How and with what to wall the walls for wiring: briefing on the construction work

When overhauling or finishing a new building, all masters are faced with the need to supply communications and masking wires. The best way to lay utility networks is to place them in the wall. The work is quite laborious, requires certain skills and the availability of special tools.

We will tell you how and with what to wall the walls for wiring, when you can get around with improvised equipment, and when it is better to use professional equipment. We will also describe the features of preparing a furrow on different walls, and give a step-by-step guide to gating and sealing channels.

The content of the article:

Requirements and norms for strob

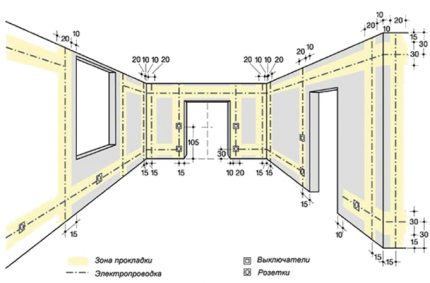

Before choosing a tool and getting to work, it is necessary to draw up an electrical wiring drawing in the apartment or private house taking into account building norms (requirements are regulated by Construction Norms and Regulations 3.05.06-85).

The diagram should indicate the location of all lighting devices, junction boxes, sockets, switches and the route along which the connecting wires will pass.

Important nuances:

- The depth of the furrows should not exceed 2-3 cm, and the width - 3 cm.

- The maximum length of one channel from the junction box to the switch or device is 3 m.

- The wires and, accordingly, the strobes under them can be led only vertically and horizontally, checking the level of parallelism with the main structures of the building. But to reduce the distance "directly" with the help of oblique and even more wavy lines is impossible. An exception to this rule can only be wiring in the attic room - in this case, the grooves are punched parallel to the inclination lines of the walls.

- The minimum spacing from the floor slabs to the horizontal girders should be at least 15 cm, and from the heat and gas pipelines - at least 40 cm.

- Vertical wiring should be held at a distance of 10 cm or more from door and window openings.

- It is important to plan the wiring so that the wires have as few bends as possible from the junction boxes to lighting fixtures or outlets. Ideally, you need to drive the path in a straight line from the box or use no more than one transition at right angles.

- On the bearing walls, floor slabs and corners it is impossible to gouge - this can weaken the strength of the structures of the entire building and lead to an accident.

The following photo selection will clearly demonstrate the restrictions stipulated in the PUE:

If you follow the drawing and the subsequent gating in compliance with these rules, hidden wiring will work without problems and failures.

Choosing a tool for wall chipping

Conducting deep grooves is easier and faster with the help of special electrical equipment. But even if you have at your disposal only a minimal set of home tools, do not rush to give up the intention to do the work yourself.

We will tell you in detail how you can ditch the walls for wiring, consider options from the "grandfather" methods to professional methods.

What is suitable from the arsenal of a home master

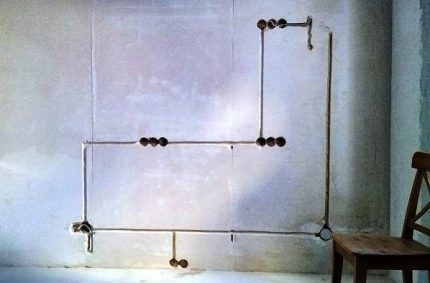

The simplest toolkit that will almost certainly be found in the stocks of any home master is a chisel (chisel) and a hammer. We set the chisel with a sharp edge to the drawn marking, hit with a hammer to penetrate deeper into the wall.

Smoother lines are obtained if you additionally use a hacksaw - it makes cuts along the length of the grooves, which slightly facilitates and accelerates the process.

But in any case, it will be the most time-consuming and time-consuming option for making a strob for wiring.

This method is good in that it does not require expensive equipment and special skills in working with it. Therefore, it is still successfully used for arranging short grooves on the walls of ductile material.

For example, if there is a need to extend an existing route for connecting one or more new devices, with carrying outlet etc.

But if the room has concrete or brick walls, it is better to abandon the intention to make grooves with a hammer and a chisel, and use more effective methods of gating.

A simple power tool to help manual labor

An ordinary electric drill will help to improve the speed and effectiveness of manual gating. But problems with concrete walls may arise - the drills will “burn”, so we will consider several important nuances and the principle of the work.

You need to proceed according to the following scheme:

- Draw markings on the surfaces of the walls.

- Choose a drill with a diameter of 8-10 mm for the drill.

- Make a “point path” - drill holes of the required depth along the lines with an interval of about 0.5-1 cm. At the same time, hold the tool perpendicular to the wall so that the drill does not bend or break. If you need a wide groove, make holes in a checkerboard pattern.

