Adjoining the roof to the ventilation shaft: arrangement of the passage of the ventilation unit through the roof

Any ventilation system that was used in the construction of a private house needs two main elements - a clean air intake point and a contaminated exhaust hole. Agree that without these elements the entire ventilation system loses any meaning.

There are many options for arranging these points, but most often they are located under the roof or directly on the roof.

This article discusses the main options for the implementation of the ventilation unit through the roof, the variety of which depends on the type of ceiling on the roof. Practical advice is also given on how to properly adjoin the roof to the ventilation shaft in order to prevent rainfall from entering the house.

The content of the article:

Ventilation pipe installation requirements

Compliance with the requirements that are put forward to installation of a ventilation unit - the guarantee that there will be no mold or high humidity in the house. One of the tasks of the roof is to protect the room from the penetration of rainfall, as well as maintaining the optimal temperature regime, which is comfortable for residents of the house.

Ventilation pipe - a through hole passing through the roof. That is, in order to conduct ventilation through the roof, it is necessary to make a through hole that will open the precipitation into the house.

That is why the place of entry of ventilation needs additional isolation from precipitation, melt water. In addition, it must be protected against condensation. The latter occurs due to the high temperature difference between the one that was achieved indoors and the one on the street. Thus, the basic requirement for vent pipe - its complete tightness and thermal insulation.

Also, it is important to ensure that rainfall flows freely from the roof, i.e. the ventilation pipe does not interfere with this. The task is not easy.On the one hand, nothing should interfere with the flow of fresh air into the room. On the other hand, the pipe should allow only air to pass through, but interfere with the penetration of sediments, insects, etc.

To solve these problems, you can install special access nodes. With their help, uninterrupted transportation of air flows is provided, without significant interference with the functionality of the roof.

The basic requirements for installing a ventilation shaft are as follows:

- protection from the so-called "cold bridges" - to prevent the formation of places through which heat can leave the room;

- sealing;

- a mandatory requirement is a tight fit of the ventilation pipe to the roof;

- installation of additional protective elements - after sealing, the joints are covered by additional structures (they perform both a decorative and a practical function).

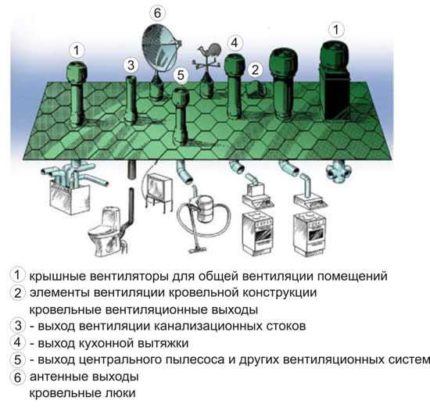

If there are several exits on the roof, for example, chimney, a television antenna or satellite, you can create one common shaft through which they will exit.

You can add a ventilation hole to all these outputs, that is, the adjoining of the roof to the ventilation shaft will occur through a special outlet. The mine is constructed of metal or wood, it is advisable to think about a way to remove ventilation and other communications at the time of construction of the roof.

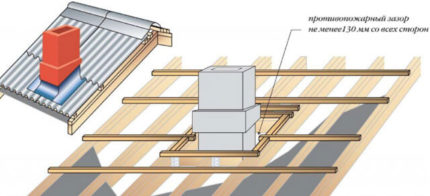

It is worth remembering that for the perfect connection of the air ducts to the metal roof or roof from any other material, it is better to make the ventilation pipe square or rectangular.

In this case, to ensure the correct abutment of the duct, use a square pad. It is put on top of the pipe and provides its protection. The space formed between the ventilation pipe and the cover is filled with sand or any other non-combustible mixture.

Sealant is used to protect the room from moisture penetration for joints, and is installed in the upper part of the ventilation pipe deflector.

Additional requirements are established for the length of the ventilation pipe, in the absence of traction in it, mounted fans.

