Do-it-yourself washing machine repair: an overview of possible breakdowns and how to fix them

Damage to the washing machine is a real tragedy for the hostess. Hand wash is gradually becoming a relic of the past, and you don’t feel like returning to it due to a malfunction of the equipment. Not always there is time and desire to wait for the master, in half the cases repair of the washing unit is within the power of even a novice home craftsman.

We will talk about how to carry out simple repairs of the washing machine with your own hands. In the article we presented, typical variants of violations in the operation of household equipment are given, methods for restoring its operability are described in detail. Based on our tips, you can rectify the situation without any problems.

The content of the article:

- The device and operation of the machine

- Top Common Symptoms

- No. 1: the water in the drum does not heat up

- No. 2: the washing machine knocks and vibrates

- No. 3: dripping water from the hatch or leaking below

- No. 4: water in the drum before or after washing

- No. 5: the washing does not start - there is no water

- No. 6: the washing machine does not respond to inclusion

- No. 7: the drum does not spin or rotates in one direction

- Handyman Guide

- Conclusions and useful video on the topic

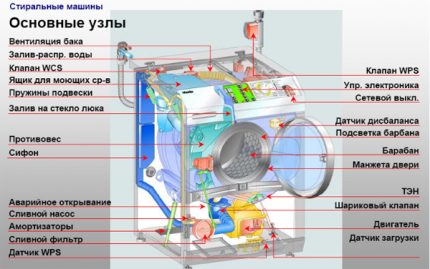

The device and operation of the machine

To decide to repair the machine with your own hands, you must first of all have a good idea of its structure and principle of operation.

The main parts of the unit:

- engine;

- electric heater;

- drain pump;

- water tank and drum;

- electronics (control panel);

- water intake valve;

- body.

After selecting a program and starting it, the first wash cycle begins. It includes a set of water and heating it. Water can be heated to a certain temperature, which is controlled by a sensor and a timer. Detergents are added.

Water is drawn through the valve. When there is a signal that there is enough water, the valve closes.Depending on the selected mode, several set-drain cycles are carried out. After the last rinse, the spin begins. Here the drum spins at full power.

The case includes not only the walls of the washing machine, but also the hatch. A round door on the front wall allows you to monitor the movement of linen in the drum and has protection against inclusion in case of a loose closure.

After turning off, the door does not open immediately. This protection is based on a bimetal sensor. The latch opens only after the sensor cools.

Top Common Symptoms

Unprofessional can not immediately determine what exactly failed. But there are signs that may indicate the cause of the malfunction. The most common symptoms listed and possible causes of breakdowns will help with diagnosis.

No. 1: the water in the drum does not heat up

Often this breakdown is not immediately detected. Most of the cars behave as if nothing had happened: they start the washing, rinsing, spinning modes. You take out the laundry from the drum and do not even suspect that all the processes took place in cold water.

If you encounter such a problem, conduct an experiment: during the active mode of the washing machine at high temperature, gently touch the glass of the drum door. It should be heated by hot water. If this does not happen, most likely the water in the system does not heat up.

There may be several reasons for this:

- damage to the heater;

- thermostat breakdown;

- failure of the electronics - programmer.

Of course, there is another option for choosing the wrong mode, when washing in cold water is provided for by the program. Before you sound the alarm, read the instructions and make sure that the mode is selected correctly.

Burnt heater - a common story in the workshop. With such a breakdown, people handle it very often. Due to a power surge, short circuit, or factory defect, the heater may burn out. The average life of the heater is about 5 years.

If the temperature sensor breaks down, the machine behaves differently. The heater is OK and ready to heat the water, the programmer sets the desired temperature, but the regulator - the temperature sensor - gives a false signal that the water has already heated up. Thus, the machine washes in cold water. Most often it must be replaced.

If the problem is software (the firmware has flashed or the board is damaged), the washing machine simply gives the wrong command and the water does not heat up. After the update, the washing is started again and, if the problem persists, the programmer is changed.

No. 2: the washing machine knocks and vibrates

Some washing machines knock from the first wash. This may be a feature of the design of the device. This is often found in older models, when during spinning the washing machine looked like a rocket during launch. Modern washing machines are quiet.