- When working with concrete or brick, you need to turn on the drill at low speeds and periodically stop to cool the drill in cold water (just make sure that the liquid does not penetrate the device).

- Then, using a hammer and a chisel, it remains to knock out the gaps.

Although the technology is quite primitive, it justifies itself when conducting a strob on small and medium distances. For example, when wiring in one room, a tandem drill and chisels will significantly save on the services of builders or the purchase of expensive equipment.

But for a thorough redevelopment of wiring in the entire building or multi-room apartment, it is better to acquire a specialized tool or invite a master electrician.

Professional equipment for quick installation

To make shtrobov, having spent at the same time a minimum of effort, it is possible using a special shtroboreza. Two diamond-coated discs can be mounted on this tool at once, so that neat and perfectly even grooves are obtained on any surface in one pass.

At the same time, the circles themselves will be covered by a casing, on which there is a branch for connecting a vacuum cleaner, to prevent the spread of dust throughout the apartment.

In addition, the design of the cutter allows you to independently change the distance between the circles and set the desired width and depth of the groove.

In a word, this is an excellent solution with a single drawback - the price of equipment is quite high, so it will be cheaper to invite a hired craftsman than to buy a shtorez for a one-time repair.

Quickly perform gating walls for wiring will help:

- Impact drill or hammer drill with interchangeable nozzles. Both devices work according to the same principle: first, holes are drilled with a short drill at intervals of 1-1.5 cm. Then the nozzle changes to a pointed “chisel” or “blade”, is installed at an angle of 45 degrees to the wall, the device switches to “without drilling ”and cleans the groove from the remaining material. This method is good for its speed, but not quality - the groove is still sloppy, with torn edges, cracks and chips.

- Bulgarian (angle grinder) - if you equip the device with a sintered diamond or turbo-diamond disk, it will cope perfectly with making smooth strokes. Truth, work with grinder quite dusty and exacting to accuracy - according to the marking you need to cut 2 parallel lines in 2 passes, maintaining a gap to the width of the future channel. Then, material is knocked out inside the groove with a puncher with a “spatula” nozzle or other percussion instrument.

Strobes with a grinder are almost as smooth and neat as when using a stroborez, but the sawing process is accompanied by such a huge amount of dust (especially if the walls are concrete or aerated concrete) that it is simply impossible to work without a respirator.

To remove at least part of this “cloud”, you can use the construction or industrial vacuum cleaner: while one person is performing the chipping, the second will have to hold the suction hose close to the cutting line.

All objects that cannot be removed from the room during the operation of the grinder and drill should be covered with foil to avoid the penetration of small construction debris. Humidification of the wall with water will also help to reduce the amount of dust, but it is important not to overdo it, since working with wet concrete or brick will not be easy.

Features of working with various materials

If you have a correctly made diagram and suitable tools, it is not difficult to perform wall chipping even for a beginner in the construction business. But this is if the wall is not bearing and covered with a thick layer of pliable plaster.

But what if the internal partitions are made of high-strength concrete, lightweight aerated concrete, or even wood? Consider the nuances of working with various materials.

Strobes in concrete and brick

On masonry, bonded with a mixture of sand and cement, you can even hollow out horizontal grooves with a chisel and a hammer if you "get" into the seam. For vertical shtrob it will be better to use a power tool - a grinder, a puncher or a chisel cutter.

If the masonry is covered with plaster, primitive manual equipment can handle it, however, the process will take a lot of time.

In principle, there is nothing complicated in working with concrete - although the material is strong enough, the grooves on it can be made with any suitable tool for chipping, with the possible exception of a hammer and chisel.

But the punch will still be the best choice, although the evenness of its grooves leaves much to be desired (however, the plaster will correct all the nuances).

This percussion instrument has high power, so it will cope with any hard surfaces. It does not form such a large dust cloud as a grinder, and does not require an additional tool to clean up the remaining material inside the furrow.

The puncher and drill are suitable for forming round holes, though for this the master will need experience:

In addition, it is unsafe to use a grinder (and its analogues - a circular saw, angle grinder) on concrete walls of increased strength - with strong pressure, the circle may break.

How to work with wood and aerated concrete

You can make grooves in the walls of aerated concrete or foam blocks with the help of a grinder, a drill, a puncher or a circular saw. But if you want to minimize the amount of dust - use a special manual chipper, designed to work with ductile material.

Its pointed arc easily cuts through a neat groove, and the desired depth can be achieved in just 3-4 passes.

By the way, such a tool is easy to make with your own hands from a plate sharpened on one side or a rigid punched tape. To do this, you need to bend an arc of a small piece of improvised material and fix the edges with a wire or electrical tape.

