How to punch a well into water: options and drilling technologies that are in demand in practice

For a comfortable life in the country or in a private house, you need your own source of clean water. It can be a mine or tubular well, that is, a well. The device of the second option is a priority due to less investment of effort, time, money.

We will talk about how to break a well into the water with our own hands or with the help of invited drillers. In both cases, knowledge of the technological subtleties of the process is useful to the owner of the site. Those who wish to independently drill and equip an autonomous water source with us will find a detailed guide with valuable recommendations.

The content of the article:

Features of mechanical drilling

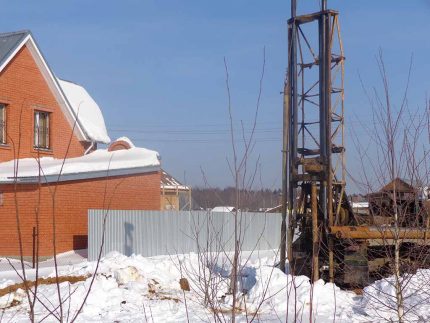

The services of a hired team are not cheap, but the work is usually done quickly and professionally. In order for the process to proceed as efficiently as possible, it is necessary to create suitable conditions for the operation of drilling equipment.

First you need to choose a place:

- for a well;

- to place the rig;

- for auxiliary equipment;

- for draining waste water;

- for storing tools and materials.

It is recommended to carry out all work on a flat area, its optimal size is 4 × 12 m. In addition, care should be taken about the possibility of free passage of equipment: a drilling rig, a water carrier, etc.

It is desirable that the width of such an entrance is about three meters. If an electric wire is stretched over the place of work at a height of less than two meters, it will have to be removed or shifted.

The location of the rig depends on its type and dimensions. For drilling with the UGB machine, permanently located on the machine, entry to the site to the drilling point and free exit must be provided. It should be remembered that when moving on cultivated land, freight vehicles can “land” in the ground and become stuck for a long time.

Portable team drilling rig, which can be made or leased, put in any place convenient for work. She usually does not have a high rig.

However, it is worth considering that water intake should not be placed next to the foundation, as in the process of many years of pumping water, soil particles will be washed out with it. As a result, the mineral base under the foundation will be weakened due to erosion.

Secrets and subtleties of finding a place for a water well given here. We recommend reading the article on this issue.

Overview of Basic Methods

Drilling methods vary depending on the type of soil, but they have a common operating principle. The rock needs to be destroyed, removed to the surface, and then the walls of the resulting hole should be strengthened. To destroy the rock, many drill shells have been invented that allow you to drill and reach cohesive, disconnected and rocky soils to the surface.

There are other ways of destroying the soil: using explosions, heat treatment, electrical discharges, but they are usually not suitable for wells.

The following are used to extract the destroyed rock. drilling technology:

- mechanical;

- hydraulic;

- pneumatic;

- combined.

The most common can be called a mechanical method, in which equipment such as glasses, spoons, chisels, baits, screws, etc. are used. Hydraulic methods consist in flushing out the rock with the help of a large volume of water, which is pumped under pressure into the mine.

Pneumatic methods in which compressed air is used to remove loose rock are used much less frequently. Most often they combine mechanical and hydraulic methods. The solution, which is fed into the well during mechanical drilling, facilitates the movement of the drill and cools it.

With methods and tools used in manual drilling, will familiarize you with an article that examines in detail this very interesting question.

Principle of Hydro-Drilling Technology

Hydro-drilling is a fairly common method. The working fluid is pumped into the face under pressure using a pump. She goes outside, carrying away particles of destroyed rock. The spent solution is collected in a separate tank for sedimentation.

Then the water is reused. In this case, you should constantly study the characteristics of the soil in order to understand which layer passes the drill at this moment. When there is extraneous water in the well, you can skip the aquifer and continue unnecessary drilling.

A mixture of water and clay is needed as a hydraulic solution on incoherent soils. Clay particles will additionally bind the rock and strengthen the walls of the well. But if during the drilling process you have to go through a clay layer, you do not need to make a solution. The clay particles will naturally dissolve in the water as the water moves inside the trunk.

