How to arrange a well without a caisson: an overview of the best ways

If a well is drilled in the area, it is worthwhile to establish an autonomous water supply system. But the organization of private water intake in a standard way with the installation of a caisson is a very expensive undertaking. It is not necessary to spend substantial sums on this overall structure.

We will show you how to complete a well without a caisson. For you, we have provided step-by-step technologies, described in detail the methods and nuances of implementation. For a clear perception of information and a clear understanding of work processes, we supplemented the material with photo and video instructions.

The content of the article:

Pit construction: pros and cons

If there is no way to spend impressive funds on caisson device, the problem is solved in two ways: a pit is constructed and equipped, or a downhole adapter is installed.

The simplest solution from the point of view of installation is a pit.

It is a simplified analogue of the caisson, which simultaneously performs several functions:

- protects installed equipment from the cold;

- protects the wellhead from atmospheric precipitation and domestic waste;

- acts as a structure inside which it is convenient to place a set of mechanisms that ensure the smooth operation of the pump.

Due to the lack of tightness of the structure, the pit is not suitable in areas with a subsurface groundwater table close to the surface. When marking their mirrors at a depth of more than 5 m, the construction of the pit is a completely profitable and justifiable solution.

The only design flaw is the lack of tightness.The joints between the concrete rings and the brickwork can pass the overhead water and precipitation and domestic waste. For this reason, it is not recommended to install a hydraulic tank and an automation system in the pit.

DIY pit construction

Earthwork is preferably carried out in the offseason. During this period, the cooled moist soil has a denser structure and therefore does not crumble.

Digging a foundation pit

For the construction of the pit, a pit is excavated with a depth of 1.5-2 meters. Its dimensions should be 30-40 cm larger than the internal section of the structure under construction. The bottom of the pit is leveled and carefully tamped. To protect the walls of the pit from water, it is worth temporarily overlaying them with a film.

The most popular and easiest to execute are rectangular and round pits.

Is it necessary to concrete the bottom of the pit - a moot point. On the one hand, a monolithic “floor” is convenient for repair work and well maintenance.

It will exclude the penetration of flood waters into the annulus if the structure is flooded during the off-season. However, soil shifts occurring due to periodic freezing and thawing can significantly damage and warp it.

The best way to equip the bottom of the pit is to build a “pillow” of crushed stone and sand 10-15 cm thick. Clay can be used as a waterproof layer. The fossa resulting from shrinkage of the soil will only need to be periodically aligned.

The construction of the walls of the structure

The walls of the pit can be built using concrete rings for wells or broken brick remaining after the dismantling of any building. To build walls of the desired thickness, the brick is laid in one layer.

If desired, the walls of the structure can be made concrete. To do this, formwork is put together from old unedged boards at a distance of 7-10 cm from the walls of the pit. And then the formwork cavity is poured with concrete mortar.

After 5-7 days, when the solution acquires the necessary strength, the pit is blocked with wooden beams or boards.

To reduce the likelihood of erosion of the walls of the pit with flood water, they are covered with a layer of gravel on the outside. On the inside, it is better to lay out the structure with a layer of insulation, for example, with sheets extruded polystyrene foam.

The pit head can be covered for choice:

- concrete cover;

- metal hatch;

- wooden board reinforced with wooden boards.

The lid of the pit is removable so that it is possible to carry out a routine inspection at any time or to carry out repair work. For example: dismantle the pipe or lift the pump.

Priyamok - in fact, is a home-made caisson. Simple methods for its arrangement are described in the article - How to make a caisson for a well with your own hands: device options and methods for their implementation

Wellhead completion

If it is not planned to deepen the wellhead into the ground, it is equipped by downhole installation. It will protect water from dust and dirt, as well as from the penetration of insects and rodents into the trunk.

The disadvantages of an open arrangement scheme include the inability to place additional equipment near the mouth and the lack of protection against vandal attacks.

The device and the principle of operation of the adapter

The second inexpensive way to equip the well involves the use of a special device - an adapter. In this case, the output of the water pipes is through the casing.

This arrangement method is also suitable for irregular use of the well, which involves “freezing” the structure for several months, and for continuous year-round water intake.

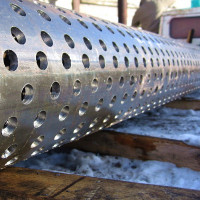

The adapter is installed on everything types of casingmade of polymer or steel alloy. Pipes must have sufficient strength, as they are designed to support the weight of the submersible pump and the communications connected to it.

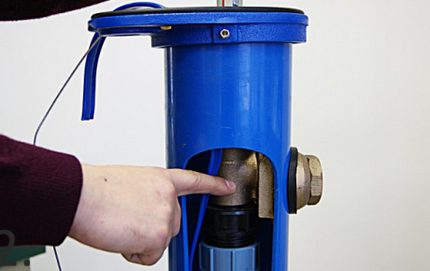

The adapter is a device consisting of two body parts fastened together by a quick-disconnect screwless connection. The main task that is solved by installing this device is to protect the external branch of the water supply system from freezing.

