Which pipes are best for the well: an overview and comparison of all types of suitable pipes

When planning the organization of independent water supply at home, it is necessary to study the technology and the nuances of creating a well. One of the key points in arranging an autonomous water supply system is the choice of casing.

The wellbore performs diverse tasks and in many respects determines the durability and uninterrupted operation of an autonomous water supply system. Agree, having invested a lot of money and effort in the arrangement of the well, the last thing I want to do is to fix the problems associated with poor quality of water intake.

Therefore, at the design stage it is necessary with all responsibility to approach the choice of casing. We will tell you which pipes are best for the well, what material and type of connection of the bore segments it is preferable to use in a given situation. The knowledge gained will save you from buying the wrong product.

The content of the article:

Wellbore Requirements

Arrangement of an individual source of drinking water is a costly and time-consuming process. Investing in well drilling, each owner of a summer cottage or a private house expects to receive a long-term result.

The service life, well head and the quality of the produced water largely depend on the characteristics of the pipes used to create the casing string.

A water-lifting pipeline solves a number of important tasks:

- protects trench walls from collapse into the borehole space;

- provides well integrity at pressure and ground movements;

- prevents pollution - the ingress of untreated sewage and groundwater (top water) into the trunk;

- prevents siltation wells.

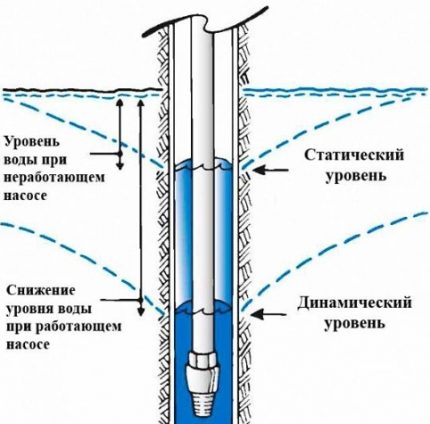

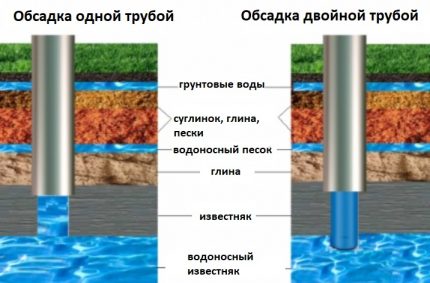

When drilling into a single pipe, the casing is also operational - it accumulates water from the aquifer, which the pump transports upward.

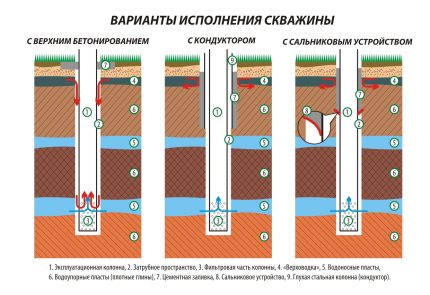

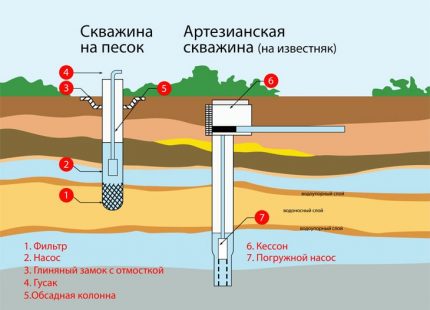

As a rule, drilling a well in a household plot, if it is intended exclusively for irrigation and other household needs, is performed in one column. For drinking water supply, the barrel includes two pipes: casing and carrier filter.

Therefore, high requirements are put forward to the quality and material of the pipes used:

- high strength and resistance to deformation during the entire period of operation (about 20 years);

- complete tightness walls and joints;

- corrosion resistance and the negative effects of chemically active elements;

- environmental friendliness - the material should not affect the composition of the produced water;

- straightforwardness production casing.

For standard applications, distortion is permissible along the length of the casing within 0.7 mm per linear meter.

Casing Selection Parameters

The only true benchmark for drilling does not exist. Method well organization determined individually.

Many indicators are taken into account: the structure of the soil, the height of the groundwater and aquifers, pumping equipment parameters, water quality, diameter and depth of drilling.

Any drilling company will offer its own version of the project and recommend, in their opinion, the optimal type of pipe. The final decision on the choice of casing string is made by the customer.