On calcareous soils, water drilling with clean water is considered effective. This breed has the ability to absorb water. If the solution is consumed at an accelerated rate, we can talk about reaching the aquifer and proceed to the final stage of drilling.

Strengthening the walls of the well

As the well deepens, the casing is lowered into the hole and its length is increased. The most suitable for this are steel alloy structures.

Both seamless pipes and welded are considered suitable. Threads are usually used to connect the individual elements, but high-quality welding is also acceptable. To extend the life of the well and provide it with a filter, a plastic insert with a perforated first link is placed in the casing.

It is believed that on cohesive soils with a relatively small depth of drilling, you can first go through all the layers of the rock to the aquifer, and then lower the pipe immediately to the entire length of the well. But experienced drillers believe that it’s better not to take risks even with a low probability of collapse.

Pumping and arrangement of the structure

After reaching the aquifer, drilling is continued to go deeper into the ground by about a meter. After that, a plastic column with a filter is installed in the mine and perform well pumping, i.e. A large amount of water is pumped out of it until it becomes clean.

Pumping contaminated water can take several days. If drilling fluid was used, more efforts will be required to clean the structure. It is sometimes recommended to use another cleaning method. In the finished well, water is supplied from above under pressure to clear the space around the lower end of the pipe.

Lower the pumped well submersible pumpequip a head, etc. The owner is issued a passport of the hydraulic structure. It reflects a number of important indicators, such as depth, well flow rate, its statistical and dynamic levels.

How to make a well yourself?

The high cost of hired team services encourages amateur craftsmen to look for ways to drill manually. These methods are considered budgetary, but require time and effort. The principle of the work is the same as with mechanized drilling. It is necessary to grind the rock and remove it, gradually lowering the casing into the bottom.

The destruction of the soil is carried out using various types of drills: chasers, spoons, glasses, coils. Instead of a drilling rig, they put a metal or wooden tripod. Its center should be exactly above the place chosen for the well, and the dimensions should allow two or three employees to be close to the place of work.

A winch block is also placed at the top. This design will facilitate excavation of the tool with soil. It is possible to turn the winch manually, but it is more convenient to use an electric motor for rotation, if there is such an opportunity.

The use of homemade drilling tools

The drill can be made independently or purchased ready-made. There are different types of tools for manual drilling. It is selected depending on the type of soil. For example, a spoon drill is best used on sand, and clay layers should pass through a coil.

First make an initial hole, about a meter deep. It sets the direction for the movement of the main tool. Then the selected drill is lowered into the hole, several turns are made and it is removed together with the soil destroyed and captured by the drill.

The upper edge of the drill rod extends into the hole inside the tripod, this helps to maintain the correct direction of drilling. It is not necessary to use a tripod. The guide post may be of another shape.

The procedure is repeated again and again. The well is deepened, additional links are attached to the upper rod immersed in the ground in the column, which are fixed to the thread or clamps. Usually they turn the drill together, sometimes you need another person who hits the tool from above to facilitate work.

But this is not necessary. Many craftsmen share the experience of building a well alone. But they note that in this case they will have to work long enough. The whole process can take several weeks or even months. If possible, it is better to invite a partner.

Use of chisels and chisels

If you need to pass rock, you will need a chisel. In shallow workings, characteristic for the arrangement of suburban areas, the need for a bit is rare. Most often this happens if the drill string rests on a boulder that completely covers the trunk or a large pebble is stuck in the casing.

A stone is literally broken with a chisel. The tool is attached to a winch cable mounted on a tripod, lifted and thrown down several times. Then the destroyed rock is removed using a bailer or washed with drilling mud.

The bailer is a long and narrow glass made of a pipe. Its diameter is slightly smaller than the hole for the well. From below the pipe is covered with a valve so that the soil that has got inside does not fall back.

On cohesive clay soils bastard do not use because of too low drilling speed and low efficiency. It is used for drilling incoherent rocks: sand, gravel and gravel deposits.

To release the projectile from the contents along such a bunker, a narrow slot is made through which the destroyed soil is simply unloaded to the ground near the well. If a lump of loam clogs the billet or a large pebble sticks, the bore is cleaned through a slot with a metal bar.