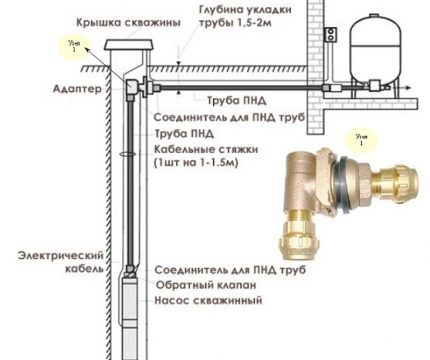

Thanks to its use, the pipeline from the well can be laid below the horizon of seasonal freezing of soils.

The main elements of the adapter are:

- Fixed element. It is a threaded pipe. It is fixed on the casing below the freezing level through a specially made hole. Forms a sealed unit for the exit of the pipeline supplying water to the house.

- Reciprocal removable element. Outwardly resembles a tee with one blank wall. On one side it is mounted on a water intake pipe leading to a deep pump. The second is connected to the stationary element of the adapter. It is equipped with a connecting technical thread, which is necessary for tight joining of both parts of the adapter.

In the process of pumping out of the well, water first rises up the column, then moves to the adapter, through which it is redirected and enters the pipeline leading to the house. With a partial separation of the elements, the water begins to simply merge into the well.

Downhole adapters are made of bronze, brass, stainless steel. A wide assortment of products on the market includes products made from combined metal alloys.

Advantages and disadvantages of using the device

A well without a caisson device equipped with an adapter has a number of indisputable advantages.

Among the main advantages of this type of arrangement it is worth highlighting:

- Cost saving. The cost of the device is many times lower than the price of caisson equipment. And the costs of installing and connecting it are minimal.

- Easy installation and maintenance. The installation of the fixture does not imply complicated work stages using the same welding equipment. Even a master who owns only the basic skills of repair work can perform it.

- Universality of application. The device is used for tapping a water pipe into all types of casing pipes. Due to the fact that the links of the device are closely adjacent to each other, the maximum tightness of the structure is achieved.

The compact dimensions of the adapter allow it to be installed on the walls of the well so that it becomes almost invisible to outsiders. And this is especially true provided that theft is not so rare.

True source, equipped with an adapter, has several disadvantages.

These include:

- The complexity of the repair. To perform repair operations or routine inspection, you will first have to dig out the adapter connection point, which is not always possible.

- Power limitations. Although manufacturers declare the device’s ability to withstand large pressure drops, when arranging a well using an adapter, pump units with high performance should not be chosen.

In comparison with the arrangement of the pit, the installation of the adapter loses in that accumulator, cranes and automation system will have to be taken out to a separate room.

In addition, if the elements are incorrectly connected during the operation of the hydraulic structure, it is quite problematic to control the return flow to the groundwater production trunk.

Depressurization of elements can occur even if the connecting elements of the structure are made of dissimilar metals, which have different aging wear and react differently to the effects of temperature and moisture.

Adapter installation technology

When choosing an adapter for a well, compare the size of the device with the diameter of the casing and the size of the submersible pump, if it is planned for operation.

To perform the work, the following materials will be required:

- downhole adapter;

- crown milling cutter;

- puller;

- connecting fittings;

- metal stakes.

When calculating the dimensions of the device, be aware that it should protrude approximately 1-3 cm from the inside of the casing.

Use a neutral, water-repellent grease to process structural elements before digging in.

From the tools should be prepared:

- bayonet shovel;

- bucket for excavation;

- adjustable wrench;

- mounting pipe;

- Fum tape.

The mounting key can be made with your own hands from a metal or plastic pipe cut of a suitable diameter with a thread. As a result, it will take the form of a T-shaped structure, a length equal to the installation depth of the device plus a half meter-meter for easy installation.

The thread is needed in order to be able to wind the counterpart of the adapter onto it. The opposite end is equipped with a tee, simplifying the process of twisting the device after fixing the mounted part of the device.

Earthworks

To lay the pipeline, dig a trench from the well to the point of entry of the system into the house. The depth of the trench is 30-40 cm below the level of seasonal freezing. They are needed to form a compacted sand cushion of about 20 cm and to exclude the possibility of accidental freezing of the pipeline.

For mid-latitudes, the level of seasonal freezing of soils is estimated at 1.2-1.8 m, depending on the type of soil.

When digging a trench, it should be noted that the pipeline must be laid with a slope from the house to the hydraulic structure in case of draining water from the system before conservation. The slope should be 3 cm per meter.

That is, we look for the depth of the adapter connection point by adding the freezing level, 30-40 cm by the pillow device and multiplied by 3 lengths of the external water supply branch.

With a distance of 10 m from the house to the well, the calculation will look something like this: 1.5 m + 0.4 m + 0.3 m.