For small volumes, such a device is quite enough, but if you need to carry out a network of channels with a total length of more than 20 m, it is worth equipping the device with a convenient handle from the pipe.

As for the walls of profiled timber or logs, then, according to the rules of fire safety, it is recommended here installation of open wiringso that in case of force majeure, the ignition source can be quickly neutralized.

In an extreme case, for wooden walls, you can use a special milling cutter, a grinder with a circular disk for wood and a chisel, with which you can remove the material remaining between the cuts.

But, we repeat, it is better not to risk with masking the wires and perform the installation without violating the regulations of the PUE and the integrity of the wooden coating.

Nuances with load-bearing walls

As already mentioned, it is forbidden to grate the supporting structures - if the upper layer in the wall is damaged, the reinforcement is exposed, as a result of which corrosion can begin, which will weaken the entire frame of the building. But what about the owners of apartments in a house where part of the partitions is reinforced concrete or most of the walls are load-bearing?

There are several options:

- Official approval - obtain permission to carry out work on gating at the local construction department. You can try, if you prove that the depth of the grooves will not affect or damage the reinforcing mesh, deformation of which leads to softening of the supporting structures.But if we are talking about a prefabricated house - the chances are practically zero, but for a frame-brick building, permission will most likely be issued.

- Apply plaster to the wall and carry out gating, without delving into the very design of the plate. Typically, the reinforcement lies under a 1.5-2 cm layer of concrete, so if you level the wall with a stucco mixture, the depth of the grooves will not affect the metal.

And the last way that will help solve the problem with any problem wall is to hide the wires behind drywall or in special electrical skirtings.

Step-by-step description of the gating process

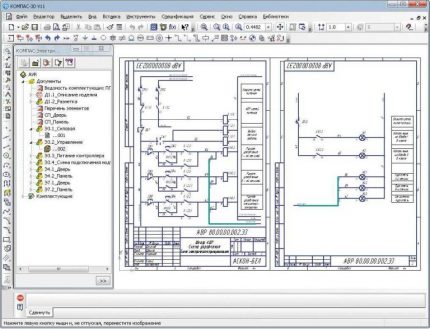

First you need to make a diagram with a detailed indication of all the elements of the electric highway. Those who are computer friendly can use special programs, for example, Compass Electric, ProfiCAD, QElectroTech or other graphic editors.

Step-by-step process of wall breaking through wiring:

- If possible, we protect the room from construction debris - we close the doorway with a damp cloth, we remove the furniture and appliances or close them tightly.

- If there is wallpaper on the walls, they must be removed so that pieces of paper do not get stuck in the power tool.

- Then we transfer the wiring diagram to the walls using a drawing made in advance, a marker and a building level.

- We check the marked area with an indicator or metal detector for the presence of old wiring - if one is found, it will be necessary to dismantle or indent at least 10 cm. Ideally, the apartment should be completely de-energized and the wire should be drawn to the neighbors, because if you accidentally stumble upon a cable that was missed during inspection live voltage can cause serious injury.

- Now you can make strobes using protective equipment and any convenient tool that suits your wall material.

- When the entire route is completed, the grooves need to be cleaned from residual material and dust, then treated with a deep penetration primer.

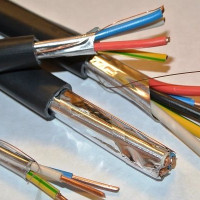

- When the impregnation dries, you can mount the wiring.

Note that the strobes are different, because the grooves are designed not only for the cables themselves, but also for masking the socket, switches and junction boxes.

Usually, the boxes themselves are placed immediately below the ceiling (in the place where the main electric main passes), and the sockets are indented 30 cm from the floor level. And they will need to make a recess in the shape of a circle.

Of course, hollow out such strobes for installation of sockets it can be done manually by drawing a circle line with a drill or a chisel, but it is much more convenient and faster to do this with a punch and a “crown” of suitable diameter. The same nozzle can be made and a recess for switches.

How to mask strobes with wiring

Covert duct work is usually done before plastering, so that after the wiring of the communications, the entire surface of the wall is leveled to apply the topcoat. But if the wiring is replaced after the rough finish of the walls, you need to proceed carefully so that the strob does not turn the spot repair into a major one.

The easiest way to process the channels is gypsum plaster. It must be applied after the grooves have been cleaned of dust and primed, and all the wires are installed according to the plan-scheme.

To reduce shrinkage, it is recommended to moisten the wall at the gate with water.Then you need to prepare a thick solution of gypsum plaster mixture and fill the channel with a spatula / spatula.

