a corrugation or a set of a corner and a short branch pipe is used for contact. The toilet itself will be connected via a rubber cuff.

Instruction # 3 - connecting the toilet with an oblique outlet

Since the mid-twentieth century, it was the oblique shape of the sewer outlet that was equipped in the houses, and the pipeline itself was made of cast iron.

Now it became necessary to dock the toilet drain with such sockets. Detailed instructions for installing a toilet with an oblique outlet given here.

Initially, a mixture of minium and drying oil is made in a ratio of 1: 3. The composition must be constantly mixed - the meerk quickly settles to the bottom. The solution processes the drain hole of the toilet.

After this, you need to tightly wrap the heel on the socket, with one end being free. Then, a second time, supernatant is applied. Only after this release of the monoblock is inserted into the sewer.

You can use another, less dirty way. This refers to the use of rubber cuffs. It is mounted on the drain pipe and connected to the sewer pipe. If necessary, using the corrugation, you can perform a displacement of the toilet bowl relative to the central drain.

You can connect the drain block to a plastic drainage line in the same way as described above with one clarification: contact sealing is not required.

About installation of hinged plumbing

The corner installation is installed almost the same as the mounted model. First of all, all communication is displayed.

Instead of a flexible supply of water to the tank, it is better to use a metal pipe. A corrugated pipe can be used for the drain system.

The installation frame is fixed to the wall with anchors. This ensures reliable fastening and immobility of the frame structure. The bowl is located 400-500 mm above the floor. At the finish stage, the toilet is connected to the communication system.

If you have never been involved in the independent installation of hanging plumbing, we recommend that you read more detailed installation instructions angular installation, as well as useful recommendations for selection.

Conclusions and useful video on the topic

Details on the intricacies of choosing an angular toilet model can be found in the video:

Useful tips or how to connect a toilet bowl and not create problems:

The nuances of installing and connecting different installation systems:

In most cases, buying a corner toilet is more a necessity than a personal preference. However, this plumbing item fully justifies its purpose, and installation difficulties do not arise if you stick to the scheme.

Are you seriously thinking about purchasing an angular toilet bowl model and want to clarify the nuances that we missed in this article? Ask your questions under this material - our experts and other visitors to the site will help you figure it out.

Or maybe you are one of the angular-type toilet users? Share your experiences and photos of your toilet model, tell us which of the shortcomings you consider to be significant, and which of the pluses are the most significant.

Vertical release toilet: device, pros and cons, installation features

Vertical release toilet: device, pros and cons, installation features  Wall-hung toilet with installation: selection rules, pros and cons of such a solution + installation steps

Wall-hung toilet with installation: selection rules, pros and cons of such a solution + installation steps  Monoblock toilet: device, pros and cons, how to choose

Monoblock toilet: device, pros and cons, how to choose  How to clean the toilet from urinary stone, rust and other deposits: the pros and cons of various methods

How to clean the toilet from urinary stone, rust and other deposits: the pros and cons of various methods  Laying between the tank and the toilet: types, purpose, installation features

Laying between the tank and the toilet: types, purpose, installation features  How to install a toilet on a tile with your own hands: step-by-step instruction + installation features

How to install a toilet on a tile with your own hands: step-by-step instruction + installation features  How much does it cost to connect gas to a private house: the price of organizing gas supply

How much does it cost to connect gas to a private house: the price of organizing gas supply  The best washing machines with dryer: model rating and customer tips

The best washing machines with dryer: model rating and customer tips  What is the color temperature of light and the nuances of choosing the temperature of the lamps to suit your needs

What is the color temperature of light and the nuances of choosing the temperature of the lamps to suit your needs  Replacement of a geyser in an apartment: replacement paperwork + basic norms and requirements

Replacement of a geyser in an apartment: replacement paperwork + basic norms and requirements

There are a lot of toilets in stores now, but I would not recommend taking the corner option to solve problems with the area. In principle, in any apartment you can place a regular toilet. But the corner will be not only more expensive, but also more difficult to maintain. Indeed, if necessary, change the drain system in the tank there will be problems with its selection, since not every option is suitable for a tank made with bevels.

They wanted to put a porcelain corner toilet, but the prices were biting, I had to take a simple earthenware toilet (they didn’t even consider acrylic! From the top neighbors with the same layout, it quickly deteriorated!). We found only one advantage of the corner installation: this is an excellent layout of the space. The rest of the toilet is ordinary, but still had to invest moral and material resources in the installation. If the space allowed not to save it, then they would put the toilet down as usual.