The washing machine does not wring out or makes noise during an extraction: analysis of the causes of breakdown and repair instructions

During the operation of the washer, users repeatedly encounter various malfunctions in the operation of the equipment. Often there are a lot of reasons when the washing machine does not wring out or gives out a system malfunction in electronic control.

In order to prevent or timely eliminate such situations, it is necessary to deal with the prerequisites for their occurrence, agree? In the article, we examined the most likely causes of the lack of spin and the appearance of strong noise, and also suggested ways to restore the washing machine.

The content of the article:

- The reasons for the lack of spin and their elimination

- No. 1 - washing clothes without twisting

- No. 2 - imbalance of loaded laundry in the drum

- No. 3 - a problem with the drain pump

- No. 4 - malfunction or wear of the pressure switch

- No. 5 - malfunctions of the control system

- No. 6 - failure of the electric motor

- No. 7 - clogging of the sewer

- No. 8 - garbage in the drain device

- Possible causes of noise and repair malfunctions

- Prevention of breakdowns in washers

- Conclusions and useful video on the topic

The reasons for the lack of spin and their elimination

The washing machine has a simple design, but often the parts wear out and fail. As a result of this, a series of breakdowns can occur when a technology stops performing the functions inherent in its electronic system.

One of the main problems that may arise during operation is poor-quality spinning or its complete absence. Even the owners of completely new washing machines can face the problem of lack of spin. Consider the possible causes in more detail.

No. 1 - washing clothes without twisting

Modern models of cars are equipped with a large number of options, innovative technologies that allow you to get washed items from the drum completely dry or, conversely, wet.

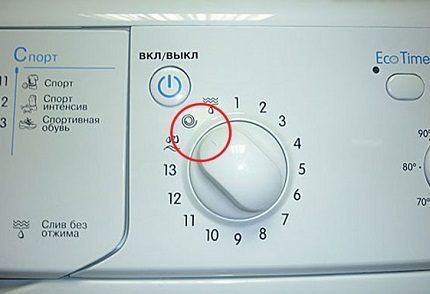

If you find that things have not gone through the unscrewing procedure, you must check the “no spin” button. Perhaps, when choosing a program, the function without twisting was accidentally turned on.

No. 2 - imbalance of loaded laundry in the drum

Expensive washing machines have more features and capabilities for economical and efficient washing. One of the additional functions - the distribution of loaded things inside the drum - helps prevent things from dropping into a single com.

In the absence of such a function, washing machines may fail during the execution of a running program.

No. 3 - a problem with the drain pump

In this case, the spinning process occurs, but the waste water does not spill into the sewer. Thus, things remain wet after twisting. To fix the breakdown, it is necessary to make pump replacement (pump).

Let's see how the pump is replaced in brand cars Samsung, Whirpool, LG, Aristonother

To do this, you must:

- Disconnect the equipment from all sources: power, water and drain.

- Install the product body in the lateral position.

- Disconnect the bottom to gain access to the pump.

- Loosen the screws, pull out the pump by pressing it from the drain valve side.

- Disconnect the wires from the pump.

- Remove the clamps, drain the remaining water into a previously prepared container.

After this, it is necessary to disassemble the pump, remove and clean the cochlea (if it is suitable), and replace the pump. At the end, assemble all parts in reverse order.

No. 4 - malfunction or wear of the pressure switch

The mode of twisting the laundry may not be activated if the sensor for entering and discharging water is broken.

If the signal is incorrect, then the spin does not turn on, and the sensor must be replaced.

No. 5 - malfunctions of the control system

The electronic or mechanical control system may malfunction after sudden changes in electricity, due to the long life of the equipment, failure of the stabilizer.

Damage to the RPM sensor is quite rare, but if it is present, the machine performs low-quality spin. In this case, you will need to reflash the control system or replace the board.

No. 6 - failure of the electric motor

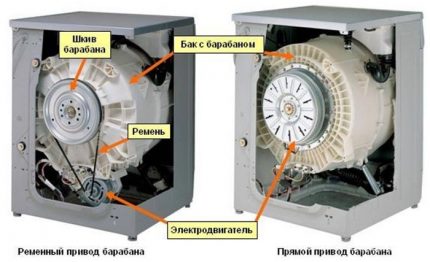

If the motor breaks down, the spin function in the product does not turn on at all. The cause of engine failure may be a malfunction of the windings, their breaks, wear of the lamellas or brushes. To repair this unit, you need disassemble the washing machine, remove and inspect the motor.

How to determine engine failure:

- if the engine sparks during inspection, urgent brush replacement is necessary;

- in the presence of strong noise and overheating of equipment, the cause may be a violation of the integrity of the winding;

- peeling of lamellas and the appearance of burrs on them can also lead to the appearance of sparks.

