DIY rings for a well: step-by-step technology for manufacturing reinforced concrete rings

For the construction of well mines, only natural materials were once used: stones and logs. With the advent of reinforced concrete products, the technology for constructing autonomous water supply facilities has become much simpler.

Now, reinforced concrete rings for wells, which are produced in the factory, are used to strengthen the walls of the mine. However, it is possible to make such elements yourself - the technology is quite simple, does not require special skills and expensive materials.

We will tell you which ring size is best for the well, describe the method of manufacturing the concrete mix and how to construct demountable molds for pouring the structure. We supplemented the step-by-step technology with visual photo instructions, diagrams, and video clips.

The content of the article:

Typical sizes of reinforced concrete rings

If for some reason it is impossible to use finished products, then the owner of a suburban or summer cottage should think about options for their independent production.

For this, it is necessary to make a mold from improvised materials, install a reinforcing mesh in it, and then pour in a concrete solution mixed in strictly defined proportions.

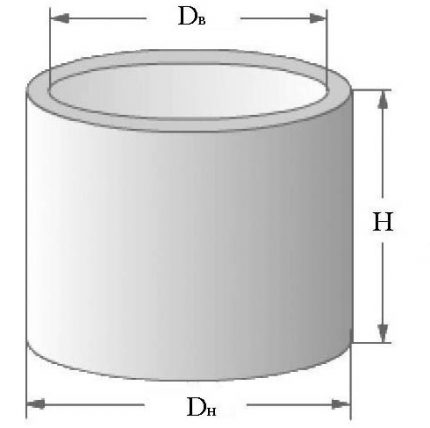

In factories producing reinforced concrete products and designs, special product labeling is used. Typical well ring sizes:

- height standard and is 900 mm;

- thickness - 70-140 mm;

- diameter - 100-200 mm.

The wall thickness of the cylinder and its diameter can be different.

With an increase in the diameter of the ring and the thickness of its walls, the consumption of concrete increases. Product weight also depends on the given sizes. To reduce the mass of the finished product, they try to reduce only the height of the jb-ring, and make the walls as thick as possible.

On sale you can see products with a height of 350, 450 or 500 mm. They are also called additional rings and are installed at the end of the work, when the product of standard sizes is no longer included entirely in the dug well.

Another way to “legitimately” reduce the weight of a well ring is to use a reinforcing mesh. Moreover, the wall thickness can be 6-8 cm, which does not impair the strength characteristics of the product. Therefore, with your own hands it is better to make reinforced concrete rings for the construction of a well on a site.

It is necessary to reduce the weight of the well ring in order not to use lifting equipment during installation work. This is important for gardeners and gardeners who decided not only to make products with their own hands, but also to move them around the site without involving special equipment.

Homemade rings - a practical and affordable solution not only for well arrangements, but also to solve other problems. For instance: creating a drainage well or drain pit.

Concrete mixing

For the preparation of concrete, going further to the manufacture of rings, you will need:

- cement (cementitious material);

- sand (fine aggregate);

- crushed stone (coarse aggregate);

- water.

To obtain high-quality concrete, they buy cement of the “400” grade, packed in 25 kg paper bags. If you do not intend to immediately use building material, then worry about its proper storage.

Bags are stored in a dry place. It is even better to pour cement into closed iron containers. If possible, use purchased cement immediately after purchase.

For mixing concrete, stock up on quartz sand, which is considered the ideal fine aggregate. Sludge, clay and other types of impurities contained in the bulk material brought in will adversely affect the quality of the concrete mix. Therefore, such sand is washed with water, saving it from unnecessary impurities.

Not every crushed stone is suitable for mixing concrete, which is used for casting rings. Granite crushed stone with grains having a cubic shape is selected, which contributes to better adhesion of the material to other ingredients of the concrete mixture.

Do not use crushed stone lamellar (needle) shape. Clay contaminated rubble is also washed with water prior to kneading.

For casting reinforced concrete rings, granite crushed stone with a fraction size not exceeding a quarter of the thickness of the product is purchased. For a ring with a 10-centimeter wall, crushed stone, the grain size of which will not exceed 20 mm, is suitable.

The ratio of ingredients in concrete mortar

The properties of concrete mortar directly depend on the number of components included in its composition, as well as on their volume and mass. When compiling the ratio between the three main ingredients necessary to obtain high-quality concrete, it is assumed that the amount of cement is one.

For casting well rings, the concrete mixture is shut, taking cement, sand and gravel in a proportional ratio by volume of 1: 2: 3 or by weight of 1: 2.5: 4.