A knock may be a sign:

- improper installation;

- hit of a foreign object between the drum and the tank;

- bearing failure;

- failure of shock absorbers;

- uneven distribution of linen.

The first thing you should pay attention to is washing machine installation. It is improper installation that causes knocking during washing in most cases.

The machine should be aligned with the floor and stand firmly on it. For adjustment, special legs are provided that allow you to separately adjust the height of each of the control points.

When you do not take a trifle, nails and paper clips from your pockets, before you send laundry to the laundry, you risk breaking the washing machine. The fact is, small things can easily penetrate the tank to heat water through the gap between the tank and the drum.

Bearings ensure no friction during drum movement. They also have a service life and most often they fail before other parts. To understand that the matter is in bearings, is simple: in addition to knocking, the machine will make a creak. If you hear such sounds - get ready for bearing replacement.

Shock absorbers dampen vibrations of the drum during rotation. If one of them breaks, it immediately affects the operation of the washing machine. The drum can visually shift, bend.

A cause of knocking, which is not a malfunction, can occur when the laundry in the drum is not evenly distributed, that is, gathered on one side. This often happens when washing bedding in older models. You can’t call it a breakdown, but rather a feature of the work, which can cause a knock.

No. 3: dripping water from the hatch or leaking below

If you notice a puddle under your washing machine, do not rush to clutch your head and buy new equipment.

Most often, the cause of the appearance of water from the washer is:

- failure of the gasket on the inlet hose;

- rush hatch cuffs;

- pipe rush.

These structural elements are not so expensive and change quite quickly, with experience and knowledge in this area. Any depressurization of joints, of course, leads to leakage. The task of the master is to detect the source of the leak and eliminate it.

An excess of foam in the drum leads to the fact that it begins to seep through all the smallest cracks and minimal technological holes. The result is a puddle on the floor. If the machine does not flow when washing other things, then this can be attributed to the design feature and add less detergent to wash the curtains.

No. 4: water in the drum before or after washing

If after the end of the full washing cycle you open the drum and observe water there, your machine has a problem with draining. During the spin process, all water that can be squeezed out of the laundry must go into the sewer.

If this does not happen, you need to look for the cause of the breakdown. Most often it is:

- clogged filter;

- broken pump.

Remember the last time you cleaned the filter of your washing machine. If you do not know where it is, most likely you already know the cause of the malfunction. A clogged filter can not only cause inconvenience in the form of water in the drum, but also cause a more serious breakdown - the drain pump.

Another problem: water in the drum before turning on. That is, you are going to wash, open the door and everything is flooded there. Evaluate the quality of this water: it is clean or dirty.

Clean indicates a valve breakdown in the area where the machine is connected to the water supply. Dirty comes from the sewer.Most likely, the siphon is clogged and there is simply nowhere to go after washing.

No. 5: the washing does not start - there is no water

The inverse problem is that there is no water. That is, you turn on the washing machine as usual, start the wash cycle, but the wash does not start and an error appears that there is no water in the system.

If you checked the water supply in the water supply, and also opened the tap, look for a malfunction in another place:

- clogged feed hose;

- the inlet filter is broken;

- software breakdown of water supply.

To diagnose a malfunction, it is necessary to disassemble the appliance, rinse each element in the water supply system, reinstall it and try to start the wash. If water does not flow, you will have to make repairs or replacements.

No. 6: the washing machine does not respond to inclusion

The worst thing is the owner of the machine at the moment when the device stops responding to the power button. The washing machine does not turn on - the mistress’s nightmare.

There may be several reasons:

- power supply burned out;

- the power strip or socket is broken;

- The firmware flashed.

Everything that concerns electricians and electronics needs to be repaired with extreme caution, and it is better not to take it at all if you are not a master. However, anyone who is minimally familiar with the basics of electrical engineering can repair or replace the outlet.

When the drum is not tightly closed, the protection is activated and the washing does not turn on. And if the latch is broken and does not close completely, the selected program cannot start the cycle.