The lamels must be checked during disassembly simultaneously with graphite brushes.

Failures are repaired in the following order:

- It is necessary to disconnect the machine - disconnect the drain, water pipes and mains.

- Disassemble the product body: remove the back panel and belts.

- Remove all bolts that secure engine.

- Disconnect the terminals, wiring that connect to the other nodes.

- If the tank interferes with free access to the motor, it is necessary to slightly raise it.

- Different models have a different structure from each other, so you will need to remove the side walls of the machine to successfully remove the engine.

Next, replace the broken parts or tighten their fasteners for normal operation.

After the manipulations, you should install the repaired motor, assemble the washing machine in the correct sequence and check its operation.

No. 7 - clogging of the sewer

If the reason is not the breakdown of parts or malfunctions of the electronic control system, then maybe the pipes for draining the waste water into the sewer are clogged.

You may need to clean the nozzle with a cable. If a breakdown is found, then the machine will work correctly, and stagnant debris will come out of the tube.

No. 8 - garbage in the drain device

If the spin function in the washing machine does not work or if there are any malfunctions in the process of starting things unscrewing, it is necessary to check for the presence of foreign objects in the drain element.

The item is at the bottom of the machine. Recommended clean the drain filter at least twice a year. In the event of a malfunction in the operation of the equipment, clean immediately.

If faults in the washing machine associated with the spin function are detected, it is recommended to immediately diagnose the product.

You should pay attention if:

- appliances stopped twisting laundry well (stays wet);

- water remains in the tank even after turning on the pump;

- spinning is quite noisy.

It is also recommended that regular washing machine cleaningall components and filters to prevent possible damage or clogging.

Possible causes of noise and repair malfunctions

In addition to low-quality extraction or its complete absence, a technician can signal a breakdown in a different way, namely, to produce unusual loud sounds - noise, buzz, ringing, etc.

The following recommendations will help you figure out what the reason may be and how to eliminate it.

Problem # 1 - shipping bolts not removed

After the selected equipment is delivered home, buyers, as a rule, save on the cost of installing the machine and do the procedure on their own.

Connecting the product to the water supply and sewer system is quite simple. But to remove the mounting bolts that secure the drum during transportation, forget.

After detecting this problem, unscrew the remaining bolts and check the operation of the equipment again.

Problem # 2 - foreign objects in the drum

Putting things for washing in the drum, it is necessary to check without fail the presence in the pockets of various items - keys, coins, receipts or checks.

If they get into the drum or tank of the machine, you can hear tapping.

Also, things that are decorated with metal rivets, large zippers with fasteners, chains, etc. can make noise when washing.To prevent them from knocking on the drum, you should turn things inside out, and then only place them in the washing machine.

Malfunction # 3 - wear of bearings in the machine

The drum in the washing machine rotates thanks to the bearings. If parts are damaged, the drum stops rotating properly and makes an uncharacteristic noise.

To check whether there is a reason in them, it is necessary to turn the empty drum from side to side. In case of wear and failure, bearings prevent free rotation, play is felt. During washing, the appliance is very humming and may vibrate.

If the cause is set correctly, bearings should be replaced.

To do this, you need to perform the following list of actions:

- Disconnect the washing machine from the sewer, water supply, disconnect power.

- Disassemble the back and top panels according to the instructions.

- Remove the dispenser, control unit by unscrewing the screws.

- Loosen the clamp, remove the counterweight, the heater, pipes and other parts that impede access to the engine.

- Remove the motor.

- Remove the drum tank.

- Unscrew the drum to remove the pulley and twist the shaft.

- Knock out the bearing using a special tool - bump.

- Replace oil seals.

- Install a new bearing in the seat.

- Assemble the equipment in the reverse order.

The joints of the tank are best lubricated with a hermetic. For convenience and remembering the procedure, all the steps taken can be recorded using a photo or video.

Problem # 4 - Drum Mount Problems

A characteristic feature of a pulley loosening is the presence of a click when the drum rotates. The identified problem is resolved quickly enough. Disassembly of the washing machine is carried out in the same manner as when replacing bearings.

After the procedure, you will need to check if the washing machine is noisy during the spin cycle. It is better to start a short wash program with twisting to make sure that it works correctly.

Malfunction # 5 - tank counterweights are poorly fixed

In order to keep the tank during washing, counterweights are provided in the machine. If you hear a loud noise during operation, you should check the fact of loosening of the mountings of this unit.

If the assembly fails, you will need to remove the machine panels, untwist all the parts that impede free access to the balances. Next, you need to check their integrity and tighten the fastenings.

Problem # 6 - improper installation

At installing a washing machine users do not always pay attention to the quality of the floor surface and the presence of irregularities on it.

