Bath harness: overview of the types of drain-overflow systems + step-by-step installation instructions

Modern innovations have an impact on the field of sanitary engineering, where a lot of interesting new products have appeared recently. One of them is a bath strap, which is also known as a “drain-overflow system”.

Initially, such devices consisted of two separate elements: a siphon and overflow tubes, the installation of which was carried out independently of each other. Later, these parts were combined into a compact design.

Installing a drain-overflow does not cause any special difficulties - any home master can do the work. But first you need to determine the type of strapping and get acquainted with the technology of its installation. You will find all the necessary information in our article.

We described in detail the features of different models of plumbing fixtures, provided practical tips for choosing piping, and also prepared step-by-step instructions for installing the system on the bathtub.

The content of the article:

The principle of operation and design of the device

A standard bath tub is essentially a more complex design than a regular siphon. It comes with a special tube and controls that attach to the overflow hole.

Thanks to the pipe, excess liquid is discharged to the siphon, which prevents the overflow of the bath and overflow of water over the edge.

The drain-overflow system also makes it possible to control the outflow of water. To do this, a rotary handle is mounted on the overflow hole, connected by a small metal cable to the drain valve, which is installed in the bottom siphon.

By turning the handle in different directions, you can adjust the cable tension, which in turn affects the flow capacity of the siphon drain.

Varieties of sanitary ware by material

Ties for bathtubs are made in a wide range.

According to two fundamental criteria, there are two options for the accepted classification.

- by the material of which the product is made;

- on technological features of the design.

The following materials are used for the production of most of the plumbing systems:

- high strength polymers;

- non-ferrous metals / alloys - bronze, copper, brass;

- stainless steel, which is coated with chrome as a protective layer.

Consider the features of products made of different materials.

Option # 1 - Plastic

For systems made of high-strength plastic, the following features are characteristic:

- long period of operation;

- the material is not destroyed even with prolonged exposure to moisture;

- relatively low price;

- ease of installation and operation;

- smooth inner surface, preventing the formation of blockages;

- resistance to modern cleaning products, the composition of which often includes harsh chemicals.

At the same time, the plastic strapping with corrugation has certain disadvantages, the main ones being the excessive fragility of the material, which requires special attention during installation, as well as softening of the polymer under the influence of hot water.

Hot water leads to pipe deformation in places where stress areas have formed due to improper installation.

Option # 2 - metal

Plumbing devices made of non-ferrous metals or polished / chrome steel are somewhat inferior in popularity to plastic counterparts. They are strong and durable, but have a much higher cost.

The disadvantage of such products is also the difficulty in installation: during the installation of the structure, it is necessary to precisely fit the product details using special tools.

Metal ties are prone to the formation of fat and other deposits, they can suffer from active substances (acids, alkalis), which are sometimes added to household chemicals.

Design features of drain-overflow systems

According to the technical features of the model can be divided into the following categories:

- universal;

- semi-automatic;

- automatic.

The most popular is the first design option, characterized by simplicity and affordable cost.

Simple universal fixtures

A characteristic difference of such devices is the well-known chain with an attached stopper that closes the drain of the siphon. Such devices are mounted on standard bathtub models, in which the distance from the center of the overflow hole to the middle of the drain does not exceed 57.5 cm.

Installation of a universal type system is extremely simple, almost everyone can install it, even without a lot of experience or special skills.

The device consists of four components, namely:

- located directly under the siphon bath;

- a drain neck designed for the lower hole;

- trellised overlay complementing the previous component; the overlay has a recess in which the lid is mounted;

- corrugated pipe, through which the upper overflow hole is connected with a water seal designed to drain excess water to prevent overfilling of the bath.

Such bindings can be made from different materials described above.

Convenient semi-automatic strapping

Such a system differs from the universal one by the mechanism attached to it, which makes it possible to regulate the discharge. To do this, not only a corrugated pipe, but also a rotary handle connected with a metal cable to the lower drain hole is installed on the hole located at the top.