No. 7: the drum does not spin or rotates in one direction

If the washing starts, but looking at the window on the door, you find that the drum is stationary, look for the cause of the malfunction of the washing machine, most often this:

- tore drive belt;

- the engine is broken;

- a foreign body is caught between the drum and the tank;

- software breakdown.

One of these reasons can be detected without even understanding the technique. Unplug the appliance and try manually rotating the drum.

If a foreign object interferes with the movement, it will be enough to remove it. A serious breakdown will require more time and money to buy a new spare part.

Handyman Guide

If you decide to do it on your own and knowledge, read the procedure for repairing or replacing worn parts of a washing machine.

Having in front of you a rough plan of what follows, it will be easier for you to understand the technique and not make mistakes. However, keep in mind that it’s best not to try to fix some of the breakdowns with your own hands, even if they are very itchy. Sometimes it’s better and cheaper to contact a service shop.

Most often, we encounter breakdowns of the washing machine during the washing process. In this case, any repair work will have to start with the standard procedure - with draining the water from the tank:

The scope of opportunities of the independent master

Like it or not, during the independent repair of washing machines, you risk adding yourself even more trouble. This household appliance has a complex structure and a large number of components and parts.

When undertaking repairs with your own hands, you should be aware of all responsibility and not take up work without experience and knowledge in this area.

As a rule, do-it-yourself repair involves replacing a broken part with a new one, it can be a replacement:

- drive belt;

- a pump;

- temperature sensor;

- a filter;

- control boards;

- TENA;

- cleaning of nozzles and filters.

These works do not involve disassembling and repairing complex components; they can be dealt with even without special tools.

If you diagnosed a breakdown yourself and found out that the washing machine requires shock absorber replacement, oil seals, lock, cuff hatch, it is better to seek professional help for repairs.

Before you repair your washing machine, prepare such a set of tools:

- screwdriver (flat and cross);

- flat wrench (by 8/10 and by 19);

- pliers;

- long-nose pliers;

- ticks.

Actually, such a tool is in the box at most home masters.

To repair the control board, sensors and electronics in general, you may need a soldering iron and everything connected with it. But if you do not plan to repair the programmer, the ability to solder you will not be useful.

Filter cleaning - basic operations

The simplest thing the owner of a washing machine can do with his own hands is to clean the filter. To do this, open the small rectangular door at the bottom of the machine. If this is difficult to do, you can pry the door with a screwdriver. Caution, do not scratch the paint.

You will see a rubber or plastic cork in front of you. It should be unscrewed. You can do this with your bare hands by turning the cork counterclockwise several times.

Then rinse the filter under running water. Look into the hole, there often gathers garbage, the remains of thread, wool, hair and more. All this must be removed by hand. To see better, light yourself a flashlight. Replace the filter, screw it in, put the front panel in place.

In addition to this filter, some washing machines are equipped with a particle trap at the inlet. It cleans the water coming from the water supply from large particles of sand, dirt, rust. This filter can also clog and cause equipment damage. Therefore, you need to clean it regularly.

It is located in front of the water intake valve. It looks like a small plastic mesh. To clean the inlet filter, remove the inlet hose, and use a pair of pliers to remove the filter from the hole.

After washing, everything is collected in the reverse order, and the washing machine is connected to the water supply. The higher the level of water pollution in the water supply system in your area, the more often you need to carry out preventive cleaning of the inlet filter.

If you find that it is damaged when removing the filter device, replace filter. The procedure is extremely simple, but requires competent selection of details. The technical and technological subtleties of the process will be introduced by our recommended article.

Replacing a Worn or Torn Drive Belt

If the drive belt of your washing machine is worn out or even torn, do-it-yourself repair will not help here, you just have to change the part. Using the full name of the model of your household appliances, select the appropriate drive belt for the marking.

The process itself disassembling the washer and belt replacement is as follows:

- Disconnect the washing machine from the power supply and the water supply.

- Remove the bolts securing the rear wall.

- Immediately behind the rear panel you will see a pulley and a protruding motor shaft, on which the belt should be pulled.

- Remove the old drive belt by turning the pulley with your other hand.