The executing organization, first of all, defends its own interests, therefore their decision is not always objective. Some contractors specialize in any one type of device of the downhole system and try to “impose” an option that is beneficial to them.

The only right decision is to decide in advance which pipe to choose and use for the well, comparing all the pros and cons, and after that, apply for the development and implementation of the project.

When making a decision, it is necessary to take into account the main parameters of the choice of a water pipe:

- The material of manufacture. This parameter determines the budget for installation work, the bearing capacity for reservoir loads, the maintainability and durability of the well.

- The method of joining the elements of the column. The choice of method depends on the material of the pipeline, the depth of drilling and the diameter of the casing. In any case, the connection must be completely tight, otherwise the water quality will deteriorate over time, and the pump and the well as a whole will fail.

- Pipe diameter. The calculation of the value is made taking into account the maximum possible water flow per day.

The larger the diameter of the supply pipe, the higher the productivity of the well.

Types of materials and their characteristics

Downhole pipes are made of metal, asbestos cement or plastic. Very rarely, when organizing water intake, wooden products are used - they are absolutely environmentally friendly, but, despite the protective treatment, they are susceptible to soil moisture and prone to deformation.

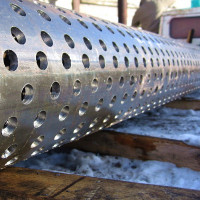

View # 1 - strength and durability of metal

Metal feed pipes are presented in two versions:

- cast iron;

- steel, which can be enameled, galvanized, made of stainless steel.

Very rarely cast iron analogues are used for casing. Among metal counterparts, these pipes are the most affordable, but the material is very fragile and heavy.

Steel is a traditional, decades-proven casing material. Steel almost 100% meets the requirements for downhole pipes.

Ferrous metal products adequately withstand tests in wells of different depths, regardless of the type of soil.

Arguments for rolled steel pipes:

- structural rigidity - the material is equally good for small wells (50 m) and for deep drilling (up to 300 m);

- precise axial alignment assembly and reliability of annular joints;

- material stability - in contact with water, steel does not emit harmful substances;

- service opportunity - due to mechanical strength and resistance to vibration in the installed casing string, cleaning of the borehole channel, drilling out in case of siltation or clogging is acceptable.

The main disadvantage of the steel line is the high cost of the material. Manufacturers of cheaper analogues, praising their products, appeal with another drawback of steel - the formation of rust.

There is an opinion that the resulting pollution worsens the quality of the water and increases its iron content. However well water analyzes show that this is a myth.

Corrosion-resistant metal products are superior in price to conventional steel pipes, but the technical and operational features of the materials cast doubt on the appropriateness of overpayment.

Enameled pipes. The coating prevents corrosion, however, it is very fragile and it is unlikely to be able to avoid damage during casing. The places of chips and microcracks of enamel are the points of rust.

In the process of fracture, through corrosion can form in the damaged area, since in the production of enameled pipes a metal of lesser thickness is used.

Galvanized pipe. With regular contact with water, zinc oxide is formed on the pipe walls - a substance hazardous to health. The use of galvanization is permissible only during the construction of a technical well.

Stainless steel. The material has all the advantages of steel metal and even higher cost. The stainless steel is characterized by the presence of corrosion resistance, which positively affects its period of operation.

The installation of a metal line is economically justified in the construction of a deep artesian well, designed for regular use.

It is advisable to make “surface” sand channels of seasonal use from more accessible materials.

View # 2 - corrosion resistance of asbestos cement

For years, asbestos cement pipes used in the organization of water disposal for more than 70 years have also been tested.

The material is characterized by some positive qualities:

- asbestos cement is absolutely not subject to corrosion;

- neutral composition of the material - the components do not enter into chemical reactions;

- unlimited service life - more than 60-70 years;

- low cost.

Despite significant advantages, asbestos-cement elements are rarely used today in the development of a "water source".

The negative sides of asbestos cement include:

- Installation difficulties. The installation of a fragile highway requires highly skilled performers. Work is carried out using lifting equipment.

- Lack of thread. The sections of the line are joined together end-to-end - to achieve complete tightness of the fixation points without threading is problematic.

- Doubtful safety. There is a theory that asbestos fibers contain chrysotile - a source of carcinogens that adversely affect health. However, in practice this statement has not been proved.

- Difficulty cleaning. Concrete is a porous material in which microcracks accumulate dirt. To perform high-quality cleaning of the casing walls, the well will have to be completely drained.

After the installation of asbestos-cement casing, subsequent drilling operations in the well are excluded.

