How to install ventilation pipes: mounting technologies for wall and ceiling mounting

Ducts are transport networks of a ventilation system. Their device and installation are regulated by strict installations of regulatory documents and technological maps. Compliance with regulatory requirements during construction is a guarantee of the smooth operation of the network, ensuring stable air exchange.

We will talk about how to install ventilation pipes in accordance with building requirements. Every developer is required to know the basic rules for laying and fixing ducts. Information will also be useful to owners to understand the cause of the problem and decide how to fix it.

The content of the article:

Duct design and requirements

The movement of air flows inside the building and outside is carried out through vertical and horizontal ventilation ducts. Installation of ventilation pipes is carried out according to design marks indicated in the working drawings. Installation rules are given in the normative collections SP 73.13330.2016 and SP 60.13330.2016.

Ventilation ducts can be laid out inside the main walls or located inside the house under the ceiling or along the walls. Often circumstances dictate the design of ducts outside the building.

Separation of channels by functionality:

- forced-air - through them fresh air enters the house;

- exhaust - to remove contaminated air masses.

With natural ventilation in a private house, all exhaust ducts can pass in one shaft. For this room with high humidity, unstable temperature and characteristic vaporization, from which used air is removed, the designers try to place them next to each other.

A number of requirements are imposed on ventilation ducts:

- tightness;

- noiselessness;

- compactness, location in hidden parts of the house;

- strength, durability.

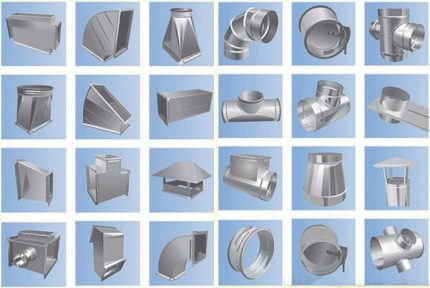

During installation, the spatial structure of the ducts is created from individual typical parts. For its construction, in addition to rectilinear elements, additional shaped parts are used.

According to the external configuration, round and rectangular ducts are used. Pipes with cylindrical shapes have optimal data for the unhindered movement of air masses. Rectangular ducts allow you to save free space, they are easy to hide behind false walls and suspended ceilings.

Air ducts are rigid and flexible. Rigid trunks are made in a round and rectangular version according to VSN 353-86, TU-36-736-93.

For the hard version, the following materials are used:

- cold rolled galvanized steel - 0.5 - 1.0 mm;

- hot-rolled sheet steel - 0.5 - 1.0 mm;

- polymers - 1.0 - 1.5 mm.

For wet rooms suitable plastic ducts or stainless steel with a thickness of 1.5 - 2.0 mm. In chemically active zones, pipes made of metal-plastic, aluminum and its alloys are used.

Flexible channels are made in the form of pipes made of soft material. They are often used as convenient inserts for connecting rigid ducts to ventilation equipment.

Curved ventilation ducts are suitable for moving air at low speed and pressure.

In residential buildings often mounted PVC ventilation pipes with high heat and sound insulation properties.

Typical PVC parts are joined using:

- one-piece contacts - butt welding or weld-in couplings;

- detachable elements - flanges, couplings, sockets.

Fastenings to PVC ducts are used both hanging and supporting.

Thermal insulation protects the ventilation ducts from condensation. This mainly applies to industrial and unheated premises. For private homes and offices, thermal insulation is used for ventilation ventilation in the attic. Soundproofing of pipes is carried out in living rooms.

Be sure to ground the metal ventilation pipes to relieve the accumulating static voltage.

Connection options for vent duct assembly

Ducts are assembled from individual parts. Docking is carried out using flanges or other connecting elements.

Angled flanges are mounted at the ends of the sections to be joined. Holes for mounting bolts are drilled on them. Sealing gaskets are placed between the flanges.

For durability of flange connections bolts with a nut and a suitable key size are carefully tightened. Nuts are on one side of the joint. When installing vertical pipes, the nuts are located on the bottom flange side.

The disadvantages of this connection are the significant weighting of the structure, high metal consumption, and high labor intensity.

Lighter flanges are made of profile galvanized strip. Z-shaped flanges are connected using a rail having a section in the form of the letter C, and a seal.