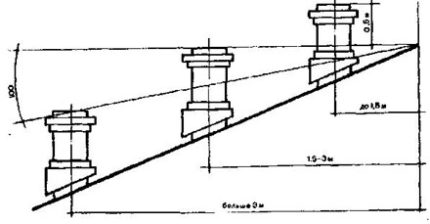

The height of the pipe should be no less than the chimney. In addition, the distance between the joint and the deflector should be sufficient for the free movement of air masses.

The ventilation unit can be located along the roof slope. It is in this case that the pipe will not create obstacles for snow to flow or free flow of rain from the roof.

The most ideal place is a skate, like the top of a roof. This is the only way to ensure maximum traction, without installing additional fans.

Selection of materials for sealing

To seal the joint of the ventilation pipe with the roof, you can use a sealant or a special tape. Both options are suitable for this stage of installation, a specific type is selected taking into account the type of roof overlap.

For any type of roof, a characteristic feature is the high temperature range. In hot summers, the roof can warm up to +70 degrees, and in severe frosts - it drops to -40 degrees Celsius.

Therefore, it is important to choose the sealant that will be very flexible and resistant to such temperature extremes. So, if during construction, a bulk roof or overlapping with bituminous tiles was used, then it is better to use acrylic sealants.

However, if the house is located in a cold climate, where the temperature is often below freezing, then acrylic sealant can only be used to process internal joints. Also, bitumen sealants can be used to process internal joints. Polyurethane products are more universal, as they are suitable for any type of roof and do not have special requirements for temperature conditions.

Using a tape for sealing, it is possible to significantly facilitate the process of processing the junction of the roof and ventilation pipe.

The tape is a thin strip of foil that is attached with glue or has its own adhesive base. It completely repeats the contours of the joint, due to which perfect sealing is achieved.

How to bypass the pipe?

Pipe sewing is a way to cover the junction and, in some cases, the duct itself.

This is done for such reasons:

- the appearance of the roof;

- Despite compliance with the requirements for pipe height, there is no draft;

- there is no certainty about the quality of the material from which the ventilation shaft is made; there are fears that it will collapse under the influence of precipitation.

Various materials are used to bypass the ventilation pipe. They vary in cost, as well as in their characteristics.

The most popular is galvanized material, which is coated with a polymer. This is the cheapest way to bypass the pipe, it is durable in use and has a presentable appearance. Since the ventilation pipe is not considered flammable, siding can be used to sheathe it.

In some cases, it becomes necessary to bypass the ventilation pipe with soft tiles, which is only reasonable if the entire roof is made of such material.

The rules for laying flexible tiles do not differ when bypassing the ventilation pipe. At the same time, it is worthwhile to ensure that the joints of the tiles do not pass water to the joint of the duct, and also do not interfere with the free flow of rain from the roof.

The main options for adjoining the ventilation unit

The choice of the method of adjoining the ventilation unit depends on the material of which the roof is made.

An equally important role is played by the type of pipe, which serves to duct:

- a simple pipe made of metal or polypropylene, which does not have any additional functions;

- complemented by a fan;

- pipe, supplemented by a valve control system, with rod or manual control;

- sophisticated ventilation systems with several additional features.

The more functions the duct has, the higher the requirements for mounting the ventilation unit.

The easiest option for laying the ventilation unit can be carried out on a soft roof. To do this, it is necessary to make a hole in the roof, which in diameter fits to the ventilation pipe laid in the house.

A flange support is attached to the hole using self-tapping screws, necessarily supplemented by a flexible gasket. A flange is placed in the flange (fastened with self-tapping screws) and a galvanized pipe. The empty space between the glass and the pipe is filled with insulating material.

When using other materials for covering the roof, it will be necessary to use more complex methods of fastening, with additional sheets of waterproofing.