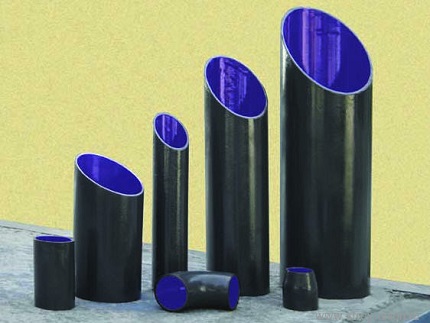

View # 3 - wear-resistant and affordable plastic

Relatively recently, the casing market has replenished with plastic pipes. Modern technology has competed with traditional steel pipes.

Comparative advantages of elements from polymers:

- immunity to water - even with constant contact with a humid environment, corrosion does not form on the plastic;

- over time they retain their structure and do not collapse;

- do not affect the composition of drinking water;

- the material does not provoke the development of pathogens;

- ease of installation and transportation due to light weight;

- it is possible to use a threaded connection to assemble the column, ensuring absolute tightness of the joints;

- profitability - a well with plastic pipes will cost an order of magnitude cheaper than metal or asbestos-cement casing.

The estimated service life of the polymer waterway is about 50 years. This theory is based on the corrosion inertness of the material.

An additional argument against the use of plastic elements is their sensitivity to temperature extremes and mechanical stress. Plastic casing will not withstand ground movements and is deformed in severe frosts.

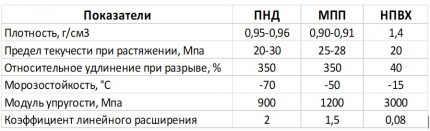

Polymer water intake pipes are made from different types of raw materials: unplasticized polyvinyl chloride (PVC), frost-resistant polypropylene (MPP) and low-pressure polyethylene (HDPE).

Choosing a supply pipe for well pump based on the technical characteristics of polymers.

The weak point of elements from unplasticized polyvinyl chloride is sensitivity to frost. This problem is solved by installing a heating cable in the well.

Polymer MPP and PND pipes have good indicators of frost resistance. However, their density is often insufficient for use as an independent casing. Most often, such plastic is used as an production pipe in a two-column well arrangement.

View # 4 - Combined Pipeline

In order to reduce corrosion processes and improve the quality of the supply water, some drilling companies suggest casing the well according to technology "Pipe in pipe".

A plastic channel from the HDPE food polymer is inserted into the steel line.

Advantages of the combined method:

- Pollution protection. A plastic pipe acts as a kind of barrier between water and steel casing walls - less rust, which is dangerous for a pump installation, gets into the line.

- Maintainability. If the operational polymer pipe is damaged, it will be possible to replace it with a new one, preserving the integrity of the casing string;

- The possibility of subsequent deepening of the well. If necessary, the plastic “sleeve” is extended, the hole is drilled, and the polymer line is installed back with emphasis on a new horizon.

The technology "pipe in pipe" allows high quality serve a well - regularly clean and change in a timely manner filter.

Which column assembly option is better?

The set of requirements for casing pipes and downhole string segment connection technologies is shown in GOST 632-80. The provision allows the use of different assembly methods.

Based on the connection method, the appropriate type of pipe is selected, so this issue must be resolved at the well design stage.

No. 1 - one-piece contact of pipes for welding

Welding provides the most rigid connection of metal pipes. The main advantage of the method today is called into question by representatives of a number of drilling companies.

Arguments against the use of welding:

- probability of insufficient tightness of the weld;

- the possibility of deflection of the pipe along the vertical axis, which complicates the installation of the column into the well;

- insufficient corrosion protection of the seam.

However, with a high level of professionalism of the welder, the listed defects will not be. Most building structures (bridges, farms, oil pipelines) are made of steel and, as a rule, they are welded.

Another issue is that high-quality work requires welding equipment and the involvement of a qualified electric welder. These measures increase the cost of the work performed, reducing the profit and competitiveness of the executive organization.

No. 2 - threaded water channels

When casing a well with rolled metal, 90% of drilling companies use a threaded connection, indicating GOST standards. It sounds quite convincing, but managers of organizations often are silent that the standards are relevant for pipes with a diameter of 146 mm and a wall thickness of at least 6 mm.

The use of threaded technology significantly reduces the life of the casing string.