The connecting rail resembles a collapsible flange. It is made of a galvanized metal profile in the form of the letter G. The length of the larger side is from 20 to 30 mm. The kit comes with a seal and a corner. The advantages include low labor intensity and low financial costs.

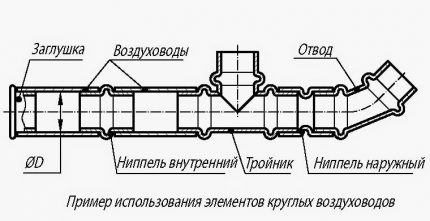

Among the flangeless joints used to assemble round ducts, the most commonly used are:

- nipple;

- bandage.

The thickness of the nipple should not be less than the thickness of the pipes.

The nipple is inserted inside or worn over the mating elements in such a way that its width captures both sides of equal length for pipe diameters:

- 100 - 315 mm - not less than 50 mm;

- 355 - 800 mm - not less than 80 mm;

- 900 - 1250 mm - not less than 1000 mm.

Instead of the nipple name, the term coupling is often used.

The bandage connection is considered a connection of a high degree of strength and reliability. The edges of the straight and shaped parts of the ducts are bent and combined. Then, a bandage filled with sealant is applied and tightened on the pipes at the seam.

When connecting the ducts, the seams seal:

- elastoplastic tapes of the Guerlain type at a temperature up to 40 degrees;

- non-hardening mastic based on synthetic rubber (for example “Buteprol”), silicone and other seals that can withstand heat up to 70aboutWITH.

The seam of the pipe or duct is located on top.

When moving an air mixture with a temperature above 70aboutC as a sealant use elastic bundles of polyisobutylene, bituminous mastic (PMG) and other fire-resistant non-combustible materials.

Before joining the channel elements with thermal insulation, the heater is carefully bent from both ends. The sections hermetically connect and return the insulating layer to its place. The seam in the thermal insulation is clogged with aluminum tape or clamps.

Fixing ventilation pipes to the wall and ceiling

Non-insulated metal ducts are fastened to the ceilings and walls by means of various designs: supports, brackets, suspensions, clamps.

Features of installing hard ventilation ducts

The distances between the fasteners are strictly standardized:

- for round pipelines with a diameter of less than 400 mm - not more than 4 meters;

- for diameters equal to or greater than 400 mm - not more than 3 meters;

- for baskets with a section side of less than 400 mm - no more than 4 meters;

- with a section side equal to or greater than 400 mm - no more than 3 meters.

To remove the resulting condensate, horizontal sections of air ducts are laid with a slope of 0.01 - 0.015. Water droplets slide down an inclined surface into drainage receivers.

Laying a ventilation pipe with a diameter of up to 630 mm with flange and coupling (nipple) joints in a horizontal position is carried out using various fasteners. The distance between them does not exceed 6 meters.

In other versions - no more than 4 meters. At tie-in or corner points, the stability of the air duct is enhanced by additional supports.

Pendants and supports of horizontal sections of metal rectangular boxes with a perimeter of up to 1600 mm with flange or busbar connections are placed at a distance of no more than 6 m from each other. With other connections, not more than 3 m, while the tie-in points and cornering corners are also further strengthened.

The installation step of fastenings for metal ducts of any sections and dimensions with insulation, as well as for pipes without insulation with a diameter of more than 2000 mm or ducts with a side of more than 2000 mm, is indicated in the working drawings.

Fixture vertical ventilation pipes is carried out every 4.5 m. In high-rise buildings with floor heights of up to 4.5 m, air ducts are fixed in the floors. When the height of the rooms from floor to ceiling is more than 4.5 m, the ventilation pipes are fixed to the walls in accordance with the design documentation.

Vertical deflection of ventilation pipes is allowed within 2 mm per 1 meter of duct length.

A uniform tension distribution over the suspensions is achieved by adjusting their length. It is forbidden to fix extensions on the flanges of the joints. Fixing collars should not freely hang on an air duct, but should fit snugly to its circumference or perimeter.

All non-standard fixtures are calculated and displayed in the working drawings.

