Installation of cassette air conditioners: technological rules for installing a household “cassette”

Cassette air conditioning ─ high-performance equipment with a modern design and low noise characteristics. This is ideal for air conditioning, but the installation of cassette air conditioners is possible only if the room has a suspended ceiling and the appropriate dimensions.

In the article we will talk about the operational capabilities of cassette-type air conditioners. We will familiarize with the installation rules of this technique.

The content of the article:

Design features of the "cassette"

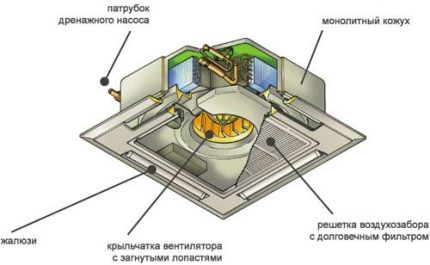

Cassette air conditioning, although it is a type of split system, but differs from other types of specific device internal module. Mostly it has the shape of a square and is designed to be embedded in a suspended ceiling structure.

For the installation of a cassette-type air conditioner into the ceiling, all its parameters are sharpened:

- the external panel has dimensions of about 50x50 cm;

- depth, from 20 to 35 cm, coincides with the corresponding parameters of the suspended ceiling - the standard cell size and the distance from the surface of the canvas to the ceiling.

The air conditioner can work both in cooling mode and to heat the room if necessary.

The outdoor unit is equipped with a compressor and condenser. In the inside there is an evaporator and a drainage system.

Advantages of a cassette air conditioner

Structurally, the “cassette” is designed so that the cooled air is blown out in 4 directions. While a wall-mounted analog cools relatively small rooms, cassette air conditioner can cover a fairly large area.

In addition to a large coverage area, this practical technique has several other advantages:

- Aesthetics. Indoor units remain invisible because they are located behind a suspended ceiling. Flush mounting does not change the interior of the room, which allows the use of such climatic equipment in representative rooms, offices.

- Almost complete absence of noise during operation. The fan, built into the unit, creates a natural circulation of air masses, does not arrange turbulence, effectively pumps air.

- The maximum coverage of the room. As warm air accumulates in the zone where the air conditioner is located, the temperature in the room will decrease gradually from top to bottom.

- Convenient airflow control. By means of rotary levels it is possible to direct air streams at own discretion.

Cassette air conditioning systems of large rooms are controlled not only by portable remote controls, but also by installing stationary shields connected to the building’s power grid.

Many cassette systems have additional features. They can carry out space heating, ionization and air humidification. To enable full coordination of the operation of air conditioners, you can install a single climate control system.

Mounting a cassette air conditioner

Installation in new buildings and in premises of a different kind is identical. Although there are some nuances, but in general the technology is similar.

The whole process can be divided into several stages:

- installation of blocks - external and internal;

- laying ducts and power lines;

- installation of a control panel if the air conditioner is installed at a large facility;

- testing, adjustment.

The installation of the air conditioner must be carried out taking into account the climatic conditions of the region. If the air contains aggressive substances, they can adversely affect the operation of the device, therefore, an additional air filter will be required.

The guarantee of the success of the air conditioner is compliance with all the rules mounting an external unit and internal module:

- The wiring must be thick enough to withstand high loads.

- In industrial premises, in the air of which there is evaporation of acids, other toxic and combustible substances in high concentrations, it is not recommended to install any air conditioners.

- Cassette air conditioners must not be installed in places where they may come into contact with technical oils.

- The room should not be less than 2.6 m in height.

- The ceiling should be strong and as horizontal as possible.

- The unit must be fully earthed, both the circuit and the metal base.

- In the installation area of the air conditioner, upon completion of work, no obstacles should remain.

- Between the case of the conditioner and the extreme points of the holes, the gaps should be the same.

The installation order of the air conditioning units does not matter, but until it is at the installation site, it is not recommended to be unpacked. The “cassette” works most effectively when the indoor unit is installed in the center of the ceiling.

Mounting the indoor unit

In most cases, a sample of cardboard with identical sizes comes with an air conditioner. But even if it is absent, you need to perform it yourself. It is useful as a template for markup.

