Installation of ventilation on the roof: installation of the ventilation outlet and air supply units

The problem of lack of fresh air in a private house is standardly solved by properly arranging an air exchange system. Thanks to her work in the housing, the microclimate will always be ideal for work and leisure. For stable operation of the system, installation of ventilation on the roof is required, which enhances the draft in the exhaust pipe.

Through the ventilation outlets on the roof, exhaust air with moisture generated during human life is utilized. The speed of air movement in the system largely depends on them. The greater the draft, the more efficient the ventilation.

In the article we present, you will find detailed information about the device of the outputs of ventilation communications to the roof. You will learn how to correctly install and fix them. Independent home craftsmen will receive valuable recommendations.

The content of the article:

Ventilation Output Functions

In one- and two-story houses, exhaust ducts from the kitchen, bathrooms, showers, pools, technical rooms (laundry, drying room, the room in which the boiler is installed) and the basement are displayed on the roof through the attic or attic.

According to the requirements of the regulations, in ventilation it is impossible to combine air ducts leading from the kitchen and bathrooms neither with each other nor with the chimney into one channel. Therefore, usually several ventilation pipes and a chimney are routed through the roof of the house.

It is permissible to lay them in separate channels in one ventilation shaft. The air duct from the basement is usually carried out along the facade of the building and also has a separate exit.

The correct calculation of the ventilation output is the key to good traction. Natural draft is formed due to the difference in air pressure between the street and inside the chimney.

It is necessary to take into account the height of the ventilation riser, the correspondence of the diameter of the ducts inside the house to the length exhaust pipe, its location on the roof. The higher the ventilation pipe, the stronger the draft will be in it. Strengthen the draft will help the ventilation installation on the roof.

To close the rain access above the outlet of the pipe or duct, an umbrella is mounted. This is the simplest kind of deflector, working well in areas with high and medium wind loads. With gusts of wind inside the duct, a vacuum is created thanks to it, greatly enhancing traction.

In natural air exchange systems operating in areas with low wind activity, a turbine deflector is installed at the mouth of the hood. Such a device is able to increase traction even with a slight blow of a virtually imperceptible breeze.

In addition to protection against all types of external pollution, any type of deflector prevents the air flow from tipping over due to lack of draft in the pipe.

Thus, it depends on a properly arranged ventilation outlet:

- the presence of good traction in ventilation ducts;

- good air exchange in the interior;

- lack of smells in the house;

- humidity reduction in wet rooms (bath, laundry, shower).

If the width or height of the ventilation outlet was not calculated correctly, a draft may disappear in the ducts or reverse draft may occur. In this case, in addition to the deflector, it is also desirable to put a check valve, which excludes the reverse movement of the exhaust air mass.

Ventilation duct assembly

The ventilation through passage on the roof is a pipe made of metal or plastic, which is placed in an opening in the roof. The pipe is fixed in a metal cup. After its installation, the hole is sealed and insulated from the outside and from the inside. The duct connects to the bottom of the unit, and a deflector is installed on top.

It is more convenient to use a finished factory shaped product for mounting the ventilation duct passage. Manufacturers of ventilation systems offer many models that vary in design, shape and color. For each type of roof, its own types of ventilation pipes are developed.

The most in demand are galvanized steel pipes wrapped in a layer of polypropylene. In the lower part of such a product there is a seal, and on top there is a cap with a deflector.

The mounting features of the ventilation duct passage assembly depend on a number of factors:

- by type of roof - complex or flat, single or gable;

- from roofing material - metal or ceramic tiles, decking, soft tiles, etc .;

- from the angle of the pitched roof.

Sealing and warming of the roof at the installation site of the passage element must be carefully performed. If this is not done, moisture will penetrate through the joint of the coated pipe into the insulation layer of the roofing cake and into the room, which will destroy the structures.

What are the main requirements for the passage node:

- pipe outlets must be strictly vertical so that the air does not encounter obstacles when moving upward;

- for each duct - from the kitchen hood, from the sewer riser, from the bathrooms there should be a separate exit to the roof;

- the best option is that the exhaust exits pass close to the ridge edge of the roof, but so that the run is not disturbed and the entire rafter system resting on it is not weakened;

- Selected shaped products should ensure unhindered movement of air masses and tightness.

The main element of the passage unit is the exit - shaped product: a pipe with a flexible metal base made in the form of a flange. It is pressed against the roof covering, giving the relief of the roof to which it is mounted. During the installation, the geometry of the roofing materials used is achieved and the unit is perfectly sealed.

On sale you can find different types of shaped products that facilitate and accelerate the installation of the ventilation outlet on the roof. It is possible to purchase separately - the outlet for the hood, separately - for the sewer, etc.

There are several varieties of passage elements:

- Valveless / with valve. Valveless models are perfect for arranging ventilation outlets in a private house. Valves are more suitable for industrial buildings.

- With insulation / without insulation. In cold regions, it is better to choose a ventilation outlet with thermal insulation. Moreover, insulation is necessary if the pipe is placed close to the cornice. In regions with warm winters, an option without insulation will suffice.