The distance from the plane of the wall of the house to the outer surface of the round ventilation duct is at least 50 mm, from the ceiling surface - 100 mm.

For rectangular ducts, this parameter depends on the dimensions of the sides of the duct section:

- with side 100 - 400 mm - 100 mm;

- 400 - 800 mm - 200 mm;

- 800 - 1500 mm - 400mm.

The minimum distance to water, gas, and heat supply networks is 250 mm. Up to power supply lines of at least 300 mm. The smallest interval between two round ducts is 250 mm.

When passing through walls and ceilings, flange and other types of connections of air ducts are placed at a distance of at least 100 mm from their surface. Fasteners are installed no closer than 200 mm from the place of detachable connection.

Fasteners for rigid ducts

Below will be described: with what devices and how to fix the ventilation pipe to the ceiling.

Among the fasteners used for these purposes are:

- A hairpin and a shaped profile in the form of letters Z or L provide additional support to the duct from the bottom. The method is suitable for mounting heavy structures. The connection is fixed with screws and a rubber gasket between the stud and the profile.

- Clamp with a hairpin - the best choice for ventilation ducts in the form of pipes.

- The crosshead with two studs is suitable for main ventilation passages with a rectangular cross-section side of more than 600 mm. The air duct is laid on the beam, which can be metal plates and profiles.

- Clamp without stud - used for short sections of flexible ducts.

- Perforation tape - mount for light pipes and rectangular channels with a diameter and side up to 200 mm. To cover a round surface, a loop is made from the tape, in the punch tape boxes it is fixed to bolted joints.

The opposite ends of the above mounting devices are connected directly to the ceiling of the room in the form of an anchor element or attached to metal beams using bolts or clamps.

The ventilation pipes are fixed to the wall by means of embedded parts and cantilever structures.

For the production of fixation using:

- Brackets. They are embedded in the walls of buildings or shot at them with dowels from the mounting pistol PC-52-1. Horizontal ducts are laid on brackets made of steel of angular profile.

- Traction. They are used for hanging air ducts to building structures. With the help of adjustable suspensions, the tension of the braces of the ventilation ducts is controlled. Standard 1 mount for 2 meters of duct length.

- Clamps.Designed for fixing pipe ducts on rods, grips, hooks. The width of the steel band clamp with a duct diameter up to 400 mm - 25 mm, with a diameter of 450 - 1600 mm - 30 mm. Fastened with anchor bolts or dowels.

In one ventilation system, different types of mounts are used. How to properly fix the ventilation pipe to the wall is shown in the photo below.

Since an extremely light weight medium is transported through the ducts, there are no special requirements for the strength of the brackets. The main thing is that they can keep the weight of the highway itself.

Fixation of flexible ventilation ducts

To connect the air ducts to the fans, inserts of vibration-insulating soft materials are used, providing flexibility, tightness and durability of the connection.

Air ducts from a polymer film on straight sections can have bends of no more than 15 degrees. The transition through building structures helps them overcome metal liners.

Flexible pipes are placed on rings of wire with a diameter of 3-4 mm with a frequency of 2 meters. The diameter of the duct is 10% less than the diameter of the mounting ring.

Along the axis of the pipe, a bearing cable is pulled from a metal wire with a diameter of 3-4 mm, which is attached to the structures of the house every 20-30 meters. Steel rings are hung on a cable using wire or cut-out steel plates.

Flexible pipes are used for connection:

- hard channels to ventilation equipment;

- complex fittings;

- silencers and other devices.

For main ventilation pipelines flexible corrugated pipes apply prohibited. Soft ducts cannot be used in vertical channels longer than 2 floors.

The procedure and methods for installing ducts

Before starting the installation of the ventilation system, a project for the production of works is developed. It outlines the individual stages of the assembly of large nodes. Depending on the dimensions of the structures, their masses choose installation methods and a sequence of steps. Make markings of the mounts and check their completeness. In the graphic part of the PPR mark the parking lots of hoisting mechanisms: winches, blocks, etc.

In the basement and basement floors, only rigid ventilation lines are installed.

For passing through walls and partitions, special inserts and metal cartridges are used.

In order to minimize the loss of speed, the turning angles of the route are rounded off with a circle radius of at least 2 duct diameters.