Moving the handle allows you to control the opening level of the drain neck, so that it is possible to adjust the outflow of water without using a special cover.

In such systems, the overflow device is disguised as a drain design control handle, which gives the system an aesthetic and stylish look.

At the same time, the design of the handle of the strapping of the semiautomatic device for the bath can be the most diverse, namely in the form:

- decorative valve;

- buttons

- lever;

- swivel ring.

An important advantage of the design is the comfort of use, since the handle is located at the top of the bath: the user does not need to bend to the bottom or even wet his hands.

It is worth adding that the installation of a strapping involving a semi-automatic drain is rather complicated for non-professionals, since it requires certain knowledge.

Automatic bath systems

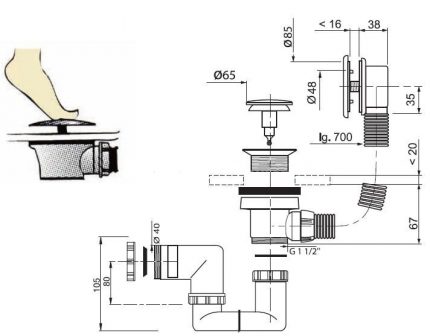

The functioning of this type of strapping occurs without the use of cables and rotating elements. Like the previous device, the machine is equipped with an overflow pipe, and at the bottom of the drain there is a special valve: when you click on it, an opening through which water flows into the siphon becomes accessible.

Pressing the lever is easy enough: this can be done with your hand or even with your foot. It is also provided that the valve is held pressed so that it does not have to be held until all the liquid has left the bath.

The disadvantages of such products include:

- Fairly high cost. It is several times more expensive than a conventional mechanical device.

- The need for extra movements. Close the drain to let water into the bathtub or to use the tank for other purposes (for example, for washing), you can only bend over.

- Possible breakdowns. The most vulnerable part of the automatic fixture is the spring holding the valve and actuating it. If it breaks, you will have to completely replace the entire system.

When choosing such products, it is better to give preference to well-established manufacturers in order to minimize the risk of malfunction.

Other types of devices

A subspecies of the automatic system is a strapping having a filling option. Similar models take on the functions of a bathroom faucet.A water pipe is brought to the strapping, so that the tank is filled using a mechanism that is located on the overflow hole.

In addition, there are special models that are performed at the request of the customer or manufacturer for custom bathtubs. They take into account the special dimensions of the tanks and the communications supplied to them.

Features of the operation of devices

For the correct installation of the harness relating to any type, it is necessary to carefully study the instructions that came with the kit: it contains a detailed diagram of the installation of the product. It is also advisable to study the properties of the material of which the system is made, as well as recommendations for the operation and cleaning of the structure.

Of particular importance are the points on the use of cleaning substances: some of them contain acids and alkalis that can damage metal parts, which will lead to the failure of the strapping.

Installation of the bath piping system

In order to mount the device, you need to purchase the device in a specialized store, as well as stock up with tools, the set of which may differ depending on the type of strapping selected.

Tools necessary for the installation of strapping:

- To install a cast-iron or steel siphon, you will need a grinder with a cutting wheel (you can replace it with a narrow metal sheet of good strength) and a hammer.

- When installing an automatic device, you need to stock up on a small flat screwdriver, as well as a set of hexagons.

In addition, two screwdrivers (Phillips, flat), pliers, silicone sealant and cotton napkins are needed.

Dismantling of old equipment

The work should be carried out in several stages:

- The first step is to thoroughly rinse and clean the outer layer of the bath, after which it is necessary to dismantle the old device.

- An obsolete plastic siphon is twisted using pliers, the overflow is removed with the same tool.

- The cast iron harness is removed with the help of a grinder, into which a 115 mm disk must be inserted. Work is carried out in a circle, sectors.

- After that, you should drive a flat screwdriver to pick up and remove the upper part of the old siphon adjacent to the bathroom.

The same manipulations (loosening or sawing) should be carried out with overflow. Then you need to take a hammer and use it to try to loosen the siphon, and then pull it out of the sewer pipe.