- With manual and auto control. The choice depends on the design budget. Very popular among owners of private houses are products with a cable for regulating air circulation.

For ventilation devices You can’t buy a similar part for the chimney, as they have fire protection that is unnecessary for ventilation outlets.

Installation and Mounting Recommendations

You can do it yourself on the roof of the ventilation outlet. The installation location of the pipe should be chosen so that it could, if possible, pass through the attic without turns. At the same time, it must not cross the rafters and especially the ridge run.

The best option when the vent pipe is located directly above the internal riser of the ventilation shaft or duct. If this is not possible, a corrugated pipe can be used for connection.

When placing pipes or an exhaust duct, the smallest permissible distance from the supply air intake must be taken into account:

- horizontally - 10m;

- vertically - at least 6m.

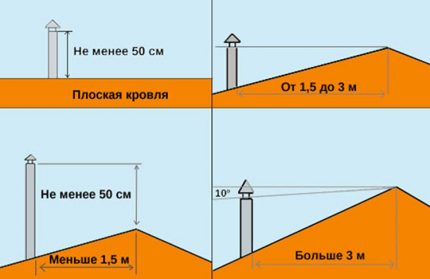

The height of the ventilation pipe is determined as follows:

- if it is located near the ridge, the final opening of the hood should rise half a meter above the ridge;

- if the ridge remains from one and a half to three meters, the hole should be flush with it;

- if the pipe is located further than three meters from the ridge, the hole is displayed on the side of the angle of 10 degrees to the horizon with the top on the roofing ridge;

- if the ventilation outlet is near the chimney, the length of the pipes should be the same;

- on a flat roof, the height of the pipe is calculated according to a special table, but it should not be lower than 50cm.

When installing the pipe on a pitched roof, the ventilation outlet should be placed as close as possible to the highest point of the roof - the ridge. In this case, the largest part of the pipe will be in the attic or attic space, will be protected from strong temperature extremes and gusts of wind.

For a flat roof, the main role is played by the geometry of the duct, which must be located directly under the exhaust pipe so that the air freely exits onto the street.

Installation of ventilation outlet

Installation of the ventilation outlet is carried out in accordance with a previously developed scheme of the location of the exits. Installation features depend on the type of roof and pipe construction. In the configuration of shaped products, there is always an installation instruction.

In general, the installation is performed according to the same algorithm:

- At the pipe exit, marking is carried out corresponding to the diameter of the hole. If there is a template in the set of the passage element, the marking is applied according to the template.

- A hole is cut out in the roofing pie with a chisel or scissors for metal: in the roofing material, in the layer of waterproofing and insulation.

- The sealant is attached with a liquid sealant.

- A walk-through element is placed on the gasket and fastened with screws to the roof. The base of the passage must be attached to the roof as tightly as possible.

- The duct pipe is attached to the passage element and fixed with screws. When working, it is advisable to use a plumb line or a building level to fix the pipe vertically.

- From the attic side, the outlet of the duct to the roof is sealed.

The outlet of the ventilation pipe is the most technically vulnerable unit in the entire ventilation system in the house. It is especially important here not only to solve the aesthetic problem, but also to provide reliable waterproofing of the passage with preserving the properties for the entire life of the roof.

To increase the draft in the ventilation system, the head of the ventilation pipe must the deflector is put on. A deflector is a nozzle in which under the influence of wind rarefaction of air masses occurs. Thus, the aerodynamic resistance to flow is reduced.

So the deflector acts as a traction amplifier. In addition, the exhaust device:

- protects the ventilation system from precipitation;

- prevents the wind from blowing inside the vent pipe;

- prevents the phenomenon of backdraft.

The principle of operation of any type of deflector is based on rarefaction of the air mass at the mouth ventilation ductas a result of which the exhaust air rapidly moves in its direction without mechanical impulse.

Types of vents for ventilation systems

To date, the following types of deflectors are used:

- TsAGI with diffuser - expansion of the ventilation duct: the most efficient design when the wind flow is more than 2 m / s. The design consists of a lower cup with an extension at the end, a cylindrical steel case, an umbrella cover and a rack for attaching the cover.

- Cylindrical fungus Volper-Grigorovich - successfully compensating for pressure loss at the nozzle outlet. It consists of a lower glass, an upper glass with concave walls, a conical umbrella and mounts. The Volper fungus protects the ventilation system better from the wind than TsAGI.

- H-shaped pipe manifold It is an element of pipes in the form of the letter N. This rather bulky design completely protects against wind blowing, moisture, reverse traction, freezing. However, the traction design increases minimally.

- Weather vane cap when working, it always turns backwards to the wind, which prevents blowing inward. A zone of reduced pressure appears behind the nozzle body and the air stream quickly leaves the vertical channel. Effective for increasing traction, but poorly protects from rain.

- Turbo deflector - This is a spherical rotational deflector having many semicircular blades that rotate in the wind. A rarefaction appears inside the ball. Ineffective in calm weather.