On separate hidden sections of the ventilation pipe routing (in mines, under ceilings), acts of acceptance of work on duct installationwhere the main characteristics and bindings of the mounted structures are fixed. A sample preparation of the document is given in Appendix B of the code of rules SP 73.13330.2016.

According to Appendix A of the same joint venture, the dimensions of the holes in the walls and floors of the building for laying ventilation ducts should be wider by 150 mm of the corresponding diameter or side of the air duct.

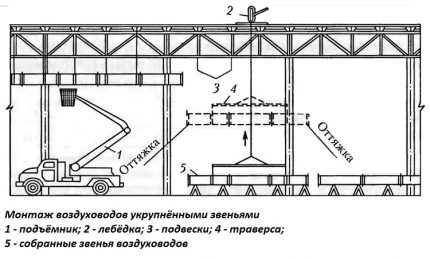

Installation of horizontal channels inside the building

The ventilation pipes are laid in accordance with the TTK regulations, section 07.33.01.

Work execution order:

- checking the availability of all necessary parts and fixtures;

- marking of fasteners;

- embedment of anchors in the floor slab or support beams in the form of corners, channels;

- assembly of individual parts into enlarged units;

- installation of a lifting mechanism;

- sling of the first node;

- fixing stretch marks at both ends of the node;

- trial suspension to clarify the center of gravity of the structure;

- lifting to the design location and fixing with pendants;

- control of the accuracy of placement and distribution of the block;

- rearrangement of the winch for mounting the next unit.

At the last stage, check the accuracy of the block placement, remove the slings and rearrange the winch for mounting the next node.

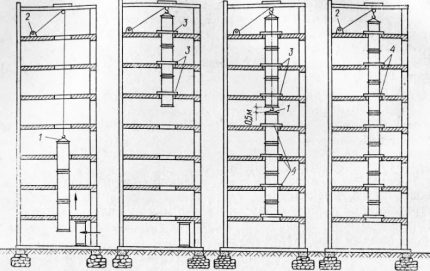

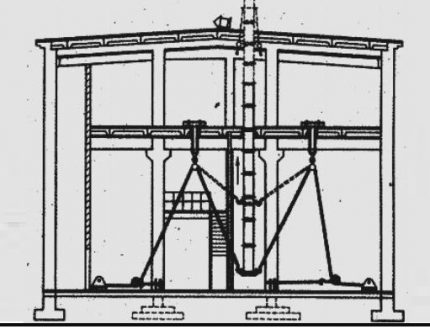

Assembly of vertical ducts using the “build-up from below” method

The installation process is performed according to TTK 07.33.05, consists of a sequence of the following technological operations:

- Installation of a lever winch over the mounting opening.

- Slinging of the first part behind the head attached to the flange.

- The rise of the first element is slightly higher than the height of the second part.

- The connection of the second and first parts of the ventilation pipe with a flange connection with gaskets.

- Raising the connected elements No. 1 and No. 2 to the height of the third part.

- Connection from the bottom of part No. 3 to elements No. 1 and No. 2.

- Extension of the structure in a similar way until the full use of parts.

- Installation of the ventilation pipe in the design position.

At the end, they check the correctness of the location, fixation on the consoles by means of clamps or flanges, removal of lifting devices.

Installation of vertical channels "building on top"

The algorithm of actions is described in TTK 07.33.08. This method is used to connect heavy nodes created by the technology of "building from the bottom."

At the top of the shaft, a support beam is fixed, on which a lever winch is fixed. Separate links are collected in large blocks using the “bottom-up” method. The air ducts are raised to the upper floor and are located next to the ventilation shaft.

The first element is lowered down to the design location and finally fixed to the supports. Then, such operations are repeated for the remaining blocks up to 100% of the assembly of the standing duct.

Installation of vertical ducts "extrusion"

Installation of the ventilation duct in the design position according to TTK 07.33.06 is carried out using two winches fixed in the lower part of the building. To the lower flange of the lower node, assembled by the method of "building on top", a base plate with brackets for slinging is mounted on bolts.