- Put the new belt on the motor shaft.

- While rotating the pulley, gradually put the belt on it. Make sure that there are no torsions.

- Check the tension. The belt should be tight enough, but bent when pressed.

After repairing the belt, make a few revolutions of the pulley to make sure everything is as it should. Close the back of the machine and try to start the test wash mode.

Water heater - replacing the heater in the home

If the repair of the washing machine involves the complete replacement of the heater, you will have to do the following operations. Remove the back cover.Most often, the heater in the washing machines is located at the rear, but there are other placement options.

If you do not know exactly which side the heater is in your model of car, look at the instructions or start from the back cover at random. The fact is that removing it is much easier than the front. Therefore, even in case of an error, screwing the panel into place will not be difficult.

Disconnect the terminals. Removing the cover, you will not see the heater, but only its connection. The terminals must be disconnected and the element checked for operability. A multimeter comes to the rescue.

In order to remove the defective heater, unscrew the nut with a wrench. Then push on the hairpin, it is better to use a screwdriver.

To ensure that the heater is stable, it is installed using a rubber seal. For dismantling, pry up the rubber and begin to get out the part, gradually "picking out" it from the seal with a screwdriver.

It is recommended to remember, and it is better to photograph the location of the parts and the connection of wires before dismantling. So you can easily assemble everything into place after the repair is done with your own hands.

When the old heater is removed, you can proceed directly to the replacement. Take the new part and replace it with the old one in the same position. Then, in the reverse order, screw the nut onto the stud. Make sure that the sealant is not deformed and does not bite. The nut should be tightened tightly, but not too tight so as not to squeeze out or warp the heater.

To check the correctness of the repair, start the laundry without washing in the mode with hot water (above 50 degrees). Lean your hand against the door glass after 15-20 minutes of operation. If the glass is warm to the touch - the heater works.

Installing new shock absorbers

If your washing machine began to make too much noise during the spin cycle and vibrate, then the problem will have to be solved by installing new dampers (shock absorbers):

We have taken the above steps in order to remove the tank with the drum of the washing machine from the housing, since changing the shock absorbers in such models without this step will not work. Next, we will deal with the shift, i.e. take out the drum, unscrew the worn damping devices and put in new ones.

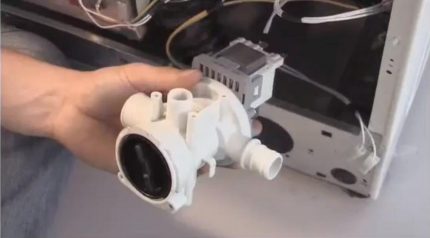

Replacing the washing machine pump

In most popular models of washing machines, a pump that has come out of a standing position can be easily repaired by yourself. For a person who does not often face repair of various kinds of equipment, it is hardly possible to fix a broken pump. Much easier and faster to replace it. To do this, you need to buy a part of your brand.

Before you fix the washing machine itself, in which the pump has broken, you should turn it in such a way as to have unhindered access to the bottom.

Remove the bottom panel. It can be fixed on latches or on bolts. The pump itself is attached to the housing by screws. They need to be unscrewed with a screwdriver.

Apply a little effort and push the drain valve from the outside, pushing the pump into the body. With your other hand, pull the pump out. Disconnect the wires to the pump.

To install a new pump, repeat all the steps in the reverse order: connect the pipe and hose, connect the wires, put the equipment in place and fasten with screws to the casing. Then install the bottom of the washing machine and put it in working position.

Conclusions and useful video on the topic

Some types of DIY repair are easier to show visually than to describe in words. Useful videos with step-by-step instructions for repairing parts of washing machines, such as the electric motor, control board, and bearings, will help you understand all the intricacies.

Electric motor repair: do-it-yourself brush replacement:

Repair of the control unit of the washing machine. How to fix the programmer:

Simple repair or replacement of worn parts of the washing machine can be done even by an inexperienced master.

If your equipment is no longer in warranty service and you are sure that you can cope with the repair or at least do no harm - proceed with disassembling the washer. But faced with a serious breakdown, you do not need to take risks, but it is better to immediately contact a service center.