For example, a bucket of cement, two buckets of sand and three buckets of gravel are poured into a container. Add half a bucket of water. Or they take 100 kg of cement (4 bags), add 250 kg of sand and 400 kg of crushed stone. Add 50 liters of water.

The preparation of one cubic meter of concrete takes 300 kg of cement M-400, 750 kg of sand and 1200 kg of gravel. The mixture is diluted with 150 liters of water.

How is the amount of water calculated?

Water affects the mobility of the concrete mixture and the strength of the products after it hardens. The ratio of water to cement in the solution is called the water-cement ratio and is designated W / C.

For reinforced concrete rings, this value should be no more than 0.5-0.7. In the above examples, the I / O was 0.5. In this case, the mass or volume of cement taken is divided in half and the required volume of water is obtained.

A more liquid solution is easier to fill in and compact, but it will have to be kept longer in the workpiece. The time for initial hardening of the solution increases.

A mixture that does not creep out after squeezing it with a palm into a lump allows you to immediately remove the workpiece and use it to stamp the next product. True, ramming it is more convenient with the help of vibrators.

Methods of mixing concrete

The manual method of mixing the components of the concrete mixture is rarely used now. Concrete mixers factory and artisanal production better cope with this time-consuming task.

Sand and cement are poured into the concrete mixer, then water is added, and then crushed stone, previously moistened with water. Having received a homogeneous mass, the equipment is turned off and the solution is poured into a container on wheels. This allows you to bring heavy concrete to the place of pouring the ring.

Making molds

Before you start making rings for the construction of a well with your own hands, you must first make a metal demountable mold for pouring concrete or wooden formwork from components. Both that, and another is made from improvised materials available on a site or borrowed from friends.

Finished forms for the manufacture of reinforced concrete rings are offered by many companies. It is unprofitable to purchase them for one time, it is better to rent them. You can see how they are designed, and borrow some elements for assembling your own form.

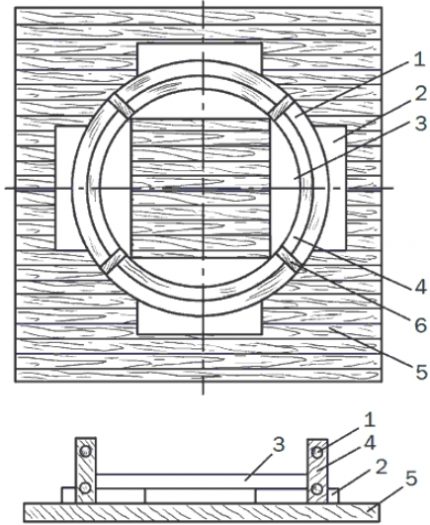

How to make a metal mold?

A home-made collapsible mold, consisting of two rings of different diameters, is made of metal barrels, pipes, ducts and other metal structures suitable for this purpose.

Two cylinders are inserted one into the other so that between them there remains the same distance equal to the thickness of the well ring. So that the outer and inner part of the mold can be easily removed after setting concrete, it is necessary to cut them into two parts with a grinder.

It is more convenient to remove the inner cylinder if it consists of three separate parts. Although the two can be managed, you only have to tinker longer inside the ring.

On all components of the mold, it is necessary to provide for the presence of fasteners that do not allow the mold to move apart while filling the annular space with concrete.

As fasteners use:

- door or window canopies;

- welded ears, tightened by a bolted connection;

- other devices that can cope with the task.

It is advisable to weld the handles on the cylinder walls to make it easier to tear the mold from the concrete. To make the shooting process as easy as possible, the surfaces of the cylinders in contact with concrete must be lined with plastic wrap. You can lubricate them with used engine oil, but this is not welcomed by environmentalists.

To maintain the same distance between the cylinders, use wooden or metal struts, reliably fixing the position of the two annular parts of the form.

It is important to ensure that the outer blank form of the formwork for reinforced concrete rings easily opens outward, and the inner - also freely moved in the opposite direction.

How to assemble a wooden formwork?

It is not difficult for a good carpenter to make formwork for casting concrete rings from scraps of lumber. Two cylindrical surfaces are obtained from wooden rings, to one side of which boards are nailed. Their thickness should be at least 20 mm, but not more than 40 mm.

On both sides the boards are well rounded, making the surface as smooth as possible. For ease of disassembly, the wooden cylinder is cut into four parts. To fasten adjacent workpieces, wooden planks, bolts, hooks, steel brackets and other devices are used.

The inner wall of a wooden formwork having a smaller diameter is assembled in a similar manner. Only the basis are two wooden rings of smaller diameter and the same board (20-40 mm) for lining. If in the first case the boards are nailed in the inner circle, then in the second - in the outer one.