With the help of two winches and blocks, the slings are pulled and the ventilation pipe is squeezed out 0.5 m above the roof. An umbrella is installed on the upper flange from the roof and stretch marks are fixed. Then the air ducts are lifted to the design elevation by winches, fixed with permanent fasteners, the base plate and lifting rigging are removed.

Air duct hitch

Bendable pipes are often used in ventilation systems of apartments or private houses, offices, small retail premises.

Installation sequence:

- determination of the actual location of the channel with reference to the building marks;

- installation of fasteners in the ceiling in the direction of laying the air duct, put dowels every 400 mm and hang clamps;

- stretching the flexible sleeve to the maximum and cutting pieces of the desired length.

A soft sleeve is put on a rigid pipe with a minimum approach to its surface of 5 cm. Installation of flexible ducts is carried out taking into account the direction of moving air flows. Oriented by marks on the surface of the pipes. The attachment points of such a channel are located at a distance of 1.5-3 m from each other.Sagging of the sleeve is allowed no more than 5 cm per 1 meter of total length.

If a flexible hose is laid behind a suspended ceiling parallel to its surface, the supporting clamps are placed at a distance of 100 mm. With vertical installation, the free areas between the fasteners can increase up to 1800 mm. Flexible ducts need protection from direct sunlight.

Elastic pipes have the ability to accumulate static voltage, it is important to ground the channel. To do this, the ground wire is fixed at one end to the metal frame of the sleeve.

Work safety

Most of the installation work is carried out at height. Lifting mechanisms are required. It is imperative that the installers receive safety instructions.

For the successful outcome of the work phase at height, it is required that:

- Work was carried out only by trained, qualified installers.

- The place of work was fenced, the passage of people near the object is limited.

- To reduce the risk of installation at height, all preparatory processes were carried out at zero.

When performing work in private homes, they use reliable strong scaffolds, inventory forests. Works on laying ventilation pipes with thermal insulation are carried out in protective gloves, glasses.

With the specifics of arranging the passage of ventilation pipes through the roofing cake will introduce next article, which we recommend reading.

Conclusions and useful video on the topic

The process of assembly and installation of a ventilation system with the fastening of ducts to floor slabs is shown. Viewing speed and volume can be adjusted in the video settings. Installers use a hammer drill, fasteners, sealant, scaffolds, scaffolding.

The video material in two parts will introduce the specifics of the device of the duct network:

Continuation of the video guide:

Properly laid and secured ducts will provide an unhindered supply of fresh air and the removal of the spent mass from the treated premises. Ventilation ducts will not be blocked by dust deposits and cause inconvenience to the owners of the house or apartment. Installation work in accordance with construction requirements will exclude violations and damage to the system.

Do you have information on the topic of the article that is worth sharing with site visitors? Want to complement the information presented for consideration? Write comments, please, in the form below the block, post a photo and ask questions about obscure and controversial issues.

Ventilation plastic pipes for hoods: the nuances of selection and installation

Ventilation plastic pipes for hoods: the nuances of selection and installation  Duct mounting distance standards: calculation of the geometric data of the ventilation route

Duct mounting distance standards: calculation of the geometric data of the ventilation route  Design and installation of ventilation systems: the best schemes + installation nuances

Design and installation of ventilation systems: the best schemes + installation nuances  Ducts for ventilation: classification, features + installation tips

Ducts for ventilation: classification, features + installation tips  Ventilation from plastic sewer pipes in a private house: the possibility of construction and the best options

Ventilation from plastic sewer pipes in a private house: the possibility of construction and the best options  Calculation of air ducts for speed and flow rate + methods for measuring air flow in rooms

Calculation of air ducts for speed and flow rate + methods for measuring air flow in rooms  How much does it cost to connect gas to a private house: the price of organizing gas supply

How much does it cost to connect gas to a private house: the price of organizing gas supply  The best washing machines with dryer: model rating and customer tips

The best washing machines with dryer: model rating and customer tips  What is the color temperature of light and the nuances of choosing the temperature of the lamps to suit your needs

What is the color temperature of light and the nuances of choosing the temperature of the lamps to suit your needs  Replacement of a geyser in an apartment: replacement paperwork + basic norms and requirements

Replacement of a geyser in an apartment: replacement paperwork + basic norms and requirements