As a rule, the tile is quite slippery and the machine can ride on the floor. To do this, glue the rubber tips on the legs in case of their absence.

Special rubber floor mats are also sold in stores.

Problem # 7 - High Noise Specific Models

The increased noise level may not cause any damage. Some cars of the budget series are notable for high noise.

When buying a product, you should definitely be interested in this feature.The indicator in the technical passport is indicated in dB. More quiet models Do not exceed the level of 54 dB during washing and 65 dB during twisting.

In case of detection of a problem of increased noise, it is necessary to check the product characteristics indicated in the documentation.

Prevention of breakdowns in washers

It is possible to anticipate the occurrence of problems associated with increased noise levels, strong vibrations, and the absence of a spin function if you adhere to the basic recommendations for the care and use of equipment.

Experts advise you to perform the following actions with washing machines:

- load the amount of things, not exceeding that specified in the passport of the machine;

- check for foreign objects in pockets;

- use covers for washing small items;

- less often include programs that involve working at high speeds and using hot water;

- Perform regular filter cleaning;

- use only high-quality detergents, water softeners for washing.

In case of power fluctuations, it is advisable to connect the equipment to the network through surge protectors or use a stabilizer.

If problems are identified, it is necessary to diagnose the product, replace the failed nodes for the correct operation of the machine.

Timely and correct replacement of parts will extend the life of the equipment and prevent more serious damage.

Conclusions and useful video on the topic

The proposed videos will help to independently determine the cause of increased noise in the machine or lack of spin, as well as make the replacement of components and parts with your own hands.

Instructions for self-changing gland and bearing:

How to replace the brushes in the engine:

Elimination of the cause of the lack of spin in the machine:

Repairing a washing machine usually does not take much time, but basic skills are needed to identify the cause of noise and other malfunctions, as well as to replace spare parts or even basic cleaning.

If you doubt your abilities, it is better to contact a service center, where after the initial diagnosis they will quickly determine the cause of the breakdown and name the cost of the repair.

Have you ever had to repair a washing machine yourself? Please tell us what kind of damage you encountered, whether you managed to repair the equipment. We are waiting for your comments, questions and tips on how to repair the washer - the contact form is located below.

Why the washing machine does not turn on: causes of failure + repair instructions

Why the washing machine does not turn on: causes of failure + repair instructions  The washing machine does not pick up water: causes of breakdown and possible ways to fix it

The washing machine does not pick up water: causes of breakdown and possible ways to fix it  The washing machine drum does not spin: 7 possible reasons + repair recommendations

The washing machine drum does not spin: 7 possible reasons + repair recommendations  DIY Samsung washing machine repair: analysis of popular breakdowns and repair tips

DIY Samsung washing machine repair: analysis of popular breakdowns and repair tips  Inverter washing machine: how is it different from the usual + TOP-15 of the best models

Inverter washing machine: how is it different from the usual + TOP-15 of the best models  DIY LG washing machine repair: frequent breakdowns and troubleshooting instructions

DIY LG washing machine repair: frequent breakdowns and troubleshooting instructions  How much does it cost to connect gas to a private house: the price of organizing gas supply

How much does it cost to connect gas to a private house: the price of organizing gas supply  The best washing machines with dryer: model rating and customer tips

The best washing machines with dryer: model rating and customer tips  What is the color temperature of light and the nuances of choosing the temperature of the lamps to suit your needs

What is the color temperature of light and the nuances of choosing the temperature of the lamps to suit your needs  Replacement of a geyser in an apartment: replacement paperwork + basic norms and requirements

Replacement of a geyser in an apartment: replacement paperwork + basic norms and requirements

In the vast majority of cases when the machine is very noisy and vibrates during the spin cycle, it was simply installed incorrectly. Often the bathroom floor is uneven, plus slippery tiles. Therefore, it is normal to adjust it according to the building level. The second most popular source of noise is foreign objects falling into the drum. Be sure to check your pockets before washing. But if the machine does not wring out at all, then this is a more difficult problem and it is better to contact the master.

There are quite different problems with spinning washing machines. Maybe your things just got stuck in a single com, because of which the washing machine determines the uneven distribution of things and gives an error, it is also worth paying attention to the overload of things. In my case, there was a failure of the drain pump, and therefore the machine simply could not pump water into the sewer.

Somehow, the car stopped pressing me. Buzzed, and that’s it. As much as it cost me to repair it every time (our old woman is already 10 years old), so it was already possible to buy a new one for the money. I called the master and I think: well, that's it. If you break the price - I’ll spit and go for a new one. The master came, poked around and after all, it turned out that in the hose that is connected to the pipes, a stick for cleaning the ears was stuck. How she ended up there, I have no idea. The wand was pulled out, and the car continues to work like a clock.