The flap is attached to the cable, like a chisel, and is also thrown down several times, and then it is brought to the surface and freed from the soil that has accumulated inside. This is a very effective way for loose and water-saturated soils. Such a tool is especially useful when sand saturated with water needs to be practically scooped up.

A valve flap can also be used for sandblastingwhose filter no one cleaned for a long time.

A home-made well also needs to be rocked, as well as an industrial-made structure. You will need a pump that can pump out water with sand. Some have successfully used inexpensive models such as “Baby” for this.

They are easy to repair in the event of a breakdown, and if the device burns out during operation, you can always buy a new one. A conventional submersible or surface pump for these purposes should not be used, since an expensive device will quickly deteriorate during such inappropriate use.

Some useful tips

No matter how expensive the services of drillers are, you should not hire a team that offers too low a price. It is possible that such a saving will have to pay for the quality of the hydraulic structure. If you want to save money, it makes sense to think about drilling a well in winter.

The workload of drillers at this time is reduced, they offer good discounts. Even the most experienced driller cannot accurately predict how drilling will progress. Each such structure is individual.

It should be remembered that payment is made according to the actual drilling depth, and only the predicted value is indicated in the contract.The acceptance certificate should be signed only after clean water begins to enter the house without visible impurities of sand and other such contaminants.

But for the presence or absence of microelements or microorganisms in the resulting water, drillers are not responsible. A few days later, after the start of active operation of the well, a water sample should be taken and given to a laboratory for research.

Based on the results, it will be necessary to determine which filters need to be installed at the entrance of the water supply to the house. This rule is also necessary for wells that are made independently.

Conclusions and useful video on the topic

Video # 1. Detailed experience of self-drilling:

Video # 2. Industrial option for creating a well:

Well drilling methods are diverse, but they are time-tested. Collaborating with an experienced team, you can almost always get a reliable and durable construction. But a self-created water source can last several decades.

Want to talk about how you or your neighbors drilled a well in the country? Share your own experience or useful information on the topic of the article. Please leave comments in the block below, post a photo with a step-by-step demonstration of the process, ask questions.

Do-it-yourself water-boring for water wells: a review of technology

Do-it-yourself water-boring for water wells: a review of technology  Drilling a borehole: a complete overview of shock-rope technology

Drilling a borehole: a complete overview of shock-rope technology  How to swing a well: methods for pumping after drilling and during operation

How to swing a well: methods for pumping after drilling and during operation  Auger drilling of wells: features of technology and shell for manual drilling and installation

Auger drilling of wells: features of technology and shell for manual drilling and installation  Rotary Well Drilling: An Overview of Drilling Technology and Essential Equipment

Rotary Well Drilling: An Overview of Drilling Technology and Essential Equipment  How to drill a well with your own hands: ways to budget independent drilling

How to drill a well with your own hands: ways to budget independent drilling  How much does it cost to connect gas to a private house: the price of organizing gas supply

How much does it cost to connect gas to a private house: the price of organizing gas supply  The best washing machines with dryer: model rating and customer tips

The best washing machines with dryer: model rating and customer tips  What is the color temperature of light and the nuances of choosing the temperature of the lamps to suit your needs

What is the color temperature of light and the nuances of choosing the temperature of the lamps to suit your needs  Replacement of a geyser in an apartment: replacement paperwork + basic norms and requirements

Replacement of a geyser in an apartment: replacement paperwork + basic norms and requirements

We made a well in the area in order to save on water for irrigation, because if you water the garden from the central water supply, it is easier to go broke. And so you spend only on electricity for a pump pumping water and on the operation of the irrigation system. Drilled, of course, hired workers with special. technique. After drilling, a long pipe was driven into the well so that the earth did not crumble and nothing was deformed. Everything was done in a few hours. Naturally, I had to spend money, but there have been no complaints about the well for years. And our neighbors decided to save. They fumbled for several days, as a result, they spread the dirt in the yard, and as far as I remember, they didn’t even get to the water. Then they also called the brigade)))

It is very true that in such matters it is not worth saving. They drilled a well in a country house last winter to a depth of 15 meters, the team made a 30 percent discount. And this despite the fact that the drilling process was not easy. But the neighbor hired woeful specialists who offered cheap services ... And it turned out that he paid twice for fixing errors.