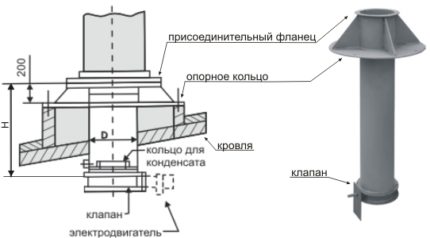

If we are talking about the industrial version of the ventilation unit on the roof, then they are pretty standard.

This is an air duct that has the shape of a square or circle, and around it is a mounting washer with additional stiffening ribs.Passage units are made of three types - those that are produced without a valve or with an electric valve or manual control. In addition, the passage assembly may vary in shape.

In order to select the necessary materials, you need to decide on the option of the node passing through the roof. The easiest way is to install the unit on a soft roof, which is made, for example, of flexible tiles.

To do this, you need an elastic rubber seal, cup and adapter flange. Installing this design is not difficult - you can do it yourself.

In those cases when other material is laid on the roof, for example, corrugated board or slate, it will not work out with a standard set of materials. In addition, if the ventilation pipe is too high or there is a significant layer of insulation under the roof, the method described above is not suitable.

Then you have to use a site that consists of a steel cup, and under it should be a metal platform. As in the previous case, the work begins with determining the exact place where the pipe will be cut, as well as creating holes of the desired diameter for the pipe and platform.

First of all, a waterproofing layer is laid, the edges of which are launched under the roof. In the place where the passage assembly is located directly, its edges are treated with sealant.

In order to cope with the problem of the high height of the ventilation pipe, you can make an additional lining of plywood. For particularly large or heavy structures, an additional frame of wooden beams is made. Alternatively, you can install a stretch of metal cables, which will securely fix the pipe on the roof.

In the case of a concrete roof, it is rational for it to use a standard set of materials (plastic cup, seal and flange), since on structures of this type, exits for ventilation or other pipes are usually planned in advance.

Conclusions and useful video on the topic

You can see how to mount the ventilation unit in the video:

Thus, the withdrawal of ventilation through the roof is a rather painstaking and complicated process. Failure to comply with the requirements that are put forward for installation can lead not only to the cessation of ventilation, but also to the appearance of excessive humidity and mold in the house.

Therefore, if there is no certainty that everything will turn out right, it is better to entrust this work to professionals.

Have you ever had to equip the ventilation passage through the roof yourself? Perhaps at the same time there were some difficulties? Please share your experience in arranging the ventilation passage through the roof. Leave your comments, ask questions - a block for communication under the article.

How to make a node of the passage of ventilation through the roof: arrangement of roofing penetration

How to make a node of the passage of ventilation through the roof: arrangement of roofing penetration  Ventilation on the roof of a private house: the construction of the passage of the duct through the roof

Ventilation on the roof of a private house: the construction of the passage of the duct through the roof  Ventilation pipes for the roof: tips for choosing a pipeline + installation instruction

Ventilation pipes for the roof: tips for choosing a pipeline + installation instruction  Ventilation pipes on the roof of the house: arrangement of the exhaust outlet through the roof

Ventilation pipes on the roof of the house: arrangement of the exhaust outlet through the roof  Arrangement of ventilation from sewer pipes: the construction of ducts from polymer products

Arrangement of ventilation from sewer pipes: the construction of ducts from polymer products  Exhaust ventilation through the wall to the street: installing the valve through an opening in the wall

Exhaust ventilation through the wall to the street: installing the valve through an opening in the wall  How much does it cost to connect gas to a private house: the price of organizing gas supply

How much does it cost to connect gas to a private house: the price of organizing gas supply  The best washing machines with dryer: model rating and customer tips

The best washing machines with dryer: model rating and customer tips  What is the color temperature of light and the nuances of choosing the temperature of the lamps to suit your needs

What is the color temperature of light and the nuances of choosing the temperature of the lamps to suit your needs  Replacement of a geyser in an apartment: replacement paperwork + basic norms and requirements

Replacement of a geyser in an apartment: replacement paperwork + basic norms and requirements