One of the improved varieties traditional fungus on the pipe is an Astato-type statodynamic device which consists of 2 truncated cones that are turned with their vertices towards each other. Above is an electric fan and an umbrella.

The system is effective even in complete calm. The only drawback is the high price.

When choosing a deflector, you need to consider:

- The nozzle size must be selected according to the diameter of the exhaust barrel. If the house has a rectangular shaft, you will have to use an adapter.

- TsAGI and the Volper deflector are maintenance free.

- In the absence of traction, it is better to set dynamic options for caps.

- When buying a rotating deflector, you need to choose more expensive models with a sealed bearing that does not freeze in winter.

- In areas with strong winds, it is better to choose an H-shaped deflector or turbo-reflector, for other climatic conditions - TsAGI.

If you have a budget in any region, you can install Astato. The device requires periodic maintenance.

Let's look at how to properly install a ventilation hood on the roof. After the purchase, the model needs to be assembled and all the mounts securely fixed. Then, when mounting the device on the pipe, you need to carefully drill holes for fastening. The device is fixed on screws or rivets. Additionally, you can put a clamp.

Roof Fan Features

Another element of the ventilation system is a roof fan. Using these devices, the waste polluted air is removed from the premises.

They are mainly designed to work in general ventilation systems without ventilation ducts, but they are also used with air ducts. The main advantage of roof fans is their use reduces the required length of air ducts.

Options for roof fans vary in size, power, performance, sound pressure level.

The following common types can be distinguished:

- axial aerospace defense is installed on industrial buildings;

- BLOOD can be used in private homes;

- VKRM and VKR are connected to air ducts.

What are the advantages of roof fans?

- installation does not require a separate room;

- simple maintenance;

- hinged models make access to the main parts easier.

When choosing a roof fan, you need to pay attention to the performance of the model, the material of the housing, the method of power supply, the noise generated.

Most products are manufactured as centrifugal or axial:

- An axial fan is used to pump low-pressure air masses. Gas when moving through the rotor does not change direction, moving along the axis of the engine.

- The centrifugal fan is equipped with special blades that distribute air on the sides, which further advances to the outlet.

The types of roof fans are divided in the direction of discharge. Horizontal exhaust fans are installed where the exhaust air is not contaminated and there is no risk of mixing it with fresh air entering the house.

Roof fans can be installed on different types of roofs. The technology of the device node passage in a hard roof is simple. A technological opening is cut through the ceiling, and a brick foundation for the fan is built onto the ventilation shaft.

To simplify installation work, special glasses are used, which sometimes come complete with fans. The glasses have holes on the mounting flanges and are attached to the roof with anchor bolts. The fan and the cup are flanged to the bolted joints.

Between the flanges should be a rubber gasket for greater tightness. The glass during installation should be exposed strictly vertically. The fan on the glass is mounted horizontally. After installation, possible clearances are removed with sealant. Then a steel apron is installed.

Conclusions and useful video on the topic

Large manufacturers of ventilation systems issue video instructions for installing on the roof and fastening supply and exhaust units, fittings, aerators, deflectors:

The arrangement of the exit through the roof to the roof of the ventilation pipe of the house should be approached with particular care. Indeed, in natural ventilation systems, the presence of traction in the system depends on the state of this unit.

Do not allow the pipe to rain or icing. Therefore, much attention is paid to sealing the assembly itself and installing protective additional parts. Similarly, the installation of supply devices is carried out.

Ventilation pipes on the roof of the house: arrangement of the exhaust outlet through the roof

Ventilation pipes on the roof of the house: arrangement of the exhaust outlet through the roof  How to install ducts: installing flexible and rigid ventilation ducts

How to install ducts: installing flexible and rigid ventilation ducts  Ventilation on the roof of a private house: the construction of the passage of the duct through the roof

Ventilation on the roof of a private house: the construction of the passage of the duct through the roof  Ventilation pipes for the roof: tips for choosing a pipeline + installation instruction

Ventilation pipes for the roof: tips for choosing a pipeline + installation instruction  Adjoining the roof to the ventilation shaft: arrangement of the passage of the ventilation unit through the roof

Adjoining the roof to the ventilation shaft: arrangement of the passage of the ventilation unit through the roof  Installation of plastic ventilation ducts: a guide to the construction of a system of polymer pipes

Installation of plastic ventilation ducts: a guide to the construction of a system of polymer pipes  How much does it cost to connect gas to a private house: the price of organizing gas supply

How much does it cost to connect gas to a private house: the price of organizing gas supply  The best washing machines with dryer: model rating and customer tips

The best washing machines with dryer: model rating and customer tips  What is the color temperature of light and the nuances of choosing the temperature of the lamps to suit your needs

What is the color temperature of light and the nuances of choosing the temperature of the lamps to suit your needs  Replacement of a geyser in an apartment: replacement paperwork + basic norms and requirements

Replacement of a geyser in an apartment: replacement paperwork + basic norms and requirements