For difficulties with rusted bolts, you can use the means at hand: a kitchen knife or an opener. With these devices, it is quite possible to cut the stainless steel and get the lid that covers the drain hole.

Removing an automatic system is fairly simple. First of all, remove the plug and unscrew the fixing bolt with pliers or a key. In order to remove the overflow bolt, you need to unscrew the lamb with a small flat screwdriver. After removing it, you need to unscrew the bolt and without any problems dismantle the entire structure.

Mounting a standard bath piping

Assembly begins with the lower gasket, which must be found in the kit (it is thicker than the upper). This part is coated with silicone, and then put in place.

This is done in the following way: one hand from below pushes the element under the bathtub, the other - picks it up from above, tucking it into the hole.

The lower mating part is installed from below, while the overflow grid with a connected bolt is inserted from above. The design is neatly twisted with a flat screwdriver. Movement should be done clockwise.

After that, in the kit, it is important to find the upper overflow and disassemble it. To facilitate the installation of this important part, a silicone layer is applied to the gasket seat, so that the part will not fall off during installation.

A thin gasket is attached to the diameter of the circumference of the seat, which also needs to be coated with silicone in order to improve moisture resistance.

After that, a small corrugated tube is taken, which is slightly stretched, and then alternately put on the nut and cone gasket - the wide side should rest against the nut.

The corrugated structure is mounted in its proper place and secured with a flat screwdriver. At the same time, slightly pull it with two fingers, however, this should be done carefully so as not to damage the plastic part. The bolt is first held by fingers, and then tightened with a screwdriver.

If the nut falls out, you can slip a piece of the bag inside or use other methods. The edge of the thin overflow corrugation is inserted into the drain hole, after which the plastic nut is tightened.

Assembling a new water trap (siphon)

A water trap serves to eliminate odors. It is easier to assemble it separately before connecting to the rest of the parts. At one end, it attaches to the drain hole, and at the other, to the discharge corrugation. The corrugation, in turn, is inserted into the drain hole of the sewer.

To check the build quality, just turn on the water and let it drain into the sewer. If there are no leaks, the installation is completed correctly.

For step-by-step installation instructions for the siphon in the bathtub, see this article.

Installation of automatic fixture

Installation of the siphon machine is carried out similarly to the procedure described above.

- First of all, you need to open the package and find the gasket that will be installed on the drain.

- Align it with the hole in the bathtub so that the part with the smaller thickness is at the top. If the siphon is placed on cast iron plumbing, it is advisable to cover it from the inside plumbing sealant.

- From overflow, unscrew the chrome-plated pressing front.

- The gasket landing site is treated in a circle with silicone to improve the strength of the joint. In addition, the gasket mounted on the sealant will not fall and move from place, which simplifies installation.

- The resulting structure with one hand on the outside of the bath is pushed to the overflow hole, while the chrome-plated pressing part is wound with the other hand.

- The next stage is the lamb, which must be carefully planted on the stock. After installing the element, tighten the nut with a small flat screwdriver. This must be done with the utmost care so as not to damage the part.

- After that, it is important to tackle the drain. The lower part of the structure is brought to the hole, while the drain mesh with a bolt that we hold with our fingers is inserted from above. The connection neatly twists.

- Next, try on the plug with the adjusting bolt. To do this, insert the drainage grid into the hole of the clamping bolt and tighten if necessary.After that, the locking nut is adjusted, which should lower to the lower mark, and then rise again.

At the end of the work, a gasket and a nut are inserted into the hydrolock part; the mating part of the drain is installed, the nut is fixed. In the reciprocal part of the siphon, a sewer pipe or corrugation with a diameter of 40 mm is connected.

Having mounted the strapping machine for the bath, a test run should be carried out to check its reliability.

You can also seal the problem area with silicone, but this process is not recommended for the overlay located between the water seal and the upper part of the bathtub.

After installing the drain-overflow, connecting plumbing to the sewer and water supply, you can build bath screen, providing the possibility of access to the elements of the harness.