The result is two attached cylinders, forming a space between their surfaces, subsequently filled with concrete. A smaller cylinder is cut into three parts. If sawed in half, it is necessary to provide for a small gap (1.5-2 cm), which facilitates the shooting of internal formwork.

The method of manufacturing wooden rings

Wooden formwork rings are cut out from a square shield, knocked down from 20-mm boards, laid in two layers perpendicular to each other. The first layer is laid across, and the second along.

The side of the square shield is calculated taking into account:

- the inner diameter of the concrete ring (1000 mm);

- its wall thickness (80 mm);

- formwork board thickness (20 mm);

- width of the wooden formwork ring (150 mm).

In parentheses are approximate numbers that allow you to calculate the side of the square shield. So, we add twice to 20 mm to 1000 mm, then two times to 80 mm and two times to 150 mm. As a result, we get: 1500 mm or 1.5 m.

A large ring for external formwork and a small ring for internal formwork are immediately sawed from one shield.The rings are marked on the shield with a pencil and a rope replacing a pair of compasses.

The nail is driven into the intersection point of the diagonals of the square, which is found by crossing two stretched flagella connecting the opposite corners of the shield.

A rope is tied to a nail and, measuring the necessary distances, four concentric circles are drawn with a pencil. The radius of the largest circle is 750 mm, the second is 600 mm, the third is 500 mm, and the fourth is 350 mm.

Next, a hacksaw, a jigsaw or a chainsaw is sawed on drawn circles, getting two rings of formwork. Do the same thing again, getting a second pair of rings.

It remains to nail to the rings on the right side of the board, the thickness of which is 20 mm, and the length is one meter (the height of the concrete ring). The boards are arranged as densely as possible to each other.

After the manufacture of the cylindrical walls of the outer and inner formwork, proceed to sawing them into four parts. So get a detachable wooden mold for the manufacture of reinforced concrete rings at home.

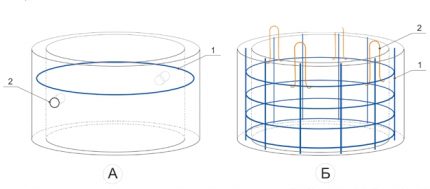

Reinforcing frame manufacturing

The use of reinforcement can reduce the thickness of the ring, and therefore its weight. At the same time, the strength characteristics of the product and its life are increased.

For the reinforcing frame, you will need:

- steel rods with a diameter of 8-10 mm (10 pieces);

- steel wire with a diameter of 8-10 mm (about 5 m);

- thin wire.

We calculate the length of the frame. To do this, we recall the formula for calculating the circumference: the number Pi (equal to 3.14, rounded to 3) must be multiplied by the diameter. We take the diameter of the circle equal to 104 cm, so that the frame passes in the middle of the concrete ring.

We multiply this number by 3, we get 312 cm. Divide this number by 10, we get at 31.2 cm. Round to 31 cm. So, we lay out the steel rods on a flat surface at a distance of 31 cm from each other.

Next, we weld to them pieces of wire 315-318 cm long through 160 mm. We take the wire a little longer than the calculated length of the frame, so that when rolling the workpiece into a ring, you can weld its ends or twist it.

From steel thick wire, we manually bend the mounting loops and weld them to the frame (you can screw them with a thin wire). Everything, the frame is ready. If there is no welding machine, then all the elements of the frame can be twisted with a thin wire.

Pouring concrete mixture into the mold

When all the preparatory work is completed, begin to manufacture a well ring.

Work order:

- Foundation preparation. A sheet of iron or a wooden board is laid on a flat surface.

- Mold assembly. Set the workpiece (one to another), carefully fix the parts of the formwork.

- Form reinforcement. Between the outer and inner walls of the formwork, the reinforcing frame is lowered, fixing its position with wedges.

- Construction fill. Thick concrete mortar (W / C = 0.5) is placed in the annular space in small layers (about 100 mm) and compacted using a steel pin with a diameter of 20 mm. WITHa methane-like solution (W / C = 0.7) is immediately poured into the mold to the edges, and then the mixture is compacted with a pin.

- Ring alignment. After filling out the entire form, proceed to leveling the end face of the concrete ring, reporting with the trowel the solution where it is missing. ANDThe item is covered with polyethylene or a thick cloth.

- Formwork removal. Formwork is started after 3-4 days (if the concrete was thick), after 5-7 days (if the solution was liquid), leaving the ring on a metal sheet or wooden board.

- Concrete ripening. The reinforced concrete ring is wrapped with a packaging film so that the composition ripens evenly for 2-3 weeks, gaining final strength.

It is recommended to wet the product with water every 4-5 days during the maturation of concrete.