Before you begin to mount the indoor cassette units of the air conditioners to the ceiling, you must first draw a contour on the floor, and then transfer it to the ceiling. Further, a small incision is made in the ceiling profile. If the hinged structure vibrates, a piece of foam is glued to the ceiling.

Next, they mark the mounting points of the module, drill holes in the marked places to a depth of about 50 mm with a diameter of 12 mm and insert the studs into them. A nut, a washer, and another nut are screwed onto each stud. After that, the internal module is lifted up, the studs are inserted into the slots designed for them, and the nuts are bent.

The indoor unit is installed so that it fits flush with the surface of the ceiling web. This will happen if the distance between the main and false ceilings is identical to the immersion depth of the cassette case.

The horizontal plane is controlled by level. If you skip this procedure, drainage fluid inside the module will leak and drip onto your head. When the condition of flatness of the plane is met, tighten the nuts well. The distance between the modules of the unit is measured in order to subsequently lay the freon line.

At the next stage, the trunk is cut. This operation requires great accuracy, down to the millimeter. A mistake with size will complicate a lot. Insufficient length is an additional financial investment. Larger quantities can be hidden in the interfloor space.

For pipe sections, a disk pipe cutter is most suitable. Do not cut with a hacksaw for metal or grinder. These tools can leave metal shavings, and its presence will subsequently adversely affect the performance of the air conditioner.

The slice is carefully cleaned with a file or sandpaper, the chips are torn out. The hole formed as a result of cutting the pipe is closed with tape or tape, the pipe itself is insulated.

Studs with hooks are fixed under the ceiling to fix the freon pipeline. If it is necessary to change the geometry of the pipe, a pipe bender is used, but before that, the insulation is cut and the insulation is slightly pushed back. After completing the procedure, the ceiling surface is sealed back.

If it is necessary to build up the pipeline, a special flare is used, which increases the internal section of the pipe to match its external. Adjust the size gradually - making about three penetrations, each time the size of the collet is increased. Otherwise, the pipe may burst.

Hoses lead to the holes of the internal module, unscrew the fixing nuts and put them on the tubes. The ends are cleaned with a file, the chips are collected with a vacuum cleaner. Using a flare, expand the diameter of the pipe so that it covers the nozzle of the indoor unit. The tube is clamped, fixed with a nut using keys. One of them holds the nozzle, and the second tightens the nut.

The docking place is insulated, tightened with clamps. Next, remove the intake grille and temporarily lay it aside. Then they take out 4 corner plugs, find the motor with which the movement of the blinds is carried out. This position must necessarily be combined with the connection point of the freon highway.

Fix the pad in the area of the brackets on the block, carefully move the latter so that it exactly gets into the hole. Using the level, the lining is exposed, the intake grille is returned to its place, fixing it on the sides with plugs.

The use of units is limited by the installation height of the cassette air conditioner, as they cannot be mounted in an apartment with a ceiling height of 2.5 m. Based on this requirement, it is recommended to use “cassettes” in rooms with a height of at least 3 m.

Outdoor unit installation

Installation of the outdoor unit is possible subject to certain points:

- rigidity of the surface intended for installation;

- lack of barriers to the exit of air flow;

- the presence of metal plates to protect the unit from strong gusty winds;

- the closest distance between the blocks;

- accounting for the difference between the geometric center of the block and its center of mass.

When moving the unit, do not tilt it more than 45⁰. Never place the module on its side.

In the case when the option of “floor” fixing the outdoor unit is selected, it needs its own concrete foundation, otherwise the structure will not be able to resist gusts of wind. Mounting is carried out by means of an arm for the air conditioner.

After that, a pipeline is introduced into the room to remove refrigerant from the condenser. The main thing is to ensure a minimum of cold losses in the segment of the highway from the external to the indoor unit.

The installation location should be chosen so that snow and foliage do not sweep onto the module. When the air conditioner runs for heating, condensate discharged from the outdoor unit should not cause inconvenience.

The nuances of installing the pipeline and drainage system

To increase the life of the air conditioner, it is necessary to take into account several nuances:

- Do not exceed the length of the line designed for refrigerant circulation.

- More than 15 bends in the pipeline must not be allowed. Bends over 90⁰ and a radius greater than 9-10 cm are not allowed.