Popular manufacturers of drain-overflow systems

Among the companies in the assortment of which are presented the lines of various types of sanitary products, we can name:

- Aniplast - A well-known Russian company, whose products are of good quality and affordable price;

- Alkaplast - a Czech company that produces budget siphons with automatic lifting plugs for draining;

- Hansgrohe - a well-known German brand that produces high-quality expensive plumbing, including strapping;

- Jimten - A Spanish manufacturer specializing in plastic products. The products are characterized by excellent performance and attractive design.

In specialized stores you can find products of other companies - domestic and foreign.

Conclusions and useful video on the topic

The video below shows a detailed process for assembling a plastic siphon and attaching it to the bath.

When choosing a bath strap, it is important to consider not only the design features of the model, but also the manufacturer’s reputation: high-quality devices are durable and provide a guarantee against leaks.

To prevent such troubles, it is equally important to carefully carry out all the stages of installation, as well as pay attention to a thorough check of the assembled structure.

Looking for a reliable drain-overflow system? Or is there an experience of self-tying the bath? Please leave comments on the article, ask questions and participate in discussions. The contact form is located below.

How to arrange a shower drain in the bathroom floor: step-by-step installation instructions

How to arrange a shower drain in the bathroom floor: step-by-step installation instructions  Drain overflow for the bath: operating principle, installation diagram and installation rules

Drain overflow for the bath: operating principle, installation diagram and installation rules  Restoring a cast-iron bath at home: step-by-step instruction

Restoring a cast-iron bath at home: step-by-step instruction  How to install a bath on bricks: step-by-step instruction on how to install

How to install a bath on bricks: step-by-step instruction on how to install  Connection of a shower cabin to the sewerage and water supply: step-by-step instruction

Connection of a shower cabin to the sewerage and water supply: step-by-step instruction  DIY acrylic bathtub installation: detailed step-by-step installation instructions

DIY acrylic bathtub installation: detailed step-by-step installation instructions  How much does it cost to connect gas to a private house: the price of organizing gas supply

How much does it cost to connect gas to a private house: the price of organizing gas supply  The best washing machines with dryer: model rating and customer tips

The best washing machines with dryer: model rating and customer tips  What is the color temperature of light and the nuances of choosing the temperature of the lamps to suit your needs

What is the color temperature of light and the nuances of choosing the temperature of the lamps to suit your needs  Replacement of a geyser in an apartment: replacement paperwork + basic norms and requirements

Replacement of a geyser in an apartment: replacement paperwork + basic norms and requirements

I want to try to put the harness on the bath myself. My bathtub is standard, cast-iron, and the piping, respectively, is also old and also cast-iron. Probably worth it since the construction of the house. If I don’t see any problems with the installation of the new strapping, at least everything looks simple and clear from the pictures and videos, but with the dismantling of the old one, I feel I’ll have to suffer. I do not see any reason to install anything other than plastic at the moment, it serves for a long time, it changes easily. And who will see under the bathroom your beautiful chrome pipes, which also stand decently?

Here you already know whether everyone decides which pipes to put and the harness for him.It is clear that if all communications are hidden behind the screen, then putting expensive elements with chrome details is a waste of money.

But there are options when plexiglass bath screens are made, for example. In this case, the binding of chrome pipes will be an excellent solution. In addition, I saw such an option, where backlighting was also done behind glass screens from LEDs, it looks really cool. One of the clients even implemented such a solution, I’ll attach a photo to make it clearer.

Of the strapping options that are proposed in the article, I like the semiautomatic device most of all. Here the maximum functionality with minimal preventative maintenance. The machine is more convenient, but you need to monitor it so that none of the elements breaks down.

I also don’t see the point in steel strapping. Is that the bath is separate, on the podium, and all the pipes are visible. But this is true in large private houses, and in apartments, where every centimeter counts, plastic steers.

I have a normal strapping with a gag on a chain. Actually, only then I found out what is with the regulator, which controls the outflow of water, and wanted to do this.