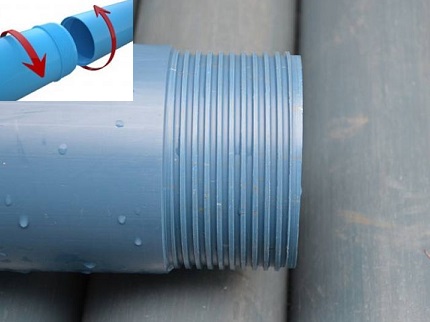

The use of a threaded connection on plastic lines does not have such deplorable consequences, but on the contrary, is considered the most reliable.

There are several options for joining polymer pipes:

- Nipple. Thread is cut from the inside of the plastic pipes. Two elements are connected through a nipple to an external thread. The diameter of the pit does not increase.

- Coupling. An external thread is provided at both ends of the pipe. Docking occurs with the help of an overhead sleeve, which increases the diameter of the penetration.

- Bell-shaped threaded. Threaded segments are used on the outer and inner surfaces - docking is carried out without additional elements.

With a bell-shaped docking, a slight expansion of the diameter at the joints is permissible.

Pressure or non-pressure piping?

The only true option is the use of pressure pipes. Only such products can withstand bilateral pressure. From the outside, buoyancy of soils acts on the walls of the column, and water pressure inside.

The video reviews below will help determine the best option for casing the well.

Conclusions and useful video on the topic

Comparison of the quality of the threaded connection on the PVC-U pipes:

Overview of steel pipes with welded and threaded connections:

Checking the strength characteristics of a metal and plastic pipe:

From the foregoing, the conclusion suggests itself: for a house with year-round living, where the well is the only constant source of drinking water, it is important to ensure the stability and reliability of the water pressure system.

The best option is a two-pipe column made of steel and plastic. The polymer is suitable for a shallow mine when setting up a "seasonal" well.

Looking for the right pipe option for your well? Or have you already made your choice? Please leave comments on the article and ask your questions. Feedback form is located below.

Drilling a borehole: a complete overview of shock-rope technology

Drilling a borehole: a complete overview of shock-rope technology  How to make a do-it-yourself filter for a well: an overview of the best home-made options

How to make a do-it-yourself filter for a well: an overview of the best home-made options  Self-repair of a well: an overview of the best methods of restoration and resuscitation

Self-repair of a well: an overview of the best methods of restoration and resuscitation  Do-it-yourself well cleaning: a review of common clogging causes and best cleaning methods

Do-it-yourself well cleaning: a review of common clogging causes and best cleaning methods  How to arrange a well without a caisson: an overview of the best ways

How to arrange a well without a caisson: an overview of the best ways  Well or well - which is better? Detailed comparative review

Well or well - which is better? Detailed comparative review  How much does it cost to connect gas to a private house: the price of organizing gas supply

How much does it cost to connect gas to a private house: the price of organizing gas supply  The best washing machines with dryer: model rating and customer tips

The best washing machines with dryer: model rating and customer tips  What is the color temperature of light and the nuances of choosing the temperature of the lamps to suit your needs

What is the color temperature of light and the nuances of choosing the temperature of the lamps to suit your needs  Replacement of a geyser in an apartment: replacement paperwork + basic norms and requirements

Replacement of a geyser in an apartment: replacement paperwork + basic norms and requirements

Like it or not, but I adhere to an unshakable opinion that the most correct option is to use steel pipes. Although they cost an order of magnitude more expensive alternative polymer products, they will last much longer, without compromising the quality of the water, which is extremely important. In such cases, it’s definitely not worth saving. And cast iron, as for me, is not an option at all.

I have been working in this field for a long time. Therefore, I boldly say that no one has been installing steel pipes for a long time (they simply rot, pressure drops due to leaks, and it's expensive). The first place in demand is occupied by plastic pipes, since people are familiar with them, but we still recommend asbestos cement pipes, the price is not high, the quality is excellent. I advise you to take this matter seriously in order to avoid unnecessary costs in the future.

But not that asbestos is extremely harmful? Similar recommendations from the "specialist" to say the least surprise.

It so happened that I had no pipes at all in the well. Only hose and pump. There was dense loam on top, it holds the walls without casing, and the water was opened in limestone, which they also decided not to plant at all. The method, of course, is risky, because at any moment the loam could collapse and clog the mine. I would have to drill again. And it’s not a fact that they would fall into the same trunk during drilling. With pipes, everything is much more practical and reliable, but also more difficult to install.

And yet, which casing to use? Is it worth it to dwell on modern steel or is it better to buy HDPE if the well is about 40 meters? We plan to arrange it in the country for watering and drinking. More in the summer, in winter (respectively) less.