- After mounting the sockets, a mandatory vacuum cleaning of the circuit from excess air, dust, moisture is required. For this, an external valve is connected to the pump. During the procedure, all tubes should be visually checked for integrity.

- To fully verify the integrity of the system, the joints can be coated with soapy water after filling the tubes with freon.

If necessary, charge the system with refrigerant. Filling is required when the pipeline in one direction has a length of more than 8 m.

The installation of the drainage system begins with the connection of a plastic pipe to the drainage pump of the indoor unit. It is put on the pipe and secured with a clamp. Next, the pipe is pulled to the place of discharge. Usually the outer diameter of the pipe is 37-39 mm, the inner ─ 32 mm.

Laying is performed at a slight slope - for each square meter, literally a few centimeters. In general, the slope is a maximum of 30⁰, ─ the rise is not more than 20 cm. The workout should leave the air conditioner by gravity and in no case return to the collection.

The other end of the drain pipe should not be immersed in liquid. To check the operability of the drainage system, water is poured into a special hole and the air conditioner is turned on in cooling mode. In this situation, the pump and the drain will show their work.

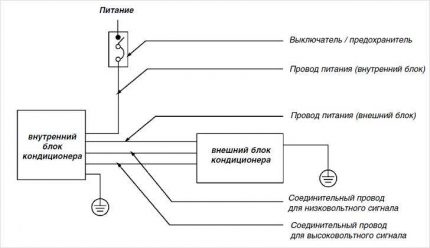

Connecting the air conditioner to the mains

A feature of the cassette air conditioner connection diagram is that it can only be connected to an individual machine. If there is no voltage regulator in the general wiring, it is advisable to add this element to the circuit.

Both the indoor and outdoor units must be grounded. Subsequently, the grounding will be combined into a single circuit. If an extension cord is necessary, it needs a cable of the same type and cross section.

It should be noted that the wires should not intersect with refrigeration pipelines or shut-off valves. Fuses must be present in the power circuit.

Upon completion of the installation, you need to click on the control panel and run the unit in test mode. You should listen to how the engines work in blocks. If there are abnormal sounds, rattling or vibration, the unit must be turned off and the cause of the malfunctions must be found.

Conclusions and useful video on the topic

Installation experience of the “cassette” indoor unit in these two videos:

The second part of the manual:

You will learn how to connect pipelines and power to a cassette air conditioner from this video material:

Installation of cassette air conditioners, as a rule, is performed by the masters from the after-sales service. This is due to both the complexity of fastening, the organization of air communications, and the need for adjustment work. The latter require some experience, since in the design of the equipment there are many nodes, including Electronics and automation.

Tell us about how to install cassette air conditioning in your office or country house. It is possible that your recommendations will be very useful to site visitors. Write comments, please, in the form below the block, ask questions and publish photos on the topic of the article.

What is a multi split system: principle of operation + installation and connection rules

What is a multi split system: principle of operation + installation and connection rules  Air conditioner rotation unit: device, connection rules and module settings

Air conditioner rotation unit: device, connection rules and module settings  Errors of air conditioners Zanussi: codes of malfunctions and instruction on their elimination

Errors of air conditioners Zanussi: codes of malfunctions and instruction on their elimination  Standard sizes of air conditioners: typical sizes of outdoor and indoor units

Standard sizes of air conditioners: typical sizes of outdoor and indoor units  Errors of Aux conditioners: how to identify a malfunction and restore the operation of the split system

Errors of Aux conditioners: how to identify a malfunction and restore the operation of the split system  Condensate drainage from the outdoor unit of the air conditioner: organization methods and best technological solutions

Condensate drainage from the outdoor unit of the air conditioner: organization methods and best technological solutions  How much does it cost to connect gas to a private house: the price of organizing gas supply

How much does it cost to connect gas to a private house: the price of organizing gas supply  The best washing machines with dryer: model rating and customer tips

The best washing machines with dryer: model rating and customer tips  What is the color temperature of light and the nuances of choosing the temperature of the lamps to suit your needs

What is the color temperature of light and the nuances of choosing the temperature of the lamps to suit your needs  Replacement of a geyser in an apartment: replacement paperwork + basic norms and requirements

Replacement of a geyser in an apartment: replacement paperwork + basic norms and requirements