Tell us about how you repaired the washing machine with your own hands. Share useful information and technological nuances that are worth sharing with site visitors. Please leave comments in the block form below, post a photo and ask questions about the topic of the article.

Do-it-yourself Indesit washing machine repair: an overview of common problems and how to fix them

Do-it-yourself Indesit washing machine repair: an overview of common problems and how to fix them  DIY Samsung washing machine repair: analysis of popular breakdowns and repair tips

DIY Samsung washing machine repair: analysis of popular breakdowns and repair tips  DIY LG washing machine repair: frequent breakdowns and troubleshooting instructions

DIY LG washing machine repair: frequent breakdowns and troubleshooting instructions  The washing machine drum does not spin: 7 possible reasons + repair recommendations

The washing machine drum does not spin: 7 possible reasons + repair recommendations  Samsung washing machine errors: how to understand the malfunction and repair

Samsung washing machine errors: how to understand the malfunction and repair  Filter for a washing machine: overview of types, selection criteria + installation features

Filter for a washing machine: overview of types, selection criteria + installation features  How much does it cost to connect gas to a private house: the price of organizing gas supply

How much does it cost to connect gas to a private house: the price of organizing gas supply  The best washing machines with dryer: model rating and customer tips

The best washing machines with dryer: model rating and customer tips  What is the color temperature of light and the nuances of choosing the temperature of the lamps to suit your needs

What is the color temperature of light and the nuances of choosing the temperature of the lamps to suit your needs  Replacement of a geyser in an apartment: replacement paperwork + basic norms and requirements

Replacement of a geyser in an apartment: replacement paperwork + basic norms and requirements

I do not quite agree about the replacement of bearings, in the sense that you need to contact the master. I myself changed the bearings in my typewriter, after watching a few videos on YouTube. There is nothing complicated there, but efforts are needed, of course. It was more difficult to find a temperature sensor for our model, this was still that problem.

I do not quite agree about the bearings: in the sense that they must be replaced with the help of a wizard. I watched several videos on YouTube and did everything myself. There is nothing complicated about it. But efforts, of course, need to be made. It was much more difficult to find a temperature sensor for our model of machine. This is a very big problem - spare parts for washing machines released ten years ago.

From a hostess's point of view, I managed to fix a rather serious breakdown on my own. The tank started to leak. Wife in a panic, you need to buy a new washing machine. I took it apart, I thought, and what if I fix the leakage point with cold welding? And it turned out. The machine has been working, after my repair, the fourth year. And now you need to buy a new car only because this one has already turned yellow, and I want more.

Thank you for the interesting and, most importantly, useful material! Recently, the handle in the typewriter has broken - the lock has worked, and the typewriter has not even begun to wear off, i.e. virtually all things remained there in the typewriter and FIG knows how to get them. I was looking for a cable in the upper panel and in the lower one near the filter ... as a result, I had to remove the upper cover, grop the lock and somehow open it. I bought a new pen, now I study the useful repair info further, I was somehow interested in it myself)

Hello. I live in a village, it's difficult to call a master. Maybe you know what the breakdown is? I didn’t want to fill in the water, I started to wash without water (even the pump didn’t turn on), then I squeezed it badly (I already filled it in water), then after writing it I wrote error F02, after rinsing I started to write this error. Now it doesn’t even allow you to select a function, and when you close the door, it beeps F03.

Hello. If an error occurs on the control panel, you need to look at its code in the instrument passport. If you cannot cope with the breakdown yourself, you need to contact the master, and not continue to stubbornly operate the machine until the problem becomes stalemate. F3 in most washing machines - problems with the control or the heater sensor.

F2 - damage to the tachometer, engine rotor, control module, something with wiring or contacts.

Immediately contact the service center or an experienced master, you need a high-quality dialing system. It seems to me that the control module is wedging. But defining a “disease” without inspection is problematic.

Recently, the washing machine broke, could not figure out what exactly broke. I had to call the master to the house - I had a breakdown in the pump. It got a pretty penny: ((

Hello, is it possible to transfer the machine to a village type on its own? ... there is no central water supply