Using the same technology cesspool rings. Detailed information on the classification and methods of manufacturing concrete rings for sewage can be found in this article.

Useful video on the topic

In the video clip, the master independently collects the metal mold, covers its walls with waste oil, prepares the concrete mortar and fills the formwork. Using special equipment, the mixture in the mold is carefully compacted so that there are no defects in the walls of the well.

The video shows how easier it is to remove the formwork, starting with the inner ring. By the way, the well ring is made without a reinforcing frame, so the thickness of the product is at least 15 cm.

In this video clip, the mold is designed to cast a thinner reinforced concrete ring. As a reinforcement, the master uses steel wire.The plot shows in more detail the process of laying the ingredients in a concrete mixer.

As you can see, making a reinforced concrete ring for a well is quite within the power of any healthy man. Special skills in the manufacture of molds and mixing of concrete are not required.

Little tricks can be seen in the video stories on this topic. In a month, a person alone can cast up to ten reinforced concrete rings using one mold. This is quite enough to equip the well shaft. Its depth depends on the level of the aquifer in your area.

Have experience making concrete rings? Please share information with our readers, tell us about the features of your method. You can leave comments and ask questions about the topic of the article in the form below.

Do-it-yourself well arrangement at the cottage: step-by-step instruction + advice from experienced craftsmen

Do-it-yourself well arrangement at the cottage: step-by-step instruction + advice from experienced craftsmen  A do-it-yourself well in a country house: a guide for arranging a typical well from rings

A do-it-yourself well in a country house: a guide for arranging a typical well from rings  Do-it-yourself well warming for the winter: an overview of the best materials and methods of warming

Do-it-yourself well warming for the winter: an overview of the best materials and methods of warming  Well bumper: device, options and do-it-yourself manufacturing schemes

Well bumper: device, options and do-it-yourself manufacturing schemes  Do-it-yourself well repair: routine and emergency repairs

Do-it-yourself well repair: routine and emergency repairs  Digging a well with your own hands: types of well structures + an overview of the best digging technologies

Digging a well with your own hands: types of well structures + an overview of the best digging technologies  How much does it cost to connect gas to a private house: the price of organizing gas supply

How much does it cost to connect gas to a private house: the price of organizing gas supply  The best washing machines with dryer: model rating and customer tips

The best washing machines with dryer: model rating and customer tips  What is the color temperature of light and the nuances of choosing the temperature of the lamps to suit your needs

What is the color temperature of light and the nuances of choosing the temperature of the lamps to suit your needs  Replacement of a geyser in an apartment: replacement paperwork + basic norms and requirements

Replacement of a geyser in an apartment: replacement paperwork + basic norms and requirements

We did right on the spot. Cement for rings is needed as dry as possible. An ordinary concrete mixer will not mix. I had to make it more fluid and withstand a couple of weeks in the formwork until it hardened. Made in advance 4 pieces, with one we would have to do this a month. For formwork, metal barrels of various diameters with walls of 6 mm thick were found. Steel sheets were laid on the floor. Inside the reinforcing cage. Ring sizes 106 outer diameter, 90 inner, height 90. Made without locks. Covered with a canopy from precipitation. The formwork was solid, they were not wetted with water. There are also plastic well rings, but they do not withstand frost.

I wonder who bothers with homemade rings and how beneficial is it? Five to ten rings go to the well, the cost at the moment is around 1000-1500 rubles, plus delivery, we get 6000-20000. One concrete mixer from three thousand, metal formwork, as in the article, you will not do for free, and wooden will cost money. Plus wire reinforcement cage, plus lowering ears, plus technology compliance. My opinion: it’s not worth it.

I believe that in this case, the game is not worth the candle, as they say. A tremendous amount of time is spent, plus there is a high probability of getting a serious marriage. It is easier to order ready-made rings for your home or summer house and not to suffer.

We wrote above about casting rings using iron barrels of different diameters. Here in this case, the idea is advisable when the form for filling the rings is already there.Collecting from iron is very expensive, there isn’t so much from wood, but still some experience is needed. Conclusion: for a special case, such manipulations are relevant only if there is a ready-made form for pouring rings (for example, barrels of different diameters, as in the post above. Otherwise, it is justified if you engage in commercial purposes.

And if you do not remove the formwork? More precisely, but not quite. Let’s put it on the bottom of the pit and gradually pouring it in and letting the concrete grab hold up. Get concrete pipe?

I would not advise doing so, since it will be difficult enough in such conditions to get a concrete pipe of a solid construction. First, the joints must be reinforced carefully, and secondly, such an undertaking involves the presence of a pit of a wider diameter for installation work. Conclusion: it is easier to dig a normal hole, make rings separately, then mount them in turn.