So that the plaster layer does not collapse over time and does not sink, you can use a special mesh for reinforcement. Then smooth the mixture perpendicular to the groove (processing the vertical furrow from the bottom up) and remove excess solution with a smoothing machine.

Conclusions and useful video on the topic

For a better idea of gating walls, we offer to look at the work of masters with various tools and learn practical tips about the many nuances that may arise during the installation of wiring.

If you are not sure which tool to choose for chiseling, we suggest that you study the master class by comparing the work of a puncher, grinder and chamfer:

Despite the noise, the punch remains one of the most popular construction tools for the execution of the strob. More about the principles of working with this tool - in the following video:

A grinder is an excellent device for creating smooth channels. And to minimize the amount of dust will help the installation of a protective casing with a dust extraction:

How to make a manual wall chaser for working with gas and foam blocks:

If the provided examples did not inspire you to wall shut yourself, you can always call a wizard with professional equipment so that he makes a network of channels and spread wires through them.

Have experience with wall chipping? Share practical tips and tricks with our readers. Please leave comments and ask questions. The feedback box is located below.

How to conduct wiring in the apartment with your own hands from the shield: basic schemes and rules + installation steps

How to conduct wiring in the apartment with your own hands from the shield: basic schemes and rules + installation steps  Calculation of cable cross-section by power and current: how to calculate wiring correctly

Calculation of cable cross-section by power and current: how to calculate wiring correctly  Installation of open wiring: a review of the technology of work + analysis of the main errors

Installation of open wiring: a review of the technology of work + analysis of the main errors  Do-it-yourself wiring in the kitchen: wiring diagrams + features of the electrical work

Do-it-yourself wiring in the kitchen: wiring diagrams + features of the electrical work  Wiring in the apartment: an overview of the main schemes and the procedure for performing work

Wiring in the apartment: an overview of the main schemes and the procedure for performing work  Wiring in a wooden house: design rules + step-by-step installation

Wiring in a wooden house: design rules + step-by-step installation  How much does it cost to connect gas to a private house: the price of organizing gas supply

How much does it cost to connect gas to a private house: the price of organizing gas supply  The best washing machines with dryer: model rating and customer tips

The best washing machines with dryer: model rating and customer tips  What is the color temperature of light and the nuances of choosing the temperature of the lamps to suit your needs

What is the color temperature of light and the nuances of choosing the temperature of the lamps to suit your needs  Replacement of a geyser in an apartment: replacement paperwork + basic norms and requirements

Replacement of a geyser in an apartment: replacement paperwork + basic norms and requirements

He did new wiring in the apartment, did not make a drawing of new lines before the start, imagined everything. I don’t think many do it. Wall strobil using a grinder. Since there was little experience with it, the lines were not everywhere parallel and the channel width was not the same everywhere, but in the end it did not affect the work much. As for the dust, it’s really true, there is a lot of it! Why is it so categorically impossible to dash oblique lines? What is this fraught with?

You can’t ditch it diagonally because in 10 years you will either forget how you did it or the repairs will be done by people who entered after you and there is a great risk of damage to the cable.

Good afternoon, Denis.

You're right. There is such an expression: the rules are written in blood.For example, the accident investigation instructions provide for the clause: which paragraphs of the Rules need to be reviewed, supplemented to exclude what happened?

The verticality, horizontality of home wiring is regulated by the "Instructions for the installation of wiring ..." developed by the Association "Roselectromontazh" - the developers took into account the causes of accidents. The document is assigned No. I 1.00-12. A screenshot of the desired section was attached to the comment.

In addition to the wiring project, I note that it is required to draw up executive drawings. After all, gating, mounting sockets, switches, other elements will always have a deviation from the drawing.

In general, the current SNIP prohibits, except in attics, the diagonal wiring. But, in principle, the guys are right, indeed, in the future, you yourself will not even be able to nail a nail without markings in such a gating, not to mention the new owners and home. As for dust, moisten the place of future trenches with water before chipping. A surface that has absorbed water will produce far less volatile dust.

A drawing (and a photo of the work) will be needed in the future, when under the fine finish you forget how the wires were laid. In violation of the requirements, I slanted oblique wiring under a stretch ceiling. I don’t think there will be a problem. He also ditched the walls with the help of a grinder - he cursed everything and I think that he caused damage to furniture, clothes, etc., although he tried to cover everything with a film. A conventional vacuum cleaner will not help here, but a construction one is still expensive. As well as a chipper, although to professional electricians, in my opinion, it is necessary. Yes, and I do not see the point of installing sockets 30 cm from the floor or in the baseboards, it is inconvenient to bend over every time.