Next to the well, the trench needs to be expanded and dug up in the form of a pit, the dimensions of which are determined from the calculation of the convenience of placing the adapter installer in it. A half-meter wide pit is enough to carry out work on inserting the device.

Equipping a pitless adapter with a well

Installation of equipment is carried out in two stages. First install the main part of the device. For this, a hole is drilled in the casing at the depth of laying the water pipe using a crown cutter. The diameter of the hole can be 1ʺ, 1 1/4or 2. The main thing is that it matches the size of the adapter.

The stationary part of the device is inserted into the hole drilled in the casing and fixed with a union nut. Using a pipe wrench, tighten the nut all the way.

The rubber gasket-seal ensures the tightness of the structure at the joints, minimizing the likelihood of groundwater entering the well.

Before mounting the reciprocal part of the device, the pipe, electric cable and cable are connected to the pump. The cable and power cable must be oriented so that they take up space on the opposite side of the adapter.

The water pipe is fixed by a threaded connection through a sleeve. In order to increase the tightness, the joint is sealed with FUM tape.

Since during the operation the vibration of the pump together with the heaviness of the water-filled pipe will create significant loads, a brass sleeve should be used to connect the adapter to the water-lifting pipe.

The difficulty of mounting the reciprocal part of the device lies in the immersion and precise penetration of the stationary element into the thread. To simplify your task, you can use the T-shaped mounting pipe. To speed up the process, some craftsmen additionally highlight a hole with a flashlight lowered on a rope.

The adapter parts are connected through the dovetail assembly. The reciprocal part of the device is fixed using a mounting pipe. After installation is complete, the mounting pipe is removed to the surface.

After the assembly of the system is completed, at a given depth lower the pump, and the end of the pipe is cut off. This work is more convenient to carry out with a partner: the first immerses the pump, the second - holds the equipment and straightens the hose.

At the final stage, it remains only to power up the equipment and check its performance.

During the subsequent operation of the structure, it is necessary to check the condition of the adapter gaskets once a season. Keep in mind that the outer gasket directly in contact with the ground becomes unusable in 2-3 seasons.

Docking elements can stick to each other over time. To prevent this phenomenon, it is necessary to periodically disassemble and lubricate them.

Additional information on the installation and use of the downhole adapter is provided in this article.

Conclusions and useful video on the topic

Which is better: downhole adapter or caisson?

Video tips for building a pit:

Option to equip the well by installing an adapter:

Each of the above methods has its advantages and disadvantages. Therefore, when choosing the best option, you should focus on the location of the hydraulic device and the type of equipment used to equip the system.

Have experience with a well without a caisson? Or have questions about the topic? Please share your opinion and leave comments in the form below.

Self-repair of a well: an overview of the best methods of restoration and resuscitation

Self-repair of a well: an overview of the best methods of restoration and resuscitation  How to warm a well for the winter: an overview of the best ways + material selection

How to warm a well for the winter: an overview of the best ways + material selection  Arrangement of a water supply system at a dacha from a well: schemes, nuances, an overview of the necessary equipment

Arrangement of a water supply system at a dacha from a well: schemes, nuances, an overview of the necessary equipment  Do-it-yourself well warming for the winter: an overview of the best materials and methods of warming

Do-it-yourself well warming for the winter: an overview of the best materials and methods of warming  How to make a do-it-yourself filter for a well: an overview of the best home-made options

How to make a do-it-yourself filter for a well: an overview of the best home-made options  Water purification from a well: an overview of the best and most effective ways

Water purification from a well: an overview of the best and most effective ways  How much does it cost to connect gas to a private house: the price of organizing gas supply

How much does it cost to connect gas to a private house: the price of organizing gas supply  The best washing machines with dryer: model rating and customer tips

The best washing machines with dryer: model rating and customer tips  What is the color temperature of light and the nuances of choosing the temperature of the lamps to suit your needs

What is the color temperature of light and the nuances of choosing the temperature of the lamps to suit your needs  Replacement of a geyser in an apartment: replacement paperwork + basic norms and requirements

Replacement of a geyser in an apartment: replacement paperwork + basic norms and requirements

From an engineering point of view, this is the simplest and most economical way to equip a well. Took a note. It does not require special labor, all the work can be done with your own hands. The main thing is that the groundwater level does not rise above 5 meters. The disadvantages include problems with performing repairs. It will be necessary to dig out the adapter connection point. This is associated with certain difficulties and is not always possible.

Do you mean the adapter? Yes, this is much cheaper than the caisson, but in the sharply continental climate in winter, the adapter, I am afraid, is not applicable.

Yes, Bogdan is talking about an adapter, but as for me, the benefits of its use are relative. This option will not greatly affect the budget during implementation, but on the other hand, two significant disadvantages are obtained:

1. It is difficult to access the adapter itself and its elements if repairs are needed;

2. Seasonality of use.

The last point is quite important, because if the winter drags on, it will make operation impossible. Therefore, it is better to invest in more stable options described in the article, although more costly. But this is the case when the game is worth the candle.